from tut.fi

advertisement

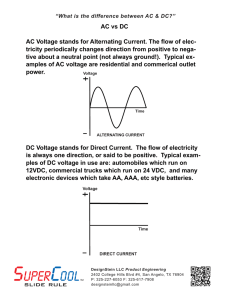

CIRED 17th International Conference on Electricity Distribution Barcelona, 12-15 May 2003 A METHOD TO INCREASE THE INTEGRATION CAPACITY OF DISTRIBUTED GENERATION ON WEAK DISTRIBUTION NETWORKS Sami REPO, Ari NIKANDER, Hannu LAAKSONEN, Pertti JÄRVENTAUSTA Tampere University of Technology - Finland sami.repo@tut.fi ABSTRACT The paper investigates the effects and potential of distributed generation (DG) on the operation of weak distribution networks. It focuses on the development of a new method to increase the integration capacity of DG in an existing network. The paper considers voltage issues and the load transfer capability of distribution network including windmills. The proposed method is based on ring operation of the distribution network and control of windmill active and reactive power. The applicability of the proposed method is tested with load-flow simulations on a real life distribution network and planned windmills. The studies have proved the capability of the proposed method to increase the integration capacity of DG units without major network investments. 1. INTRODUCTION The fast propagation of DG at distribution network will have a major influence on distribution networks. This implies many new factors which are not usually considered. The experience of distribution network companies of these topics is so far slight. However, these topics will become a part of normal operation, not just special cases. This will necessitate the existing networks and operation methods in order to consider DG in the distribution network. The voltage drop of a medium voltage network has been one of the main planning issues in rural distribution networks in Finland [1]. There are networks where the length of 20 kV feeders is as much as 100 kilometers and the demand in sparsely populated areas is very low. The impedance of these feeders is remarkably high. If a large DG unit is installed far from a primary substation, voltage rise problems may occur during low demand periods [2]. The voltage rise problem is acute in coastal and skerries areas due to wind power installations. The integration capacity of DG units on weak distribution network is limited by the voltage rise problem. The propagation of DG may be seen either as a change of load curves when production replaces a part of the load or as an addition of production units to the distribution network. Some changes in the structure of distribution network are needed due to DG. The structure and operating principle of the distribution network will move towards a distribution system (active distribution network) with several active components along the network. Meshed operation of distribution network may allow more enhanced control and operation principles than today. These issues at least should be taken into account in most potential areas of DG in long-term planning studies [2]. TAM_Repo_A1.doc Session 4 Paper No 60 2. PROPOSED METHOD Medium voltage networks are normally operated radially although they are constructed meshed for reasons of reliability. Typically a rural overhead medium voltage network includes remotely controlled disconnectors at important nodes where radial feeders may be connected. The proposed method is based on meshed operation of distribution network and control of DG unit active and reactive power. The meshed operation of the distribution network will divide power flows to the feeders more evenly than radial operation, losses will be minimised and voltage rise due to DG can be limited. The integration capacity of a DG unit may also be increased by controlling the active and reactive power of the DG unit. At least for the case studied the control of the DG unit may be based on terminal voltage. The consumption of reactive power is used to limit the voltage rise problem when necessary. If this is not enough, the production of active power must also be limited. This possibility to control the integration capacity should be considered in the interconnection contract. The control of DG unit may benefit both parties when network investments are avoided. The proposed method is quite different from the “minimum load maximum production” planning principle because the integration capacity is flexible and dependent on network conditions. In ring operation the protection of feeders may be based on existing protection devices, if extra delay is allowed for in the protection [3]. The proposed protection solution is straightforward and economically attractive. When a fault occurs the task is to indicate and locate the faulty ring. When the ring is opened the conventional feeder protection may operate. The amount of load interrupted due to the fault is the same as in a radially operated network. The proposed solution requires some changes in the feeder terminals software and replacement of disconnectors with fast switch-disconnectors at remotely controlled nodes. 