PCF Series - TT Electronics

advertisement

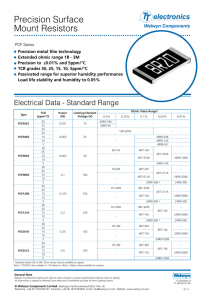

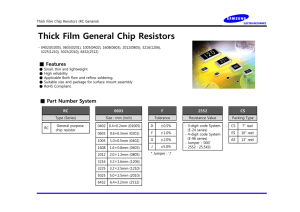

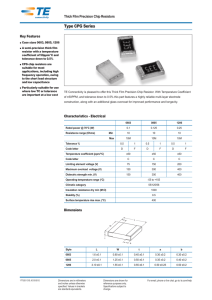

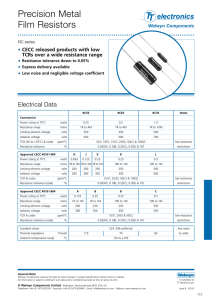

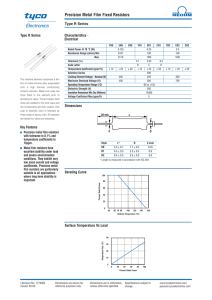

Resistors Precision Thin Film Nichrome Chip Resistors PCF Series Precision thin film technology Extended ohmic range 1R - 3M Precision to ±0.01% and 2ppm/°C Passivated range for superior humidity performance Load life stability and humidity to 0.05% Pb-free standard with SnPb option AEC-Q200 grade available All Pb-free parts comply with EU Directive 2011/65/EU (RoHS2) Electrical Data - Standard Range Type TCR (ppm/°C) Power (W) 50 0.031 25 50 25 15 PCF0402 10 0.063 5 3 2 50 25 15 PCF0603 0.063 10 5 3 2 50 25 15 PCF0805 0.1 10 5 3 2 50 25 15 PCF1206 0.125 10 5 3 2 50 25 15 PCF1210 0.2 10 5 3 2 50 25 15 PCF2010 0.25 10 5 3 2 50 25 15 PCF2512 0.5 10 5 3 2 Note 1: Standard values E24 or E96. Other values may be available by request. PCF0201 Limiting Element Voltage (V) 15 1% & 0.5% 49R9-33K 49R9-5K 0.25% 0.05% 0.01% - 4R7 – 511K 25 Ohmic Value Range1 0.1% 10R – 255K 49R9 - 33K 49R9 - 12K 49R9 - 5K - 49R9 - 4K99 1R – 1M 50 4R7-332K - 1R-2M 100 4R7-1M 4R7-332K 24R9-100K 24R9 – 15K 4R7-2M 4R7-511K - 4R7 – 1M - 4R7-511K 24R9-200K 24R9-30K 24R9-30K 24R9-30K 1R-2M5 150 4R7-2M5 4R7–1M - 4R7 – 1M - 4R7-511K 24R9-500K 24R9-50K 24R9-50K 24R9 – 49K9 1R-2M5 150 4R7-2M5 4R7–1M - 4R7 – 1M 24R9-50K 24R9-500K 24R9-50K 24R9 – 49K9 1R-3M 150 4R7-1M - 1R – 3M 150 General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. 4R7-3M 24R9-500K 24R9-100K 4R7-3M 4R7-1M - 4R7-1M 4R7-1M 24R9-500K 24R9-100K BI Technologies IRC Welwyn www.ttelectronicsresistors.com © TT Electronics plc 09.16 Precision Thin Film Nichrome Chip Resistors PCF Series Electrical Data - AEQ-Q200 Grade - Standard Range Type TCR (ppm/ºC) 50 PCF0402…A 25 50 PCF0603…A 25 50 PCF0805…A 25 50 PCF1206…A 25 50 PCF1210…A 25 50 PCF2010…A 25 50 PCF2512…A 25 * Standard values E24 or E96. Power (W) Limiting Element Voltage (V) 0.063 25 49R9 – 100K 49R9 – 10K 0.063 50 10R – 332K 10R – 49K9 0.1 100 10R – 100K 0.125 150 10R – 200K 0.25 150 0.25 150 0.5 150 Ohmic Value Range * 1% 0.5% 0.25% 0.1% 0.05% 10R – 1M0 10R – 499K Electrical Data – High Power Range Type PCF0603H PCF0805H PCF1206H PCF1210H PCF2010H PCF2512H TCR (ppm/°C) 50 25 15 10 5 3 2 50 25 15 10 5 3 2 50 25 15 10 5 3 2 50 25 15 10 5 3 2 50 25 15 10 5 3 2 50 25 15 10 Power (W) Limiting Element Voltage (V) 0.5% 0.25% Ohmic Value Range * 0.1% 4R7-1M 0.1 4R7-332K 75 0.01% 4R7-332K 24R9-100K 24R9-15K - 24R9-15K 1R-1M 0.125 0.05% 4R7-1M 4R7-332K 4R7-511K 150 4R7-511K 24R9-30K - 24R9-30K 4R7-1M 0.25 200 24R9-500K 24R9-50K - 24R9-49K9 4R7-1M 0.33 200 24R9-500K 24R9-50K - 24R9-49K9 4R7-1M 0.33 200 24R9-500K 24R9-50K - 0.75 200 24R9-200K 1R-2K 24R9-49K9 4R7-2K 24R9-2K * Standard values E24 or E96. Other values may be available by request. General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. BI Technologies IRC Welwyn www.ttelectronicsresistors.com © TT Electronics plc 09.16 Electrical Data - High Power Range Electrical Data - Power High Limiting Power Range TCR Element Ohmic Value Range TCR Power Limiting Element Ohmic Value Range * 0.05% Power Limiting 0.5% 0.25% 0.1% (ppm/ºC) (W) Voltage (V) TCR (W) Element 0.5% 0.25% 0.1% 0.05% (ppm/ºC) 50 Voltage (V) 25 4R7-332K 50 PCF0603H 0.1 75 4R7-1M 15 25 10 4R7-332K 15 PCF Series 0.1 75 PCF0603H 5 24R9-15K 4R7-332K 10 50 4R7-1M 4R7-511K 525 24R9-15K PCF0805H 15 0.125 150 50 1R-1M 4R7–1M 10 4R7-511K 25 4R7-511K 24R9-30K 0.125 150 PCF0805H 155 4R7-1M 50 10 4R7-511K 525 24R9-30K 4R7-1M PCF1206H 0.25 200 15 50 Limiting Ohmic Value Range * 10 TCR Power 25 Type Element 5 4R7-1M 24R9-50K 15 (ppm/ºC) (W) 0.25 200 PCF1206H 1% 0.5% 0.25% 0.1% 50 Voltage (V) 10 525 24R9-50K 50 15 PCF0603H…A 0.1 75200 10R –4R7-1M 332K 50 PCF1210H 0.33 25 25 10 4R7-1M 15 0.33 200 505 PCF1210H 24R9-50K PCF0805H…A 0.125 150 10 25 24R9-50K 5 50 50 PCF1206H…A 0.25 200 25 25 10R4R7-1M – 1M0 0.33 200 15 PCF2010H 50 Ohmic Value Range * 10 PCF1210H…A 0.33 200 TCR Power Limiting Element 25 5 24R9-50K Type (ppm/ºC) (W) Voltage (V) 0.5% 0.25% 0.1% 0.05% 50 50 25 PCF2010H…A 0.33 200 50 0.75 200 1R-2K PCF2512H 25 25R-25K4R7-2K 15 25 PCF0402P 0.063 25 10 15 49R9-12K * Standard values E24 or 50 E96. Other values may be available by request. 25R-332K PCF0603P 25 0.063 50 15 25R-100K 50 10R-800K PCF0805P 25 0.1 100 Limiting Ohmic 25R-200K Value Range * 15 TCR Power Element 50 Type 10R-1M (ppm/ºC) (W) Voltage PCF1206P 0.125 150 25 0.5% 0.25% 0.1% 0.05% (V) 15 25R-500K 50 50 0.166 100 10R-332K10R-1M PCF0603X 25 PCF2010P 25 0.25 150 50 15 25R-500K 0.25 150 10R-500K PCF0805X 25 50 50 0.333 200 10R-1M 10R-1M PCF1206X PCF2512P 25 0.5 150 25 15 25R-500K 50 1 200 1R-100R 4R7-100R PCF2512X 25 Type Type Precision Thin Film Nichrome Chip Resistors Electrical Data - AEQ-Q200 Grade – High Power Range Electrical Data - Passivated Range 0.01% 0.01% 24R9-100K 24R9-100K 24R9-200K 24R9-200K 24R9-500K 24R9-500K 0.05% 24R9-500K 10R – 49K9 24R9-500K 10R – 100K 10R – 200K 24R9-500K 10R0.01% – 499K 24R9-2K Electrical Data - Extended High Power Range 0.01% * Standard values E24 or E96. Other values may be available by request. Physical Data Dimensions (mm) & Weight (mg) Electrical Data - Passivated Range L Tmax A 0201 Type 0402 0603 PCF0402P 0805 1206 1210 PCF0603P 2010 2512 PCF0805P W L TCR Power 0.6 ± 0.05 0.3 ± 0.05 (W) 1.0 ± (ppm/ºC) 0.05 0.5 ± 0.05 1.6 ± 0.250 0.8 ± 0.2 0.063 2.0 ± 0.225 1.25 ± 0.2 15 1.6 ± 0.2 3.2 ± 0.250 3.2 ± 0.225 2.6 ± 0.2 0.063 2.4 ± 0.2 4.9 ± 0.215 6.3 ± 0.250 3.1 ± 0.2 25 0.1 15 50 Tmax A Limiting Element 0.26 0.12 ± 0.05 (V)± 0.1 0.40 Voltage0.2 