GL 08 Hard Suction Connection

advertisement

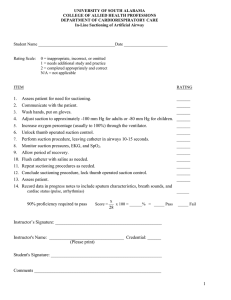

DFES BEB GUIDELINE No : GL – 08 TITLE : Hard Suction Connections Issued: March 2015 Replaces: January 2015 Valid until: March 2017 Prepared by: Built Environment Branch Authorised by: Manager, Built Environment Branch Page: 1 of 13 PURPOSE: To provide guidance to hydraulic consultants and building designers when submitting proposals to the Department of Fire & Emergency Services (DFES) involving hard suction connections for fire appliances to draught water from tanks, dams or other suitable water sources as referred to in AS2419.1. This information should be read in conjunction with Australian Standard 2419.1. INTRODUCTION: Suction connections should be designed and installed to meet the operational needs of the DFES Fire Service. Where a water source is being used to supply either a hydrant or an Early Suppression Fast Response (ESFR) sprinkler service and is from a static source, or provided in conjunction with on-site pumps, suitable hard suction connections and emergency vehicle access must be installed to permit the Fire Service the ability to draw water from the source. Therefore, if pump malfunction were to occur, firefighting can continue. Notwithstanding the above, each project will be assessed on a case-by-case basis and Consultants or Architects are advised to liaise with DFES Built Environment Branch to ensure that systems being installed meet operational requirements as detailed below. COMMENT: Hard suction connections are required to be installed on all fire water storage tanks. However, exceptions may apply and DFES should be consulted as required. For example: i) Within the Perth CBD where two parallel street water mains may meet the minimum flow and pressures, or ii) Where break tanks are installed and the water supply is fed from a compliant reticulated water main capable of maintaining the required residual pressure. Please refer to DFES Technical Note 02/14 for more information in regards to reticulated mains. Note: Hard suction connections are not to be connected directly to the fire pumps, Water Corporation or other utility water mains. 1 1. INSTALLATIONS AND DIMENSIONS OF HARD SUCTIONS AND ANCILLARY EQUIPMENT: The following figures and pictures provide guidance on what is considered as meeting operational requirements. 1.1 Connection dimensions as indicated in figures 1 and 2. Figure 1. 100mm Male Camlock Coupling Figure 2. Typical 125mm Storz Coupling 1.1.1 Country and outer metropolitan suburbs within bushfire prone areas: Within country and outer metropolitan regions a variation in suction connection sizes and fittings may be required to be installed on all water storage tanks used for fire fighting. This would be because of where a particular type of DFES fire-fighting appliances is located. Typically, 2 x 100mm Male Camlock fittings should be specified for static water supplies where bushfire appliances are located in country regions. Please refer to DFES Built Environment Branch for further information before proceeding with drafting final working drawings of the fire hydrant system. 1.2 Height installation dimensions of connection/(s): The height requirement for a Storz connection installation from the ground to the centre line of the coupling is to be no less than 450mm, and no more than 600mm. The Camlock connection is to be no less than 450mm and no more than 1000mm. This is indicated in figures 3 and 4. 2 Maximum camlock Height 1000mm Maximum Storz Height 600mm Figure 3. 125mm storz Figure 4. 2x100mm male camlock and 125mm storz 1.3 Minimum hose/hard suction connection clearances: The clearance around the Storz & Camlock connection handles is to be no less than 100mm on all sides to facilitate hose coupling. Figure 5. 125mm Storz Minimum Clearances 700mm fully extended (Includes 100mm hand clearance) 100mm hand clearance 100mm hand clearance 3 Figure 6. 100mm Camlock Minimum Clearances 100mm hand clearance 1.4 Suction hoses: There are a number of different hard suction hoses. Two examples are shown below. Figure 7. Typical camlock connection suction hose 4 Figure 8. Typical 125mm storz suction hoses. 1.5 Cabinet or Enclosure: Where cabinets or enclosures of brick construction are supplied, they shall be of sufficient size to house all equipment and be of a design that facilitates access to and handling of the equipment with ease. Cabinets or enclosures shall contain only fire fighting equipment and must be of weather proof and anti-vandal construction, be provided with a square taper (budget key) locking device and no closer than 10m to the building. Refer to figures 9 and 10. In addition to the above, the ground surface between the booster assembly and the fire appliance must be free from any obstacles and be of suitable hardstand material such as all-weather pavement, concrete or similar. Note: Where building design or site restrictions may affect fire fighter access to the booster or suction location, early discussions should be undertaken with DFES to address any further Fire Service operational requirements. 5 Figure 9. Typical hydrant booster cabinet. Square taper key locked The area between the booster assembly and DFES appliance should be of suitable hardstand material Figure 10. Separate hard suction only enclosure HARD SUCTION CONNECTION 50mm lettering 1.6 Connection clearance within cabinets or enclosures: For operational efficiency, the face of the suction connection shall be placed not more than 150mm from inside the front edge of the cabinet, or the front plane of any recess. 6 Figure 11. Maximum of 150mm clearance from face of Storz connection to face of cabinet (as shown below). 