in-service partial discharge testing of generator insulation

advertisement

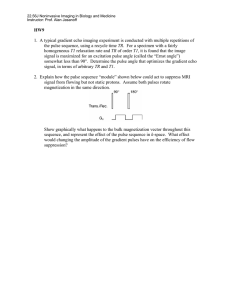

IN-SERVICE PARTIAL DISCHARGE TESTING OF GENERATOR INSULATION M. Kurtz and G. C. Stone, Ontario Hydro, Research Division Toronto, Canada IEEE Trans. Electr. Insul, Vol EI-14 No 2, April 1979 ABSTRACT Progressive degradation of high-voltage generator insulation, whether due directly to the erosive effects of internal or slot discharge or to other debilitating factors such as heat and vibration, may be detected and monitored as a function of time by in-situ partial-discharge tests. This paper describes new diagnostic test techniques for assessing the condition of generator insulation with a minimum of service interruption. An improved means of coupling or data acquisition is described, as well as a versatile single-channel pulse height analyzer with characteristics adequate for a field application of this type. Some typical test data are given. These studies were sponsored by the Canadian Electrical Association and are presented with their permission. INTRODUCTION Generator insulation systems, however perfect their initial state, inevitably degrade in service. Heat, thermal cycling, bar forces, vibration, mechanical shock, shrinkage of support structure such as wedges and spacers, and the presence of a high electric stress, act and interact to impair the integrity of the dielectric system. At some stage, partial discharges will start or begin to increase, providing an additional erosive aging factor. This usually occurs at abraded outer shielding, in cavities or delaminations, or in the end-turn structure. The number, magnitude and distribution of the partial discharge pulses can conceivably identify predominant aging mechanisms. Changes in these quantities, as a function of machine age, become a measure of cumulative insulation deterioration. “CONVENTIONAL” DIAGNOSTIC TEST A relatively inexpensive technique for the detection and display of partial-discharge pulses in generators has been developed and used by Ontario Hydro for over 20 years for the assessment of stator insulation condition [1]. In its present form, portable discharge-free coupling units, fabricated from approximately 2.5 m looped lengths of single conductor 27.6 kV concentric-neutral power cable are used, one for each phase of the generator as shown in Figure 1. The core conductors of the cables are connected to the generator’s respective terminals at any conveniently accessible point on the machine side of the disconnecting switch. The cable shields, the “low” sides of these high voltage coupling capacitors, are respectively connected, via lengths of shielded coaxial cable, to three five-stage RC high pass filters with a cut-off at about 30 kHz. After the machine is brought up to rated speed and voltage, the filter outputs are observed, together with a power-frequency trigger signal taken from one of the filter inputs, on an oscilloscope with a four-channel display as shown in Figure 2. The discharge patterns in Figure 3 are typical of a new and an old winding. Experience shows that as the magnitude of the highest partial discharge pulse increases, damage to the stator insulation also increases. Fig. 1: Cable-type portable partial-discharge coupling capacitors being connected to the three phase-conductors of a. machine prior to test. Fig. 2: Typical display showing the partial discharges from three phases of a machine and one power-frequency reference signal. Tests are usually done with the machine (a) isolated from the system, (b) synchronized at no load and (c) a full load. In many cases, a skilled operator can distinguish between pulses originating in the machine winding and external noise entering from the power (?). Large differences between the data for the (?) test modes may be caused by movement of bars in response to dynamic forces as the load changes. These movements result in a change in the contact resistance between the bar shielding paint and the iron in the (?). causing discharges in the slot to change. Such (?) are subject to abrasion, cumulative damage to shielding, increasing slot discharge with further (?). more loosening, more movement and the beginning of a runaway condition to failure. The major limitations of “conventional” partial-discharge tests are: 1. Noise originating from external sources, whether from other equipment in the station, or from the power system in the synchronized-mode tests, tends to mask the desired information. Such external noise can be as much as an order of magnitude higher than the pulses related to discharges in the machine. The phase position and the general shape of the “external noise” pulses may be the same as the “internal noise” pulses. (The pulse shapes are indeed largely a characteristic of the generator, and the coupling and filtering equipment characteristics.) 2. The discharge pulses, with rise times in the nano-second range, usually do not recur at the same phase position in successive cycles of power frequency. Estimation of the highest pulse magnitude is difficult and test results tend to be highly subjective, i.e., different operators report different data. Capturing of the highest pulses with an oscilloscope camera, even with fast film, is uncertain and undependable. Fig. 3: Partial discharge displays, one phase only, of asphaltic-mica insulated windings. These are from two identical machines. The upper trace is from a 3 year old winding, the lower from a 24 year old winding. 