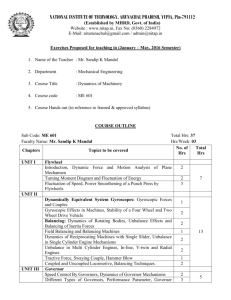

CHAPTER 13 DYNAMIC BALANCING OF ROTORS

advertisement

CHAPTER 13 DYNAMIC BALANCING OF ROTORS Till last chapter, we concentrated on transverse and torsional vibration analyses of rotor-bearing systems, e.g., free vibrations, forced responses and instability analysis. These analyses are very much useful tool for designers of rotating machineries to predict the behaviour of such machineries before actually their manufacturing and commissioning. These analyses help in the modification of design if operating speed is close to critical speeds or in the instability zones. In the present and subsequent chapters, we will address another class of practical and the most common problems related to rotating machineries that practicing engineers face during the commissioning of new rotating machine, during operation, or after every major overhaul of such machineries. Some of these fault are unbalances, misalignments, rotor-stator rubs, bent or bowed shafts, fatigue cracks, the wear and tear of various moving and stationary components, loose components, and faults related to components of bearings, gears, coupling, blades, seals, etc. Among various faults, the most common fault is inherent unbalances (or residual unbalances) in machineries occur due to manufacturing error (fits and tolerances), material in-homogeneity, improper commissioning, thermal deformation, during operation due to the wear and tear, residual stresses, and so on. Basic definition of the unbalance and its type for rigid rotors has been introduced earlier in Chapter 2. To prevent vibration we must first decrease this unbalance (or to balance the rotor), which is the major source of vibration. In the present chapter, the procedure of static and dynamic balancing of rotor will be discussed in great details. For dynamic balancing, rotors are classified in two major categories, e.g., the rigid and flexible rotors. In fact, the same shaft of a rotor can be considered as rigid if it is operating much below its first critical speed and the flexible when it is operating near or above the first critical speed. That is why sometime it is also called the slow and high speed rotor balancing. Basic principles of rigid and flexible rotor balancing are quite different. Necessary principles and theories for dynamic balancing will be outlined before describing practical methods of balancing. For rigid rotor balancing two methods are described, e.g., the conversional cradle balancing machine method (off-site or offfield balancing) and the modern influence coefficients method (on-site or field balancing). Similarly, for the flexible rotor two basic methods are available, e.g., the modal balancing method and the influence coefficient method. In general, the rigid rotor can be balanced by putting correction masses in two balancing planes, however, in flexible rotor case it can be balanced by N balancing planes, where N is the number of flexible modes need to be balanced. Some time it is suggested to balance flexible rotor by (N+2) balancing planes (i.e., to balance rigid rotor modes by 2 planes at low speeds and flexible rotor modes by N planes at high speeds). 767 The unbalance in rotors will not only cause rotor vibrations, but also transmit rotating forces to the bearings and to the foundation structure. The force thus transmitted may cause damage to the machine parts and its foundation. If the transmitted force is large enough, it might affect even the neighbouring machines and structures. Thus, it is necessary to remove the unbalance of a rotor, to as large an extend as possible, for its smooth running. The residual unbalance estimation in rotor-bearing system is an age-old problem. From the state of the art of the unbalance estimation, the unbalance can be obtained with fairly good accuracy (Kellenburger, 1972; Drechsler, 1980; Gnilka, 1983; Krodkiewski et al., 1994; Darlow, 1989). Now the trend in the unbalance estimation is to reduce the number of test runs required, especially for the application of large turbogenerators where the downtime is very expensive (Edwards et al., 2000; Tiwari, 2005 ). 