Bare Overhead Conductors

Bare Overhead Conductors

AAC, ACSR, ACSR II

A global cable expert

Bare Overhead Conductors

Nexans is a diversified wire and cable manufacturer. Nexans has been designing, manufacturing and delivering cables to customers in

North America since 1911. Major utilities, distributors and contractors recognize Nexans as a quality supplier and a technology leader.

Substantial investment in research and development of product and process technologies continuously reinforces our commitment to excellence.

Nexans offers a combination of sales, design, manufacturing and quality control which ensures that all relevant standards of design and service are met. With our multi-plant manufacturing base, we are able to produce all standard types and sizes of bare overhead conductors, as well as a wide range of non-standard conductors, for virtually every application.

Applications

The bare overhead conductors described in this brochure are suitable for installation in all practical spans on transmission towers, wood poles and other structures. Installations range from long-distance EHV transmission lines to sub-service spans at distribution or utilization voltages on private premises.

The choice of conductor size, type and strength should take into account factors such as electrical load, voltage regulation, corona losses, ice and wind loading, extreme temperatures and vibration. Nexans is prepared to assist in the evaluation of these factors as they relate to the design of a transmission or distribution line.

Specifications

Nexans’ bare overhead conductors are designed, manufactured and tested in accordance with the following specifications:

ASTM B 231 Standard Specification for Concentric-Lay-Stranded Aluminum

1350 Conductors

ASTM B 232 Standard Specification for Concentric-Lay-Stranded Aluminum

Conductors, Coated-Steel Reinforced

(ACSR)

Packaging is provided as per

Aluminum Association Packaging

Standards for Aluminum Conductor and

ACSR, Sixth Edition

AAC Bare Overhead

Conductor

Product Construction

Bare all aluminum conductors (AAC) are concentric-lay-stranded consisting of one or more layers of aluminum alloy 1350 wires wrapped helically around a central wire. Each successive layer has six wires more than the underlying one. Increasing the number of wires for any given cross-sectional area provides greater flexibility. The most commonly used strandings consist of 7, 19, 37, 61 and 91 wires.

Class AA strandings are used for bare overhead lines. The direction of lay for the outer layer is right-hand and is usually reversed in successive layers.

The temper of the wires is full harddrawn (H19).

Class A strandings are used primarily for overhead conductors that are to be covered. They have greater flexibility than Class AA. The outermost layer is right-hand lay and the temper is normally H19. Successive layers are reverse lay.

Features and Benefits

AAC conductors are the most economical since their lighter weight means lower unit length costs, easier handling during installation and the use of simpler fittings. They are inherently corrosion resistant due to their homogeneous construction.

Applications

Stranded bare AAC conductors may be used in overhead line installations where the design parameters do not require the higher tensile strength or temperature ratings provided by ACSR,

ACCR or other types of conductors.

ACSR Bare Overhead

Conductor

Product Construction

ACSR is a composite concentric-lay stranded conductor consisting of a central steel core around which are stranded one or more layers of aluminum alloy 1350-H19 wires.

The steel core may consist of a single wire, 7, 19, 37 or more concentrically stranded wires. They are normally protected against corrosion by the application of zinc coating. The standard Class A coating is usually adequate for ordinary environments.

Heavier Class B or C coatings may be specified for greater protection. A special high-strength steel core with a

Class A coating is also available.

There are numerous combinations of aluminum and steel wires and layers that are available. The sizes and strandings most frequently used for overhead lines are listed on the following pages.

Features and Benefits

ACSR conductors have a long service record due to their economy, dependability and favourable strength to weight ratio. Such conductors combine the lightweight and high conductivity of the aluminum wires with the tensile strength and ruggedness of the steel core. For overhead line design, this enables higher tensions to be used with less conductor sag and longer spans than would be possible with most other types of conductors.

Applications

Aluminum conductors, steel reinforced

(ACSR) are widely used for overhead transmission and distribution lines.

