E-Line_KO-II

advertisement

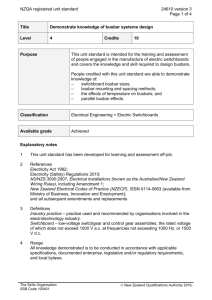

EAE has full right to make any revisions or chances on this catalogue without any prior notice. IR Y A N D EN V QU ME 04 ISO 9001 14001 M IT AL E S s MENT SYSTE T E AG IEC 60439-2 MENTAL MAN ON Catalogue 13-Eng. / 00 1.000 Pcs 15/05/2009 Cakmakli Mahallesi, 2. Cadde, 119. Sokak, No:12 34522 Kirac-Hadimkoy-Istanbul-TURKEY Tel: +90 (212) 886 23 90 Fax: +90 (212) 886 24 20 ATA MATBAACILIK / A.C.E./ 612 40 66 www.eae.com.tr Busbar Systems 160...800 A www.eae.com.tr CONTENTS Introduction 2-3 Design 4 Order Code System 5 Technical Characteristics 6 Standard Components 7 Elbows 8-11 Standard Components 12-13 Feeder Boxes 14-15 Selection Of Feeder Boxes 16 Panel Connections 17 Tap-off Boxes 18-20 Fixing Elements 21-22 Fire Barrier 23 Determination of Special Length 23 Installation of End Closer 24 Mounting Instructions for Joints 24 EC Declaration Of Conformity 25 Certificates 26 Product Overview 27 Project Design Form 28 ELINEKOIntroduction E-Line KO- Busbar System distributes electrical energy, both vertically and horizontally at premises where there is a need of electricity between 160 A and 800 A. It provides a prefabricated and flexible electrical distribution system for all factories engaged in mass production, like automobile plants, textile plants, furniture factories and for buildings where there is a need for frequent energy supply like business centers, hotels, hospitals, warehouses and all high rise buildings. Fast, Flexible Engineering The large number tap-off points makes it possible to engineer the power supply systems at an early stage, even before the final disposition of loads is known. Modern Outlook Other than its functional advantages E-Line KObusbar system also creates a modern outlook at buildings where it is used. Lower Life Cycle Cost Busbar components can be added, deleted or relocated after the initial installation, saving time and money. Tap-off Points Energy can only be supplied by E-Line KO- tap-off boxes. Where necessary the use tap-off points can be limited by sealing. Dust covers protect the system from any accidental contacts and also prevents the access of pollution from the environment. Fast and Easy Mounting Energy is easly supplied to machines by E-Line KO- . The erection of the system does not require any expertise. Supports and accessories are available for mounting the system either to the celling or to the wall. 55 Nm Safe Energy Distribution and Transportation E-Line Busbar Systems increase personnel safety by their special structures. Lower Total Installed Cost Busbar Material costs are often equal or less than wire and counduit. Flexible Power Supply Tap-off points at short intervals make electrical power available in all locations, the power supply can be adapted to different production processes simply by relocating the tap-off units. Being built up of basic elements, it can at any time be extended, modified, dismantled and re-used. Conductors - Copper and Aluminium conductors are continously plated. 2 Secured Energy Take Off The earth of the tap-off box first contacts the busbar and ensures the safety, of the box and the system that’s been fed. - Cross-section of neutral conductor is the same as phase conductor. - Upon request KO- group of busbars can be manufactured also with 5 conductors. ELINEKO“One Bolt Joint” Tap-off Boxes E-Line KO- Busbars are easily installed by tightening the “one bolt joint”. Belleville spring washers on both ends of the bolt retains the original contact pressure ensuring a more secure and reliable joint. Energy upto 400A can be supplied by tap-off boxes. Standard tap-off boxes are equipped with interlock mechanism which prevents the cover of tap-off boxes to be opened before the energy is turned off. Tap-off boxes are easily mounted to the busbar without any additional mounting equipment. Boxes are fixed to E-Line KO- Busbar by a safety bolt. The standard type tap-off boxes with fused switches can not be disconnected from busbar mechanicaly if the power is on. Double Headed Nut Busbar System KO- Broken Nut KB Busbar System 3 ELINEKODesign Utilization Factor (a) While designing an electrical distribution system with E-Line KO- a few approximate details will be necessary. Location, number, type and approximate ratings of loads, Transformer rates and short-circuit capacities, Utilization