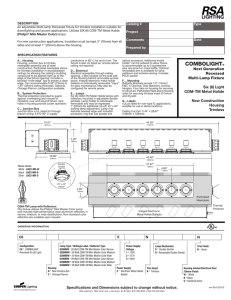

Architectural Floodlights

advertisement