1

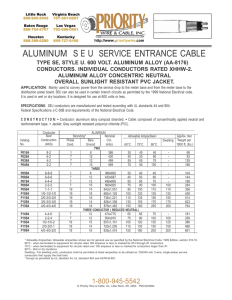

Physical Data for Aluminum 1350 Conductors

Diameter (inch)

Codeword

Size

(AWG/kcmil)

No. of

Wires

Individual

Wires

Complete

Conductor

Peachbell

Rose

Iris

Pansy

Poppy

Aster

Phlox

0xlip

Daisy

Laurel

Tulip

Cosmos

Syringa

Zinnia

Dahlia

Orchid

Violet

Arbutus

Magnolia

Bluebell

Columbine

Coreopsis

Cowslip

Lupine

266.8

266.8

336.4

477

477

500

556.5

636

1/0

2/0

3/0

4/0

6

4

2

1

715

795

954

1033.5

1351.5

1590

2000

2500

37

19

19

37

7

19

19

19

7

7

7

7

7

7

7

7

61

61

91

91

37

37

37

37

0.0612

0.0772

0.0974

0.1093

0.1228

0.1379

0.1548

0.1739

0.1952

0.1185

0.1331

0.1584

0.1135

0.1622

0.1226

0.1311

0.1391

0.1466

0.1606

0.1672

0.1489

0.1615

0.1482

0.1657

0.586

0.593

0.666

0.792

0.795

0.811

0.856

0.918

0.184

0.232

0.292

0.328

0.368

0.414

0.464

0.522

0.974

1.026

1.124

1.170

1.340

1.454

1.630

1.823

Rated

Strength

(Ibf)

4830

4970

6150

8360

8690

8760

9750

11400

563

881

1350

1640

1990

2510

3040

3830

12800

13900

16400

17700

23400

27000

34200

41900

Weight

(lb/kft)

671.0

745.3

894.5

968.4

1266

1489

1873

2365

24.6

39.1

62.2

78.4

98.9

124.8

157.2

198.4

250.2

250.1

315.5

446.8

446.8

468.5

521.4

596.0

2

Electrical Data for Aluminum 1350 Conductors

Resistance Reactance at 60 Hz**

Codeword

Size

(AWG/kcmil)

DC at 20°C

(ohm/kft)

AC at 25°C

(ohm/kft)

AC at 50°C

(ohm/kft)

AC at 75°C

(ohm/kft)

Peachbell

Rose

Iris

Pansy

Poppy

Aster

Phlox

Oxlip

Daisy

Laurel

Tulip

Cosmos

Syringa

Zinnia

Dahlia

Orchid

Violet

Arbutus

Magnolia

Bluebell

Columbine

Coreopsis

Cowslip

Lupine

6

4

2

1

1/0

2/0

3/0

4/0

266.8

266.8

336.4

477

477

500

556.5

636

715

795

954

1033.5

1351.5

1590

2000

2500

* Ampacity is with sun and wind at 2 ft/s

** Reactance at 1 foot equivalent spacing

0.659

0.414

0.260

0.207

0.164

0.130

0.103

0.0816

0.0647

0.0648

0.0513

0.0363

0.0363

0.0346

0.0311

0.0272

0.673

0.423

0.266

0.211

0.167

0.133

0.105

0.0835

0.0663

0.0663

0.0527

0.0373

0.0373

0.0356

0.0320

0.0282

0.0241

0.0217

0.0181

0.0167

0.0250

0.0227

0.0191

0.0177

0.0275

0.0248

0.0208

0.0193

0.0128

0.0128

0.0138

0.0120

0.00865 0.00994 0.0107

0.00699 0.00845 0.00907

0.0151

0.0130

0.739

0.465

0.292

0.232

0.184

0.146

0.116

0.0917

0.0727

0.0727

0.0578

0.0409

0.0409

0.0390

0.0352

0.0309

0.806

0.506

0.318

0.253

0.200

0.159

0.126

0.100

0.0794

0.0794

0.0629

0.0445

0.0445

0.0426

0.0383

0.0335

0.0299

0.0269

0.0227

0.0210

0.0163

0.0141

0.0115

0.00970

0.581

0.581

0.560

0.533

0.533

0.533

0.522

0.511

0.766

0.729

0.692

0.671

0.655

0.634

0.618

0.602

0.502

0.494

0.479

0.473

0.452

0.439

0.421

0.404

Capacitive Inductive at 25°C Ampacity*

(megohm-kft) (ohm/kft) (A)