1.7 Emergency Vehicle Access: It is important that AS2419.1 is adhered to, and in particular with reference to the maximum vehicle hardstand access for suction connection. The distance between hard suction connection and vehicle hardstand is to be no more than 4.5m from the pumping appliance whilst in operational mode. See figure 12. Hard suction connection to be no more than 4.5m from vehicle hardstand Figure 12 7 A hard suction connection should be placed within the immediate vicinity of a hydrant booster assembly. However, in the case where the supply is from a static source such as a dam or lake situated remote from a hydrant booster, the installation will require below ground flooded pipe work to the boosting point. Please also refer to Guideline 06. Emergency Vehicle Access - two or more appliances using suction connections: Where a building is provided with sprinkler protection and hydrant services that are separately fed from static water sources, placement of equipment and location of DFES pumping appliances is an important factor as shown in Figure 13. The sprinkler and hydrant booster assemblies utilising hard suction connections are required to have suitable hardstand with a minimum separation distance of not less than 8m between the two hard suction connection assemblies. Figure 13. Minimum separation between two assemblies. Minimum 8m separation required between hard suction connections Note: Current DFES pumping appliances are generally configured with transverse mounted (side mounted) centrifugal pumps. The minimum 8m separation, allows for two side mounted pumping appliances to deploy delivery and suction hoses separately when setting up individual boosting operations. 1.8 Isolation valves for Suction connections: An isolation valve must be installed directly adjacent to the hard suction connection, refer to Figure 14, and the water supply. This should be of an approved ‘full flow’ type (Butterfly or Outside Screw & Yoke – see Figures 16 and 17) in accordance with AS2419.1. An isolation valve must be capable of providing unhindered operation by Fire Service personnel. 8 IMPORTANT SAFETY NOTE: To relieve stored pressure between the Storz end cap and in-line isolation valve and therefore to ensure the safety of DFES personnel or other users of the installed system, a bleed device or drilled hole (8-10mm diam) must always be provided within the head assembly end cap. Refer to Figure 15. Figure 14 Isolation valve adjacent Storz connection Figure 16. Ratchet type butterfly valve Figure 15 Storz end cap with bleed hole Figure 17. Gear type butterfly valve 4.9 Other DFES operational Considerations: i) Effective suction lift. Where hard suction connections are supplied directly from a remote water source such as a dam, river, lake or tanks that requires pipe work to be laid direct to a booster cabinet or separate connection, consideration should be given to the maximum practical lift that DFES pumping appliances are capable of achieving to the eye of the pump. 9 DFES will accept no greater than 3m effective suction lift from the water supply to its pumping appliance. See Figure 18 and Guideline 06 for more details. Note: In the case a permanently ‘flooded’ suction line to the elbow riser that runs to the booster assembly is required. DFES will consider the installation of a priming line to obtain a flooded connection. This priming line will not be greater than 25mm in diameter, must have a backflow device installed and be able to be isolated from within the booster cabinet by the operation of a ball /butterfly valve. It should be noted that the intent of the priming line is not to act as a water source to the hard suction connection but to prime the drafting line with water to the underside of the isolation valve installed in the drafting line. ii) Above ground tanks. The maximum suction hose pressure is to be no greater than 1.5 bar when supplied by tanks installed on upper floors of a building or in an elevated platform location. iii) Block plans. Suitable signage and notation on the hydrant block plan is required indicating hard suction connections and isolation points where they are located in a separate cabinet and where applicable: The effective capacity (Litres) of pump suction tank/s or alternative water supply (dam, lake etc) is to be noted on the hydrant block plan or on a separate sign as appropriate. The height of lift required to provide water to the eye of the Fire Service pump All pipes, valves and fittings used above or below ground in systems must comply with the requirements of AS 2419.1 Section 6 and any other associated Australian Standard. Figure 18. Examples of Fire Brigade Suction Connections a) Open water source. 10 b) Below ground tank. c) 11 d) Above-ground external storage tank. SUMMARY REQUIREMENTS FOR HARD SUCTION CONNECTIONS: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Minimum and maximum installation heights and clearances for hard suction connections shall apply (Storz & Camlock). Cabinets and enclosures to be of sufficient size to house all equipment. Emergency vehicle access to comply with DFES requirements. Approved isolation valves to be provided to AS 2419.1 requirements. Special consideration for systems involving two or more suction connections. Maximum lift for suction connections to be no more than 3m height. Final specifications to be determined by DFES according to site conditions. Suction connections must be gravity fed only – not pressurized by fire pumps or Water Agencies mains. Maximum hard suction hose pressure to be no greater than 1.5bar. For safety, a bleed hole (8-10mm) MUST be provided within the Storz end cap assembly. 12 REFERENCES: Australian Standard 2419.1 – Fire hydrant installations Part 1: System design, installation and commissioning Please note: This is a controlled document. DFES Guidelines are available on the DFES Website: www.dfes.wa.gov.au under Regulation and Compliance, Building Plan Assessment then click on Publications/Guidelines. Should the information provided in this guideline require further clarification, please contact DFES Built Environment Branch on telephone number 9395 9800. Disclaimer The information contained in this publication is provided voluntarily as a public service by the Department of Fire and Emergency Services (DFES). This publication has been prepared in good faith and is derived from sources believed to reliable and accurate at the time of publication. Nevertheless, the reliability and accuracy of the information cannot be guaranteed and DFES expressly disclaims liability for any act or omission based on reliance on the information and for any consequences whether direct or indirect, arising from such act or omission. The publication is intended to be a guide only and readers should obtain their own independent advice and make their own necessary enquiries. 13