0.55 0.65 0.65 0.50 0.65 0.65 0.3 ± 0.2 25 0.4 ± 0.2 0.5 ± 0.2 50 0.45 ± 0.2 0.5 ± 0.2 0.5 ± 0.2 100 C 0.12 ± 0.05 0.2 0.5% ± 0.1 0.3 ± 0.2 0.4 ± 0.2 0.5 ± 0.2 0.5 ± 0.2 0.6 ± 0.2 0.6 ± 0.2 Wt Ohmic Value Range * 1 0.25% 3 6 9 20 25 36 55 C 0.1% T 25R-25K A 49R9-12K L W A 25R-332K Wrap-around terminations (3 faces) 10R - 1M 50 Construction 25 10R-1M 0.125 150 PCF1206P A thin-film material is15selectively deposited on a 96% alumina substrate together with metallic contacts at each end of the resistor. 50 10Rcontrolled - 1M5 The unadjusted resistors are heat treated to give the required TCR and stability, then a precisely laser trim process adjusts 25 0.25 150 PCF2010P the resistance value. 15 Epoxy protection is applied and wrap-around terminations are added and 25Rplated - 1M with Nickel then Tin. Each resistor is measured immediately before packing into tape. 50 PCF2512P 25 0.5 150 10R - 1M5 15 25R - 1M Terminations *The Standard E24 or E96.with Other100% values may available by request. chipsvalues are supplied Sn be matte plated wrap-around terminations suitable for soldering. General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. BI Technologies IRC Welwyn www.ttelectronicsresistors.com © TT Electronics plc 09.16 Precision Surface Precision Thin Film Mount Resistors Nichrome Chip Resistors PCF Series PCF Series Physical Data L 0201 0.58 0.05 0402 1.0 0.05 0603 1.6 0.2 0805 2.0 0.2 1206 3.05 0.15 1210 PCF Series3.10 0.15 PCF Series 2010 4.9 0.2 2512 6.3 0.2 Dimensions (mm) and Weight (mg) W T max A 0.29 0.05 0.26 0.15 0.05 0.5 0.05 0.55 0.2 0.1 0.8 0.2 0.65 0.3 0.2 1.25 0.2 0.65 0.4 0.25 1.55 0.15 0.65 0.35 0.25 2.4 0.15 0.65 0.55 0.25 2.4 0.2 0.65 0.5 0.25 3.1 0.2 0.65 0.5 0.25 Precision Surface Surface Mount Mount Resistors Resistors Precision C 0.12 0.05 0.2 0.1 0.3 0.2 0.3 0.2 0.42 0.2 0.4 0.2 0.6 0.3 0.6 0.3 Wt 1 3 6 9 20 25 36 55 C T A L A W Wrap-around terminations (3 faces) Construction A thin-film material is selectively deposited on a 96% alumina substrate together with metallic contacts at each end of the resistor. The unadjusted resistors are heat treated to give the required TCR and stability, then a precisely controlled laser trim process adjusts the resistance value. Epoxy protection is applied andWeight wrap-around terminations are added and plated with Nickel then Tin. Each Dimensions (mm) and and Weight (mg) Dimensions (mm) (mg) resistor is measuredL immediately Wbefore packing T max into tape. A C Wt Physical Data 0201 L 0.58 0.05 0805 1206 1206 1210 1210 2010 2010 2512 2512 2.0 3.05 3.05 3.10 3.10 4.9 4.9 6.3 6.3 W 0.29 0.05 T max 0.26 0.15 0.65 0.65 0.65 0.65 0.65 0.65 0.65 0.65 0.65 0.4 0.35 0.35 0.55 0.55 0.5 0.5 0.5 0.5 A C 0.05 0.12 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.3 0.42 0.42 0.4 0.4 0.6 0.6 0.6 0.6 0.05 Wt 1 0.2 0.2 0.2 0.2 0.2 0.3 0.3 0.3 