3. TEST RESULTS 3.1 Test system The method was tested with a case study on a distribution network of Fortum Sähkönsiirto Oy in south-west Finland including windmills in archipelago skerries. The distribution network in this area is relatively weak, because the length of -1- CIRED 17th International Conference on Electricity Distribution medium voltage lines (20 kV) is long and the amount of load is small. There are also considerable restrictions for network expansions due to environmental reasons. The calculations are based on real hourly load curves and network data. The network studied (Figure 1) consists of one HV/MV substation, which feeds two MV feeders (Kasnäs and Byholmen). The other short MV feeders of the substation were not included in the network model used. Calculations were carried out with an equivalent network, where some of the branch conductors of the MV network are omitted. In the PowerWorld [4] case the constant current loads were located in the middle of a certain part of the feeder. These loads were summed up from that particular part of the feeder (based on different customer groups). For the estimation of load demand customers’ annual unit consumptions and customer group based load curves are needed. The complete load model includes mean values and variations of power demand for every hour of the year. The models are presented as 365*24 tables, known also as topographies. The load curve models for 46 different customer groups published by Association of Finnish Electric Utilities are the most extensive collection of load models collected in Finland [5].The voltage of the lowervoltage side of the HV/MV transformer (110/21 kV, 16 MVA) was maintained at 20.4 kV with on-line tap-changer. The Kasnäs feeder is 71 km long and based on information from the network information system its minimum load was 364 kW (Sunday 18 August 03:00 a.m., simultaneously the load of the Byholmen feeder was 350 kW) and maximum load was 1174 kW (Monday 18 February 12:00 p.m., the load of the Byholmen feeder was simultaneously 800 kW). Wind turbines (4*750 kW) will be constructed on the island of Högsåra and they are to be connected to the Kasnäs feeder 22 Kasnäs 0,065 MW 0,019 MVR 4 3 2 1 20,41 kV 20/110 kV 110 kV 0,9810 20,60 kV 23 20 5 22 21,55 kV 6 18 21,41 kV 0,096 MW 0,028 MVR 21,50 kV 15 21,54 kV 20,37 kV 20,38 kV 20,35 kV 26 28 0,030 MW 0,009 MVR 0,074 MW 0,021 MVR24 20,36 kV 12 0,027 MW 0,007 MVR 7 11 0,013 MW 0,004 MVR 0,160 MW 0,047 MVR 21,42 kV 16 21,68 kV 0,040 MW 0,012 MVR 25 21,26 kV -2,03 MW 0,06 MVR Byholmen 20,38 kV 19 21,76 kV 20,95 kV Slack bus 110,08 kV110,0 kV 0,051 MW 0,015 MVR 21,11 kV Wind mill 8 20,39 kV 0,063 MW 0,018 MVR 10 20,79 kV 21 3,00 MW 9 -1,28 MVR Barcelona, 12-15 May 2003 20,33 kV 20,31 kV 0,032 MW 17 0,009 MVR 20,31 kV 0,006 MW 0,002 MVR 13 20,32 kV 14 0,071 MW 0,020 MVR27 20,31 kV 20,31 kV Figure 1. Study case “minimum load of Kasnäs feeder and maximum production of wind mill”. Table 1. Network transfer capabilities. Load of KasnäsMaximum production [kW] feeder [kW] Radial Ring 364 1120 1900 473 1250 2000 572 1300 2100 690 1350 2300 825 1550 2500 992 1750 2700 1174 2000 2900 TAM_Repo_A1.doc Minimum voltage [kV] Radial Ring 20,30 20,40 20,23 20,39 20,19 20,40 20,19 20,40 20,05 20,40 19,97 20,40 19,95 20,40 Session 4 Paper No 60 Reactive power of generator [kVar] Radial Ring -480 -810 -530 -852 -553 -895 -575 -980 -660 -1065 -745 -1150 -852 -1150 -2- 17th International Conference on Electricity Distribution km away from the HV/MV substation. The windmills will be equipped with frequency converters, which allows power factor control between 0.92 – 1.00 inductive or capacitive. The Byholmen feeder is 53 km long and its calculated minimum load was 300 kW and maximum load was 1490 kW. Figure 1 represents the “minimum load of the Kasnäs feeder and maximum production of the windmill” in the study case. The upper limit of MV voltage is 21 kV, which is exceeded in several locations although the generator is consuming reactive power at full capability. The maximum production capacity is 1.1 MW according to network transfer capability. The reactive power consumed at the generator is coming from a 44 km long sea cable between nodes 18-7-6 and a few other shorter cables. 3.2 Ring operation The ring operation of the feeders at Kasnäs and Byholmen may be realised with an automatic switch-disconnector. Currently node 12 includes a remotely controlled disconnector, which does not have capability to switch fault currents. However, the ring operation of these feeders has a remarkable advantage compared to radial operation of feeders. The network transfer capability for the windmill studied may be increased from 1.1 MW to 1.9 MW by operating the network as a ring in the minimum load case (Table 1). The network transfer capability increases as a function of the Kasnäs-feeder load. The network transfer capability during maximum load condition is 2.0 MW and 2.9 MW for radial and ring operated networks respectively. The voltage profile of the radial network is very different at the Kasnäs- and Byholmen feeders. The voltage of the Kasnäs feeder is very high in all cases and at the same time the voltage of the Byholmen feeder is determined by the loading of the feeder. The control of voltage at the primary substation must be a compromise between these two competing