13.1 Unbalances in the Rigid and Flexible Rotors Unbalance in a Single Plane: Such unbalance occurs in gear wheels, grinding wheels, single stage compressor, propeller of aircraft engines, etc. Figure 13.1 shows a rigid thin disc with the single plane unbalance. O is the centre of rotation of the disc and G is the centre of gravity of the rotor. The eccentricity, e, is defined a distance between the centre of rotation and the centre of gravity. The unbalance in the disc is defined as U = me (13.1) where U is the unbalance with a unit of kg-m or g-mm, m is mass of disc, e is the eccentricity in the disc (length OG in Fig. 13.1). y G m O x Figure 13.1 A unbalance in a single plane Unbalances in Two or More Planes: Figure 13.2 shows two types of unbalance in a rigid rotor system. The rotor consists of a rigid rotor and a massless elastic shaft. First (Fig. 13.2a) is the static unbalance, which is the state represented by a geometric eccentricity e of the center of a gravity of a rotor from the centerline of the shaft. The unbalance produces a centrifugal force proportional to the square of the rotational speed. This static unbalance can be detected without operating the rotor since the unbalance is always directed 768 downward if the shaft is supported horizontally by bearings having little friction. Theoretically, it is similar to the single plane unbalance described above, except the unbalance in uniformly distributed along the length of the rigid rotor. Second type of unbalance is couple unbalance, which is the state represented by the angular misalignment of the principal axis of moment of inertia of the rotor with respect to the centerline of the shaft. The magnitude of the couple unbalance ( M = ( I d − I p ) ω 2φ = F ω 2 rl ) is determined by the angle φ as shown in Figure 13.2b. This type of unbalance cannot be detected without rotating the shaft. Figure 13.2(a and b) shows these unbalances as models with one and two concentrated masses, respectively. That means static unbalance can be balanced by a single plane balancing and couple unbalance has to balance with two balancing planes. With the above definition now the dynamic unbalance in a rigid rotor means the state with the both static and couple unbalances. (i.e., combination of Figures 13.2a and b). However, for such a case also two-plane balancing will be enough. On the other extreme case would be the unbalances in a continuous rotor (i.e., a flexible rotor with distributed mass) as shown in Figure 13.3. Here we require N plane balancing, where N ≥ 2 and generally for balancing up to mth mode N = m for m ≥ 2 . (a) Static unbalance (b) Couple unbalance Figure 13.2 Unbalances in a long rigid rotor system Figure 13.3 Variation of the unbalance in a continuous flexible rotor 769 13.2 Principle of Rigid Rotor Balancing Now some basic principle of rigid rotor balancing will be outlined and this will pay the way to understand balancing methods for practical rotors. 13.2.1 Static Balancing (Single plane balancing): The unbalance force, for a single plane disc as shown in Fig. 13.1, is given as F = mω 2 e (13.2) where ω is the spin speed of the rotor. If we want to know correction mass, mc, at a radius of r, it will be given by mc = e/r m (13.3) The correction should be placed 1800 away from unbalance mass m. Such a correction is called a single plane balancing of the rotor, which eliminates the inertia forces transmitted to the foundation (or bearing). 13.2.1 Static Balancing (Two plane balancing): We represent eccentricities and centrifugal forces as vectors, for which both magnitude and direction are necessary. (a) Actual system (b) Equivalent force model Figure 13.4 Elimination of the static unbalance Balancing is attained if the centrifugal force F = meω 2 is cancelled by the other centrifugal forces, due to balancing weights m1 and m2 . In practical machines, the positions of the correction planes are determined from the shape of the rotor. Balancing is done by removing parts of the rotor or by attaching correction masses in plane I and II. In practice, removing some part is done by drilling, milling or grinding. Addition of weight would require the use of wire solders, bolted or riveted washers and welded weights. Let the masses m1 and m2 are attached to the surface at radii a1 and 770 a2 , respectively. To cancel the unbalance force F = meω 2 by centrifugal force FI = m1a1ω 2 and FII = m2 a2ω 2 , the following relationship must hold FI + FII = F FI l1 = FII l2 and (13.4) where l1 and l2 are shown in Figure 13.4. Equation (13.4) can be solved as FI = l2 F l1 + l 2 FII = and l1 F l1 + l 2 (13.5) 13.4.2 Couple unbalance Figure 13.5 Couple unbalance ( ) The moment M = I d − I p ω 2φ due to couple unbalance can be replaced equivalently by a couple of forces P = M d , which is separated by the distance d. We add correction masses m1 and m2 to cancel moment M by the centrifugal forces PI = m1ω 2 a1 and PII = m2ω 