0.3 9 20 20 25 25 36 36 55 55 C C 0201 0.29 0.05 0.26 0.15 0.05 0.12 0.05 1 0.58 0.05 Terminations 0402 0.05 0.5 0.05 0.05 0.55 0.2 0.1 0.1 0.2 0.1 0.1 1.0 0.05 0402 0.5 0.55 0.2 0.2 33 1.0 T The standard termination is 100% Sn matte plated wrap-around suitable for soldering. SnPb plated option is available for Tstandard 0603 0.2 0.8 0.2 0.2 0.65 0.3 0.2 0.2 0.3 0.2 0.2 1.6 0.2 0.8 0.65 0.3 0.3 66 1.6 range0603 PCF over the restricted range below. A 0805 1.25 0.2 0.65 0.4 0.25 0.3 0.2 9 2.0 0.2 A 0.2 0.15 0.15 0.15 0.15 0.2 0.2 0.2 0.2 1.25 1.55 1.55 2.4 2.4 2.4 2.4 3.1 3.1 0.2 0.15 0.15 0.15 0.15 0.2 0.2 0.2 0.2 Performance DataOption - Standard SnPb Termination RangeRange Test Parameters TCR (ppm/°C) Conditions Power (W) L L A A W W Wrap-around terminations Wrap-around terminations (3 faces) (3 faces) Maximum change (+0.05R) Limiting Element >0.05% tolerance Voltage (V) 1% 0603 to 2512 Ohmic Value Chip size Range ≤0.05% tolerance Type Construction 0.5% 0.25% 0.1% Construction 0603 to 2512 0201, 0402 A thin-film material is is selectively selectively deposited deposited on on aa 96% 96% alumina alumina substrate substrate together together with with metallic metallic contacts contacts at at each each end end of of the the resistor. ALoad thin-film material 0.05%resistor. 0.25% 0.5% life 1000 hours rated load @ 70°C 50 10R – 250K The unadjusted resistors are heat treated to give the required TCR and stability, then a precisely controlled laser trim process adjusts The unadjusted resistors are heat treated1000 to give the@required TCR and stability, then a precisely controlled laser trim process adjusts 0.05% 0.3% 0.3% Humidity hours 90 - 95%RH PCF0805 value. 0.1 100 terminations the resistance value. Epoxy Epoxy25 protection is is applied applied and 40°C, wrap-around terminations are are added added and and plated plated with Nickel then then Tin. Each Each 10R –with 100KNickel the resistance protection and wrap-around Tin. 0.05% 0.5% 0.5% Short term overload immediately 6.25packing x rated Power , or 2 x LEV, for 5 sec resistor is measured before into tape. 15 10R – 100K resistor is measured immediately before packing into tape. High temperature operation 1000 hours at 125°C 0.25% 0.25% 0.25% 50 10R – 500K Terminations Terminations 0.05% 0.1% 0.1% Temperature 5 cycles -55 C, 125°C PCF1206cycle 25100% Sn matte0.125 150suitable for soldering. 10R –option 200K is available The standard termination is plated wrap-around SnPb plated for standard standard The standard termination is 100% Sn matte plated wrap-around suitable for soldering. SnPb plated option is available for 0.05% 0.2% 0.2% Resistance to solder heat 270°C, 10 sec 15 10R – 200K range PCF over the restricted range below. range PCF over the restricted range below. Solderability 235°C, 2 sec 95% minimum coverage Performance Data - High