factor = a System co-ordination with other distribution systems (heat, water, etc.) Determining the route of E-Line KO- on layouts, Deciding on suitable supports, If necessary, co-ordination of E-Line KB and E-Line MK-KAP with E-Line KO- runs. Utilization factor(a) depends on the type and number of loads. It is usually around 0.7 or lower. The utilization factor of a line that supplies electricity to motors and lighting systems is usually 0.6 It is as low as 0.5 in weld shops of car factories, (a) can be 1 in lines where only one big load is supplied. Applications As each building’s structure is different than the other for vertical and horizantal applications special projects has to be designed. End Of Line Rated Current a= ...... The current is calculated using the following equation. Special Length Busbar Ö3.U.cos j IB = Operating Current (A) P = Installed Load (W) a = Utilization Factor U = Supply Voltage l ca rti rt Ve ppo u S a= ...... e r Fir rrie Ba Po in t Pl ug -İn Ta p B -o ff B ox Pl ug Po in t A -in Tap-off Point 1. l ca rti rt Ve ppo Su h= ...... a= ...... a= ...... a= ...... P11 6.Floor P10 5.Floor 4.Floor 3.Floor h= ...... a= ...... ) ing m eil s (c ) Cnes a k ( ic Th P12 7.Floor h= ...... a= ...... h= ...... -in P13 8.Floor h= ...... ug a= ...... h= ...... Pl (H) Height of storey measured from ceiling (cm) 3. Standard Length Busbar P14 9.Floor h= ...... a= ...... Busbar Current rating is chosen as equal to or higher then the calculated IB current. After the voltage drop calculation if the chosen current rate is not convenient, a higher rating is chosen. 10.Floor h= ...... P.a Expansion Unit IB = a= ...... P9 P8 P7 P6 P5 2.Floor Supply From Panels Figure 1 Vertical Disribution The details on this page briefly explain the necessary informations for drawing a vertical applications project. Pre-Project Design and cost Analysis The details below should be sent to our Project and Design Department for Pre-Project design and cost analysis. 4 Location and dimensions of the shaft where busbar will be installed, (h=) Number, height and ceiling thickness of each storey, (a=) Connected load for each storey, (p=) Supply type of the vertical line (Busbar or Cable). ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Order Code System KO A 06 5 5 - Busbar Type Aluminium Copper Components Aluminium Conductor Type A C Busbar Rated Current Copper - B - DDT Busbar Code 160 01 6x20 250 02 6x25 315 03 6x30 400 04 6x50 500 05 6x62,5 600 06 6x75 250 02 6x20 315 03 6x25 400 04 6x30 600 06 6x50 800 08 6x75 IP 55 5 Busbar Code Protection Degree L1 4 5 wire 5 4 ½ wire 6 5 wire (CPE) 7 4 ½ wire (CPE) 9 Right Elbow Left Elbow Downwards Elbow Upwards Elbow R L A Y Right Upwards Combined Left Upwards Combined Right Downwards Combined Left Downwards Combined Upwards Right Combined Upwards Left Combined Downwards Right Combined Downwards Left Combined KRU KLU KRD KLD KUR KUL KDR KDL Upwards Vertical Offset Downwards Vertical Offset Right Horizontal Offset Left Horizontal Offset UV DV RH LH “T” Component Cross Reductions T D RD End Closer Horizontal Expansion Vertical Expansion Flexible S YDT DDT F Feeder Box 1 Feeder Box 2 Central Feeder Box 1 Central Feeder Box 2 B1 B2 BO1 BO2 Panel Connections Panel Connections P10 P11 UNPAINTED PAINTED B Configuration Code 4 wire STD X FTD FX Paint Conductor Configuration Number of Conductors Plug-in Standard Length Plug-in Special Length Feeder Standard Length Feeder Special Length L2 L3 N PE ½ PE CPE ½ CPE PE (Housing) 5 ELINEKOTechnical Characteristics Aluminium Conductor (KOA) A In Rated Current 160 250 315 400 500 600 250 315 400 600 800 01 02 03 04 05 06 02 03 04 06 08 Busbar Code Standards IEC 60439-2: 2000 Rated Insulation Voltage Ui 1000 V Rated Operational Voltage Ue V 1000 Rated Frequency f Hz 50 / 60 Protection Degree IP Rated Peak Withstand Current Ip kA 17 30 30 63 63 73,5 36 36 52,5 73,5 73,5 Rated Short-time Withstand Current (1 sec) Icw kArms 10 15 15 30 30 35 18 18 25 35 35 Rated Peak Withstand Current (N) Ip kA 10,2 15,3 15,3 36 36 44,1 21,6 21,6 30 44,1 44,1 Rated Short-time withstand Current (N) Icw kA 6 9 9 18 18 21 10,8 10,8 15 21 21 Rated Peak Withstand Current (PE) Ip kA 10,2 15,3 15,3 36 36 44,1 21,6 21,6 30 44,1 44,1 Rated Short-time Withstand Current (PE) Icw kA 6 9 9 18 18 21 10,8 10,8 15 21 21 R 20 20°C R 20 mW/m 0,242 0,193 0,161 0,097 0,077 0,064 0,150 0,120 