extruded brass flatback butt hinges

advertisement

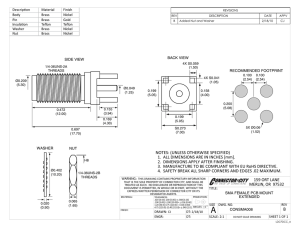

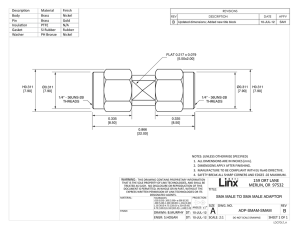

EXTRUDED BRASS FLATBACK BUTT HINGES PAGE 205 These hinges are sold individually. Size: 4” x 3” Polished 205HG1P Unfinished 205HG1 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Size: 4” x 2 5/8” Polished 205HD1P Unfinished 205HD1 Size: 3” x 1 5/8” Size: 2 1/2” x 2” Size: 3” x 2” Polished 205H1P Polished 205H63P Polished 205HS1P Unfinished 205H1 Unfinished 205H63 Unfinished 205HS1 Our English extruded brass butt hinges cover the range from large architectural sizes down to the smallest cabinet sizes. The design and manufacturing is uniform across all sizes. The extruded section is milled and drilled for smooth operation and very long life. The architectural sizes offer a cost effective alternative to quality American door hinges. These hinges are fully capable of supporting the heaviest of doors and are historically appropriate. Undrilled hinges are shown on page 248. PAGE 206 EXTRUDED BRASS FLATBACK BUTT HINGES These hinges are sold individually. Undrilled hinge blanks are shown on page 248. Size: 2 1/2” x 1 1/2” Polished 206H40P Unfinished 206H40 Size: 2” x 1 1/2” Polished 206H5P Unfinished 206H5 Size: 2 1/2” x 1 3/8” Polished 206H2P Unfinished 206H2 Size: 2” x 1 1/4” Polished 206H6P Unfinished 206H6 Size: 2 1/2” x 1 1/8” Polished 206H3P Unfinished 206H3 Size: 2” x 1 1/8” Polished 206H7P Unfinished 206H7 Size: 2” x 7/8” Polished 206H8P Unfinished 206H8 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Size: 1 1/2” x 7/8” Polished 206H11P Unfinished 206H11 Size: 1 1/2” x 3/4” Polished 206H12P Unfinished 206H12 Size: 1” x 5/8” Polished 206H14P Unfinished 206H14 EXTRUDED BRASS FLATBACK BUTT HINGES PAGE 207 These hinges are sold individually. Code 8 Size: 2” x 1 1/4” Polished brass 207H91P Polished chrome 207H91PC Satin nickel 207H91SN Code 8 Size: 3” x 1 5/8” Polished brass 207H89P Polished chrome 207H89PC Satin nickel 207H89SN Code 8 Size: 1” x 1” Polished brass 207H94P Polished chrome 207H94PC Satin nickel 207H94SN Code 8 Size: 2 1/2” x 1 1/2” Polished brass 207H90P Polished chrome 207H90PC Satin nickel 207H90SN Code 8 Size: 1 1/4” x 1” Polished brass 207H93P Polished chrome 207H93PC Satin nickel 207H93SN PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 8 Size: 1 1/2” x 1” Polished brass 207H92P Polished chrome 207H92PC Satin nickel 207H92SN The design of our English flatback hinges is also the direct SWAGED & FLATBACK HINGES. consequence of past manufacturing methods, though in We carry both swaged and flatback hinges in all their case, a century or more older. The first English brass sizes for both cabinet and architectural applications. butt hinges were hand fitted and finished sand castings. To Here follows an explanation of these two outwardly compensate for the brittleness of this material, the hinges similar hinge types. The traditional English hinge were made as thick as possible within the limits of the is a flatback design while the traditional American Flatback hinge particular hinge size. The flatback design allows the hinge is a swaged style. The American swaged form thickness of each hinge leaf to be close to half the diameter is the result of a manufacturing tradition that of the hinge barrel. Even though hinges are no longer sand extends back to the early part of the last century. cast, the profile of the modern English hinge remains the Then, as now, by far the bulk of American hinges same as it was 200 years ago. A subtle detail found in our were formed of sheet material. The practicalities of English butt hinges is the tapering of the leaf. When these forming hinge sections from sheet material generally hinges were still cast brass, the greatest weakness was favored the use of thinner material than might Swaged hinge where the leaf section meets the barrel. In contrast, the otherwise be desired and in order to make a edges of the leaf are under no stress and could be thin, so the stronger, more wear resistant product, the barrel of the hinge was enlarged to create bigger bearing surfaces. Standards that hinge makers would taper the leaf away from the barrel. eventually became defined by trade and government agencies naturally For any given hinge size, the leaf thickness of a flatback hinge will tend to be greater and the barrel diameter smaller than the equivalent swaged reflected the then current state of technology. So all American hinges to this day, however they are manufactured, still bear the characteristics of hinge. Your choice between these two hinge types should ultimately be based on taste and period. The flatback hinges with their slender elegant an economical, mass produced product. Our American made swaged barrels should certainly be your choice if you are replicating the flavor of hinges are milled from solid brass extrusions, rather than folded from period furniture, while the more imposing barrels of the swaged hinges sheet material. This results in a hinge with a more precise fit, a much suit heavier late 19th and 20th century styles. longer life and far better finish. PAGE 208 HINGES SIZE Picking an appropriate hinge for a particular application is one of the multitude of small decisions the furnituremaker must make which ultimately makes their work look unmistakably their own. As long as one stays within reason, the choice you make will invariably function quite adequately. As a set of general rules, a typical cabinet door of between 24” and 36” will need two hinges. While 2” hinges may suit a 24” door, 2 1/2” hinges might look better on a 36” door, and a taller door on a wardrobe may warrant 3” hinges. A door bigger than 36” may also need a third hinge to keep the door from warping. Having decided on a hinge length, the choice of hinge width must be considered. Some woodworkers like to mortise across the full thickness of the door and try to select a hinge accordingly. In the instance of a 3/4” thick door, a 1 3/4” wide hinge will occupy the full width of the mortise. It is generally better practice to cut a stopped mortise in both the door and the cabinetwork and use a narrower hinge. This not only looks neater, but provides a positive location in two planes for the hinge. 