0.659

0.414

0.260

0.207

0.164

0.130

0.103

0.0816

0.0647

0.0648

0.0513

0.0363

0.0363

0.0346

0.0311

0.0272

0.0241

0.0217

0.0181

0.0167

0.0128

0.0128

0.00865

0.00699

440

445

510

640

640

660

700

760

105

135

185

215

245

285

330

380

820

880

980

1030

1210

1230

1520

1700

3

Physical Data for ACSR Conductors

Codeword

Diameter (inch)

Size Stranding Complete

(AWG/kcmil) (AI/Steel) Steel Wire Aluminum Wire Steel Core Conductor Aluminum

Turkey

Swan

Swanate

Sparrow

Sparate

Robin

Raven

Quail

Pigeon

Penguin

3/0

4/0

Waxwing 266.8

Partridge 266.8

Merlin

Linnet

336.4

336.4

Oriole 336.4

Chickadee 397.5

2

1

1/0

2/0

6

4

4

2

Ibis

Pelican

Flicker

Hawk

397.5

477

477

477

Hen

Osprey

477

556.5

Parakeet 556.5

Dove

Rook

556.5

636

Grosbeak 636

Drake

Tern

Rail

Cardinal

Curlew

Bluejay

Bittern 1272

Lapwing 1590

Bluebird 2156

6/1

6/1

7/1

6/1

7/1

6/1

6/1

6/1

0.0661 0.0661 0.066

0.0834 0.0834 0.083

0.1029 0.0772 0.103

0.1052 0.1052 0.105

0.1299 0.0974 0.130

0.1181 0.1181 0.118

0.1327 0.1327 0.133

0.1489 0.1489 0.149

6/1

6/1

0.1672 0.1672 0.167

0.1878 0.1878 0.188

18/1 0.1217 0.1217 0.122

26/7 0.0788 0.1013 0.236

18/1 0.1367 0.1367 0.137

26/7 0.0884 0.1137 0.265

30/7 0.1059 0.1059 0.318

18/1 0.1486 0.1486 0.149

26/7 0.0961 0.1236 0.288

18/1 0.1628 0.1628 0.163

24/7 0.0940 0.1410 0.282

26/7 0.1053 0.1354 0.316

30/7 0.1261 0.1261 0.378

18/1 0.1758 0.1758 0.176

24/7 0.1015 0.1523 0.305

26/7 0.1138 0.1463 0.341

795

795

954

954

24/7 0.1085 0.1628 0.326

26/7 0.1216 0.1564 0.365

26/7 0.1360 0.1749 0.408

45/7 0.0886 0.1329 0.266

45/7 0.0971 0.1456 0.291

54/7 0.1329 0.1329 0.399

1033.5 54/7 0.1383 0.1383 0.415

1113 45/7 0.1049 0.1573 0.315

45/7 0.1121 0.1680 0.336

45/7 0.1253 0.1880 0.376

84/19 0.0961 0.1602 0.481

598.8

598.7

749.0

748.9

899

899

973

1049

374.1

446.8

449.5

448.6

449.7

521.1

524.2

523.9

1198

1498

2040

155.9

197.6

249.8

250.4

315.5

316.5

317.0

372.5

24.4

39.0

39.0

61.9

62.3

78.1

98.4

124.2

0.977

0.990

1.108

1.063

1.165

1.196

1.245

1.259

0.783

0.814

0.846

0.858

0.883

0.879

0.914

0.927

1.345

1.504

1.762

0.502

0.563

0.609

0.642

0.684

0.720

0.741

0.743

0.198

0.250

0.257

0.316

0.325

0.355

0.398

0.447

Weight (lb/kft)