2 a2 (Fig. 13.5). For this case the following relationships must hold PI l1 + PII l2 = M and PI = PII (13.6) The latter is the condition to prevent a new static unbalance due to the addition of m1 and m2 . Vectorially they should be P1 = − P2 . Equation (13.6) gives PI = PII = M l1 + l2 It is assumed here that we know the plane of couple unbalancing. (13.7) 771 13.4.3 Dynamic unbalance Figure 13.6 Static and couple unbalance The static and couple unbalances effects i.e. force and moments may not be in the same plane; however, they will be perpendicular to the bearing axis (Fig. 13.6). The balancing is attained by adding correction weights in the correction forces RI and RII determined by the vector relationship RI = PI + FI and R II = PII + FII (13.8) The balancing method described above is called the two-plane balancing. On the contrary as we have seen above, when a rotor is thin, the balancing is attained practically by adding a correction weight in one plane. This method is called the single-plane balancing. Practical balancing machines are made based on such principles. Basic principles of flexible rotor balancing will be described subsequently. 13.2.4 Various expressions of unbalance In this section various terminologies used in industry related to unbalance is described. When a static unbalance exists, a centrifugal force meω 2 exists. This unbalance force is eliminated if mass m1 , which satisfied the relationship meω 2 + m1aω 2 = 0 , is added at radius a in the same plane as the center of gravity G. From this condition it is clear that the product me or m1a is more important than the eccentricity itself. Therefore, the quantity U = me (g-mm) (13.9) 772 is called an unbalance vector and its magnitude U = me is called a magnitude of unbalance. These quantities are sometimes called simply unbalance. Different types of expressions are described in the general case where an eccentricity e and an inclination φ of the principal axis of moment of area coexist. (a) Resultant Unbalance” U and “Resultant Unbalance moment V : Figure 13.7 Equivalent concentrated unbalances U 1 and U 2 A thinly sliced disc with thickness dz, which is perpendicular to the rotor axis, is considered (Fig. 13.7). Let the mass of the disc is dm = µ ( z ) dz , where µ ( z ) is a line mass density of the rotor and the eccentricity of the center of gravity be e ( z ) . Then its unbalance is represented by dU ( z ) = e ( z )dm = e ( z ) µ ( z )dz . Summation of such unbalance, called a resultant unbalance, is given by U= l1 + h dU ( z ) = l1 l1 + h e ( z ) µ ( z )dz (13.10) l1 where l1 is the distance between the origin o and the rotor and h is the length of rotor. Multiplying this by ω12 , we get the resultant unbalance force of the centrifugal force. F = ω 2U (13.11) The quantity V= l1 + h l1 l1 + h ( ziˆ ) × dU ( z ) = ( ziˆ ) × e ( z ) µ ( z ) dz l1 (13.12) 773 is called a “resultant unbalance moment” concerning point o, where iˆ is a unit vector in the direction of the bearing centerline and × is the cross product of vectors. Multiplying this by ω 2 , we get the moment N produced by the centrifugal forces of all elements. N = ω 2V (13.13) This moment is called a “resultant moment” of the unbalance force. We can represent the unbalance of a rigid rotor by using the “resultant unbalance U ” and the “resultant unbalance moment V ”. (b) Dynamic unbalance U1 ,U 2 : U (Resultant unbalance) and V (resultant unbalance moment) are to be replaced by the concentrated unbalance U I and U II in the correction plane I and II, respectively. For this replacement, the following relationship must hold U1 + U 2 = U and ( z iˆ ) × U + ( z iˆ ) × U 1 1 2 2 =V (c) where z1 and z2 are positions of the correction planes. The balancing is attained if we add −U 1 and −U 2 , which cancel U 1 and U 2 , respectively. This set U1 ,U 2 is called the “dynamic unbalance” represented at positions z1 and z2 . (c ) Static unbalance U and couple unbalance U C , −U C : Figure 13.8 Replacements of unbalances 774 The resultant unbalance U = U1 + U 2 is also called the static unbalance because it can be detected without rotating the shaft. This expression shows that the dynamic unbalance mentioned in section (b) contains the static unbalance quantitatively. Now, we replace the dynamic unbalance U1 ,U 2 by the static unbalance U and a couple whose forces are located in the correction planes I and II, respectively, as follows: 1. Suppose that the static unbalance U and the dynamic unbalance −U are added at position, z3 , as shown in Figure 13.8(a). Since U − U = 0 holds, balancing as a whole does not change due to this addition. 