1 1/2” hinges work well on 3/4” stock. They allow a full 1/8” backstop against which the hinge can be registered. Back when fragile cast hinges were in general use, a narrower hinge leaf was preferred because it the screws closer to the hinge barrel and so reduced the unsupported width of leaf material. If a sense of historical accuracy is important then choose a 2” x 1 1/4” or 2 1/2” x 1 3/8” hinge. The last dimensional choice to be decided upon is the barrel diameter. This need not vary much in order to have a significant effect on the visual weight of the hinge. For cabinet hinges, the three common diameters available today are 7/32”, 1/4”, 5/16”. The choice will depend more on visual effect than strength considerations. Slender hinge barrels compliment the elegant lines of period furniture. The heft of much 19th and 20th century cabinetwork can suit hinges of greater visual weight. LOOSE PIN HINGES This century we have seen the advent of loose pin hinges on furniture and cabinet work. Originally conceived for architectural doors and casement windows their removable hinge pins allow a door to be taken on and off its casework quickly and without tools. Perhaps this development serves both the cabinetmaker and the user equally well. The cabinet maker gains a little time, while the customer acquires decorative tips at top and bottom of his hinges. These hinges suit architectural cabinetwork particularly well as, in effect, they are smaller relatives of standard door hinges and so allow a design continuity throughout a house. Their applicability to furniture use is less historically justified and as they are built with clearance to allow the pin to be easily withdrawn, they are not as precise as their fixed pin cousins. The voting these days is clearly in favor of loose pin hinges, but a user needs to be aware that a fixed pin hinge without balls or finials is not lacking any vital part. FINISH Throughout most of the 18th and 19th centuries the common butt hinge was expected to do its job without drawing attention to itself. Functional elements such as hinges and locks were not meant to be in competition with designed Projection of plain hinge Projection of loose pin hinge elements for the user’s attention. These days, perhaps because we are starved of contact with quality materials, we like to display them to the best effect. If you are reproducing period cabinetwork, your choice should be with standard finish hinges. These can be finished along with the surrounding woodwork and will blend unobtrusively. INSTALLATION Traditional flatback cabinet butt hinges are mortised into the edge of the door and cabinetwork. We sell these hinges either with or without decorative tips. The installation is the same for either type except in one detail. Decorative tip hinges are set further forward of the cabinetwork than are their untipped counterparts. The plain untipped butt hinge should function without drawing attention to itself. It should therefore be fitted as shallow as possible, the hinge mortise should be cut to a depth that leaves only the barrel of the hinges and a hair extra forward of the cabinetwork. The tipped butt hinge must have a full diameter of its barrel forward of the cabinetwork. This allows the pin to be removed without interference (see illustrations). For regular butt hinges, set a marking gauge to a measurement taken from the edge of the hinge leaf to a point just short of the center of the hinge pin. Use this setting to scribe lines on the casework where you have chosen to place the hinge. Next, measure accurately the hinge length and bring corresponding lines forward to the front of the casework with a square. A scalpel or other sharp knife is the best marking tool for this layout. Set a small router with a sharp 1/4” high-speed steel straight cutter to a depth that equals the hinge barrel diameter minus desired door gap with the result divided in half. Waste away the mortise and square up the corners with a sharp chisel. Set the door in place and shim it to create equal gaps. Mark lines on the door to match those on the casework. Use your existing marking gauge setting to mark the vertical lines on the door edge. Set the door in a bench vise and route the mortises. The door can now be installed. Use only one screw per hinge at this time. If the door closes properly, then fit the remaining screws. Small adjustments to the depth of the mortise can go a long way to compensate for a slightly twisted door. The same technique will work for installation of a tipped hinge, with the exception of the marking gauge setting. For a tipped hinge, the gauge will be set to the inside width of the hinge leaf. ARCHITECTURAL DOOR HINGES PAGE 209 These hinges are sold individually. Code 11 Size: 3” X 3” Polished brass 209MH1P Antiqued brass 209MH1A Polished chrome 209MH1PC Polished nickel 209MH1PN Satin nickel 209MH1SN Size: 3 1/2” X 3 1/2” Polished brass 209MH2P Antiqued brass 209MH2A Polished chrome 209MH2PC Polished nickel 209MH2PN Satin nickel 209MH2SN Size: 4” X 4” Polished brass 209MH3P Antiqued brass 209MH3A Polished chrome 209MH3PC Polished nickel 209MH3PN Satin nickel 209MH3SN Size: 4 1/2” X 4 1/2” Polished brass 209MH4P Antiqued brass 209MH4A Polished chrome 209MH4PC Polished nickel 209MH4PN Satin nickel 209MH4SN Size: 5” X 5” Polished brass 209MH5P Antiqued brass 209MH5A Polished chrome 209MH5PC Polished nickel 209MH5PN Satin nickel 209MH5SN Globe tip Acorn tip Cone tip Steeple tip Many respected American brand name hinges are now manufactured in the Far East and the quality is no longer what it once was. Ours are made in Pennsylvania and the quality of materials, machining and finish are better than ever. The hinges are sold individually, complete with button tips as shown. The decorative tips are sold by the pair to suit one hinge. Ball tips Polished brass 209MT1P Antiqued brass 209MT1A Polished chrome 209MT1PC Polished nickel 209MT1PN Satin nickel 209MT1SN Globe tips Polished brass 209MT2P Antiqued brass 209MT2A Polished chrome 209MT2PC Polished nickel 209MT2PN Satin nickel 209MT2SN Acorn tips Polished brass 209MT3P Antiqued brass 209MT3A Polished chrome 209MT3PC Polished nickel 209MT3PN Satin nickel 209MT3SN Cone tips Polished brass 209MT4P Antiqued brass 209MT4A Polished chrome 209MT4PC Polished