0,100 0,060 0,040 Impedance Z mW/m 0,333 0,274 0,243 0,166 0,139 0,118 0,238 0,209 0,193 0,134 0,102 3I²R 1 W/m 21,96 46,13 60,73 60,00 81,75 101,52 33,75 48,82 69,12 84,24 130,56 Resistance at Steady State Temperature R1 mW/m 0,286 0,246 0,204 0,125 0,109 0,094 0,180 0,164 0,144 0,078 0,068 Reactance (Rated Current and 50 Hz) X1 mW/m 0,205 0,183 0,165 0,118 0,103 0,088 0,173 0,154 0,145 0,117 0,083 Impedance at Steady State Temperature Z1 mW/m 0,349 0,319 0,270 0,182 0,157 0,135 0,254 0,235 0,207 0,144 0,110 Housing Cross Section (Steel Sheet) mm² 583 593 603 643 668 693 583 593 603 643 693 L1, L2, L3, N mm² 120 150 180 300 375 450 120 150 180 300 450 PE (for 5 Conductors) mm² 120 150 180 300 375 450 120 150 180 300 450 Loses at Rated Current 55 mm² 60 75 90 150 187,5 225 60 75 90 150 225 mmxmm 6x20 6x25 6x30 6x50 6x62,5 6x75 6x20 6x25 6x30 6x50 6x75 kg/m 7,0 7,5 8,0 10,0 11,0 12,0 10,0 11,0 12,5 16,0 18,0 PE (for 4 ½ Conductors ) Conductor Size Weight - 4 Conductors Weight - 5 Conductors kg/m 7,3 8,0 8,7 11,0 12,0 13,0 11,0 12,5 14,0 19,0 21,0 Fire Load (3 Plug-in Points) kW/m 6,46 6,46 6,57 6,66 6,66 6,66 6,46 6,46 6,57 6,66 6,66 Voltage drop of a busbar system can be calculated with the following formula taking into account the “a“ load distribution constant. -3 DU=aÖ3.L.I.(R1.Cosj+XL.Sinj) 10 DU = Voltage Drop (V) = Load Distribution Constant a = Line Length (m) L = Line Current (A) I R1 = Resistance (mW/m) XL = Inductive Reactance (mW/m) Cosj = Load Factor a Load Distribution Factor Voltage Drop Calculation 6 Copper Conductor (KOC) Volt F= Supply L= Load 1.00 0.50 L4 F= Supply L1,L2,L3,L4 Load 0.25 L2 F= Supply L1,L2 Load 0.125 L4 F= Supply L1,L2,L3,L4 Load 0.25 F F= Supply L1,L2,L3,L4 Load L L F F L1 L2 L1 F L1 F L3 L2 L1 F L2 L3 L3 L4 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Standard Components - KO 625 375 500 500 500 500 500 500 500 500 375 625 3000 Sample Order: 250 A, Aluminium, Plug-in, IP 55, 4 Conductors KOA 0254- -STD - Plug-in Standard Length - STD 00 30 L1 L2 L3 N PE Electrical Energy up to 400A can be supplied from the busbar by Tap-off boxes. E-Line KO- Busbar is manufactured in 3m as standard, special lengths can be manufactured on request. Sample Order: 400 A, Copper, Plug-in, IP 55, 85 cm. 5 Conductors KOC 0455- -85 Plug-in Special Straight Length X X Minimum special length that can be manufactured is 35 cm. L1 L2 L3 N PE X Special Straight Length (cm) Sample Order: 315 A, Aluminium, Feeder, IP 55, 5 Conductors KOA 0355- -FTD Feeder Standard Length - FTD 00 30 L1 L2 L3 N PE L1 L2 180 L3 N PE A Current Aluminium Copper (A) (A) (A) 160 250 315 400 500 600 800 mm 70 75 80 100 112 125 - mm 70 75 80 100 125 Busbar cross-section dimensions Please call us for non-standard components. Sample Order: 160 A, Aluminium, Feeder, IP 55, 60 cm, 4 Conductors KOA 0154- -60 Feeder Special Straight Length FX X X Special Straight Length (cm) L1 L2 L3 N PE 7 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Elbows - KO - Right Elbow A B A B Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - -R R L1 L2 L3 N PE A Left Elbow B Sample Order: 600 A, Copper, IP 55, 5 Conductors KOC 0655 - -L L L1 L2 L3 N PE B A D Downwards Elbow D C D Aluminium 200 200 200 200 200 200 145 147 150 160 166 172 180 185 190 210 222 235 Copper 250 315 400 600 800 290 290 290 290 290 200 200 200 200 200 145 147 150 160 172 180 185 190 210 235 L1 L2 L3 N PE Upwards Elbow Sample Order: 600 A, Copper, IP 55, 5 Conductors KOC 0655 - -Y Y L1 L2 L3 N PE C D 8 Please call us for non-standard components. D B 290 290 290 290 290 290 A C A 160 250 315 400 500 600 Current -A C Sample Order: 400 A, Aluminium, IP 55, 4 Conductors KOA 0454 - C ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Elbows - KO X= min. 20 cm. Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - - UV - - Upwards Vertical Offset UV X L1 L2 L3 N PE C D Downwards Vertical Offset X= min. 20 cm. Sample Order: 400 A, Copper, IP 55, 5 Conductors KOC 0455 - - DV X DV L1 L2 L3 N PE C Right Horizontal Offset Y= min. 15 cm. Sample Order: 315 A, Aluminium, IP 55, 5 Conductors KOA 0355 - D - RH A RH A B B L1 L2 L3 N PE C D Aluminium 200 200 200 200 200 200 145 147 150 160 166 172 180 185 190 210 222 235 250 315 400 600 800 290 290 290 290 290 200 200 200 200 200 145 147 150 160 172 180 185 190 210 235 Left Horizontal Offset Y= min. 15 cm. A Sample Order: 160 A, Aluminium, IP 55, 4 Conductors KOA 0154 - - LH B LH Y B 290 290 290 290 290 290 Copper Y A 160 250 315 400 500 600 Current L1 L2 L3 N PE B Please call us for non-standard components. A 9 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Elbows - KO Y= min. 20 cm. Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - - KRU - - Right Upwards Combined Offset KRU A B L1 L2 L3 N PE Y Y= min. 20 cm. Sample Order: 400 A, Copper, IP 55, 5 Conductors KOC 0455 - - KLU Left Upwards Combined Offset KLU Y L1 L2 L3 N PE B KOA 0355 - - KRD A B X X= min. 20 cm. Sample Order: 315 A, Aluminium, IP 55, 5 Conductors Right Downwards Combined Offset KRD B C D Aluminium 290 290 290 290 290 290 200 200 200 200 200 200 145 147 150 160 166 172 180 185 190 210 222 235 250 315 400 600 800 290 290 290 290 290 200 200 200 200 200 145 147 150 160 172 180 185 190 210 235 Current 10 Please call us for non-standard components. X= min. 20 cm. Sample Order: 160 A, Aluminium, IP 55, 4 Conductors KOA 0154 - - KLD Left Downwards Combined Offset X A 160 250 315 400 500 600 Copper L1 L2 L3 N PE KLD L1 L2 L3 N PE B A A ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Elbows - KO Y= min. 20 cm. Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - - KUR - C Upwards Right Combined Offset KUR Y L1 L2 L3 N PE B D Y= min. 20 cm. Sample Order: 400 A, Copper, IP 55, 5 Conductors KOC 0455 - - KUL KOA 0355 - - KDR KUL C Y Aluminium Copper A B C D 160 250 315 400 500 600 290 290 290 290 290 290 200 200 200 200 200 200 145 147 150 160 166 172 180 185 190 210 222 235 250 315 400 600 800 290 290 290 290 290 200 200 200 200 200 145 147 150 160 172 180 185 190 210 235 X= min. 20 cm. Sample Order: 160 A, Aluminium, IP 55, 4 Conductors KOA 0154 - - KDL A B A Downwards Right Combined Offset B X KDR L1 L2 L3 N PE Current A Upwards Left Combined Offset L1 L2 L3 N PE X= min. 20 cm. Sample Order: 315 A, Aluminium, IP 55, 5 Conductors D Downwards Left Combined Offset D C B A X KDL L1 L2 L3 N PE C D Please call us for non-standard components. 11 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Standard Components - KO - - “T” Component A B Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - -T T L1 L2 L3 N PE Cross Sample Order: 600 A, Aluminium, IP 55, 4 Conductors KOA 0654 - -D A A D L1 L2 L3 N PE Reduction Is used to change the busbar cross section. A B Aluminium 160 250 315 400 500 600 290 295 300 320 332 345 145 147 150 160 166 172 Copper Reduction 250 315 400 600 800 290 295 300 320 345 145 147 150 160 172 Current 12 Please call us for non-standard components. L1 L2 L3 N PE Sample Order: 400-250 A, Aluminium, IP 55,5 Conductors KOA 0455 - - RD2 RD Reduced Current 160 A 1 250 A 2 315 A 3 400 A 4 500 A 5 600 A 6 0 64 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Standard Components - KO - End Closer End Closer Is used to close the end of busbar run. Sample Order: 250 A, Copper, IP 55, 5 Conductors KOC 0255 - -S S 0 26 Horizontal Expansion Horizontal Expansion For long horizontal runs and for crossing the building expansions. Sample Order: 250 A, Aluminium, IP 55, 4 Conductors KOA 0254 - - YDT L1 L2 L3 N PE YDT 00 10 Vertical Expansion For vertical applications in many storey buildings. Vertical Expansion L1 L2 L3 N PE Sample Order: 250 A, Copper, IP 55, 5 Conductors KOC 0255 - - DDT 0 70 DDT Flexibles Flexibles Are used for panel-busbar connections. Sample Order: 600 A, Aluminium, 4 Conductors 55 cm. KOA 0454 - - F55 F * L L X (Cm) Y Z * Please indicate X, Y, Z and ø measurement on order. Please call us for non-standard components. 13 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Feeder Boxes - KO - - L1 L2 L3 N PE Feeder Box 1 Sample Order: 250 A, Copper, IP 55, 5 Conductors KOC 0255 - - B1 B1 Feeder Box 2 Sample Order: 250 A, Aluminium IP 55, 4 Conductors KOA 0254 - 210 C 200 -B2 B2 D L1 L2 L3 N PE X B X Y A Current Copper Aluminium 160 14 A B C D X 550 350 350 180 85 55 52,5 Y Y 250 550 350 350 180 85 315 550 350 350 180 85 50 400 550 350 350 180 85 40 500 550 350 350 240 85 65 600 550 350 350 240 85 57,5 250 550 350 350 180 85 55 315 550 350 350 180 85 52,5 400 550 350 350 180 85 50 600 550 350 350 180 85 40 800 550 350 350 240 85 57,5 210 200 X B X Feeder Box sample equipped with MCB Please call us for special applications or for applications with MCB's ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Feeder Boxes - KO - - Central Feeder Box 1 KOA 0654 - - BO1 5 36 600 Sample Order: 600 A, Aluminium, IP 55, 4 Conductors BO1 0 21 0 L1 L2 L3 N PE 60 23 0 0 21 Central Feeder Box 2 KOA 0654 - - BO2 5 BO2 0 21 L1 L2 L3 N PE Please call us for non-standard components. 