Using Evolutionary Programming to Increase the Accuracy of an

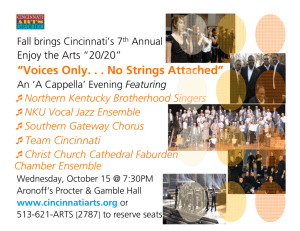

advertisement