nickel 209MT4PN Satin nickel 209MT4SN Steeple tips Polished brass 209MT5P Antiqued brass 209MT5A Lantern tip Urn tip Polished chrome 209MT5PC Polished nickel 209MT5PN Satin nickel 209MT5SN Urn tips Polished brass 209MT6P Antiqued brass 209MT6A Polished chrome 209MT6PC Polished nickel 209MT6PN Satin nickel 209MT6SN Cathedral tips Polished brass 209MT7P Antiqued brass 209MT7A Ball tip Cathedral tip Polished chrome 209MT7PC Polished nickel 209MT7PN Satin nickel 209MT7SN PRODUCT SIZE Lantern tips Polished brass 209MT8P All products are Antiqued brass 209MT8A shown full size Polished chrome 209MT8PC over a 1/4” grid. Polished nickel 209MT8PN Satin nickel 209MT8SN PAGE 210 LOOSE PIN SWAGED CABINET HINGES These hinges are sold individually. Additional tip options for the hinges are shown on the next page. Code 11 Size: 3” x 2 1/2” Polished brass 210AR12P Antiqued brass 210AR12A Polished chrome 210AR12PC Polished nickel 210AR12PN Satin nickel 210AR12SN Code 11 Size: 2 1/2” x 2 1/2” Polished brass 210AR8P Antiqued brass 210AR8A Polished chrome 210AR8PC Polished nickel 210AR8PN Satin nickel 210AR8SN PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 11 Size: 3” x 2” Polished brass Antiqued brass Polished chrome Polished nickel Satin nickel Code 11 Size: 2 1/2” x 2” Polished brass 210AR9P Antiqued brass 210AR9A Polished chrome 210AR9PC Polished nickel 210AR9PN Satin nickel 210AR9SN 210AR13P 210AR13A 210AR13PC 210AR13PN 210AR13SN Code 11 Size: 2 1/2” x 1 3/4” Polished brass 210AR14P Antiqued brass 210AR14A Polished chrome 210AR14PC Polished nickel 210AR14PN Satin nickel 210AR14SN LOOSE PIN SWAGED CABINET HINGES PAGE 211 These hinges are sold individually. Code 11 Size: 2” x 2” Polished brass 211AR6P Antiqued brass 211AR6A Polished chrome 211AR6PC Polished nickel 211AR6PN Satin nickel 211AR6SN Code 11 Size: 2” x 1 3/4” Polished brass 211AR15P Antiqued brass 211AR15A Polished chrome 211AR15PC Polished nickel 211AR15PN Satin nickel 211AR15SN PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Button tip Polished brass 211BTNP Antiqued brass 211BTNA Polished chrome 211BTNPC Polished nickel 211BTNPN Satin nickel 211BTNSN Steeple tip Polished brass 211AT1P Antiqued brass 211AT1A Polished chrome 211AT1PC Polished nickel 211AT1PN Satin nickel 211AT1SN Code 11 Size: 2” x 1 1/2” Polished brass 211AR16P Antiqued brass 211AR16A Polished chrome 211AR16PC Polished nickel 211AR16PN Satin nickel 211AR16SN Code 11 Size: 1 1/2” x 1 1/2” Polished brass 211AR10P Antiqued brass 211AR10A Polished chrome 211AR10PC Polished nickel 211AR10PN Satin nickel 211AR10SN Our cabinet hinges are made in Pennsylvania, and the quality matches that of our architectural hinges. The hinges are sold individually, complete with ball tips. The decorative tips are sold by the pair to suit one hinge. Cone tip Polished brass 211AT2P Antiqued brass 211AT2A Polished chrome 211AT2PC Polished nickel 211AT2PN Satin nickel 211AT2SN Urn tip Polished brass 211AT3P Antiqued brass 211AT3A Polished chrome 211AT3PC Polished nickel 211AT3PN Satin nickel 211AT3SN Cathedral tip Polished brass 211AT4P Antiqued brass 211AT4A Polished chrome 211AT4PC Polished nickel 211AT4PN Satin nickel 211AT4SN Ball tip (Standard no cost tips) PAGE 212 LOOSE PIN BALL TIP FLATBACK CABINET HINGES These hinges are sold individually. Code 11 Size: 3” x 2” Polished brass 212H61BP Antiqued brass 212H61BA Polished chrome 212H61BPC Polished nickel 212H61BPN Satin nickel 212H61BSN Code 11 Size: 3” x 1 1/2” Polished brass 212H1BP Antiqued brass 212H1BA Polished chrome 212H1BPC Polished nickel 212H1BPN Satin nickel 212H1BSN PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 11 Size: 2 1/2” x 2” Polished brass 212H63BP Antiqued brass 212H63BA Polished chrome 212H63BPC Polished nickel 212H63BPN Satin nickel 212H63BSN Code 11 Size: 2 1/2” x 1 1/2” Polished brass 212H40BP Antiqued brass 212H40BA Polished chrome 212H40BPC Polished nickel 212H40BPN Satin nickel 212H40BSN Code 11 Size: 2 1/2” x 1 1/4” Polished brass 212H2BP Antiqued brass 212H2BA Polished chrome 212H2BPC Polished nickel 212H2BPN Satin nickel 212H2BSN LOOSE PIN BALL TIP FLATBACK CABINET HINGES PAGE 213 These hinges are sold individually. PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 11 Size: 2” x 2” Polished brass 213H64BP Antiqued brass 213H64BA Polished chrome 213H64BPC Polished nickel 213H64BPN Satin nickel 213H64BSN Code 11 Size: 2” x 1 1/4” Polished brass 213H6BP Antiqued brass 213H6BA Polished chrome 213H6BPC Polished nickel 213H6BPN Satin nickel 213H6BSN Code 11 Size: 2” x 1 1/2” Polished brass 213H5BP Antiqued brass 213H5BA Polished chrome 213H5BPC Polished nickel 213H5BPN Satin nickel 213H5BSN Code 11 Size: 1 1/2” x 1 1/2” Polished brass 213H65BP Antiqued brass 213H65BA Polished chrome 213H65BPC Polished nickel 213H65BPN Satin nickel 213H65BSN Code 11 Size: 1 1/2” x 1 1/4” Polished brass 213H66BP Antiqued brass 213H66BA Polished chrome 213H66BPC Polished nickel 213H66BPN Satin nickel 213H66BSN The flatback cabinet hinges on these four pages are exclusive to Whitechapel Ltd. The proportions are better suited to some furniture and cabinet styles than the fatter barreled swaged types. Please see page 208 for an in-depth discussion of the choices. PAGE 214 LOOSE PIN URN TIP FLATBACK CABINET HINGES These hinges are sold individually. Code 11 Size: 3” x 2” Polished brass 214H61FP Antiqued brass 214H61FA Polished chrome 214H61FPC Polished nickel 214H61FPN Satin nickel 214H61FSN Code 11 Size: 3” x 1 1/2” Polished brass 214H1FP Antiqued brass 214H1FA Polished chrome 214H1FPC Polished nickel 214H1FPN Satin nickel 214H1FSN PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 11 Size: 2 1/2” x 2” Polished brass 214H63FP Antiqued brass 214H63FA Polished chrome 214H63FPC Polished nickel 214H63FPN Satin nickel 214H63FSN Code 11 Size: 2 1/2” x 1 1/2” Polished brass 214H40FP Antiqued brass 214H40FA Polished chrome 214H40FPC Polished nickel 214H40FPN Satin nickel 214H40FSN Code 11 Size: 2 1/2” x 1 1/4” Polished brass 214H2FP Antiqued brass 214H2FA Polished chrome 214H2FPC Polished nickel 214H2FPN Satin nickel 214H2FSN LOOSE PIN URN TIP FLATBACK CABINET HINGES PAGE 215 These hinges are sold individually. PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 11 Size: 2” x 2” Polished brass 215H64FP Antiqued brass 