36 600 Sample Order: 600 A, Aluminium, IP 55, 4 Conductors 0 60 23 0 0 21 15 ELINEKOSelection of Feeder Boxes B2 B2 B1 B1 Standard Length Busbar Ceiling 150 mm. Application of Tap-off Boxes for Horizontal Lines L1 L2 L3 N PE In horizontal installation the neutral conductor is situated as shown above. 150 mm. al rtic rt Ve ppo Su Vertical Expansion e r Fir rrie Ba Special Length Busbar B2 150 mm. 2. 1. Ceiling Plu g- in Po in t Plu g- in Po in t L1 L2 L3 N PE Wall FRONT Application of Tap-off Boxes for Vertical Lines 16 In vertical installation the neutral conductor should be on the right side. It is important for tap-off box connections. B1 ELINEKO- BUSBAR TYPE CONDUCTOR TYPE BUSBAR CODE PROTECTION DEGREE CONDUCTOR CONFIGURATION UNPAINTED / PAINTED COMPONENT Panel Connections KO Figure 1 - - - Figure 2 Busbar Feeder 410 Sample Order: 600 A, Aluminium, IP 55, 5 Conductor - P10 P10 200 KOA 0655 - Busbar Feeder z z x y x y t N A x y z t Figure Aluminium 160 250 315 400 500 600 20 25 30 50 62.5 75 40 40 40 40 33 33 20 20 20 20 20 20 8,5x17 8,5x17 12x24 12x24 14 14 26 26 1 1 1 1 2 2 Copper L1 A 250 315 400 600 800 20 25 30 50 75 40 40 40 40 33 20 20 20 20 20 8,5x17 8,5x17 12x24 12x24 14 26 1 1 1 1 2 Current L3 Panel Feeder 410 Sample Order: 600 A, Aluminium, IP 55, 5 Conductor KOA 0655 - - P11 P11 200 180 L2 PE 210 N Panel Connection Plate 410 260 Panel Feeder L1 L2 PE L3 150 50 40 70 70 E-Line KOBusbar 70 Panel Connection Plate 15 100 150 100 15 400 145 140 145 Note: 230x460mm flange plate dimensions are standard for all busbar types. 15 460 Opening on the panel board Please call us for non-standard components. 17 ELINEKO- BUSBAR TYPE BOX TYPE Tap-Off Boxes with Fused Switches (SYK) 160 A - 16 250 A - 25 400 A - 40 IP 55 5 KO P 5 1 FUSED SWITCHES TYPE S- STANDARD SYK B- EMPTY Cable Gland Plates tes) Pla es d sid n a Gl two t (a Inner Diameter (mm) Cable Gland Type Order Code Sheet Metal ---- RP0 Sheet Metal M32 RP1 25 Sheet Metal M40 RP2 32 Sheet Metal Special RP3 63 AL 2xSpecial RP4 63 AL 4xM25 RP5 18 AL 4xM32 RP6 25 AL 4xM40 RP7 32 AL 8xM32 RP8 25 Mat. BOX RATING PROTECTION DEGREE B L1 L2 L3 N KOP 1651-S A tes ) Pla es d sid n a e Gl thre at ( B KOP 2551-S L1 L2 L3 N A Fused Switches (SYK) Tap-off boxes are equipped with EAE syk fused switches that; tes ) Pla es d sid n a e Gl thre t (a Can operate under load, Are equipped with NH fuse holders, Have Interlock mechanism Padlock applicable B L1 L2 L3 N KOP 4051-S A A A mm KOP 160 370 KOP 250 480 KOP 400 625 B mm C mm 300 195 380 245 380 255 Fuse Size RPK1 RP2 RP3 NH 00 NH 1 NH2 Fused 5W Switches Order No. KYA KYA SYK Tap-off boxes can be equipped with other brand of fused switches on request. Tap-off boxes are painted in red as standard. Continuous current of tap-off boxes with fused switch should not exceed 80% of tap-off box current rating. 18 Please call us for non-standard components. 49795 49797 95053 50 CURRENT Cable Gland 30 A 30 ELINEKO- BUSBAR TYPE BOX TYPE Tap-Off Boxes for MCCB’s PROTECTION DEGREE IP 55 5 KO P 5 BOX RATING 160 A - 16 250 A - 25 400 A - 40 FUSED SWITCHES TYPE 1 Cable Gland Type Mat. (a G t lan th d re P e la si te d s e s) Cable Gland Plates Order Inner Code Diameter (mm) Sheet Metal ---- RP0 ---- Sheet Metal M32 RP1 25 Sheet Metal M40 RP2 32 Sheet Metal Special RP3 63 AL 2xSpecial RP4 63 AL 4xM25 RP5 18 AL 4xM32 RP6 25 AL 4xM40 RP7 32 AL 8xM32 RP8 25 L1 L2 L3 N KOP 1651-M1 KOP 1651-B1 (a G t lan th d re P e la si te d s e s) A L1 L2 L3 N KOP 2551-M1 KOP 2551-B1 A Special Cable Gland Plates Cable Mat. Gland Type Order Inner Code Diameter Sheet Metal ---- RPK0 ---- Sheet Metal M25 RPK1 18 Sheet Metal M32 RPK2 25 Sheet Metal M40 RPK3 32 RPK4 63 Current A A mm KOP 160 420 KOP 250 500 KOP 400 675 B mm B 1xSpecial KOP 4051-M1 KOP 4051-B1 L1 L2 L3 N A C mm 300 220 300 220 300 220 Cable Gland 5W Order No. RPK2 RPK3 RP3 35484 35486 35504 * EAE tap-off boxes can be designed for all brands of MCCB’s. 50 Sheet Metal (a G t lan th d re P e la si te d s e s) (mm) 30 Please call us for non-standard components. A 30 19 ELINEKO- BUSBAR TYPE BOX TYPE BOX RATING Tap-Off Boxes PROTECTION DEGREE 40 A - 04 80 A - 08 IP 55 5 SWITCH TYPE KO P 5 1 146 192 105 KOP 0451-B1 KOP 0851-B1 Sample Order: 40 A, IP 55, 5 wire, transparent hinged lid, suitable for MCB, empty tap off box 230 190 KOP 0451 - B1 20 30 290 135 181 105 330 KOP 0451-B2 KOP 0851-B2 Sample Order: 40 A, IP 55, 5 wire, transparent fixed lid, suitable for MCB, empty tap off box 30 290 330 20 Please call us for non-standard components. 