Design and Implementation of a Common Collector Class B RF

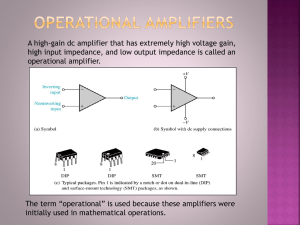

advertisement