3. Interruption to service is required. Though a Machine need not necessarily be at standstill, it is desirable, from safety considerations, to isolate the machine and open the field breaker before connecting or removing the portable coupling capacitors. 4. The portable couplers must be maintained in a safe condition. Periodic high-voltage testing is required to ensure that the couplers are discharge-free at 150% of Maximum operating voltage. To overcome these limitations the Canadian Electrical Association undertook the sponsorship of the development of a more objective technique making use of recent advances in digital methods. PULSE HEIGHT ANALYZER Examination of the oscilloscope displays of discharge pulses from different machines, insulated with a variety of systems subject to different kinds and degrees of damage, discloses subtle differences not easily characterized by quantities such as maximum pulse height and the like, and often not readily captured on film. There is clearly more information is the pulse pattern than even a trained eye can realize. A method of quantizing the data in the discharge pattern is required for future correlation with Insulation condition. A versatile dual-polarity single-channel pulse height analyzer has been built to study the characteristics of discharge pulses, particularly the uniqueness and repeatability of the pulse height distributions. This Generator Corona Analyzer (GCA) is designed specifically to accommodate the short rise time and high repetition rate (multiple sites) of these pulses and to be insensitive to “ringing”. The GCA receives data from the high-pass filter Mentioned above and counts the number of pulses during a one-second interval which fall in the “window” between lower and upper thresholds, manual 1’y variable from O.I to 1.4 V in 0.1 V steps, with a 0.1 V interval between the thresholds. (These values were selected after some experience with the first prototype circuit which permitted continuous independent variation of these thresholds.) A manual scan with a threshold selector switch permits a complete pulse height analysis in about 2 minutes. A “phase window”, adjustable in width and position relative to the power frequency cycle, allows pulse counts to be made in any desired portion of the cycle. Fig. 4: Simplified schematic of analyzer. of the output pulse from B Bust be set greater than the sum of A’s output width and the signal rise time. This concept has been used elsewhere [2]. A cross-inhibit feature between the above positive-pulse channel and a similar negative-pulse channel, prevents either channel from functioning for 3 us after the first channel has been triggered, to avoid false counts due to opposite polarity voltage swings in the partial discharge pulse. (Individual partial discharge pulses are oscillatory, generally with a duration of less than 1 us. Observation of partial discharges on many different machines indicates that two consecutive pulses are rarely less than 10µs apart.) In practice, the circuit requires an overdrive of 20 mV for 25 ns to count a pulse, and pulses separated by 5 us or more can be resolved. Fig. 6: Typical GCA Pulse Height Distribution, Mountain Chute GS, Unit 2, Blue Phase. Fig. 5: Sequence of analyzer’s operation. Only pulses greater than the tower threshold produce trigger signals. The circuit uses two types of high-speed TTL 1C logic devices: fast comparators and “non-retriggerable, edgetriggered” monostables which can also be inhibited by an appropriate logic signal. The operation of the magnitude window for the positivepositive-pulse channel may be explained with reference to Figure 4. Monostables A and B are only triggered by a positive pulse. C is triggered only when both the inhibit signal is removed and a negative wave front appears at the trigger input. The sequence of operations for a pulse with a peak magnitude falling within the window is shown in Figure 5(a). The pulse triggers an output from comparator A only, while the inverted output from mono-stable B remains high since it was not triggered, thus failing to inhibit C. When A returns to the low level, monostable C is triggered by the negative front, its output activating a pulse counter. Until non-retriggerable monostable A returns to the low level, it cannot perceive input signals, thus ignoring ringing for a preselected time, in this case, 3µs. When the input pulse exceeds the upper threshold, as shown in Figure 5(b), both A and B are triggered. Since B’s output is now low, C is inhibited from triggering when A’s output drops; hence the counter is not activated. The width It is interesting to note that the magnitudes of pulses in the 10 to 15 counts per second region correspond to the maximum pulse magnitudes observed in the “conventional” test. NOISE CORRECTION From basic considerations, partial discharges occurring during the rising portion of the applied high voltage wave, are