215H64FA Polished chrome 215H64FPC Polished nickel 215H64FPN Satin nickel 215H64FSN Code 11 Size: 2” x 1 1/4” Polished brass 215H6FP Antiqued brass 215H6FA Polished chrome 215H6FPC Polished nickel 215H6FPN Satin nickel 215H6FSN Code 11 Size: 2” x 1 1/2” Polished brass 215H5FP Antiqued brass 215H5FA Polished chrome 215H5FPC Polished nickel 215H5FPN Satin nickel 215H5FSN Code 11 Size: 1 1/2” x 1 1/2” Polished brass 215H65FP Antiqued brass 215H65FA Polished chrome 215H65FPC Polished nickel 215H65FPN Satin nickel 215H65FSN Code 11 Size: 1 1/2” x 1 1/4” Polished brass 215H66FP Antiqued brass 215H66FA Polished chrome 215H66FPC Polished nickel 215H66FPN Satin nickel 215H66FSN The flatback cabinet hinges on these four pages are exclusive to Whitechapel Ltd. The proportions are better suited to some furniture and cabinet styles than the fatter barreled swaged types. Please see page 208 for an in-depth discussion of the choices. PAGE 216 DECORATIVE TIP HINGES These hinges are sold individually. This English extruded brass hinge is very heavily built and incorporates bronze wear washers for exteended use in high load applications. These two decorative finial tip hinges are from Spain. The screw size is small so they are better suited to light duty use. PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 2 Size: 3” x 2” Polished brass 216HF1 Code 5 Size: 1 3/4” x 1 5/8” Polished brass 216HV16 Code 5 Size: 1 3/4” Polished brass 216HV10 Code 5 Size: 1 1/2” x 1 3/16” Polished brass 216HV14 Code 5 Size: 3” Polished brass 216HV12 Size: 1” x 1 1/2” Polished brass 216HA2P Unfinished brass 216HA2 Clockcase hinges Size: 1 1/4” x 1 1/2” Polished brass 216HA1P Unfinished brass 216HA1 Because overlay doors are difficult to hinge with anything but modern folded hinges they were uncommon during the era of period furniture. But for reasons unknown, the waist doors of tall case clocks were often built to partially overlay the casework. With one wide leaf and one narrow leaf the tall case clock hinges on the left allow a door to project forward enough for the moulded lip. The hinged edge of the door must be left without a rabbet while the other three are rabbeted. END VIEW These two Spanish overlay hinges are solid brass and designed to fit a 7/16” rabbet. The 90 degree fold in the hinge leaf nests into the rabbet. EUROPEAN IRON FICHE CABINET HINGES These hinges are sold individually. Code 13 Size: 5” Left hand (shown) 217HF44L Right hand 217HF44R Code 13 Size: 7” Left hand (shown) 217HF40L Right hand 217HF40R PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 13 Size: 6” Left hand 217HF42L Right hand (shown) 217HF42R PAGE 217 Fiche hinges are common on Continental European furniture. We supply French made hinges in a variety of sizes to suit most applications. These hinges consist of two steel or brass tubes capped on opposing ends by decorative tips. One tube carries a fixed pin, the other slips over this pin. The tubes are formed with tangential leaves. The leaf on the lower tube projects from one side, and on the upper tube, from the other side. We have found three techniques that can be used to install these hinges. Firstly, the correct method, and then two simpler methods TRADITIONAL METHOD FOR LIPPED DOORS Fiche hinges are traditionally used on rabbeted or lipped doors.The leaves are mortised into deep, thin mortises and held in place with pins or screws. Cutting these mortises is no easy matter. We can supply an 1/8” mortising chisel that will work well for the brass hinges, but is too wide for the iron hinges on this page. A method that can make this installation a little easier requires cutting pockets into which the flaps seat (see illustration), after the flap has been screwed into place, a wooden plate can be fitted to add finish and additional strength. BETTER METHOD FOR INSET DOORS Fiche hinges adapt well to use on flush (inset) doors. The better method for installation is as illustrated. A pocket is cut in the door and the casework to accomodate their respective leaves. Leaves on fiche hinges tend to be fairly wide and depending on the thickness of your door and casework, you may need to cut them back and re-drill the screw holes. The depth of the pockets are equal to the result of the following formula: hinge barrel diameter minus desired door gap, the result divided in half. The thin leaves of the hinges will sit down a little into these fairly deep mortises and the resulting space will provide clearance for the screw heads. QUICK NO-MORTISE METHOD FOR INSET DOORS If speed and convenience are of the essence, it is possible to use fiche hinges as no-mortise hinges. To make this possible, you will need to exchange the top leaf of a right hand hinge with the top leaf of a left hand hinge. This exchange Code 13 places the leaves on the Size: 4” same plane and allows the hinge to slip into the Left hand gap between door and frame. Depending on the 217HF46L thickness of wood you are working with, the leaves might need cutting back. Either countersink the Right hand screw holees or use round headed screws and create (shown) depressions in the adjacent wood to accommodate 217HF46R the heads. PAGE 218 FRENCH CAST BRASS FICHE HINGES These hinges are sold individually. In order to photograph at full scale, we show only the top half of the hinges on this page. The bottom half is the same. Code 31 Size: 19” Left hand (shown) 218HFB5L Right hand 218HFB5R Code 31 Size: 13 1/2” Left hand (shown) 218HFB6L Right hand 218HFB6R Code 31 Size: 11” Left hand (shown) 218HFB7L Right hand 218HFB7R PRODUCT SIZE All products are shown full size over a 1/4” grid. The hinges on this and the next page are sand cast and hand finished. This method and standard of manufacture ensures a fully authentic product that has no equal. To compliment them, we offer escutcheons on pages 190 and 191, as well as locks on page 170 of the same quality, and from the same manufacturer. FRENCH CAST BRASS FICHE HINGES PAGE 219 These hinges are sold individually. PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 31 Size: 8 1/2” Left hand (shown) 219HFB1L Right hand 219HFB1R Code 31 Size: 6 1/2” Left hand (shown) 219HFB2L Right hand 219HFB2R Code 31 Size: 5” Left hand 219HFB3L Right hand (shown) 219HFB3R Code 31 Size: 3 3/4” Left hand 219HFB4L