Electrical Products - GARD Specialists Co., Inc.

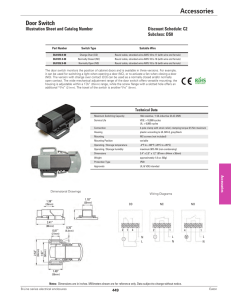

advertisement