detected as negative pulses, and vice versa. The GCA phase window may be adjusted so that in a sequence of pulse counts, one may record the distribution of positive and negative pulses in the rising and falling portions of the power frequency cycle, respectively. On the assumption that unwanted noise is more or less uniformly distributed in both half cycles, a net distribution may be derived which ore truly represents the discharge situation in the insulation system. Typical data obtained in this way are shown in Figures 6 and 7. A calibration procedure to be described later, permits conversion from a mV to a pC base. Correction for transient noise occurring at the time of measurement is achieved by a simultaneous display, renewed every second, of the count of a selected pulse polarity in both the rising and falling portions of the power frequency cycle, both counted in the same one second interval. This noise correction technique may be only partially effective because the external noise (discharges on the incoming transmission lines, transformers, bus work) tends to be phase-oriented in exactly the same way as the generator insulation discharge pulses. Yet one invariably finds that the count in the “expected” polarity far exceeds the other. A more effective approach to noise elimination is described below. COUPLER CONSTRUCTION Essentially high-voltage power cable splice materials and techniques are employed. A sufficient thickness of selfamalgamating insulating tape to insulate for 4 kV (about 2 mm) is applied first over the jumper insulation for a length limited only by the local geometry (typically 20 cm). Over this insulation, a semi-conductive, self-amalgamating tape and tinned copper braid sandwich provides a discharge-free capacitor electrode. The capacitance of the coupler is adjusted to match symmetrical pairs to within about 2%. Depending on the jumper length, a typical coupler capacitance will be in the 70 to 90 pF range. The centre conductor of a coaxial cable (RGS8C/U) is soldered to the braid and securely fastened in place, as shown in Figure 9. The shield is removed to a point beyond the braid and left open at this end. Insulating tape is applied overall for mechanical security and a final finish layer similar to that normally used over jumpers may be used. Fig. 7: GCA Pulse Height Distribution, Barrett Chute GS, Unit 4, Red Phase. PERMANENT COUPLING CAPACITORS Permanent capacitive coupling devices may be installed in the winding itself, on the circuit ring bus, or on suitable jumpers between coils or coil groups. Such couplers permit observation of the discharge condition in a machine in the presence of external noise, and with no interruptions to service, though some load variation during tests my be advantageous to search for loose bars. These may be fabricated quite simply, at least on hydraulic units, by applying a conductive layer over the bus or jumper insulation in a convenient location and providing for connection to detection equipment. If the permanent couplers are placed at corresponding points in a pair of parallels or “splits”, equidistant from the machine terminal, “differential” noise rejection is possible. (In cases where the circuit ring bus lengths are unequal, the difference may be compensated by suitable delay lines to the differential amplifiers.) A differential amplifier as shown in Figure S will eliminate not only external or common-mode noise, but also the power frequency and its harmonics, so that a filter with its associated signal distortion is no longer required. It may be noted that pulses from a third split, entering via the circuit ring bus, may be rejected like common-mode noise. Thus in order to survey a machine winding completely, every split must be equipped with a permanent coupler. Couplers were installed initially on the six splits in one phase of a 13.8 kV hydraulic machine. These were placed on coil group jumpers half way down the winding between line and neutral where the jumper conductor operates at about 4 kV to ground at 60 Hz Fig. 8: Schematic of permanent couplers in machine splits. The co-axial cables from all installed couplers are trained and secured to a common junction box, external to the machine, where each cable is terminated with a 50-ohm resistor and connected to a BNC connector. This resistor eliminates reflections and keeps the 60 Hz potential on the coupler and cable down to less than a volt. It is important to note that the cables from symmetrical coupler pairs must be matched in length to better than 1 m. PERMANENT COUPLER EVALUATION Tests on generators with permanent couplers demonstrated that pulses applied at the machine terminal were rejected in the differential mode and could not be detected. However, pulses injected near one of the couplers in a pair could be observed directly on an oscilloscope, chiefly because the difference in arrival time (50 ns) at the two couplers, and hence at the differential amplifier inputs, resulted in a net signal. Note that the polarity of an observed pulse depends on the source split as well as its phase relative to power frequency. Effective noise rejection and correlation with conventional techniques were demonstrated