tasks. However, the ring operation of the network may be used to balance the voltage profile at these feeders. The lowest voltage appears at the primary substation in all cases, which indicates a possibility for reduction of voltage profile and enhancement of network transfer capability. Barcelona, 12-15 May 2003 in a similar way. 3.3 Consideration of energy production capability The energy production capability of the windmill and distribution network studied is considered in both operation modes and compared, this enabling the technical and economic considerations to be combined. The wind is assumed to be stochastic in this study. The distribution of wind speed is modelled with two normal distributions, which have expectation values 5.5 and 8 m/s, and standard deviations 2 and 1.5 m/s. These parameters are based on approximations of monthly wind statistics from similar locations [6]. Two distributions are used to model annual variation of wind speed. The output power of the windmill is determined by the wind speed – power curve. The annual energy produced in standard atmospheric conditions would be 7868 MWh (capacity factor 0.3) when the availability of units is 100 %. The distribution of wind speed and power output of windmills is shown in Figure 2. The network transfer capability may be determined in this case by the Kasnäs feeder load in planning (Table 1) and by windmill terminal voltage in operation. In order to calculate the amount of electricity not produced due to output power limitations a certain load duration curve (Figure 3) must be assumed. The output power of the windmills (Figure 2) is compared to the network transfer capability (Table 1) in different load conditions taken from the load duration curve. The amount of electricity not produced is the difference between the output and the capability. If the real load and wind curves are known, more precise results may be calculated than with the load duration curve and stochastic wind. 500 400 Frequency CIRED 300 200 100 0 0 5 10 15 Wind speed [m/s] 1000 TAM_Repo_A1.doc Session 4 Paper No 60 800 Frequency The generator consumes reactive power at full capacity (0.92ind.) in all cases. Although the losses of generation units will be increased when the generator is consuming reactive power, the consumption of reactive power is advantageous for the network transfer capability. The control of reactive power may be based on windmill terminal voltage, because the highest voltage always appears at the windmill terminal when it is operating. If the terminal voltage exceeds the maximum limit, the consumption of reactive power is increased. If this is not enough, i.e. if the voltage still exceeds the maximum limit, then the active power must be limited. In this way the integration capacity may be higher than the capacity based only in worst case conditions. The control of voltage and reactive power may be realised at the minimum voltage limit 600 400 200 0 0 500 1000 1500 2000 Power output [kW] 2500 3000 Figure 2. Distribution of annual wind speed and power output for all units. -3- CIRED 17th International Conference on Electricity Distribution Barcelona, 12-15 May 2003 389 400 356 Load duration curve 1 Load duration curve 2 Load duration curve 3 Load [kW] 900 800 700 600 500 400 300 Minimum load = 364 kW 250 3 MW 200 2.25 MW 1.5 MW 150 100 50 0 1 0 1000 2000 3000 4000 5000 Time [h] 6000 7000 8000 Figure 3. Load duration curves. The amounts of electricity not produced are presented in Figures 4 and 5 in radial and ring operation modes for three different load duration curves and integration capacities. The distribution network operation mode has a strong influence on the amount of electricity not produced. The influence of load duration curve, however, is minor. The difference in the amount of electricity not produced between operation modes with 3 MW integration capacity is about 1200 MWh or 27400 € (using year 2001 monthly average of Nordpool elspot-price, 22.83 €/MWh). The difference in the amount of electricity not produced between 3 and 2.25 MW integration capacities is about 1000 and 300 MWh with radial and ring operation respectively. It is also interesting to note that the amount of electricity not produced is extremely low when the integration capacity is 1.5 MW in radial operation. When this is compared to the network transfer capability (1120 kW) determined by the “minimum load maximum production” planning principle, there seems to be a great opportunity to increase wind power production by changing the distribution network planning principle. 1600 1591 1556 1528 1400 1200 1000 2.25 MW 614 585 600 3 MW 562 800 1.5 MW 47,8 200 60,8 400 36,6 Electricity not produced [MWh] 321 300 0 1 2 3 Load duration curves Figure 4. Electricity not produced in radial network for three different load duration curves and integration capacities. TAM_Repo_A1.doc Session 4 Paper No 60 0 34,2 1000 350 11,5 1100 Electricity not produced [MWh] Maximum load = 1174 kW 22,9 1200 0 2 0 3 Load duration curves Figure 5. Electricity not produced in ring operation for three different load duration curves and integration capacities. 