Right hand (shown) 219HFB4R PAGE 220 FRENCH LIFT OFF HINGES These hinges are sold individually. All over Continental Europe, you will see these hinges and the ones on the next page on many doors, windows and shutters. They allow for almost instant removal by simply opening and lifting. Because opening is required before removal, this type of hinge is secure in out-swinging applications. Code 26 Rusted iron Left hand (shown) 220RELR1L Right hand 220RELR1R PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 26 Rusted iron Left hand (shown) 220RELR2L Right hand 220RELR2R BRASS LIFT OFF HINGES PAGE 221 These hinges are sold individually. Code 8 Right hand Polished brass 221HJ16P Polished chrome 221HJ16PC Satin nickel 221HJ16SN Left hand Polished brass 221HJ17P Polished chrome 221HJ17PC Satin nickel 221HJ17SN Code 8 Right hand Polished brass 221HJ10P Polished chrome 221HJ10PC Satin nickel 221HJ10SN Left hand Polished brass 221HJ11P Polished chrome 221HJ11PC Satin nickel 221HJ11SN Code 8 Right hand Polished brass 221HJ12P Polished chrome 221HJ12PC Satin nickel 221HJ12SN Left hand Polished brass 221HJ13P Polished chrome 221HJ13PC Satin nickel 221HJ13SN Code 8 Right hand Polished brass 221HJ18P Polished chrome 221HJ18PC Satin nickel 221HJ18SN Left hand Polished brass 221HJ19P Polished chrome 221HJ19PC Satin nickel 221HJ19SN Code 8 Right hand Polished brass 221HJ14P Polished chrome 221HJ14PC Satin nickel 221HJ14SN Left hand Polished brass 221HJ15P Polished chrome 221HJ15PC Satin nickel 221HJ15SN PAGE 222 LIFT OFF AND CRANKED HINGES These hinges are sold individually. Code 2 Size: 3” x 2” Polished brass Right hand 222H81P Left hand 222H82P Unfinished brass Right hand 222H81 Left hand 222H82 Code 2 Size: 3” x 1 5/8” Polished brass Right hand 222H22P Left hand 222H23P Unfinished brass Right hand 222H22 Left hand 222H23 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 2 Size: 2 1/2” x 1 3/8” Polished brass Right hand 222H38P Left hand 222H39P Unfinished brass Right hand 222H38 Left hand 222H39 Code 2 Size: 2” x 1 1/4” Polished brass Right hand 222H24P Left hand 222H25P Unfinished brass Right hand 222H24 Left hand 222H25 Code 8 Sized for 3/4” door Polished brass 222H35P Satin nickel 222H35SN METHOD #1 This approach to 270 degree opening is popular for entertainment centers and the like. The door swings open on its pair of hinges to 180 degrees, where it normally binds. At this point, the hinged vertical element of the face frame releases itself from a magnetic or ball catch and Code 8 allows the door to continue opening to 270 degrees. Width: 1 3/16” METHOD #2 Satin brass By bringing the pivot point of the front of a fully overlay 222H355SB door, our cranked hinges (222H35, 222H351, 222H352 Satin nickel & 222H353) can allow a door to open to 270 degrees. 222H355SN These fine Japanese hinges are machined from solid extruded brass section and are available to suit 3/4” or 15/16” material. Because they only have one bearing surface per hinge, they are not suitable for heavy doors. Code 8 Sized for 15/16” door Polished brass 222H351P Satin nickel 222H351SN This cranked hinge has multiple potential uses and due to the leaf thickness, can be countersunk on the reverse side to further increase its versatility. IRON OVERLAY HINGES These hinges are sold individually. Please see next page for a description of these hinges. Code 26 Overlay: 11/16” Rusted iron 223HSH2 PRODUCT SIZE All products are shown full size over a 1/4” grid. PAGE 223 IRON OVERLAY HINGES PAGE 224 These hinges are sold individually. This hinge and the others like it on these pages are hand forged in Switzerland. Many traditional European architectural doors are overlay style and the two larger hinges we offer are suited to this application. To use them on a flush door would require some creative adaptation. Code 26 Overlay: 11/16” Rusted iron 224HSH1 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. IRON OVERLAY HINGES PAGE 225 These hinges are sold individually. The face frame mounted pivot pins of these hinges are fastened with a woodscrew at the bottom and a through bolt behind the collar. These hinges are not banded. Please see page 224 for further information. Code 26 Overlay: 3/8” Rusted iron 225HSH5 PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 26 Overlay: 1/2” Rusted iron 225HSH3 Code 26 Overlay: 3/8” Rusted iron 225HSH4 PAGE 226 IRON SURFACE HINGES These hinges are sold individually. PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 13 Patinated iron 226HF16 Code 6 Black iron Right hand 226RP19R Left hand 226RP19L Code 13 Patinated iron 226HF52 IRON SURFACE HINGES PAGE 227 These hinges are sold individually. Code 13 Patinated iron 227HF50 Code 13 Patinated iron 227HF53 The hinge pins can be removed and replaced to allow these hinges to function in both right and left hand application. PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 13 Patinated iron 227HF51 Code 13 Patinated iron 227HF54 PAGE 228 IRON SURFACE HINGES These hinges are sold individually unless otherwise noted. PRODUCT SIZE All products are shown full size over a 1/4” grid. These “HL” hinges are sold as a mirror pair, one for the top of the door, and one for the bottom. A third “H” hinge can be used in the middle if needed. Code 7 Black iron 228RE78 Code 7 Black iron 228RE53 Code 7 Black iron 228RE52 The large 7” hinges on this page are very heavy forgings and quite capable of supporting substantial doors. We supply them with large round headed wood screws that will be more than adequate in most situations. Code 7 Sold as a pair Black iron 228RE54 DECORATIVE SURFACE MOUNTED HINGES PAGE 229 These hinges are sold individually. Code 1 Polished brass 229H267P Antiqued brass 229H267A Code 1 Polished brass 229H264P Antiqued brass 229H264A Code 1 Polished brass 229H268P Antiqued brass 229H268A These hinges as well as the Code 1 “H” hinges on the next page are hot forged from solid brass. The forging process results in a durable, long-wearing hinge not subject to breakage like the sand cast originals. In other respects it is nearly impossible to tell them apart. Code 1 Polished brass 229H266P Antiqued brass 229H266A Code 7 Black iron 229RE95 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. PAGE 230 DECORATIVE SURFACE MOUNTED HINGES