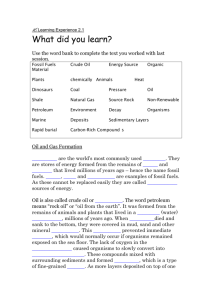

Oil and Natural Gas

advertisement