APTA-PR-CS-S-016-99 - American Public Transportation Association

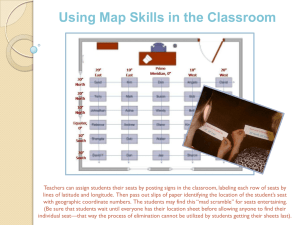

advertisement