These hinges are sold individually Code 1 Polished brass 230H265P Antiqued brass 230H265A Code 1 Polished brass 230H26P Antiqued brass 230H26A PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 1 Polished brass 230H261P Antiqued brass 230H261A Code 1 Polished brass 230H262P Antiqued brass 230H262A Code 1 Polished brass 230H263P Antiqued brass 230H263A Code 1 Polished brass 230H269P Antiqued brass 230H269A This hinge matches handles on page 34. SURFACE MOUNTED “H” HINGES These hinges are sold individually. Code 4 Antiqued brass 231H214 Code 4 Antiqued brass 231H215 Code 4 Antiqued brass 231H212 These Code 4 hinges are lost wax castings taken directly off original hinges. They are not as strong as those shown on the last pages but their visual appeal is unique. PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 4 Antiqued brass 231H213 Code 4 Antiqued brass 231H216 PAGE 231 PAGE 232 IRON SURFACE MOUNTED HINGES Our hinges are sold individually Code 7 Black iron 232RE60 The case mounted leaf of this hinge is the same as shown on the hinge to the left. Code 7 Black iron 232RE99 Code 7 Black iron 232RE61 The hinges on this page are intended for flush mounted inset doors. The hinge on the left is strong enough for interior doors. SURFACE MOUNTED STRAP HINGES These hinges are sold individually. PRODUCT SIZE Detail shown full size. Hinges shown at reduced size over a 1/4” grid. These decorative iron strap hinges are very strong and quite suitable for full scale doors. We supply round headed wood screws but larger screws or bolts could be used to increase load bearing. Code 7 Strap length: 23” Black iron 233RE93 Code 7 Strap length: 23” Black iron 233RE92 PAGE 233 STRAP HINGES PAGE 234 These hinges are sold individually, Code 7 Black iron 234RE51 The hinges on this and the last page are intended for flush mounted inset doors. They can be used in architectural applications but the smaller size is best limited to lighter plank style doors. Code 7 Black iron 234RE56 PRODUCT SIZE Hinges on left and top shown full size over a 1/4” grid pattern. Hinge on right shown at reduced size over a 1/4” grid pattern. Code 7 Strap length: 16 1/2” Black iron 234RE55 PAGE 235 IRON STRAP HINGES These hinges are sold individually. These strong forged iron strap hinges are suitable for carrying heavy doors and shutters. They are available with either surface mounted pintle or masonry type for new brick construction. We supply matching square headed lag bolts with these hinges. Code 7 Black iron Strap length: 12” Surface pintle 235RE57S Masonary pintle 235RE57M Strap length: 17” Surface pintle 235RE58S Masonary pintle 235RE58M Strap length: 21” Surface pintle 235RE59S Masonary pintle 235RE59M PRODUCT SIZE Detail shown full size. Hinge shown at reduced size over 1/4” grid pattern. Surface pintle (shownfull scale) Masonary pintle (shown reduced scale) PAGE 236 IRON STRAP HINGES These hinges are sold individually Code 13 Patinated iron Strap length: 12 1/2” Tail length: 8” 236HF62 Code 13 Patinated iron Strap length: 16 1/2” Tail length: 11” 236HF61 Code 13 Patinated iron Strap length: 9 1/2” Tail length: 8” 236HF63 These European strap hinges are suitable for cabinets and chests. While the material thickness and the rolled joint are more than adequate for those applications, they are not intended to support heavier loads. Many uses will require the hinge to be bent at 90 degrees somewhere along its length. This is easily done with the aid of a metalworking vise and hammer. The decorative leaf can show on the inside of a chest lid or door by simply punching out the hinge pin and reversing the upper leaf. The tails are parallel sided and their lengths are indicated. PRODUCT SIZE Detail shown full size. Hinge shown at reduced size over 1/4” grid pattern. IRON STRAP HINGES PAGE 237 These hinges are sold individually. Code 13 Patinated iron Strap length: 9 1/2” 237HF53S Strap length: 12 1/2” 237HF53L The straps on this hinge are the same as those on 236HF62 & 63 Code 13 Patinated iron Strap length: 14” Tail length: 8” 237HF64 PRODUCT SIZE Detail shown full size. Hinge shown at reduced size over 1/4” grid pattern PAGE 238 IRON BUTT HINGES These hinges are sold individually Code 7 Black iron Size: 2” x 1 1/2” 238RHD1 Our strong cast iron butt hinges are hand finished and, though more accurately machined than most originals, still have authentic character. All three sizes are suitable for appropriate architectural application, the largest is a typical European size for doors. Code 26 Rusted iron Size: 2 7/16” x 2 1/2” 238RHF9 Code 7 Black iron Size: 3” x 2” 238RHD2 PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 7 Black iron Size: 4” x 2 3/8” 238RHD3 Code 26 Rusted iron Size: 2” x 2” 238RHF10 PROJECTION HINGES PAGE 239 These hinges are sold individually. We can supply these hinges with button tips. If a decorative tip (like the urn tip shown) is needed, please see the notes on page 209 and select from those tips. Code 11 Size: 3 1/2” x 4 1/2” Polished brass 239MP1P Antiqued brass 239MP1A Size: 3 1/2” x 6” Polished brass 239MP3P Antiqued brass 239MP3A Code 11 Size: 2 1/2” x 3” Polished brass 239MP14P Antiqued brass 239MP14P Size: 2 1/2” x 4” Polished brass 239MP15P Antiqued brass 239MP15A Size: 2 1/2” x 5” Polished brass 239MP16P Antiqued brass 239MP16A Size: 2 1/2” x 6” Polished brass 239MP17P Antiqued brass 239MP17A The two Code 11 hinges above are American made and can be special ordered in polished chrome, polished nickel and satin nickel. The Code 2 hinge below is English and available only in polished brass. Size: 4” x 4 1/2” Polished brass 239MP4P Antiqued brass 239MP4A Size: 4” x 6” Polished brass 239MP6P Antiqued brass 239MP6A Size: 5” x 6” Polished brass 239MP9P Antiqued brass 239MP9A Size: 5” x 8” Polished brass 239MP11P Antiqued brass 239MP11A PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 2 Size: 4” Polished Size: 4” Polished Size: 4” Polished x 4” brass 239HP12 x 5” brass 239HP13 x 6” brass 239HP14 PAGE 242 BACKFLAP DESK HINGES These hinges are sold individually Backflap hinges are typically used to hinge the writing surface of drop front desks. They can also be used anywhere a wide leaf is desirable for the additional support it can offer. Code 2 Size: 2 5/8” x 1 3/4” Polished brass 242H15P