FB15 North American

advertisement

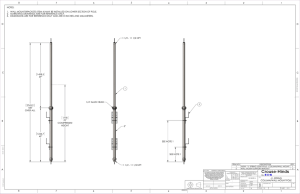

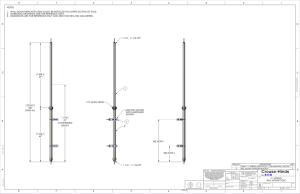

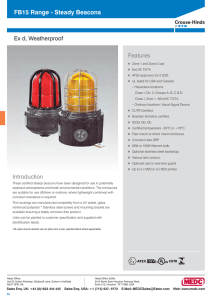

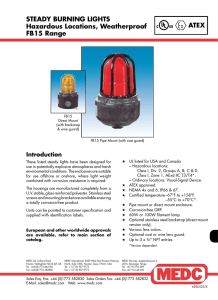

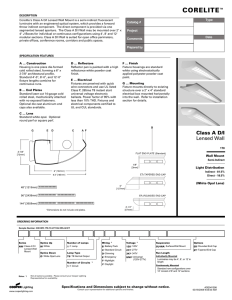

CROUSE-HINDS SERIES MEDC signalling and alarms FB15 steady burning lights range Hazardous locations, ordinary locations Overview Features These listed steady lights have been designed for use in potentiallybexplosive atmospheres and harsh environmental conditions. The enclosures are suitable for use offshore or onshore, where lightweight combined with corrosion resistance is required. The housings are manufactured completely from a U.V. stable, glass reinforced polyester.* Stainless steel screws and mounting bracket are incorporated ensuring a totally corrosion-free product. Units can be painted to customer specification and supplied with identification labels. European and other world wide approvals are available, refer to main section of catalogue. • UL certified for USA and Canada: – Hazardous locations: • . Class I, Div. 2, Groups A*, B*, C&D Pipe mount or direct mount enclosure Corrosion-free GRP • 60W or 100W filament lamp Class I, Zone 1, AExd IIB & IIC* T3/T4 • . Optional stainless steel backstrap (direct mount version only) – Ordinary locations: visual-signal device • Various lens colours . • Optional cast or wire lens guard • CSFM approved • Up to 3 x 3/4” NPT entries • ATEX approved • NEMA 4x and 6, IP66 & 67 • Certified temperature: –67ºF to +158ºF –55ºC to +70ºC *Not applicable for Canada *UL pipe mount variants use an alloy lens cover, painted black where applicable. Eaton Unit B, Sutton Parkway Oddicroft Lane Sutton in Ashfield United Kingdom NG17 5FB T: +44 (0) 1623 444 400 www.crouse-hinds.com/hac MEDCSales@Eaton.com © 2015 Eaton All Rights Reserved Printed in UK Publication No.DSMU0014/A July 2016 Eaton is a registered trademark. All other trademarks are property of their respective owners. Please check here for latest version of the datasheet All specifications, dimensions, weights and tolerances are nominal (typical) and Eaton reserve the right to vary all data without prior notice. No liability is accepted for any consequence of use. Certifications General arrangement drawing (all dimensions in inches) UL Ord Locs Cert. no. S8128. Visual signal device UL certified for use in USA Class I, Div 2 Groups A,B,C & D Class I, Zone 1 AEx d IIC UL certified for use in Canada Class I, Div 2 Groups C & D Class I, Zone 1 AEx d IIB 8-17/64” 9-13/32” 4-41/64 Cert. no. E187894 5-29/32” UL Haz Locs Specifications Finish Body: glass reinforced polyester (UL pipe mount - alloy lens cover) Lens: glass Back plate & fixings: stainless steel 316 Wire guard (optional): stainless steel wire Cast guard (optional): aluminium LM25M Painted to customer specification Voltage 24, 48V d.c. - 110, 120, 230, 240, 254V a.c. Lamp type 60W or 100W GLS filament Lamp holder E27 as standard Certified temp Weight 60W: -67ºF to +131ºF (-55ºC to +55ºC) T4. -67ºF to +158ºF (-55ºC to +70ºC) T3. 100W: -67ºF to +104ºF (-55ºC to +40ºC) T3 Pipe mount: 5¾lb/2.6kg; direct mount: 6½lb/3.0kg Ingress protection NEMA 4X & 6, IP66 & IP67 Terminals Direct mount: 12 x 14AWG Pipe mount: 8 x 14AWG Tag/duty label option Material Labels 3-35/64” 3-35/64” 9-11/64” (TOP OF LENS) 1-7/64” A/F Standard pipe: ¾” NPT Standard direct: 2 x ¾” NPT Optional direct: 1 x ½”/ ¾” NPT or 3 x ½”/ ¾” NPT Contact sales office to order optional entries Entries Electrical ratings: d.c. a.c. Voltage 24 48 110 120 230 240 254 Current (A) - 60W lamp 2.5 1.25 0.55 0.50 0.26 0.25 0.24 Current (A) - 100W lamp 4.2 2.1 0.91 0.83 0.43 0.42 0.39 Ordering requirements The following code is designed to help in selection of the correct unit. Build up the reference number by inserting the code for each component into the appropriate box Model Certification Lamp wattage Voltage Lens colour Guard Fixing Options Finish FB15 Certification Code UL UL UL (ordinary location) UW Wattage 60 100 Code 60 100 Guard None Cast Wire Code N C W Option None Duty label Tag label Blanking plug Code N D* T* P *Please specify Voltage 24V d.c. 48V d.c. 110V a.c. 120V a.c. 230V a.c. 240V a.c. 254V a.c. Code 024 048 110 120 230 240 254 Colour Red Blue Green Amber Yellow Clear Code R B G A Y C Fixing Code Pipe mount P Direct mount without backstrap D Direct mount with backstrap B Finish Black Red Blue Yellow Green White Special Code N R B Y G W S* *Please specify DSMU0014/A 07/16