inside an esc - Castle Creations

advertisement

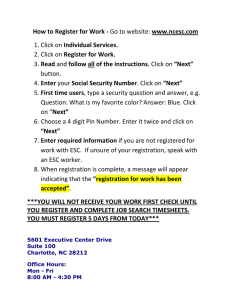

heli iq Feature INSIDE AN ESC UNDERSTANDING THE COMPONENTS THAT MAKE IT WORK words: Art Koral and Jonathan Feldkamp Y We probably underestimate just how beneficial ESC technology is. There was a time not so many years ago when ESCs for military and commercial applications were large and expensive. Now, thanks to improvements in solid-state technology and FET quality, ESCs are compact and affordable. They are at the core of the technology that makes hybrid cars a reality. 76 | WWW.RCHELIMAG.COM Basic component layout and function The job of an ESC is to take DC power solder from a battery and accurately control a 3-phase brushless, sensorless motor. Before we talk about the components A and layout of the ESC portion, it helps to understand what the motor looks B like electrically. Most brushless motors C have three wires or phases—we will call them A, B, and C. They can be connected in one of two basic ways: Wye or Delta (shown to the right; the squiggly lines represent the motor A coils [inductors electrically]). Although these two look very different, it does B not change very much electrically. The C important thing to realize is anything that we do to A and B is going to affect C; the reason for this importance will come later. Also note that without any outside influence (like a moving magnetic field) these circuits are dead shorts—exactly what the ESC has to deal with during startup. The ESC’s job is to take power from the battery and power the motor. This is accomplished with MOSFETs, high-power switches that can turn on and off in a fraction of a second. A very basic overview of a brushless power system would look something like the diagram on the next page. The image shows that by turning on the A and B switches (marked by the red *), current flows from +IN through the phase connected to A and B and then to ground. The current flowing though this phase, or coil, produces a magnetic field that either attracts or repels the magnet on the rotor and causes rotation. wye wind technology delta wind That Prius looks mean! ou have probably wondered what some of the components on the board of an electronic speed controller (ESC) are. In this article, Jonathan Feldkamp of Castle Creations details what those components do and how they work together to accomplish speed control. With this knowledge you will have a greater respect for its technology, as well as an understanding of how to size your ESC and why amp and voltage limits exist. MOSFETs (FETs): Metal Oxide Semiconductor Field Effect Transistors simplified diagram of esc connection to a delta-wind motor + IN + IN A + IN B C Causing these little spurts of rotation is easy—we can do the same thing with just a battery by touching two of the motor wires directly to the battery terminals. (Obviously, GRN GRN GRN don’t do this: It will either kill the battery or the motor if left connected for more than a fraction of a second. One of the ESC’s biggest jobs is limiting how much current is allowed to be pumped through a phase in this type of situation.) The trick to running a motor is turning the right two switches on at exactly the right time and then back off again before things get out of hand. As current flows through a phase, the magnet is attracted to it (N to S or S to N), pulling on it and rotating it toward the coil. But when the magnet has passed the coil, we change which FETs are turned on in order to make current flow the other direction, repelling the magnet (N to N or S to S) and pushing it along in its rotation away from the coil. Expand this idea to three coils, and it is pretty easy to see how you make the magnet spin all the way round—once we can do that, all we have to do is repeat the process over and over again. For a real-life example, consider the speed controller in the next picture. GRN MOSFET +IN GRN MOSFET B MOSFET MOSFET Drive Circuitry GRN MOSFET C MOSFET +IN In this picture, you can easily see the layout of the six MOSFETs and their connections to power, ground, and the three motor wires. You can also see the receiver cable and the large input capacitor that acts as a reserve for the ESC. All of the rest of the small parts are filters of some sort that are there to A ensure everything runs GRN + IN properly. The image to the right shows a B CAD version of this circuit board with GRN + IN the simplified ESC C diagram overlaid on top of it where you GRN + IN can clearly see the GRN + IN large planes of copper that make the highcurrent connections. +IN Clear view of six MOSFETs used to switch voltage on and off in each motor phase on a Castle ESC. A MOSFET Simplified functional diagram of a standard ESC Circuit LED Microprocessor RX Motor Position Detection Circuitry august 2009 | 77 And that’s the “simplified” one. Now that we have a basic understanding of what it takes to make a motor spin, we can start to look at