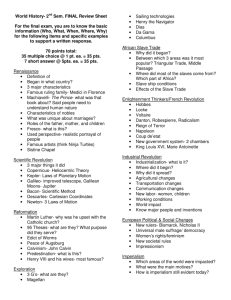

Examples of EnergyPlus HVAC Simulation Features

advertisement

Examples of EnergyPlus HVAC

Simulation Features

Michael Rosenberg, Jian Zhang, Yunzhi Huang

Building Energy Simulation Forum

• November 16, 2011

EnergyPlus – Example HVAC Simulation Features

1. Built in Energy Management System

2 Zone Air Mixing

2.

Mi ing

3. Dedicated Outdoor Air Systems

2

1. Energy Management System in EnergyPlus

Standard control in EnergyPlus

Models typical operational strategies such as:

Thermostatic control, flow control, daily and

seasonal schedules,

Outdoor temperature reset, economizer control,

Equipment load staging, and daylighting control.

T i ll predefined

Typically

d fi d control

t l sequences with

ith only

l

schedules and set points accessible to the user.

Interactions between components are limited and

are usually hard-coded in the simulation program.

3

Energy Management System in EnergyPlus

Energy management system control

EMS in EnergyPlus is a powerful tool to simulate

complex HVAC system controls

E l t the

Emulates

th types

t

off controls

t l possible

ibl with

ith the

th digital

di it l

energy management systems used in real buildings

EMS enables control interactions between components

Accesses sensor data initiates control actions

4

Energy Management System in EnergyPlus

EMS

Sensors (to “GET”)

Temperatures

Flow

Status (on/off)

Metered data

Actuators (to “SET”)

Availability on/off

AvailabilitySchedules

Setpoints (temp, humidity)

Flow

Fl

Programs – E+ Runtime Language (Erl)

Keywords (RUN, SET, IF, ELSEIF, ENDIF…)

Operators (+, -, /, …) & Built-in functions (math,

psychrometric,…)

5

Example of EMS in CBP Project

DOE’s Commercial Building Partnerships (CBP) Program

PNNL teamed with one of America’s largest retailers to explore energy design

measures by retrofitting one of their existing stores

Retrofit project goal: cutting site energy use by 30%

Pre/post-renovation metering data available to calibrate simulation

Detailed simulation is required: EnergyPlus 4.0

Location

Building type

Retail

Built

1987

Area

~100,000 ft2

No. of stories

6

Virginia

1 level

Building HVAC System and Thermal Zoning

Built‐up air handling unit (AHU)

Chilled water cooling

Central system duct furnace

Operates like a single zone VAV system with inputs from main sales floor (Control Zone).

Other areas and zones (Slave Zones) are also served by zone heaters

Control signal from main sales floor conditions

OA

VFD

RA

Sales floor (Control Zone)

Storage, offices, and other (Slave Zones)

7

Salon

Main office RTU2

RTU1

Supply Air Flow and Temperature Control

Heating setpoint 70 ºF

Cooling setpoint 75 ºF

Fan speed

control

Temperature

control

8

Modeling with EnergyPlus Standard Controls

Control

Zone

Control

Zone

Slave

Z

Zone

1

Control

Z

Zone

Slave

Zone 2

Control

Zone

9

…

…

Design schematic

Model in E+ with standard

control

Modeling with EnergyPlus Standard Controls

System

level

E+ objects and settings

Problems

AirLoopHVAC:OutdoorAirSystem

p

y

Coil:Cooling:Water

Fan:VariableVolume Max 100% Min 30%

• Slave zones

become control

zones

Coil:Heating:Gas

• Hypothetical central heating coil with zero W capacity

SetpointManager:Warmest

• Strategy: MaximumTemperature

• Supply fan stays

at minimum (30%)

at heating mode

AirTerminal:SingleDuct:VAV:Reheat

• Scheduled Minimum Flow Fraction at 30%

• Gas reheat. Duct furnace’s capacity is proportionally

split to terminal reheat coils based on design flow

Zone level • Reverse damper action

ThermostatSetpoint:DualSetpoint

• Deadband 70F - 75F for Control Zone

• Deadband

D db d 70F - 90F ffor Slave

Sl

Z

Zones

10

• Cannot realize

Heating: 34% at

1st stage, 66% at

2nd stage

• Cannot

synchronize

heating and VAV

damper positions

Simulated Controls with EMS

Control

Zone

Control

Zone

Slave

Zone 1

Slave

Zone 1

Slave

Zone 2

Slave

Zone 2

Design system

11

Simulated controls in

EnergyPlus with EMS

EMS Program Applied

IF Control Zone reheat coil

input, Q

SET

Q > = 50% capacity

2nd stage heating mode

• Slave Zone reheat coil availability = YES

• Slave and Control Zone min damper = 66%

0< Q < 50% Capacity

1st stage heating mode

• Slave Zone reheat coil availability = YES

• Slave and Control Zone min damper = 34%

• Slave Zone reheat coil availability = NO

Q=0

• Slave and Control Zone min damper = 30%

Ventilation or cooling mode • Slave Zone damper opening fraction =

Ventilation or cooling mode

Control Zone damper opening fraction

Sensor / Actuator

12

Hourly Results of Winter and Summer Days

H ti mode

Heating

d

C li mode

Cooling

d

Reheating coil availability and

VAV damper positions are

synchronized

Reheat coils input rate is not

available as actuator. EMS

EMS’

limitation

13

Other Examples of Use of EMS

Turn on a relief fan when economizer is in use

Simulate pressure control

If OA > Min Ventilation Energize relief fan

Reduce cooling temperature setpoint if space humidity

exceeds threshold

If RH > 60% Cooling

C li setpoint

t i t 75 72 d

deg. F

14

2. Zone Air Mixing in Energy Plus

ZoneMixing

Simplified treatment of air exchange between zones

User defined air transfer

Transfers energy from one zone to another (sensible and latent heat

transfer)