Power Range/Extended High Power Range Performance Data - Standard Range Test Test Parameters Parameters Test Parameters Load life Humidity Short term Load life life overload Load High temperature operation Humidity Humidity Temperature cycle Short term term overload overload Short Resistance to solderoperation heat High temperature temperature High operation Solderability Temperature cycle Temperature cycle Resistance to to solder solder heat heat Resistance Solderability Solderability Conditions Conditions Conditions Maximum Maximumchange change(+0.05R) (+0.05R) Maximum change (+0.05R) 1000 hours rated load @ 70°C 0.5% ≤0.05% tolerance tolerance >0.05% tolerance tolerance Chip size ≤0.05% >0.05% Chip size 0.5% 1000hrs @ 40°C, 90 - 95%RH 0603 to to 2512 2512 0603 to 2512 0201, 0402 0603 0603 to 2512 0201, 0402 0.5% 6.25 1000 x rated Power, or 2load x LEV, for 5 sec 0.05% 0.25% 0.5% hours rated @ 70°C 0.05% 0.25% 0.5% 1000 hours rated load @ 70°C 0.5% at 155°C 0.05% 0.3% 0.3% 1000 1000 hourshours @ 40°C, 40°C, 90 -- 95%RH 95%RH 0.05% 0.3% 0.3% 1000 hours @ 90 0.25% 5 cycles -55°C, 0.05% 0.5% 0.5% 6.25 xx rated rated Power or 22150°C LEV, for for 55 sec sec 0.05% 0.5% 0.5% 6.25 Power ,, or xx LEV, 0.2% 270°C, 0.25% 0.25% 0.25% 1000 hours10 atsec 125°C 0.25% 0.25% 0.25% 1000 hours at 125°C 95% minimum coverage 235°C, 2C,sec 0.05% 0.1% 0.1% 5 cycles -55 125°C 0.05% 0.1% 0.1% 5 cycles -55 C, 125°C 0.05% 0.2% 0.2% 270°C, 10 sec 0.05% 0.2% 0.2% 270°C, 10 sec 235°C, 22 sec sec 95% minimum minimum coverage coverage 235°C, 95% Performance Data - Passivated Range Test Parameters ConditionsRange/Extended Maximum change (+0.05R)Range Performance Data -- High High Power Power High Power Performance Data Range/Extended High Power Range 0603 to 2512 0402 Test Parameters Parameters Load life Test Load life Humidity Load life Humidity Short term overload Humidity Shorttemperature term overload overload High operation Short term High temperature temperature operation Temperature cycle operation High Temperature cycle Resistance to solder Temperature cycle heat Resistance to to solder solder heat heat Solderability Resistance Solderability Solderability Conditions Conditions 1000 hours rated load @ 70°C 1000 hours rated 90 load @ 70°C 70°C 1000hrs @ - 95%RH 1000 hours40°C, rated load @ 1000hrs @ 40°C, 90 95%RH 6.25 1000hrs x rated Power, or 2 x LEV, for 5 sec @ 40°C, 90 - 95%RH 6.25 xx rated rated Power, or LEV, for for 55 sec sec 1000 hoursor at22125°C 6.25 Power, xx LEV, 1000 hours at 125°C 155°C 51000 cycles -55 C, hours at 155°C cycles -55°C, 150°C 270°C, 10 sec 55 cycles -55°C, 150°C 270°C, 10 sec 235°C, 2 sec 270°C, 10 sec 235°C, 22 sec sec 235°C, Performance Data - Passivated Range General NoteComponents Limited Bedlington Northumberland NE22 7AA, UK © Welwyn Maximum change change (+0.05R) (+0.05R) 0.05% 