Steel Total

11.6

18.4

28.0

29.3

44.7

36.9

46.6

58.8

74.1

93.4

230.0

291.0

39.2 289.0

115.6 366.0

49.5 365.0

145.5 462.0

209.0 526.0

58.5

36.0

57.4

67.0

91.2

102.0

115.0

145.0

183.0

431.0

171.9 546.0

70.2 517.0

164.5 614.0

206.4 655.0

296.3 746.0

81.9 603.0

191.8 716.0

241.1 765.0

219.2 818.0

275.3 873.0

344.0 1093

146.1

176

329

356

205

234

292

468

895

1075

1228

1329

1254

1432

1790

2508

Rated

Strength (Ibf)

22000

25200

31500

22100

25900

33800

36600

29800

16300

11800

17200

19500

23800

13700

19800

22600

34100

42200

60300

6620

8350

6880

11300

8680

14100

17300

9940

1190

1860

2360

2850

3640

3550

4380

5310

4

Electrical Data for ACSR Conductors

Size

Resistance

DC at 20°C AC at 25°C AC at 50°C AC at 75°C

Reactance at 60 Hz **

Capacitive

Inductive at 25°C

Inductive at 50°C

Inductive at75°C

Codeword (AWG/kcmil) (ohm/kft) (ohm/kft) (ohm/kft) (ohm/kft) (megohm-kft) (ohm/kft) (ohm/kft) (ohm/kft)

