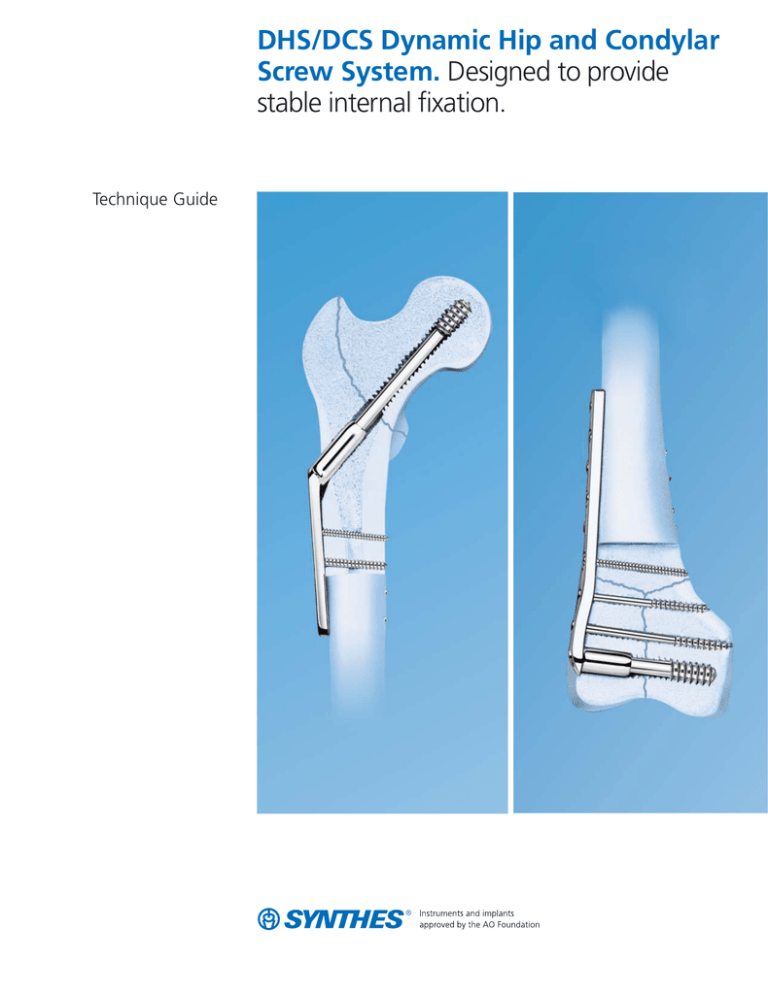

DHS/DCS Dynamic Hip and Condylar Screw System Technique Guide

advertisement

DHS/DCS Dynamic Hip and Condylar Screw System. Designed to provide stable internal fixation. Technique Guide Table of Contents Introduction Surgical Technique Special Techniques Product Information Dynamic Hip Screw (DHS) 2 Dynamic Condylar Screw (DCS) 3 Indications 4 DHS 5 DCS 14 Using the DHS / DCS One-Step Insertion Wrench 23 Using the DCS for Subtrochanteric Fractures 28 Assembling the Instrumentation 37 Reinserting the 2.5 mm Threaded Guide Wire 41 Implant Removal 42 Implants 43 Instruments 46 Set Lists 53 Image intensifier control Synthes Dynamic Hip Screw (DHS) The Dynamic Hip Screw is designed to provide strong and stable internal fixation of a variety of intertrochanteric, subtrochanteric and basilar neck fractures, with minimal soft tissue irritation. Strong The DHS plates are made of 316L stainless steel and are cold-worked for strength. Stable The number of screw holes per plate length is maximized, without compromising plate strength. This allows an increased number of fixation points with a smaller incision. DCP (dynamic compression plate) holes in the DHS side plate: – Allow angulation of 4.5 mm cortex screws, for lag screw fixation of medial fragments, and – Allow axial compression and multiple-screw fixation of the main fragment in subtrochanteric fractures with shaft extension Two flats within the DHS plate barrel correspond to the two-flat design of the DHS/DCS lag screw, preventing rotation of the lag screw within the barrel. The two-flat design also eases insertion of the plate over the DHS / DCS lag screw. Minimal soft tissue irritation The DHS plates have a low-profile design, reducing the risk of trochanteric bursitis. The DHS plates are available in a wide range of sizes and barrel angles, with standard or short barrels, for varied clinical situations. The DHS / DCS lag screw, available from 50 mm to 145 mm lengths, easily glides within the DHS plate barrel for controlled collapse and impaction of fragments. When the fracture requires additional intraoperative compression, the DHS / DCS compression screw can be used; only one size compression screw is needed. The DHS instruments provide direct measurements throughout the DHS procedure, allowing proper reaming, tapping and lag screw insertion depth. The built-in stop and locking nut on the DHS triple reamer prevent over-reaming. 2 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Dynamic Condylar Screw (DCS) The Dynamic Condylar Screw is designed to provide strong and stable internal fixation of certain distal femoral and subtrochanteric fractures, with minimal soft tissue irritation. Strong The DCS plates are made of 316L stainless steel and are cold-worked for strength. Stable The two holes closest to the barrel accept 6.5 mm cancellous bone screws. This enhances stability by allowing additional fixation of the most distal condylar fracture fragments or fixation of the most proximal subtrochanteric fracture fragments. DCP holes in the DCS side plate allow angulation of 4.5 mm cortex screws and axial compression across a shaft fracture. The number of screw holes per plate length is maximized, without compromising plate strength. This allows an increased number of fixation points with a smaller incision. Two flats within the DCS plate barrel correspond to the two-flat design of the lag screw, preventing rotation of the DHS / DCS lag screw within the barrel. The two-flat design also eases insertion of the plate over the DHS / DCS lag screw. Minimal soft tissue irritation The low-profile design reduces the risk of iliotibial band irritation (distal femoral fractures) and trochanteric bursitis (subtrochanteric fractures). The DCS plates are available with 6 to 16 holes, for varied clinical situations. The DHS / DCS lag screw is available in 50 mm to 145 mm lengths. The DHS / DCS compression screw can be used for additional compression; only one size compression screw is needed. The DCS instruments also provide direct measurements throughout the DCS procedure, allowing proper reaming, tapping, and lag screw insertion depth. The built-in stop and locking nut on the DCS triple reamer prevent over-reaming. Synthes 3 Indications DHS The DHS is indicated for the following fractures of the proximal femur: – Intertrochanteric fractures – Subtrochanteric fractures* – Basilar neck fractures The DHS is indicated for stable fractures, and unstable fractures in which a stable medial buttress can be reconstructed. The DHS provides controlled collapse and compression of fracture fragments. This results in stable fixation and prevents undue stress concentration on the implant. * For certain subtrochanteric fractures, a 95° device is the implant of choice (See “Using the DCS for Subtrochanteric Fractures,” page 28). DCS The DCS is indicated for the following fractures of the distal femur: – Intercondylar fractures** – Supracondylar fractures** – Unicondylar fractures** ** The following anatomic conditions should exist: – 4 cm of distal femur should remain intact to provide support for the implant. – A distal portion of the medial condyle should be intact for the DHS/DCS lag screw to gain good purchase. If these conditions do not exist, a Synthes 4.5 mm LCP condylar plate or LCP distal femur plate should be considered. The DCS is indicated for the following fractures of the proximal femur: – Transverse subtrochanteric fractures† – Short oblique subtrochanteric fractures† – Long oblique subtrochanteric fractures† † With the lesser trochanter avulsed or on the distal fragment (femoral shaft).1 1. Roy Sanders and P. Regazzoni. “Treatment of Subtrochanteric Femur Fractures Using the Dynamic Condylar Screw.” Journal of Orthopaedic Trauma, vol. 3, no. 3. New York: Raven Press, 1989. 206-213. 4 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Surgical Technique — DHS Plate selection Barrel length The standard 38 mm barrel length is most commonly indicated. The 25 mm short barrel is indicated for specific clinical situations, including: – Cases in which the standard barrel may not provide sufficient glide for the lag screw; i.e., a long impaction distance is expected – A medial displacement osteotomy – Unusually small femurs Barrel angle An evaluation of the angle subtended between the femoral neck and shaft axes (CCD, or collum-center-diaphysis, angle) of the uninjured femur will aid in the selection of the most appropriate barrel angle. The 135° barrel angle is most commonly indicated. Note: Greater barrel angles may produce biomechanical advantages in unstable cases; i.e., better gliding characteristics and reduced bending stresses on the plate / barrel junction, although correct placement of the implant becomes technically more difficult as barrel angles increase.2 38 mm barrel 25 mm barrel 2. P. Regazzoni, Th. Rüedi, R. Winquist, and M. Allgöwer. The Dynamic Hip Screw Implant System. Berlin: Springer-Verlag, 1985. 