0.25% Maximum 0.05% 0.5% 0.5% 0.5% 0.5% 0.02% 0.1% 0.5% 0.5% 0.05% 0.5% 0.5% 0.5% 0.02% 0.1% 0.5% 0.25% 0.02% 0.1% 0.25% 0.2% 95% minimum coverage 0.2% 95% minimum minimum coverage coverage 95% BI Technologies IRC Welwyn Telephone: (0) 1670 822181 (0) 1670 829465 Email: info@welwyn-tt.com Website: www.welwyn-tt.com 03.11 TT Electronics+44 reserves the right to makeFacsimile: changes in+44 product specification without notice or liability. Test Parameters Parameters Conditions Maximum change change (+0.05R) (+0.05R) Conditions Maximum All informationTest is subject to TT Electronics’ own data and is considered accurate at time of going to print. www.ttelectronicsresistors.com 0603 to 2512 0402 Load life ©Load TT Electronics plc life Humidity Humidity 1000 hours hours rated rated load load @ @ 70°C 70°C 1000 1000hrs @ @ 40°C, 40°C, 90 90 -- 95%RH 95%RH 1000hrs 0603 to 2512 0.05% 0.05% 0.05% 0.05% 0.02% 0402 0.25% 0.25% 0.5% 0.5% 0.1% 09.16 Performance Data - High Power Range/Extended High Power Range Test Parameters Conditions Maximum change (+0.05R) Precision Thin Film Nichrome Chip Resistors 1000 hours rated load @ 70°C 1000hrs @ 40°C, 90 - 95%RH 6.25 x rated Power, or 2 x LEV, for 5 sec 1000 hours at 155°C 5 cycles -55°C, 150°C 270°C, 10 sec 235°C, 2 sec 0.5% 0.5% 0.5% 0.5% 0.25% 0.2% 95% minimum coverage Load life Humidity Short term overload High temperature operation PCF Series cycle Temperature Resistance to solder heat Solderability Performance Data - Passivated Range Test Parameters Conditions Load life Humidity Short term overload High temperature operation Temperature cycle Resistance to solder heat Solderability Maximum change (+0.05R) 1000 hours rated load @ 70°C 1000hrs @ 40°C, 90 - 95%RH 6.25 x rated Power, or 2 x LEV, for 5 sec 1000 hours at 125°C 5 cycles -55 C, 125°C 270°C, 10 sec 235°C, 2 sec 0603 to 2512 0.05% 0.05% 0.02% 0.05% 0.02% 0.02% 0402 0.25% 0.5% 0.1% 0.5% 0.1% 0.1% 95% minimum coverage 0 100% 100% 70 100% 100% 125 35% 0% Derating Curve 155 0% © Welwyn Components Limited Bedlington Northumberland NE22 7AA, UK Telephone: +44 (0) 1670 822181 Facsimile: +44 (0) 1670 829465 Email: info@welwyn-tt.com Website: www.welwyn-tt.com Precision Surface Mount Resistors 03.11 Temperature Derating Derating Curve 100% Proportion of Pr PCF Series 80% High Power Ranges Standard & Passivated 60% 40% 20% 0% 0 50 100 150 Ambient Temperature (°C) Solderability The terminations have an electroplated nickel barrier and tin coating. This ensures excellent 'leach' resistance properties and solderability. Packaging PCF Resistors are supplied taped and reeled as as per IEC 286-3. Sizes 2010 and 2512 are in embossed plastic tape. Smaller sizes are in paper tape. Application Notes PCF resistors are ideally suited for handling by automatic methods due to their rectangular shape and the small dimensional