Turkey

Swan

Swanate

Sparrow

Sparate

Robin

Raven

Quail

2

1

1/0

2/0

6

4

4

2

0.642

0.403

0.399

0.253

0.251

0.201

0.159

0.126

0.655

0.412

0.407

0.259

0.256

0.206

0.163

0.130

0.750

0.479

0.463

0.308

0.297

0.247

0.197

0.162

0.816

0.522

0.516

0.336

0.330

0.270

0.216

0.176

0.751

0.715

0.710

0.678

0.674

0.660

0.642

0.624

0.120

0.115

0.113

0.110

0.109

0.107

0.104

0.102

0.139 0.144

0.131 0.137

0.124 0.130

0.123 0.128

0.118 0.121

0.119 0.122

0.114 0.116

0.112 0.113

Pigeon

Penguin

3/0

4/0

0.100 0.103 0.121

0.0795 0.0822 0.107

0.145

0.116

0.606 0.0992 0.108 0.109

0.597 0.0964 0.105 0.105

Waxwing 266.8 0.0644 0.0657 0.0723 0.0788 0.576 0.0903 0.0903 0.0903

Partridge 266.8 0.0637 0.0652 0.0714 0.0778 0.565 0.0881 0.0881 0.0881

Merlin

Linnet

336.4 0.0510 0.0523 0.0574 0.0625 0.560 0.0826 0.0826 0.0826

336.4 0.0506 0.0517 0.0568 0.0619 0.549 0.0854 0.0854 0.0854

Oriole 336.4 0.0502 0.0513 0.0563 0.0614 0.544 0.0843 0.0843 0.0843

Chickadee 397.5 0.0432 0.0443 0.0487 0.0528 0.544 0.0856 0.0856 0.0856

Ibis

Pelican

Flicker

Hawk

Hen

Osprey

397.5

477

477

477

477

0.0428 0.0438 0.0481 0.0525

0.0360 0.0369 0.0405 0.0441

0.0358 0.0367 0.0403 0.0439

0.539

0.528

0.524

0.0835 0.0835 0.0835

0.0835 0.0835 0.0835

0.0818 0.0818 0.0818

0.0357 0.0366 0.0402 0.0438 0.522 0.0814 0.0814 0.0814

0.0354 0.0362 0.0398 0.0434 0.517 0.0803 0.0803 0.0803

556.5 0.0309 0.0318 0.0348 0.0379 0.518 0.0818 0.0818 0.0818

Parakeet 556.5 0.0307 0.0314 0.0347 0.0377 0.512 0.0801 0.0801 0.0801

Dove

Rook

Grosbeak 636

Drake

Tern

Rail

Cardinal

Curlew

Bluejay

556.5 0.0305 0.0314 0.0345 0.0375 0.510 0.0795 0.0795 0.0795

636

795

795

954

954

0.0268 0.0277 0.0303 0.0330 0.502 0.0786 0.0786 0.0786

0.0267 0.0275 0.0301 0.0328 0.499 0.0780 0.0780 0.0780

0.0214 0.0222 0.0242 0.0263

0.0216 0.0225 0.0246 0.0267

0.482

0.488

0.0756 0.0756 0.0756

0.0769 0.0769 0.0769

0.0180 0.0188 0.0206 0.0223 0.474 0.0748 0.0748 0.0748

0.0179 0.0186 0.0205 0.0222 0.470 0.0737 0.0737 0.0737

1033.5 0.0165 0.0172 0.0189 0.0205 0.464 0.0729 0.0729 0.0729

1113 0.0155 0.0163 0.0178 0.0193 0.461 0.0731 0.0731 0.0731

Bittern 1272 0.0135 0.0144 0.0157 0.0170 0.451 0.0716 0.0716 0.0716

Lapwing 1590 0.0108 0.0117 0.0128 0.0138 0.434 0.0689 0.0689 0.0689

Bluebird 2156 0.00801 0.00903 0.00977 0.0105 0.409 0.0652 0.0652 0.0652

* Ampacity is with sun and wind at 2 ft/s

** Reactance at 1 foot equivalent spacing

Ampacity*

(A)

780

790

910

890

970

990

1040

1070

590

640

670

660

660

710

720

730

1160

1340

1610

315

365

445

455

515

530

530

575

105

140

140

185

185

210

240

275

5

ACSR-II Overhead

Conductors

ACSR-II Overhead Conductors are manufactured from two standard ACSR conductors which are twisted together with a very long lay (8-10 feet). This simple cable design is very effective in reducing ice loading and wind-induced conductor motion, and the costly damage that these can cause.

AAC (all aluminum conductor) and

AAAC (all aluminum alloy conductor) are also available in the twisted configuration, and are identified as

AAC-II and AAAC-II respectively.

Wind-Induced Conductor

Motion

Aeolian Vibration

Steady, low speed wind loading can impart vertical motion to a standard overhead conductor. At resonant frequencies, the amplitude of this motion (aeolian vibration) is sufficient to cause fatigue damage to the conductor strands, and can reduce the life expectancy of the conductor.

ACSR-II conductor reduces aeolian vibration to harmless levels through two mechanisms:

1) Prevention of resonant vibrations

2) Conversion of vertical motion to

rotational motion.

The twisted configuration of ACSR-II results in a constantly changing profile along its length. Consequently, the wind-force applied to the conductor is different at each point along its length.

This variation in wind force effectively prevents resonant vibration and reduces vertical conductor motion.

A further reduction is achieved as a result of the ease of rotation of a twisted assembly compared to a single conductor. Since a cabled conductor is much easier to rotate than a single conductor, much of the wind’s energy is dissipated through harmless rotation of an ACSR-II conductor rather than imparting damaging aeolian vibration.

Conductor Galloping

The combination of an eccentric ice coating and high wind-loading can create a situation where a standard overhead conductor is subjected to wind-induced lift. Vertical motion of several feet can result as the ice-coated conductor, behaving like an airfoil, is lifted and then dropped by the wind.

Severe damage to the conductor and accessories can result as this cycle repeats itself.

However, the twisted configuration of the ACSR-II design changes the angle of wind attack along the cable’s length and prevents the formation of an ice airfoil. This effectively eliminates one of the key causes of conductor galloping.

Sub-Conductor Oscillation

Wind speeds in excess of 20 mph can cause damaging wake-induced motion of bundled conductors in amplitudes of up to 5 feet.

However, it is known that if one of the conductors in a bundled system is a different diameter than the other, the likelihood of resonant vibrations being created is greatly reduced. When two ACSR-II conductors are used in a bundled configuration, it is very likely that at any point along the length of the bundle the apparent diameter of one

ACSR-II conductor will be different from that of the other.