5. Synthes 5 Surgical Technique — DHS continued 1 Reduce fracture Instruments 338.01– 338.04 DHS Angle Guides 900.723 2.5 mm Threaded Guide Wire Reduce the fracture. Determine anteversion by placing a 2.5 mm threaded guide wire anteriorly along the femoral neck, using the appropriate DHS angle guide. Gently hammer the wire into the femoral head. This anteversion wire will later allow correct placement of the central guide wire in the center of the femoral head. 6 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 2 Insert guide wire Instruments 310.19 2.0 mm Drill Bit 338.01– 338.04 DHS Angle Guides 900.723 2.5 mm Threaded Guide Wire Align the appropriate DHS angle guide along the axis of the femoral shaft, and place it on the femur. Point the guide tube toward the center of the femoral head. Predrilling of the lateral cortex with the 2.0 mm drill bit is recommended in dense bone. Insert a 2.5 mm threaded guide wire through the appropriate DHS angle guide, parallel to the anteversion wire and directed toward the center of the femoral head. This point of introduction varies with barrel angle. When a 135° barrel angle is used, the guide wire enters the proximal femur approximately 2.5 cm distal to the vastus ridge. Notes: Because it is designed for use with the DHS / DCS instruments and implants, the 2.5 mm threaded guide wire, and not an alternative wire, must be used. This guide wire remains in place throughout the procedure. If it is inadvertently withdrawn, reinsert it immediately (see “Reinserting the 2.5 mm Threaded Guide Wire,” page 41). Synthes 7 Surgical Technique — DHS continued 3 Confirm placement Confirm placement of the 2.5 mm threaded guide wire under image intensification. It must lie along the axis of the femoral neck in both the AP and lateral views, and parallel to the anteversion wire. If its position is incorrect, insert a new guide wire. Remove and discard the anteversion wire. 4 Determine insertion depth Instrument 338.05 DHS / DCS Direct Measuring Device Slide the direct measuring device over the guide wire to determine guide wire insertion depth. Calibration on the measuring device provides a direct reading. 8 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 5 a. Calculate reaming depth and lag screw length To calculate reaming depth, tapping depth and lag screw length, subtract 10 mm from the reading. For example: a. Direct reading 105 mm b. Reamer setting 95 mm c. Tapping depth (optional) Lag screw length 95 mm 95 mm b. c. 6 Ream to predetermined depth Instruments 338.13 or 338.43* DHS Triple Reamer DHS Triple Reamer (for short barrel plates) 532.010* Small Battery Drive 532.015* Large Quick Coupling 532.032* Battery Casing 532.033* 14.4 V Battery Assemble the appropriate DHS triple reamer (for either the standard or short barrel DHS plate) (see “Assembling the Instrumentation,” page 37). Set the reamer to the correct depth. Insert the DHS triple reamer into the small battery drive using the large quick coupling attachment. Slide the reamer over the guide wire to simultaneously drill for the lag screw, ream for the plate barrel, and countersink for the plate / barrel junction to the preset depth. When reaming in dense bone, continuously irrigate the DHS triple reamer to prevent thermal necrosis. * Also available Synthes 9 Surgical Technique — DHS continued 7 Tap to predetermined depth (optional) Instruments 95 mm 338.08 DHS / DCS T-Handle 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short If necessary, tap to the predetermined depth using the tap assembly (see “Assembling the Instrumentation,” page 38). Tapping depth can be seen through the window in the short centering sleeve. 