tolerances. Electrical connection to a ceramic substrate or to a printed circuit board can be made by reflow or wave soldering of wrap-around terminations. Wrap-around terminations provide good leach properties and ensure reliable contact. Due to the robust construction, the PCF can be immersed in the solder bath for 30 seconds at 260°C. This enables the resistor to be mounted on one side of a printed circuit board and wire-leaded components applied on the other side. PCF resistors themselves can operate at a maximum temperature of 125°C (see performance above) (155°C for High Power grades). For soldered resistors, the joint temperature should not exceed 110°C. This condition is met when the stated power levels at 70°C are used. General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. BI Technologies IRC Welwyn www.ttelectronicsresistors.com © TT Electronics plc 09.16 Precision Thin Film Nichrome Chip Resistors PCF Series Ordering Procedure This product has two valid part numbers: European (Welwyn) Part Number**: PCF0603-11-1K54BI (0603, standard, 15ppm/°C, 1.54 kilohm ±0.1%, Pb-free) P C F 0 6 1 1 3 2 Type Size - 1 3 1 - 1 K 5 4 B I 4 5 3 4 5 6 7 Range TCR Value Tolerance Termination & Packing 2 PCF 0 0201 Omit for Standard 0402 0603 H = High Power 0805 X = Extended 1206 P = Passivated 1210 2010 2512 6 7 -20 = ±2ppm/°C E24 = 3/4 characters L = ±0.01% A = AEC-Q200 grade, Pb-free -19 = ±3ppm/°C E96 = 3/4 characters W = ±0.05% I = Standard grade, Pb-free -13 = ±5ppm/°C B = ±0.1% R = ohms Standard Packing K = kilohms -12 = ±10ppm/°C C = ±0.25% 0201, 0402 10,000/reel M = megohms D = ±0.5% 0603 to 1210 5000/reel -11 = ±15ppm/°C F = ±1% R = ±25ppm/°C 2010, 2512 4000/reel T1* = Pb-free, 1K reel -02 = ±50ppm/°C 0201 to 1206, 1000/reel 2010, 2512 PB = SnPb, 1K reel 0805, 1206 1000/reel * Non-standard; enquire to confirm availability ** Applies to all Ranges, Termination and Packing options. USA (IRC) Part Number*: PCF-W0603LF-11-1541-B-P-LT (0603, standard, 15ppm/°C, 1.54 kilohm ±0.1%, Pb-free) P C F - W 0 1 6 0 3 L 2 1 2 3 3 Type Model Termination PCF W0201 LF = Pb-free W0402 (100%Sn) W0603 W0805 W1206 W1210 W2010 W2512 F - 1 1 - 1 5 4 4 1 - B 5 6 - P 7 - L T 8 4 5 6 7 8 TCR Value Tolerance Tape Packing 13 = ±5ppm/°C 3 digits + multiplier 12 = ±10ppm/°C R = ohms for 11 = ±15ppm/°C values <100 ohms 03 = ±25ppm/°C 02 = ±50ppm/°C T = ±0.01% LT = Tape & Reel P = Paper A = ±0.05% (0201 to 1210) 0201, 0402 10,000/reel B = ±0.1% E = Embossed 0603 to 1210 5000/reel C = ±0.25% (2010, 2512) 2010, 2512 4000/reel D = ±0.5% F = ±1% * Applies only to Standard Range, Pb-Free parts General Note TT Electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT Electronics’ own data and is considered accurate at time of going to print. BI Technologies IRC Welwyn www.ttelectronicsresistors.com © TT Electronics plc 09.16