Contactors Motor-Starters

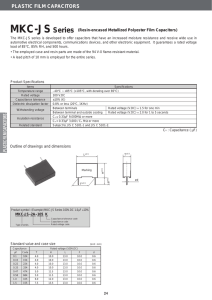

advertisement