In addition, wind vortices formed in a standard bundled system cause vertical forces and vertical conductor motion.

As stated previously, an ACSR-II conductor will convert these vertical forces into rotational motion.

Operating Temperatures

Compared to a standard ACSR conductor of equivalent cross-sectional area, ACSR-II conductor has a larger surface area. This allows for greater heat dissipation, and means that for a given current, ACSR-II conductor will operate at a lower temperature.

Similarly, ACSR-II conductor has a greater ampacity than the equivalent single ACSR conductor.

Cost Savings

The unique physical properties of

ACSR-II conductors can result in real savings in the cost of a T & D system.

— Fatigue damage to conductor strands is reduced, thus enhancing lifeexpectancy and delaying replacement.

— Accessories (i.e. vibration dampers, armor rods, and anti-galloping devices) normally used with standard conductors to reduce conductor motion can be eliminated.

— The higher installation tension permitted with ACSR-II conductor results in reduced structure costs through fewer and smaller structures.

— Lower operating temperature and resistance is obtained.

— Higher load capacity is achieved.

6

Physical Data for ACSR-II Conductors

Codeword

Size

(AWG/kcmil)

Stranding

(Al/Steel)

Steel Wire Aluminum Major Overall Aluminum

Diameter Wire Diameter Diameter * Weight

(inch) (inch) (inch) (lb/kft)

ACSR-II Turkey

ACSR-II Swan

ACSR-II Swanate

ACSR-II Sparrow

ACSR-II Robin

ACSR-II Raven

ACSR-II Quail

ACSR-II Pigeon

1

1/0

2/0

3/0

6

4

4

2

2 × 6/1 0.0661 0.0661

2 × 6/1 0.0834 0.0834

2 × 7/1 0.1029 0.0772

2 × 6/1 0.1052 0.1052

2 × 6/1 0.1181 0.1181

2 × 6/1 0.1327 0.1327

2 × 6/1 0.1489 0.1489

2 × 6/1 0.1672 0.1672

ACSR-II Penguin 4/0 2 × 6/1 0.1878 0.1878

ACSR-II Waxwing 266.8 2 × 18/1 0.1217 0.1217

ACSR-II Partridge 266.8 2 × 26/7 0.0788 0.1013

ACSR-II Merlin

ACSR-II Linnet

ACSR-II Oriole

336.4 2 × 18/1 0.1367 0.1367

336.4 2 × 26/7 0.0884 0.1137

336.4 2 × 30/7 0.1059 0.1059

ACSR-II Chickadee 397.5 2 × 18/1 0.1486 0.1486

ACSR-II Ibis

ACSR-II Pelican

ACSR-II Flicker

ACSR-II Hawk

ACSR-II Hen

397.5 2 × 26/7 0.0961 0.1236

477

477

477

477

2 × 18/1 0.1628 0.1628

2 × 24/7 0.0940 0.1410

2 × 26/7 0.1053 0.1364

2 × 30/7 0.1261 0.1261

* Minor Overall Diameter is 1/2 of Major Overall Diameter

0.396

0.500

0.514

0.632

0.710

0.796

0.894

1.004

1.126

1.218

1.284

1.368

1.440

1.482

1.486

1.566

1.628

1.692

1.696

1.766

49.0

78.0

78.0

124.0

156.4

197.4

248.8

313.4

395.4

500.6

503.4

565.8

634.2

636.2

746.2

749.4

895.6

900.2

899.2

902.2

Steel

Weight

(lb/kft)

Total

Weight

(lb/kft)

Rated

Strength

(lbf)

23.2

36.8

56.0

58.6

73.8

93.2

117.6

148.2

186.8

78.4

231.2

259.6

291.0

418.0

117.0

343.8

140.4

329.0

412.8

592.6

72.2

114.8

134.0

182.6

2380

3720

4720

5700

230.2

290.6

7100

8760

366.4 10620

461.6 13240

582.2 16700

579.0 13760

734.6 22600

730.4 17360

925.2 28200

1054

863.2 19880

1093

1036

1229

1312

1495

34600

32600

23600

34400

39000

47600

Electrical Data for ACSR-II Conductors*

Codeword

Size

(AWG/kcmil)