2. Since −U is decomposed into −U1 and −U 2 as −U = −U1 − U 2 , the summation of the dynamic unbalance +U1 , +U 2 at z1 and z2 and a given unbalance −U at z3 is equivalent to two couples which are the set of unbalance −U II , +U II U1 , −U1 at z1 and z3 and the set at z3 and z2 , as shown in Figure 13.8(b). 3. From the law of mechanics the effect of a couple is the same for any position of the rigid body. The couple U1 , −U1 at z1 and z3 can be replaced by −U 2C ,U 2C at z1 and z2 as shown in Figure 13.8(c): ( z2 − z3 )U 2 = ( z2 − z1 )U 2C . 4. Using −U1c + U 2 c = U c , the summation equivalent couple U c , −U c U1c , −U1c and −U 2c ,U 2 c is replaced by “an at the correction planes I and II” as shown in Figure 13.8(d). This set of unbalance is called the couple unbalance. From such replacements, we know that the unbalance of a “rigid rotor” can be represented by the static unbalance, U , and the couple unbalance, U c , −U c . Example 13.1 For a rigid rotor with constant eccentricity e0 in the right half of the rotor span as shown in Fig. 13.8, obtain its equivalent (a) the resultant unbalance, U, and the resultant unbalance moment, V, (b) the dynamic unbalance U1 ,U 2 , (c) the static unbalance U and couple unbalance U C , −U C . Solution: Fig. 13.9a shows a rigid rotor with constant eccentricity e0 in the right half of the rotor span. : Fig. 13.9b shows the positions of the two balancing planes. 775 Fig. 13.9 A rotor unbalance distribution and its equivalent form (a) If the line mass density µ ( z ) is a constant, the magnitude of the resultant unbalance is obtained as U= l1 + h l1 + h e ( z ) µ ( z ) dz = 0 + µ e0 l1 + h / 2 l1 dz = 1 µ e0 h 2 (a) and the resultant unbalance moment about point o is given by V= l1 + h ze ( z ) µ ( z ) dz = 0 + µ e0 l1 l1 + h 1 3 zdz = µ e0 l1h + h 2 2 4 l +h/ 2 (b) 1 This vector V is perpendicular to the plane in which e0 is acting for the present case. Since equation (b) contains l1 , the magnitude of V depends upon the origin o. From equation (b) N can be obtained by multiplying ω 2 to the V . (b) For the present example of Figure 13.9, we have (from equations c and a) U1 + U 2 = 12 µ e0 h (d) 776 and from equations (c and b), we have l1U1 + ( l1 + h )U 2 = 12 µ e0 ( l1h + 43 h 2 ) (e) On solving equations (d) and (e), we get U1 = 18 µ e0 h and U 2 = 83 µ e0 h (f) (C) From Figure 13.9, we have the magnitude of the static unbalance U is U1 + U 2 = µ e0 h / 2 . Two unbalances with the magnitude µe0 h / 2 and pointing to the upper and lower directions at the position z3 = l1 + b are considered. We replace −U and the dynamic unbalance U1 ,U 2 by the set U1′,U 2′ in the correction planes I and II (Figure 13.8d). The following relationship hold between them (Figures 13.9 and 13.8d) U1′ + U 2′ = U1 + U 2 − U = 0 and l1U I′ + ( l1 + h )U II′ + ( l1 + b )U = l1U I + ( l1 + h )U II (g) On substituting U , U1 and U 2 , we get U1′ = −U 2′ = − 12 µ e0 ( 34 h − b ) ≡ U c The static unbalance U and the couple unbalance U c , −U c (h) are illustrated in Figure 13.8(d). Answer Finally, we remark on the problem regarding to what extend we should balance rotors. The smaller the residual unbalance attained the better. However, in a practical application, we must take into account the time and expenses necessary to balance the rotor. Therefore, it is appropriate to vary the permissibility of unbalance depending on the kind of rotating machinery. A quantity εω called “balance quantity” is used to express the degree of balancing, where the quantity ε is a “correction plane eccentricity” and ω is the maximum angular velocity in the operation range. The “correction 777 plane eccentricity” ε is given by the “specific unbalance”, that is, ratio of the magnitude of unbalance to the rotor mass. In the case of single plane balancing, the correction plane eccentricity is given by εs = Us M (13.14) where U s is the static unbalance and M is the stator mass. In case of two-plane balancing, it is given by the larger value of ε I = UI U and ε II = II , where [U I ,U II ] is a dynamic unbalance. If the M /2 M /2 quantities of two rotors are equal, the loads transmitted to the bearings are the same even if the dimensions of the rotating machines are different. The permissibility of the unbalance is given by the International Standardization Organization (ISO) or various national standards. For example, balance quantity defined by the Bureau of Indian Standard (BIS) is given as