with permanent couplers installed on four machines. Inherent in the Use of the permanent couplers on all splits is the capability, by observing pulse polarities, of identifying the location of the source of anomalously high pulses to within possibly a few coils at the line end of a single split. GCA. Some 60 machines have been tested with this technique to date, though the opportunity has not yet arisen to make measurements on a machine before and after maintenance, such as re-wedging or the like. Good correspondence has been noted between the new and the “conventional” test data. The “conventional” test, using portable couplers and the oscilloscope display, has correctly identified windings in the process of deterioration. Test data have ranged from 10 to 20 mV on machines considered to be in good running condition, to 50 mV to 500 mV (2000 to 5000 pC, depending on individual machine Vibrations) for machines in trouble. One large hydraulic generator suffering from severe ground wall erosion failed within a few months of the 50 mV measurement. Fig. 9: Unfinished permanent coupler installed on jumper in generator winding. Kote the co-axial cable attachment. CALIBRATION The conversion of test data in terms of millivolts of deflection on an oscilloscope screen, into apparent charge in picocoulombs is of paramount importance for rendering the data “independent” of the detection equipment parameters, machine size and the loading effects of connected bus, etc. For this purpose, it is necessary to inject a known charge at the machine terminals and to note the response on the detection equipment. A simple means of injecting such a pulse is achieved by isolating about 15 cm at one end of the shield on a portable discharge coupler by separating the concentric neutral conductors and cutting a I mm gap in the extruded shield of the cable. This provides a 30-pF high-voltage coupling capacitance through which a suitable square wave may be supplied via a length of co-axial cable, for calibration [3]. A 50-Q terminating resistor, connected to the co-axial cable at the coupling capacitor, limits the 60 Hz rise in potential of the HV cable shield to the order of 4 mV for a 13.8 kV generator winding, and eliminates reflections. A typical input square wave and output response is shown in Figure 10. A 200 ns rise time was selected since faster fronts produced unacceptable, ringing in the response. Typical calibrations obtained to date range from 10 to 35 pC per mV, depending on the machine size. A pulse generator at a repetition frequency of 5 kHz, capable of driving 50 Ω to 20 V, has been built into the GCA and may also be used to check its operation. TEST RESULTS Pulse height distribution data is being collected using the Fig. 10: Calibration of pulse voltage magnitudes into picocoulombs. The lower trace shows the front of a negative square wave which is applied through a 50 pF ideating capacitor. The response through the filter is shown in the upper trace. The injected charge, about 200 pC, yields a calibration in this case, of 20 pC/mV. For several machines, maximum pulse height has been decreased by an order of magnitude following treatment such as slot wedge tightening, re-finishing of semi-conductive slot paint, injection of semi-conductive silicone rubber in slot sides, etc. [4]. CONCLUSIONS AND FUTURE WORK The goal of a more objective and reliable test method with reduced system cost and independence from the interfering effects of external noise has been achieved. Further refinement and time reduction for the test is possible using a multichannel analyzer. A commercial analyzer has been modified to accept pulses at intervals down to about 10 us, yielding test curves identical to those obtained with the single-channel Generator Corona Analyzer, but in a much shorter time. A prototype system has been demonstrated using a programmable calculator and a fast digitally controllable counter for the permanent installation and continuous pre-programmed periodic monitoring of discharge pulse distribution as a function of load and time. Now that data may be obtained in a consistent and repeatable manner, the enormous task remains of collecting data from the field and establishing correlations with observed insulation damage in service as a function probably of the type of insulation system in question. When such correlations are confirmed, early warning of incipient problems will hopefully be obtainable so that suitable repair and maintenance work may be scheduled. REFERENCES [1] M. Kurtz, “A Partial Discharge Test for Generator Insulation,” Ontario Hydro Research Quarterly, Vol. 23, No 4, 1973, pp 1-4. [2] H. A. Cole, “A Differential Pulse Height Discriminator,” Nuclear Instrumentation and Methods, Nov. 1976, p 551. [3] “Detection and Measurement of Discharge (Corona) Pulses in Evaluation of Insulation Systems, ASTM 0 1868, Part 39. [4] M. Kurtz and J. F. Lyies “Generator Insulation Diagnostic Testing”, IEEE Paper So. F7918S-0, PES “Winter Meeting, New York, N. Y., Feb. 1979. This paper was presented at the 1978 International Symposium on Electrical Insulation, Philadelphia, June 1978. Manuscript was received 11 August 1378, in revised form 30 November 1978.