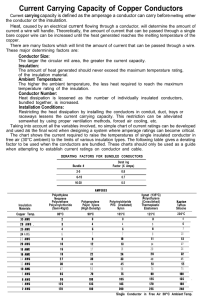

Bare Copper Solid Conductor

advertisement