Balance quantity = εω mm/s (13.15) where the unit of ε is mm and that of ω in rad/s. The balance quantity is classified into several grades: G0.4, G1, G2.5, G2.6, G40, G100, G250, G630, G1600, and G4000. For example, G100 means that the maximum permissible value of balance quantity for this grade is 100 mm/s. Based on experience, the specific balance quantity grade is recommended for individual rotating machinery. For example: G0.4 is recommended for gyroscopes and G2.5 for gas and steam turbines. (Refer standards on balancing e.g., IS 5172 (1969), IS 13274 (1992), IS 13275 (1992), IS 13277 (1992), IS 13278 (1999), IS 13280 (1992), IS 14280 (1995), IS 14734 (1999) and IS (14918)). 13.3 Balancing of Practical Rigid Rotor In the present section now practical methods of the rigid rotor balancing will be described. In practical rotors axial and radial locations residual unbalances and its orientations are unknown. Depending upon the geometry of rigid rotors, a single plane or two plane balancing methods are employed. In the present section, both the single plane balancing and the two plane balancing will be described in detail. 13.3.1 Single plane balancing: In the actual practice location (radial as well as angular)) of centre of gravity point G is unknown in the single plane rotors. The orientation of point G can be obtained by keeping the rotor on frictionless (knife edge) supports and gently allow it to rotate freely without any external drive as such (may be a small toque by hand to initiate its rotation). The rotor becomes stationary after some time with heavy spot (G) vertically downwards. It can be repeated to confirm the orientation of the residual unbalance (or heavy spot) and it can be marked by chalk or any other 778 means. Now we will place a correction mass at 1800 to the heavy spot (i.e., at the light spot) and again allow rotor to rotate freely by gentle push of the rotor. (i) If the marked heavy spot again comes vertically downwards that means the correction mass m to be increased. (ii) If the marked heavy spot comes vertically upward position, means correction mass is more, and it has to be decreased. (iii) If heavy spot rests at some other position, means rotor is nearly balanced. This can be confirmed by freely rotating the rotor again and finding whether it rests always at some indifferent equilibrium position. Such a process is called the static balancing of rotor (disc) and it is valid for a rotor with only one disc or balancing is required in the single plane only. For the single plane rotor, the static balancing rotor will also be dynamically balanced. 13.3.2 Two plane balancing (Cradle balancing machines): The rotor has to be removed from the installation and is placed on the bearings of a cradle balancing machine as shown in Figure 13.10. Two procedures will be described (i) Hit and trial method: It requires large number of measurements to obtain correction masses at two balancing planes (ii) A systematic method: It requires only eight measurements to obtain correction masses at two balancing planes. Figure 13.10 A schematic of the cradle balancing machine Hit and trial balancing method: The cradle is placed on four springs and can be fulcrum about F1 or F2 to form a simple vibrating system to oscillate about F2 or F1, respectively. Two fulcrum can be located at two chosen balance planes (i.e. I and II), where the correction mass to be added. The rotor can be driven by a motor through a belt pulley arrangement. If the spring system is such that the natural frequency of the system is in the range of motor speed, the phase angle or the location of the mass in either plane can be determined as follows. Fulcrum the cradle in plane I, by fixing F1 and releasing F2. Run the rotor to resonance, observing the maximum amplitude to the right of fulcrum F2. This vibration is due to all the unbalance in plane II, since the unbalance in plane I has no moment about F1. Use a trial mass at a chosen location and determine the amplitude of vibration. 779 Figure 13.11(a) Variation of vibration amplitudes versus trial mass angular locations Figure 13.11(b) Variation of vibration amplitudes versus trial mass magnitudes Make a plot of this amplitude for different location of the same trial mass (see Fig. 13.11a). The trial mass for correction is added at the location where the amplitude of vibration is minimum. Increase or decrease the trial mass at the same locations, until the desired level of balance is achived (see Fig. 13.11b). This will give correction mass for plane II. Similar procedure can be repeated by Fixing F2 and releasing F1 to get correction mass at plane I. This procedure is tedious and sometimes may be time consuming. Example 13.2 In a dynamic balancing of a rigid rotor by a cradle balancing machine the following measurement were obtained when fulcrumed at F1 (i) for a known trial mass at a fixed radius when kept at different angular position at regular interval of 300 the following vibration amplitudes (all in mm) were obtained: 3, 5, 8, 6, 5, 3, 2, 4, 7, 8, 6, 5. 