20 230 190 KOP 0451 - B2 B1 -Transparent hinged lid / Empty tap off box B2 -Transparent fixed lid / Empty tap off box W -Equipped with MCB 3x6 A 3x10 A 3x16 A 3x20 A 3x25 A 3x32 A 3x40 A 3x50 A 3x63 A 3x80 A ELINEKOFixing Elements Tray Supports Description L (mm) Code UAS-K4 SUPPORT (1) 200 67136S UAS-K4 SUPPORT (2) 250 67135S UAS-K4 SUPPORT (3) 300 67134S UAS-K4 SUPPORT (4) 350 67133S UAS-K4 SUPPORT (5) 400 67132S UAS-K4 SUPPORT (6) 500 67131S UAS-K4 SUPPORT (7) 600 67130S UAS-K4 SUPPORT (8) 700 67129S UAS-K4 SUPPORT (9) 1100 67128S Tij L KO-UT 40 UAS-K4 L Support Edgewise application sample 40 4 KO-UT Flat application sample Tray Supports Description L (mm) Code ASU2A-1 135 99536S ASU2A-2 250 99535S ASU2A-3 500 99534S ASU2A-4 1000 99533S ASU2A-5 2000 97043S L Tij KO-UT 46 ASU2A 31,5 Edgewise application sample 2 KO-UT Flat application sample Connection Parts L Code BRA 11-05 Threaded Rod (M8) 500 99974 BRA 11-10 Threaded Rod (M8) 1000 99973 BRA 12-05 Threaded Rod (M10) 500 99356 BRA 12-10 Threaded Rod (M10) 1000 98876 BRA 10 Extension Part (M8) - 98877 BRA 13 Extension Part (M10) - 98874 BRA 9 EAE Pull-off Dowel (M8) - 98878 BRA 9 EAE Pull-off Dowel (M10) - 98703 M8 Steel Nut - 01444 M10 Steel Nut - 01445 M8 Washer - 01422 M10 Washer - 01424 Description (mm) Current Aluminium Copper (A) (A) (A) L Threaded Rod 160 250 315 400 500 600 800 mm 70 75 80 100 112 125 - mm 70 75 80 100 125 Busbar cross-section dimensions Extension Part EAE Pull-off Dowel Diameter of the hole to be drilled M8.......Ø12 M10.....Ø14 Steel Nut Washer 21 ELINEKOFixing Elements Current (mm) A Code KOA - 1 UT Clamp 160 115 97524 KOA - 2 UT Clamp 250 120 97527 KOA - 3 UT Clamp 315 125 97523 KOA - 4 UT Clamp 400 145 97526 KOA - 5 UT Clamp 500 157 97385 KOA - 6 UT Clamp 600 170 97525 KOC - 2 UT Clamp 250 115 97524 KOC - 4 UT Clamp 400 125 97523 KOC - 6 UT Clamp 600 145 97526 KOC - 8 UT Clamp 800 170 97525 (mm) A Code KT 200 Tray Support 235 99525S KT 250 Tray Support 285 99524S Ø1 0 x2 0 10 35 42 ,5 A KO-UT Clamp 4 335 99523S KT 400 Tray Support 435 99522S KT 500 Tray Support 535 99521S KT 600 Tray Support 635 98715S TS 200 Tray Support 205 99517S TS 200 Tray Support 255 99516S TS 200 Tray Support 305 99515S TS 200 Tray Support 405 99514S TS 200 Tray Support 505 99513S TS 200 Tray Support 605 67876S TMP 8 Ceiling Support Unit - 99196S Coupling - 98869 TMP 8 14x20 ASU2A TS 6 7x1 A 16 11x KT Coupling Vertical Support Set Wall Type 66916 Vertical Support Set Wall Type 235 Code 90 30 Description Code Vertical Support Set (Z) Type 91202 22 Description (mm) Code Vertical Support Set (VS)-40 40 96017 Vertical Support Set (VS)-60 60 95996 Vertical Support Set (Z) Type 90 5 5x3 10, A A Ø10 12x20 Ø1 Ø13 Ø91 Description 15x35 135 7,5 155 125 70 25 KT 300 Tray Support 12 Description 30 10x 75 105 Description 90 35 13x Vertical Support Set (VS) Type 25 A ELINEKO- BUSBAR TYPE CONDUCOR TYPE BUSBAR CODE PROTECTION DEGREE NUMBER OF CONDUCTORS UNPAINTED / PAINTED COMPONENT Y DIMENSION A DIMENSION Fire Barriers KO B A (cm): Thickness of Fire Barrier Y (cm): Centerline of Fire Barrier Block Joint r rie e Fir r Ba Floor Sample Order: 250 A, Copper, IP 55, 5 Conductors Fire Barrier KOC 0255- 1 A -STD-150-40 Fire Barrier Fire Barriers Fire barriers are used to prevent the transition of flame and smoke from one zone to another in case of fire. Chimney effect of air insulated busbars are diminished. Dimensioning of Fire Barrier While placing an order for fire barriers that will be installed into KObelow listed information should be given: 2 Busbar Y 1- Thickness of floor or wall in cm. (A cm) 2- Centerline dimension of the fire barrier should be measured from the side without the block joint. (Y cm) 3- There will be no plug-in points at fire barrier location. 4- EAE Supplies 30 cm thick fire barrier as standard when wall or floor thickness is not stated. 