Unfinished brass 242H15 Code 2 Size: 3” x 2” Polished brass 242HL1P Unfinished brass 242HL1 PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 2 Size: 2 3/8” x 1 1/2” Polished brass 242H16P Unfinished brass 242H16 Code 2 Size: 4” x 1/2” Polished brass 242H28P Unfinished brass 242H28 Code 2 Size: 1 7/8” x 1 1/4” Polished brass 242H44P Unfinished brass 242H44 This narrow desk hinge is useful for hinging writing desk lids or other box forms. The long leaf spreads stress along the box sides rather than concentrating them in the thickness of the box back. DROP LEAF RULE JOINT AND CENTER HINGES PAGE 243 These hinges are sold individually. Code 2 Unfinished brass 243H18 Code 2 Unfinished brass 243H17 Code 1 Sanded brass 243H97 Code 2 Unfinished DROP LEAF RULE JOINT brass While at first glance, the rule joint seems simple, Code 2 the realities of this joint can be frustratingly 243H33 Unfinished troublesome. A first attempt will often result in brass a joint that scrapes and binds, or leaves 243H32 unsightly gaps. To get it right the first time requires both an understanding and application of the geometry at work. These days, the majority of us will cut the rule joint profiles with a router. Though this tool can quickly produce a very accurate pair of matching cuts, it can just as easily cut a good looking, but unworkable joint. Because different hinges will require different settings for your router, hinge selection must be your starting point. A rule joint hinge is specially manufactured with an extra wide leaf to span the joint. Because it is screwed into the underside of the CENTER HINGES table with the barrel facing up, it is countersunk on the reverse side. Center hinges are designed for Start by opening the hinge and laying it barrel upward on a flat surface. Accurately measure up from this surface doors that swing about a to the center of the hinge pin. In the case of our standard drop leaf hinges, this measurement will be up to 1/8” center, rather than an edge. (alternatively, and assuming the hinge is a traditional flat back style, you can simply measure the hinge barrel These hinges were popular in and divide by two). When this hinge is mortised into the underside of the tabletop, the center of rotation of the Europe on large knock-down table leaf will be 1/8” up from the bottom. casework. The doors are held in Most tabletops are built of 3/4” thick material, and so it seems reasonable to select a 1/2” radius cutter for the place between the pins of the joint. Many woodworkers cutting a rule joint for the first time will fail to take into account the center of rotation hinges when the top of the case described above and will assume a 1/2” radius cutter will leave a 1/4” fillet in 3/4” stock. If a 1/2” radius cutter is fitted. is set correctly, with the center of its described circle raised 1/8” above the underside of the table, the fillet will be 1/8”, not 1/4”. A 1/8” fillet is a workable minimum because, while the fillet is cut into the tabletop, the table leaf must match its profile with perhaps 1/32” clearance. With a full 3/4” material thickness, a 3/32” edge will be left, which should be regarded as an absolute minimum. If the tabletop is thinner due to planing or sanding, then a 1/2” radius cutter will be too large and must be abandoned in favor of a 7/16” or smaller pair of bits. After having established the center of rotation as defined by the hinge choice and having selected the cutter, you can run the profile on the tabletop. If you are using a 1/2” radius cutter, you will need to set the base of your router to cut a fillet of a thickness that is the result of the following formula: Tabletop thickness (3/4”) minus 1/2 barrel diameter (1/8”) minus radius cutter (1/2”). With this profile cut, you can run the mating profile in the table leaf. Ideally you would select a cutter with a 1/32” larger radius to provide a little clearance at the joint. Such cutters are not generally available, so in order to create the needed clearance, you will separate the leaves by this much when installing the hinges. The hinges can now be mortised. The first cut will be in the tabletop and will accommodate the hinge barrel. This is best cut with a 1/4” straight cutter. The center of this cut should be a 1/64” outboard of a line drawn down PRODUCT SIZE from the vertical cut left by your radius cutter. With the tabletop upside down and with its leaf nesting in place, All products are but separated by 1/32”, lay the hinge barrel in it’s mortise and with a sharp knife, scribe its outline. Finally, shown full size route a mortise to set the hinge flush with the table underside and screw into place. Make sure the table leaf over a 1/4” grid. remains firmly in place during this operation. PAGE 244 COUNTER, CARD TABLE AND BUTLER TRAY HINGES Code 8 Polished brass 244H37P Polished chrome 244H37PC Satin nickel 244H37SN Code 2 Polished brass 244H36P Sanded brass 244H36 Code 8 Polished brass Code 2 244H375P Sanded brass Polished chrome 244H30 244H375PC Satin nickel 244H375SN Code 2 Polished brass 244H19P Sanded brass 244H19 The link joint incorporated into all these hinges, with the exception of the butler tray hinge, allow a hinged counter top or the leaves of a card table to open or close face to face while eliminating the obstruction of a raised hinge barrel when in use. Even though they may appear an ideal solution for hinging the writing surface of drop front desks, none of these can be used satisfactorily in this application. Traditionally, a regular backflap hinge like those on page 242 was used, but if it is unacceptable to have the hinge barrel above the writing plane, it is possible to use a drop leaf hinge as shown in the accompanying drawing. This solution will leave a gap along the hinge line when closed, which may or may not be acceptable. The butterfly shaped 244H36 is a characteristic feature set into the bar tops of countless English pubs and is extremely strong. Both the side mounted and face mounted card table hinges perform this function on a more delicate scale. The 244H288 is used on tables with two gaming surfaces. Code 1 Antiqued brass 244H310 Code 1 Polished brass 244H31P Antiqued brass 244H31A Sanded brass 244H31S Code 4 Antiqued brass 244H288 PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 