4 (ii) when at a constant angular position and at fixed radius corresponding to the minimum vibration amplitude different masses were tried the following vibration measurements were obtained (gm, mm): (1, 1.2), (1.2, 1.4), (1.4, 1.6), (1.6, 1.4), (1.8, 0.9), (2.0, 0.8), (2.2, 1.2), (2.4, 1.5), (2.6, 1.8). Obtain the unbalance mass and its location in the plane 2. 780 Solution: From the first set of measurement the location of the angular position is 1800 corresponding to 2 mm displacement. From the second set of measurements the magnitude of the unbalance mass is 2.0 gm corresponding to the minimum vibration amplidue of 0.8 mm. Answer A systematic balancing method: This method is aimed to reduce the number of measurements while using the cradle balancing machine. This method also requires measurements in the cradle balancing machine and correction masses at plane I and II are obtained by fulcruming at F2 and F1, respectively. A procedure to determine the correction mass and location at one plane at a time can be laid down as follows, based on only four observations of amplitude : (i) without any addition of the trial mass to the rotor (ii) with a trial mass at = 00, where is measured from a conveniently chosen location on the balancing plane (iii) with the same trial mass at 1800 and (iv) with same trial mass at = ±900. This procedure has to be repeated for two cases (e.g. when fulcruming at F1 and then for F2). Let OA is the amplitude measured with trial run (1) without a trial mass, OB is the amplitude measured in trial run (2) by addition of a trial mass TR at 00 (arbitrary chosen location on the rotor). Hence, vector AB represents the effect of trial mass TR. (at this stage we do not know the location of vector OA on the rotor). OC is the vibration measured in trial run (3), with the same trial mass at 1800. So we will have AB = AC with 1800 phase difference between them (since AC vector is also the effect of trial mass Wt so the magnitudes AB = AC with a phase of 1800). We know only OA , OB and OC from test runs (1), (2) and (3) respectively, and apart from this we have information that AB = AC with 1800 of the phase. From these information we have to construct and locate points O, A, B and C on a plane. Figure 13.12 A construction procedure for finding the unbalance vector The construction procedure for finding the unbalance vector is given now in detail. Erect a line OD equal to 2 OA . With point O a center and OB & OC as radii and then point D as center and OC & 781 OB as radii draw arcs to intersect at points B & C. Construct the parallelogram OBDC (points B and C we will be obtained by above construction). Now AB represents 00 position (i.e. reference line) and AC represents 1800 position on the rotor ( OA is actual unbalance). The angular measurement may be clockwise or counter-clockwise and is determined from the fourth observation. Draw a circle with BC as the diameter and point A as the center. On the circle the fourth observation observation could be either OE or OE′ (corresponding to measurement while keeping the trial mass at ±900). If the value observed is in the vicinity of OE , then the angle to be measured in counter-clockwise direction. However, it will be clockwise if OE′ is the reading observed in the test. The fourth run also checks the validity of the linearity used in the balancing procedure. The magnitude of trial mass Wt is proportional to AB . The unbalance OA can be obtained accordingly in terms of the mass. The location of unbalance is ∠OAB and the direction from Figure 13.13 (i.e. clockwise or counterclockwise). Fig. 13.13 Procedure of obtaining the sense of the angular position of the unbalance mass In Fig. 13.13(a) the left hand side figure represents the location of the intersection of fourth measurement on the circle (i.e., at E) for trial mass kept at 900 on the disc. This gives the CCW direction as positive for measurement of unbalance angular position, φ, from 0o location (i.e., AB). The right hand side drawing of Fig. 