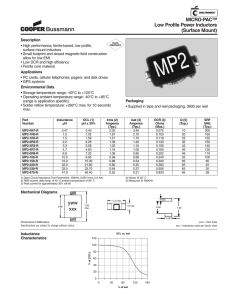

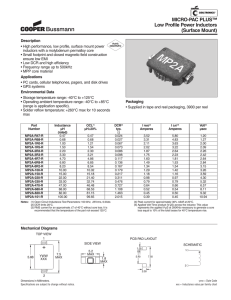

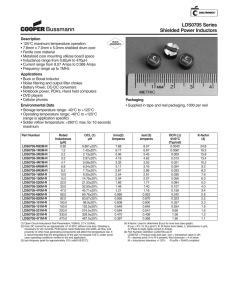

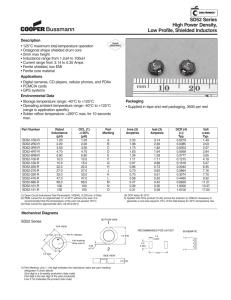

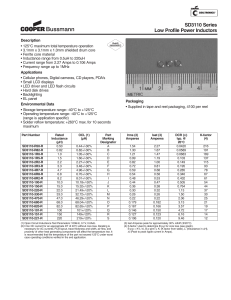

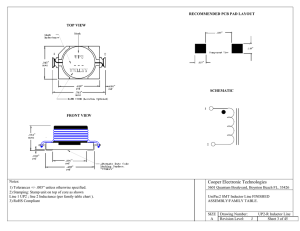

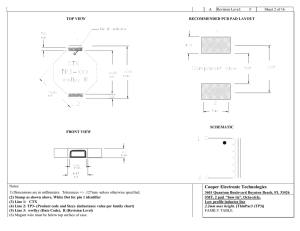

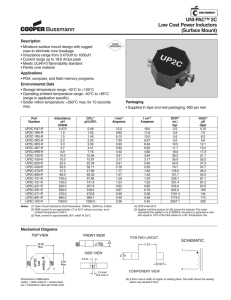

Coiltronics

advertisement