5- The minimum length for these special elements with fire barrier can be 60cm. N Determination of Special Lengths After installation of standard busbar 3m lengths, you will be in need of special lengths which are smaller then 3m. The minimum length for these special elements can be 35 cm. Please measure the lengths of these modules as shown below. Measure “A” length in cm, to determine the length of special busbar subtract 12 from “A”. X=A-12 (cm) X=Length of Special Busbar A Please call us for more information. 23 ELINEKOKO1 Installation of End Closer 4 3 2 b a 1- Busbar run ends with or without a block joint (Figure a and b). For both cases installation procedures are same. KO1 4- Busbar run with end closer. 3- Place the end closer and install the screws. 2- Dismantle the screws on the end closer and busbar. Mounting instructions for Joints 1a 3 2 Figure 3 1a 2a 1- Remove joint top cover plate, joint side cover plate and the screws from non-block joint bolt. (Pieces marked as 1a shall be thrown away.) 4 4- Tighten the double headed nut untill upper nut is broken. 7 2- Introduce bolted and non-bolted ends of the busbar into each other carefully, till joint side cover plate screws can be put on. 5 6 5- Take away the broken nut and plastic seperator. 6- Install top and bottom joint cover plates. Check the joint before fitting the last joint side cover plate. Fit the joint cover side plate and tighten and screws. Check the position of the earth conductor when installing KO-II with five conductors. 8 55 Nm (40lbft) 7- Ensure that the insulation plates of the joint, are not cracked or broken. 24 3- Fix the joint side cover of the block joint. 8- If removal is required for any reason, tighten nut by calibrated torque wrench adjusted to 55 Nm (40 lbft) after re-fixing block joint set. ELINEKODirective EC DECLARATION OF CONFORMITY According to EC - Directive 2006/95/EEC “Low - Voltage - Directive” Product Group E-Line KO-II Busbar Energy Distribution System Manufacturer EAE Elektrik Asansor End. Insaat San. ve Tic. A.S. Akcaburgaz Mahallesi, 119. Sokak, No:10 34510 Esenyurt-Istanbul This is to attest, under our sole responsibility, that the aforementioned products conforms with the regulations and guidelines of the following standards. Standard : IEC 60439-1 IEC 60439-2 Tests 1- Temperature-rise limits 2- Dielectric properties 3- Short-circuit strength 4- Effectiveness of the protective circuit 5- Clearances and creepage distances 6- Mechanical operation 7- Degree of protection 8- Electrical Characteristics 9- Structural Strength 10- Crushing resistance 11- Resistance of insulating materials to abnormal heat 12- Fire barrier E L E K T R İ K Date EAE Elektrik A.S. 11.09.2002 EAE Elektrik Asansor End. Insaat San. ve Tic. A.S. Akcaburgaz Mahallesi, 119. Sokak, No:10 34510 Esenyurt-Istanbul Tel: +90 (212) 866 20 00 Fax: +90 (212) 886 24 20 www.eae.com.tr 25 ELINEKOCertificates 26 ELINEKOProduct Overview 160A 800A BUSBAR SYSTEM PRODUCT OVERVIEW (E-LINE KO-II) 1- Standards & Certification: - Busbar system shall be designed and manufactured as per IEC 60439-2 standard. Each individual rated busbar shall have separate type test certificate from an independent internationally accredited laboratory. - Manufacturing facility of busbar systems shall have ISO 9001 and ISO 14001 certification. - Busbar system shall have CE marking. - Each product shall have a “Type Label”, which indicates the brand, type of the unit, conductor number and electrical details. 2- General Structure of Products: - Busbar system shall be Air-Insulated and Plug-in type. Aluminium or Copper conductors shall be tin plated along the entire length. Housing shall be galvanized steel or if required RAL 7038-Electrostatic painted. 2.1- Electrical Characteristics: - Busbar systems nominal insulation voltage shall be 1000V. - As per ampere rates, minimum short circuit values shall be like below; - Temperature rise shall be maximum 50K over 40°C ambient temperature for both tin plated Aluminium and Copper conductor busbars. 