Input parameters

Source zone

Receiving zone

Airflow rate – flow per zone, flow/person, flow/area, ACH

Schedule

Delta temperature availability

Outdoor air temperature availability

15

Example of Zone Air Mixing in AEDG

Advanced Energy Design Guides

Guidance and recommendations by building

type and climate

Identifies pathways to 30% and 50% energy

savings

g

Collaboration of professional organizations

and DOE

Backed by technical support documents

(TSDs)

http://www.pnl.gov/main/publications/external/

technical_reports/PNNL-19809.pdf

16

Zone Air Mixing – AEDG Quick Service Restaurant

Transfer air from dining room used as MU air for kitchen exhaust

Location

Building type

Restaurant

Built

New Construction

Area

~25,000ft2

No. of stories

17

Various

1 level

Zone Air Mixing – AEDG Quick Service Restaurant

Transfer air from dining room used as MU air for kitchen exhaust

Bathroom

Exhaust

RTU-2

RTU 2

OA2 = 3,120

OA1 = 2,080

RTU-1

RTU 1

BX = 400

SA2

KX = 4,800

RA2

0

Kitchen

18

ZoneMixing,

Kitchen_Exhaust_Fan_Mixing,

Kitchen,

Hours_of_kitchen_operation,

_ _

_ p

Flow/Zone,

1,680,

Dining,

0.0;

RA1

TRA = 1,680

SA1

0

Dining Area

!- Name

!- Zone Name

!- Schedule Name

!- Design Flow Rate Calculation Method

!- Design Flow Rate {ft3/min}

!- Source Zone Name

!- Delta Temperature {deltaF}

Zone Air Mixing – AEDG Quick Service Restaurant

ZoneMixing – Not the perfect solution

Only energy balance is affected – air balance is “left to the user’s discretion”

Kitchen – Need to account for actual kitchen exhaust energy – increased SP

Dining - Not an issue since equivalent air flow to transfer is relieved through RTU-1.

Unless ERV is also included in dining zone, then “dummy” exhaust added.

Bathroom

Exhaust

RTU -2

OA2 = 3,120

RTU-1

OA1 = 2,080

OA2 = 3,120

SP2 = SP1 x 4,800

3,120

BX= 400

BX= 400

SA 2 RA2

KX= 4,800

0

RA1

TRA= 1,680

Kitchen

Actual Design

19

RTU-2

Bathroom “Dummy”

Exhaust Exhaust

SP =0

0

Dining Area

TX= 1,680

SA2 RA2

SA1

KX= 3,120

0

Kitchen

OA1 = 2,080

RTU-1

RA1

TRA= 1,680

0

Dining Area

Simulated Design

SA1

3. DOAS in EnergyPlus

DOAS

Two parallel HVAC systems serving a single zone

Decouples OA ventilation load from space loads

Better control of space temperature and humidity

Better control over quantity of OA

Single

S

geO

OA supp

supply

ya

and

de

exhaust

aus e

enhance

a ce e

energy

e gy recovery

eco e y

20

DOAS in EnergyPlus

Like many simulation programs E+ limit is one HVAC system per zone

Only one “air loop” serving a zone

Air loop can be DOAS serving multiple zones with zonal equipment

providing space conditioning (ex. fan coils, heat pumps or radiant panels)

Air loop can be space conditioning system serving multiple zones with

zonal DOAS

EnergyPlus Air Loop

21

Example of DOAS in AEDG Medium Office

Location

Building type

Medium Office

Built

New Construction

Area

~54,000ft2

No. of stories

22

Various

3 story

Example of DOAS in AEDG Medium Office

Fan Coil Units Combined with Multi-zone DOAS

DOAS With Energy Recovery DOAS DOAS control – SA

temperature based on OA

reset schedule

Fan coil control – thermostat

setpoint

OA EA

Conditioned OA

Conditioned OA RA

RA Fan Coil 23

Conditioned OA

Conditioned OA

F C il

Fan Coil

Example of DOAS in AEDG MediumOffice

DOAS Temperature Control

SA Tem

mp Deg. F.

SetpointManager:OutdoorAirReset,

SetpointManager:OutdoorAirReset

DOAS SAT setpoint,

!- Name

Temperature,

!- Control Variable

60,

!- Setpoint at Outdoor Low Temp

!- Outdoor Low Temp

p

50,,

55,

!- Setpoint at Outdoor High Temp

60,

!- Outdoor High Temp

DOAS Supply Outlet Node;

!- Setpoint Node or NodeList Name

DOAS Supply Air Reset

Schedule

61

60

59

58

57

56

55

54

0

20

40

60

80

100

OA Temp, Deg. F.

Fan Coil Control

ThermostatSetpoint:DualSetpoint,

Core_bottom DualSPSched, !- Name

HTGSETP_SCH,

!- Heat Setpoint Temp Sched Name

CLGSETP_SCH;

!- Cool Setpoint TempSched Name

Heating Setpoint

90

80

70

60

50

40

30

20

10

0

1

24

Cooling Setpoint

3

5

7

9 11 13 15 17 19 21 23

y

Weekday

25