4 Antiqued brass 244H287 KNIFE HINGES PAGE 245 These knife hinges are sold by the pair. OFFSET AND STRAIGHT KNIFE HINGES “Brusso” knife hinges provide an unobtrusive and refined way to hinge, inset and overlay doors. Fitting is as shown in the illustrations and as long as the mortises are cut accurately before the casework is assembled, the installation should go smoothly. Because very little adjustment is possible with this style of hinge, it is vital that you be precise in your marking and cutting. To provide the opportunity for a small amount of adjustment, it is worth cutting the door mortise a hair short and at first install the hinges with only one screw per door leaf. If the door is found to be a little out of square with the case when fitted, one or other mortise can be lengthened slightly. These hinges are not handed and there is no difference between the upper and lower door hinge. They are solid brass and finished in a fine satin with no protective coating. PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. Code 14 Thickness: 7/16” 245HBR5 Code 14 Thickness: 7/16” 245HBR13 Code 14 Thickness: 5/16” 245HBR7 Code 14 Thickness: 5/16” 245HBR6 Code 14 Thickness: 5/16” 245HBR4 Code 14 Thickness: 5/16” 245HBR3 DOUBLE ACTING SCREEN HINGES PAGE 246 These hinges are sold individually Code 2 Dull brass 246H513 Code 2 Dull brass 246H515 Code 2 Dull brass 246H516 Code 2 Dull brass 246H514 Our double acting screen hinges are a good deal thicker and more precise than the hardware store products. The stainless steel version is particularly strong. The maximum panel thickness that each size can accommodate can be measured off the photograph and is equal to the width of the flat between the barrel notching. Code 2 Satin stainless steel 246H57 Code 2 Satin stainless steel 246H56 Code 2 Satin stainless steel 246H55 PRODUCT SIZE All products are shown full size over a 1/4” grid pattern. BOX HINGES PAGE 247 Box hinges are sold by the pair except where noted. Code 5 Dull brass (Sold each) 247HV13 PRODUCT SIZE All products are shown full size over a 1/4” grid. Code 14 Satin brass 247HBR632 Code 14 Satin brass 247HBR631 Code 4 Antiqued brass (Sold each) 247H290 Code 14 Satin brass 247HBR22 Code 14 Satin brass 247HBR17 Code 14 Satin brass 247HBR1 Code 14 Satin brass 247HBR12 Code 14 Satin brass 247HBR2 QUADRANT HINGES STOP HINGES It helps to remember that a quadrant hinge is simply a butt hinge with an The three Brusso stop hinges integral lid stay. The same rules that apply to installing a butt hinge apply also to shown above are a butt hinge the quadrant hinge. The leaf width of the Brusso quadrant hinges are common with a square barrel. Where straight cutter diameters, and the first step will be to determine and set the depth the knuckles of a conventional of your cuts with tis simple calculation: the desired gap between the box and lid butt hinge rotate past each subtracted from the barrel diameter, the result halved. The next step will be to other without interference, measure the box side thickness and set the fence on your router to accurately run a these square knuckles bind cut up the center of this thickness. This setting will be used to make a mortise for against each other at about the forward leg of the hinges on the upper edges of the box and the lower edge of 100 degrees. With their square the lid. The forward limit of this cut is measured off the hinge and allows half the barrel, it might appear that hinge barrel to project out of the back of the box. This can either be marked or if these hinges are intended to be many hinges are being installed, you could add a stop to the fence. fitted flush with the back of the box. This is not the case and After all four of these cuts are made, you can reset the they must project to at least the fence to make a short cut at point B. (see illustration). The fence will still be set against the side of the box, and point where half the hinge pin this cut will only be long enough to define the length of is exposed. the third cut. The third setting will connect the other two, and in this case, the fence will be set against the back of the box. The last cut will create a pocket for the quadrant in both the lid and the box. If your lid is thick enough, you can provide equal depth in both lid and box, otherwise, mortise deeper into the box than the lid. As with the first cut, you will set the fence to cut along the center of the box side. A smaller router bit will be used for this cut (approx. 3/16”). As this is a deep cut, you may want to make a series of passes. Because this cut will be covered by the hinge, you should be able to freehand its length, but be aware that if it is longer Code 1 than need be, you will lose crucial wood in front of the forward-most screw. The hinges should screw into place and operate without binding. Any problems (Sold each) that are encountered will almost always relate to the size of the stay pocket, which Polished brass may need trimming. Antiqued brass Code 4 Antiqued brass (Sold each) 247H289 247H254P 247H254A Code 5 Dull brass (Sold each) 247HV12 PAGE 248 UNDRILLED EXTRUDED BRASS FLATBACK HINGES These hinges are sold individually. Code 2 Unfinished brass Please see pages 205 & 206 for further information on these hinges. Size: (Length along hinge barrel x open width) Regular 4” x 3” 248BH1 4” x 2 3/8” 248BH2 3” x 2” 248BH3 3” x 1 5/8” 248BH4 2 1/2” x 2” 248BH5 2 1/2” x 1 1/2” 248BH6 2 1/2” x 1 3/8” 248BH7 2 1/2” x 1 1/8” 248BH8 2” x 1 1/2” 248BH9 2” x 1 1/4” 248BH10 2” x 1 1/8” 248BH11 1 1/2” x 7/8” 248BH12 1 1/2” x 3/4” 248BH13 1” x 5/8” 248BH14 Backflaps 2” x 3” 248BH15 1 1/2” x 2 3/8” 248BH16 1 1/4” x 1 7/8” 248BH17 Our extruded brass undrilled hinges are useful in repair, restoration and new work. As often as not, the problem of replacing a missing or broken hinge is finding one of the same size and drill pattern. These blanks can easily be cut to almost any size and drilled to suit existing screw holes. The hardest part of making custom decorative or functional hinges is creating the hinge joint. These solid brass blanks are an ideal starting point to which brass hinge leaves of your making can easily be silver soldered. PRODUCT SIZE All products are shown full size over a 1/4” grid pattern.