13.13(a) represents the unbalance position, φ, on the disc location that is CCW direction as positive from 0o. In case the for above measurement the intersection of fourth measurement (i.e., point E) is as shown in Fig. 13.13(b) for trial mass kept at 900 on the disc 782 then this gives the CW direction as positive for measurement of unbalance angular position, φ, from 0o location (i.e., AB). The right hand side drawing of Fig. 13.13(b) represents the unbalance position, φ, on the disc location that is CW direction as positive from 0o. Similarly, Figs. 13.13 (c and d) can be interpreted. The test is repeated by making the cradle pivoted at FII and measurements made in plane I. This procedure is little time consuming and also restricts the mass and size of the rotor. Modern balancing machines use amplitude and phase measurement in two planes for the balancing a rotor. Example 13.3 In the balancing process we make the following observations: (i) ao = amplitude of vibration of the unbalanced rotor “as is” (ii) a1 = amplitude with an additional one-unit correction at the location 0 deg and (iii) a2 = same as a1 but now at 180 deg. The ideal rotor, unbalanced only with a unit unbalance (and thus not containing the residual unbalance), will have certain amplitude, which we cannot measure. Call that amplitude x. Let the unknown location of the original unbalance be φ. Solve x and φ in terms of a0 , a1 and a2 to show that in this answer there is an ambiguity sign and prove that total four runs are necessary to solve the problem completely. Solution: Measurements are (i) a 0 = amplitude of vibration with residual unbalance U R ∠φ , (ii) a1 = amplitude with unit trial mass at an angle of 0 0 , (iii) a 2 = amplitude with unit trial mass at an angle of 180 0 , and (iv) x = amplitude with unit trial mass at an angle of 0 0 and without residual unbalance (i.e., U R = 0 ). So that OA = a0 , OB = a1 and OC = a2 . Figure 13.14 shows various parameters involved in the present problem. From OAB , we have 2 a 2 + AB − a12 cos φ = 0 2 a0 AB (a) and 2 a 2 + AC − a22 cos ( π − φ ) = 0 2a0 AC (a) Since AB = AC , we have 2 a 2 + AB − a22 − cos φ = 0 2a0 AB (c) 783 Figure 13.14 Geometrical constructions for determination of residual unbalance On equating equations (a) and (c), we get 2 2 2a0 OBcos φ = −(a02 + AB − a22 ) = (a02 + AB − a12 ) which gives 2 2a02 + 2AB − (a12 + a22 ) (d) AB = x , since AB (or AC ) are the effect of trial mass of unit magnitude. Hence, equation (d) gives x2 = 0.5(a12 + a22 ) − a02 or x=± 1 2 ( a12 + a22 ) − a02 (e) Equations (a) and (c) gives (noting that AB = AC = x ), x 2 = 2a0 x cos φ − a02 + a12 (f) x2 = −2a0 x cos φ − a02 + a22 (g) and On equating equations (f) and (g), we get cos φ = ( a22 − a12 ) 4a0 x (h) Equation (e) gives the magnitude of the unbalance and equation (h) gives the magnitude of the phase angle, the direction or sense of the phase cannot be obtained from only three measurements, a fourth 784 measurement by keeping the unit unbalance at 900 (or at 2700) will be required. Let us take a3 be the fourth measurement, now obtain the condition by which the direction angular position, θ , of the unbalance, x, can be obtained. This is left to the reader as an exercise. Answer Example 13.4 A short rotor or flywheel has to be balanced. Observations of the vibration at one of the bearings are made in four runs as follows: (i) Run 1; rotor “as is” : amplitude 6.0 µm, (ii) Run 2; with 5gm. at 0 deg.: amplitude 5.0 µm, (iii) Run 3; with 5 gm. at 180 deg.: amplitude 10.0 µm, and (iv) Run 4; with 5gm. at 90 deg.: amplitude 10.5 µm. Find the weight and location of the correction. Take the trial and balancing masses at the same radius. Solution: Figure 13.15 Geometrical constructions of unbalance vectors Figure 13.15 shows the geometrical construction of unbalance vectors for the present problem. Various lengths are given as: OA = AD = 6 cm ≡ 4.762 gm ( = a0), OB = CD = 5 cm ≡ 3.968 gm (= a1), and OC = BD = 10 cm ≡ 7.937 gm ( = a2). From Fig. 13.15, the residual unbalance is given as AB = 6.3 cm ≡ 5.14 cm ( ≡ 4.08 gm). AB is the reference line. The fourth observation intersects at E, hence angle to be measured in the CW direction (i.e. ∠BAE ). Thus, the unbalance position is given as ∠BAO = 308.7o CW or 51.30 CCW direction. The unbalance magnitude and phase can be also obtained from equations (e) and (h), we have x= 1 2 ( a12 + a22 ) − a02 = 1 2 (3.9682 + 7.937 2 ) − 4.762 2 = 4.09 gm and cos θ = 2 2 ( a22 − a12 ) ( 7.937 − 3.968 ) = = 0.6065 , 4 a0 x 4 × 4.762 × 4.09 this gives θ = 52.66o The difference in the values of unbalance and angular position is due to rounding off error and the error due to the graphical construction. 