Resistance

DC at 20°C

(ohm/kft)

AC at 25°C

(ohm/kft) (ohm/kft)

AC at 50°C AC at 75°C Capacitive

Reactance at 60 Hz **

Inductive at 25°C

(ohm/kft) (megohm-kft) (ohm/kft)

Inductive Inductive at 50°C at 75°C

(ohm/kft) (ohm/kft)

ACSR-II Turkey

ACSR-II Swan

ACSR-II Swanate

ACSR-II Sparrow

ACSR-II Robin

ACSR-II Raven

ACSR-II Quail

ACSR-II Pigeon

ACSR-II Linnet

ACSR-II Oriole

336.4 0.0255

ACSR-II Chickadee 397.5 0.0216

ACSR-II Ibis

ACSR-II Pelican

ACSR-II Flicker

ACSR-II Hawk

ACSR-II Hen

6

4

4

2

1

1/0

2/0

3/0

ACSR-II Penguin 4/0 0.0398

ACSR-II Waxwing 266.8 0.0322

ACSR-II Partridge 266.8 0.0319

ACSR-II Merlin

336.4 0.0253

336.4 0.0251

397.5 0.0214

477

477

477

477

0.321

0.202

0.199

0.127

0.101

0.0796

0.0632

0.0502

0.0180

0.0179

0.0178

0.0177

0.328

0.206

0.204

0.130

0.103

0.0816

0.0651

0.0517

0.0411

0.0329

0.0326

0.0261

0.0259

0.0257

0.0222

0.0219

0.0185

0.0184

0.0183

0.0181

0.375

0.240

0.232

0.154

0.124

0.0986

0.0808

0.0647

0.0533

0.0362

0.0357

0.0287

0.0284

0.0281

0.0243

0.0241

0.0203

0.0202

0.0201

0.0199

0.408

0.261

0.258

0.168

0.135

0.108

0.0880

0.0723

0.0579

0.0394

0.0389

0.0313

0.0310

0.0307

0.0264

0.0262

0.0221

0.0220

0.0219

0.0217

0.566

0.530

0.525

0.493

0.475

0.457

0.439

0.420

0.403

0.390

0.382

0.372

0.364

0.359

0.359

0.351

0.345

0.339

0.336

0.332

0.107

0.102

0.101

0.0967

0.0938

0.0911

0.0886

0.0861

0.0833

0.0794

0.0777

0.0768

0.0750

0.0741

0.0748

0.0731

0.0727

0.0714

0.0710

0.0701

0.117

0.110

0.106

0.104

0.100

0.119

0.113

0.109

0.106

0.102

0.0960 0.0973

0.0937 0.0945

0.0906 0.0912

0.0875 0.0878

0.0794 0.0794

0.0777 0.0777

0.0768 0.0768

0.0750 0.0750

0.0741 0.0741

0.0748 0.0748

0.0731 0.0731

0.0727 0.0727

0.0714 0.0714

0.0710 0.0710

0.0701 0.0701

* For single-aluminum-layer ACSR, the AC values are approximate, based on assumed current for 75°C, 75% of assumed current for 50°C, and 10% of assumed current for 25°C. Reactances for multi-layer conductors are not temperature dependent.

Data is adapted from conventional ACSR data given in Tables 4-15 and 4-16 of Aluminum Electrical Conductor Handbook,

Second Edition, published by the Aluminum Association.

** Reactance at 1 foot equivalent spacing

7

US Sales Office

10 North Hill Drive

Suite 2A

Warrenton, Virginia

20186

Telephone (540) 347-2839

Facsimile (540) 347-5338

Internet Web Site www.nexansenergy.com

Corporate Office

140 Allstate Parkway

Markham, Ontario

Canada

L3R 0Z7

Telephone (905) 944-4300

Facsimile (905) 944-4330

Manufacturing Locations

Weyburn, Saskatchewan

Quebec City, Quebec

Nov. 2003