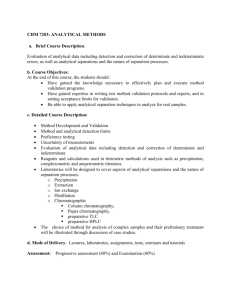

Validation of Analytical Methods

advertisement