785 13.3.3 Two plane balancing (The influence coefficient method) The influence coefficient method is also called the field balancing since the balancing can be performed at site itself woithout taking out rotor from the machine as such. The number of trial runs to obtain the residual unbalnces in two planes are also less with a minimum of three runs are required. In Chapter 2 and 8, influence coefficients in detailed, here some relevant basic concept are briefed again. In the present section, then procedure would be outlines to obtain these influence coefficients experimnetally with the help of vibration amplitude and phase measurement in a rotor system. Definition of Influence coefficients: Figure 13.16(a) shows that when a force F1 is applied at station 1 and due to this force the beam deflections at stations 1 and 2 are given as and y11 = displacement at station 1 due to force F1 at station 1 = α 11 F1 y21 = displacement at station 2 due to force F1 at station1 = α 21 F1 where α is the influence coefficient and its first subscript represents the displacement station and second represents the force station. Similarly for Figure 13.16(b), we have y12 = α12 F2 and y22 = α 22 F2 Figure 13.16 Definition of influence coefficients In Figure 13.16(c), we have y1 = y12 + y12 = α11 F1 + α12 F2 y2 = y21 + y22 = α 21 F1 + α 22 F2 y1 α α12 = 11 y2 α 21 α 22 F1 F2 786 Influence coefficients can be obtained by experimentation or by strength of material formulae i.e. α11 = y11 / F1 , α 21 = y21 / F1 etc. In soft support machines, the resonant frequency of the rotor support system is low and the rotor runs at a speed above the resonance of the support system. Vibratory amplitudes are measured, which are then converetd to forces. In hard support system, the support natural frequency is very high and they measure the rotor unbalance forces directly, independent of rotor mass and configuration. The balancing procedure is based on the influence coefficient measurement. We choose two convenient planes L and R for trial mass and two measurement planes a and b (can be chosen as bearing locations) as shown in Figure 13.17. Let Y1L and Y1R be the initial readings (i.e., without trial mass) of vibration levels (the displacement, velocity or acceleration) measured with phase angle φ1L and φ1R , respectively. Figure 13.17 Bearing response measurements and influence coefficients for a rigid rotor balancing The phase angles are measured with the same reference during the test and their relative locations with respect to rotor is initially known. In the second run, place a trial mass, TR, at a convenient location in plane R and let the observations be Y2L and Y2R with phase φ2L and φ2R , respectively in the a & b planes. The difference between Y2R and Y1R will be the effect of trial mass, TR, in right plane R on the measurement made in plane b. We can denote this as an influence coefficient α bR . α bR = (Y2 R − Y1R ) / TR (13.16) 787 where " →" represent vector since displacement has magnitude and phase information. Hence, we can be able to work with complex quantities. Similarly α aR = (Y2 L − Y1L ) / TR (13.17) We remove the trial mass from plane R and place a trial mass, TL , in plane L and repeat the test to obtain the measured values α bL = (Y3 R − Y1R ) / TL (13.18) α aL = (Y3 L − Y1L ) / TL (13.19) and With the help of equations (13.16) to (13.19), we can obtain influence coefficient experimentally. Let the correct balance masses be W R and W L in the right and left balancing planes, respectively. Since the original unbalance response is R1 and L1 as measured in right and left planes, we can write −Y1R = WRα bR + WLα bL and − Y1L = WRα aR + WLα aL (13.20) Correction masses will produce vibration equal and opposite to the vibration due to residual unbalance masses. Hence, α α bL Y1R = − bR α aR α aL Y1L WR (13.21) WL These can be calculated either by a graphical method or analytical method of vectors (complex algebra). We know a b c d −1 = 1 d −b ∆ −c a where ∆ = (ad − cb) which gives WR = Y1Lα bL − Y1Rα aL α bRα aL − α aRα bL and WL = Y1Rα aR − Y1Lα bR α bRα aL − α aRα bL (13.22) A schematic and a picture of the overall experimental for dynamic balancing of rotor setup are shown in Figs. 13.18 and 13.19, respectively. Fig. 13.20 shows measurement of the phase of the vibration signal, y(t), with respect to the reference signal, r(t).