4. DISCUSSION The proposed method has been proved to increase the integration capacity of windmills on a weak distribution network. The requirements of the method are a possibility to operate the network as a ring with fast switch-disconnector and to control the active and reactive power of the windmill. No centralised control system or operator interaction is needed to operate the network in this case. The integration capacity of windmills may be concluded by the windmill terminal voltage. The distribution network planning and calculation of windmill integration capacity based on local wind statistics gives more flexibility for planning decisions compared to the “minimum load maximum production” planning principle. The decision on integration capacity may also be easily converted into financial terms. The planning decisions of the distribution network and wind power production may be based on calculations of network transfer capabilities and electricity not produced with different amounts of integration capacities, capacity factors, wind statistics, load duration curves, etc. There are, however, a few open questions. One major question is the influence of the method on power quality. Although the number of interruptions would be the same for the whole network, the number and duration of interruptions seen from the customer side may increase. The reliability of fast switch-disconnector and protective devices also has a central role for the safety and reliability of the whole network. Voltage quality problems such as voltage dips, flicker and harmonics may also disturb a larger area than previously. Another question is what happens when the ring of two or more feeders is switched to radial operation. There exists a danger of over-voltages at the windmill terminals if the control of the windmill is not fast enough or the switching operation is not co-ordinated with windmill operation. At the same time the voltages of other switched feeders would drop decisively. In any case there would be large and sudden -4- CIRED 17th International Conference on Electricity Distribution changes in the voltage levels due to switching. This may stress the network operator during storms due to repeated switching operations. Thus it may be easier to operate the network in the radial operation mode during periods of repeated switching operations. In normal operation the voltage control is more precise and the voltage level is closer to nominal with the proposed method than with traditional radial operation. The research of the method proposed should also extended to more complex systems. It is not certain that the method proposed would work properly in cases with several windmills at different locations, with different production types or with more complicated network structure. There is also a potential to improve the voltage / reactive power control of the system and enhance the network transfer capability in this way. 5. CONCLUSIONS The proposed method based on the ring operation of a distribution network and control of active and reactive power of a windmill has been tested with a real life distribution network and planned windmills. The requirements of the method are a possibility to operate the network as a ring with fast switch-disconnector and to control the active and reactive power of the windmill. No centralised control system or operator interaction is needed to operate the network in this case. The integration capacity of windmills may be concluded by the windmill terminal voltage. The integration capacity and network transfer capability can be increased by the use of the proposed method in the weak distribution network studied. Barcelona, 12-15 May 2003 ACKNOWLEDGEMENTS The authors are grateful to the Fortum Sähkönsiirto Oy for the interesting real life research topic, comments and research co-operation. REFERENCES [1] E. Lakervi and E.J. Holmes, 1995, Electricity distribution network design, IEE Power series 21, London, UK, 325 p. [2] N. Jenkins, et al., 2000, Embedded generation, IEE Power and Energy series 31, London, UK, 273 p. [3] A. Nikarder, et al., 2003, “Utilizing the ring operation mode of medium voltage distribution network”, Proceedings of 17th International Conference on Electricity Distribution, CIRED 2003 [4] PowerWorld simulator User’s guide, version 7.0, 2000 [5] A. Seppälä, 1996, Load research and load estimation in electricity distribution, VTT Publications 289, Espoo, Finland, 118 p., (http://www.enease.fi/asepthes.pdf) [6] T. Laakso and H. Holttinen, Wind energy statistics in Finland - Monthly statistics, http://www.vtt.fi/pro/pro4/pro42/tuulitilastot/monthly.htm The proposed method allows more flexibility in distribution network and windmill planning than conventional the “minimum load maximum production” planning principle. The advantages of ring operation compared to radial operation may be evaluated by comparing initial data of the analysis. In the case studied the electricity not produced with 3 MW integrated capacity respectively is 4.5 % and 19.8 % of annual energy production capability when the network is operated in ring and radial operation mode. TAM_Repo_A1.doc Session 4 Paper No 60 -5-