the functional diagram of a speed control. There are four main functional groups that we will discuss: the power MOSFETs, the MOSFET driver circuitry, the microprocessor, and the motor-position-detection circuitry. The following image shows how these parts are connected together. heli iq feature inside and ESC We now have a pretty good understanding of how the power portion of an ESC works: The MOSFETs act as switches, turning on and off to cause current to flow through the motor coils. Sometimes, however, one MOSFET is not enough. For high-current controllers, multiple FETs are used together in tandem to act as better switches. Almost all of the heat generated in an ESC is caused by the resistance of the FETs—every time we double the number of FETs, the resistance is cut in half. Another option, besides adding more FETs, is to use better ones. High-end controllers will use the best FETs available. Sensor yourself. MOSFET drive circuitry Turning a FET on and off is not as easy as it may sound. If we look at the electronic symbol, we see three connections. The single connection that exits the part to the left is called the gate—this is the FET’s switch. In order to turn the FET on, the gate has to be driven to a voltage that is 5V to 10V higher than the leg on the bottom of the FET. (This pin is called the source.) For the low-side FETs, this is pretty easy; we just need a 10V supply to turn them on. In order to turn on the high-side FETs—those connected to +IN—a voltage of 10V higher than +IN must be applied to the gate. (Think about it: Once the FET is on, the drain is connected to +IN, and in order for it to stay on, the gate has to stay at least 5V above +IN). For example, if you’re using a 4S LiPo battery, +IN will be around 14.8V, but to turn on the FET, a voltage of 25V has to be applied to the gate. In order to accomplish this, ESC designers can choose from off-the-shelf FET driver chips or design the circuit themselves. Motor-position detection circuitry In order to know when to turn the FETs on and off, the ESC has to know exactly where the magnet is in its rotation process. This is the trickiest thing that the ESC has to do—and this is also why brushless motors and ESCs used to use separate sensors to track the magnet. (This is still popular with car controllers today.) Sensorless ESCs use a different method for this, however; while the controller is using two of the motor wires to power the motor, the third wire is left completely unconnected. We might expect this third leg to be exactly halfway between the other two, but it is not. The changing magnetic field caused by the spinning magnet induces a current in the third phase that causes the voltage to be slightly different than half. We can filter this signal and use it to determine how far the rotor has turned and when we need to switch the current FETs off and move on to the next two. Here is a typical car controller setup. Note the extra sensor wire (black) that tells the ESC where the rotor is in its rotation. Sensored setups are usefull when lower and variable RPM’s are required to prevent “cogging.” The microcontroller and its firmware Without question, the microcontroller is the brains of the whole operation. The microcontroller runs software much the same way that our computers run programs: Developers write software, compile it, and download it to the microprocessors. Besides sending signals to the FET drivers and keeping track of the motor position, the microcontroller also has to process the input from the receiver, compute the desired output power, and flash any indicator LEDs. (Don’t forget that the user may not want to run at full throttle 78 | WWW.RCHELIMAG.COM all of the time, so we have to be able to limit the output power.) Processing the input from the receiver is a pretty straightforward process. The signal is a digital pulse whose length determines the output power. A 1.0 millisecond pulse means full off (or brake), while a 2.0 millisecond pulse means full throttle, and everything in between is partial throttle. As easy as this process is, however, it is important that we remember that everything that takes away from watching the motor position could cause us to miss the time that we were supposed to change active FETs. Running at partial throttle is just a more complicated case of running a full throttle. Instead of leaving two FETs on and causing current to pull the magnet along, we instead leave one turned on and pulse the second on and off very quickly. At low throttles, this second FET is barely on at all, but as we approach full throttle it is on almost the whole time. The frequency (times per second) that we do this pulse is called the PWM frequency. heli iq feature inside an esc Hardware limitations: 4S, 6S, HV, SHV, etc. Besides the programmable features, hardware limitations also set controllers apart. Some are rated for only 12V, while others can handle batteries all the way up to 90V. Not