160A: 1sec/rms-10kA, Peak-17kA 250 and 315A: 1sec/rms-15kA, Peak-30kA 400 and 500A: 1sec/rms-30kA, Peak-63kA 600A and above: 1sec/rms-35kA, Peak-73,5kA 2.2- Housing and Structure: - Busbar system shall be of air insulated type. The bars shall be supported by insulators installed into the housing at every 25 cm. - On a three meter standard length busbar the distance between the plug-in points on one side shall be 50cms. The points shall be on both sides of the busbar making the average distance of plug-in points 25cm. - To prevent wrong alignment of the phase sequence during installation there shall be mechanical barriers on the joint that shall ensure correct mounting. - IP Plug-in covers of the busbar system should be hinged.Plug-in windows shall have automatic shutter system. This shutter shall open automatically when the earth contact of tap-off box is inserted. - Busbar system shall have all necessary accessories (elbows, offsets, panel-transformer connections, reductions, etc). Manufacturer shall supply special dimensioned units in short time, if the project conditions requires. - For horizontal runs, a horizontal expansion unit shall be used at every 40m and expansion points of the building. - For vertical applications, a vertical expansion unit shall be used at every floor. Busbar system shall be rigidly fixed by supports at every floor. 2.3- Conductors: - Busbar system shall have Nickel and Tin-plated 6101 class aluminium conductors (160-600A). / Busbar system shall have Tin-plated Electrolytic copper conductors (250-800A). - Busbar system shall have below number of conductors and phase configuration; a) 4 Conductors:(4 full size conductors + Housing ( earthing ) b) 4 ½ Conductors :(4 full size conductors + ½ earth conductor + Housing) c) 5 Conductors :( 5 full size conductors + Housing (earthing) ) d) 5 Conductors :( 5 full size conductors, 5th bar shall be used as clean earth + Housing). - Neutral conductor shall have the same cross-section (100%) of phase conductors. 2.4- Insulation: - Busbars shall have air-insulation system. - Rated insulation voltage of the system shall be 1000 V. 2.5- Joint Structure: - Electrical and mechanical connection shall be made at joints by “single bolt” joint construction and each joint shall have two “Belleville” washers. - Insulators of the joint shall be manufactured of glass-reinforced polyester. - Joints shall be realized by a torque spanner (wrench) set at 55 Nm. - To prevent the joints from transportation damages, they shall be protected by metal caps, which shall be removed before installation. - Joint bolt shall be locked from both sides (Bolt head and nut). 2.6- Protection: - Protection degree of the busbar system shall be minimum IP55. 3- Tap Off Boxes: - Rating of plug-in tap off boxes shall be up to and including 400A. Plug-in tap off boxes shall be installed, when the busbar line is energized. - Tap off boxes shall have an electrical interlock mechanism, which ensures that plug-in tap off box cannot be removed mechanically from the busbar, when the switch is at “ON” position. Mechanical interlock mechanism shall prevent the cover of the box from opening, when the switch is at “ON” position. - When the switch is at “OFF” position and the cover is open, tap off box shall provide IP2X protection level. (There shall not be any accessible live part in the box). - Tap Off boxes shall be suitable for any brand of MCB. - Contacts of plug-in tap off box shall be silver-plated copper. - While inserting the contacts of Plug-in tap off boxes, earth contact shall make first contact. - Tap off boxes up to 80A shall be manufactured of (850 GLW) type plastic material. Tap off boxes from 160A up to 400A shall be manufactured of sheet steel and epoxy painted RAL 3020. 4- Installation and Commissioning: - Busbar systems shall be installed as per single-Line drawings respect to required ampere rates and manufacturer installation guide (torque values, lockers, etc.). Electrical installer shall run an insulation test after installation according to manufacturer's test procedures. The results of the test shall be reported to the manufacturer. Minimum insulation value shall be 1Mohm. 27 28 Please dublicate this page for your own use. : : Project Project No : Signature : Date Name : : Company Item Prepared by Component Component List Quantity ELINEKO-II Project Design Form E L E K T R İ K PRODUCTTYPES E-LINE KB Compact Busbar Distribution System 800...6300A Plug-in Busbar Distribution System 160...800A E-LINE MK Small Power Plug-in Busbar Distribution System 100-160-225A E-LINE KAP Plug-in Busbar Distribution System 40-63A E-LINE DL Multi-conductor Lighting Busbar System 25-32-40A E-LINE KAM Lighting Busbar System 25-32-40A E-LINE TB Multi Conductor Trolley Busbar System 35...250A E-LINE DK Underfloor Ducting Systems E-LINE DKY Raised Floor Energy Distribution Systems 25...63A E-LINE UK Cable Tray Systems