much changes as far as the microprocessor is concerned; it is still a matter of turning on FETs as the magnet rotates. The most obvious difference is the parts that are used on the circuit board. The FETs have to be rated at higher voltages that usually mean they are not as good (and more resistive). The FET drive circuitry now has to boost even higher and be able to drive even more FETs. The large input capacitors have to change (and usually get a lot bigger). Basically, every part has to be evaluated to see if it will perform correctly at the rated voltage. Besides the obvious, though, everything gets a little tricky at high voltages. Small voltage spikes that didn’t cause any problems at 12V are now big enough to turn on FETs that are not supposed to be turned on. (Imagine a high side and low side both being turned on at the same time— this is the same thing as a direct short across the battery.) Great care has to be taken to ensure clean signals and correct operation. Got it all? BEC: Battery Eliminator Circuit Another issue with high voltage is the BEC. Back in the good old days, everyone had a gas engine for power and a small battery pack to power the receiver and servos (receiver pack). As electronic speed controls became popular, a simple device called a linear regulator was built into speed controls to create a 5V power supply that could replace the receiver packs. This simple BEC works great with servos that do not draw much current and especially well with low input voltages. The problem with the standard BEC is that it operates by turning the un-needed portion of the battery voltage into heat. With a 12V for an application. Let’s assume that we have already picked a battery and motor. Now we have battery, 6V is being wasted; if our servos use a total of 1A, that is 6 watts of generated heat. But with a 25V battery, 20V is being wasted; at 1A we are generating 20 watts of heat—that is simply too much for these linear regulators to handle, and they will shut down. The next step in the evolution of the BEC was the creation of a switching BEC. The switching BEC works in a way similar to the speed control itself: It uses a FET to turn the battery power on and off very quickly and then filters the output to create a constant output voltage. The most notable advantage is that the extra voltage is not turned into heat; a switching BEC can easily be around 90 percent efficient. to figure out how much current our setup will draw. Choose a speed control rated above the estimated full-throttle current (e.g., if 67A is considered worst-case, then a 75 amp or above would work just fine). That being said, there is never any problem with using a controller that can handle a lot more than you need. If it doesn’t add too much weight, always shoot for the larger controller. A good practice is to make a quick test flight, check the controller temperature, go for a longer flight, check again the temperature to ensure temperatures remain within safe operating limits. Calculators can be wrong, and every vehicle is different; this is a hobby, and caution should be taken, especially during the first few uses. The temperature of the controller should stay below 212 degrees F—it should not sizzle when you lick your finger and quickly touch it. Picking the rightsized controller Castle is about to release a new highvoltage BEC that can operate at 12S and deliver up to 20 amps of peak current. Now that we know a little more about how the ESC works, it is a little easier to pick the right controller So, as you can see, ESCs are fairly simple in design; however, their programming and the quality of their components is vital for proper operation. Choosing the right ESC for an application will determine whether or not a model has a smoke feature you probably don’t want. Special thanks again to Jonathan Feldkamp and the team at Castle Creations for their tremendous contributions to our hobby. 80 | WWW.RCHELIMAG.COM why running at lower throttle settings is harder on the ESC Before we get into why partial-throttle settings can generate more current, we have to briefly discuss back EMF. When motors rotate, not only do they use power to create motion, they also act like generators producing electricity or back EMF. The net result is a slip condition where more power is needed than generated, and the higher the load, the greater the slip condition. Slip is needed to generate motion, and the current required is the difference between the power pulse and the back EMF pulse. Partial-throttle or governed operation at high load is harder on the ESC than full-throttle operation because the speed controller pulses for shorter intervals yet provides more instantaneous current when under load. At lower RPMs, the back EMF is reduced, and the difference in current between the back EMF and the instantaneous on pulse can be very high. Watt meters will not pick up these spikes and will only see the average current.