8 Insert lag screw Instruments 338.06 DHS / DCS Wrench 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw 338.21 DHS / DCS Guide Shaft Select the DHS / DCS lag screw and assemble the lag screw insertion assembly (see “Assembling the Instrumentation,” page 39). Slide the assembly over the guide wire and into the reamed hole. Seat the long centering sleeve in the hole to center and stabilize the assembly. Insert the lag screw by turning the handle clockwise, until the zero mark on the assembly aligns with the lateral cortex. The threaded tip of the lag screw now lies 10 mm from the joint surface. The lag screw may be inserted an additional 5 mm in porotic bone, for increased holding power and additional controlled collapse. Note: Keep continuous forward pressure on the DHS / DCS wrench while advancing the lag screw. 10 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 9 Align handle Before removing the assembly, align the handle so it is in the same plane as the femoral shaft (parallel to the femoral shaft axis when viewed laterally). This allows proper placement of the DHS plate onto the lag screw. 10 Remove wrench Instruments 532.010* Small Battery Drive 532.022* Quick Coupling for K-Wires Remove the DHS / DCS wrench and long centering sleeve. Slide the appropriate DHS plate onto the guide shaft/lag screw assembly until it contacts the lateral cortex. Loosen and remove the coupling screw and guide shaft. Use the small battery drive in reverse, with the quick coupling for K-wires, to withdraw the 2.5 mm threaded guide wire. * Also available Synthes 11 Surgical Technique — DHS continued 11 Seat plate Instrument 338.28 DHS / DCS Impactor Gently seat the plate with the DHS / DCS impactor. The vastus ridge may be chiseled to further seat the plate on bone. 12 Fix plate to femur Using AO standard screw insertion technique, fix the DHS plate to the femur with 4.5 mm cortex screws. 12 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 13 Insert compression screw (optional) Instrument 314.27 Large Hexagonal Screwdriver For further, intraoperative compression of the trochanteric fracture, the DHS / DCS compression screw may be inserted into the lag screw. The DHS / DCS compression screw may be used in unstable fractures to prevent disengagement of the lag screw from the plate barrel in non-weight-bearing patients. Note: Use of the compression screw may cause stripping of the lag screw thread in porotic bone. Synthes 13 Surgical Technique — DCS 1 Reduce fracture Instrument 900.723 2.5 mm Threaded Guide Wire Reduce the fracture. The fracture can be temporarily stabilized with 2.5 mm threaded guide wires or Steinmann pins. Place these wires so they do not interfere with subsequent positioning of the DCS implant assembly (see illustrations accompanying Step 3 for proper implant positioning). In intercondylar fractures, the wires should be replaced with independent 6.5 mm or 7.3 mm cannulated screws or 6.5 mm cancellous bone screws with washers. 2 Determine direction of central guide wire B 25º Instrument 292.20 2.0 mm Kirschner Wire To determine the direction of the central guide wire, flex the knee to 90°, and mark the axis of the knee joint by placing a K-wire distally over the condyles (A). Place a second K-wire anteriorly over the condyles (B). Note: Placement of the guide wire determines placement of the DCS implant assembly. Misplacement of the guide wire can result in varus/valgus or rotational malalignment of the fracture fragments. 14 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide B A 3 Insert central guide wire Instruments 338.41 DCS Drill Guide 900.723 2.5 mm Threaded Guide Wire Using the DCS drill guide, insert the central guide wire (C) parallel to the distal K-wire (A) in the AP view, and parallel to the anterior K-wire (B) in the axial view. Do not insert the guide wire too far medially; consider the inclination of the medial wall of the distal femur. In the sagittal plane, the central guide wire enters the distal femur at a point anterior to the midline between the condyles, and in line with the shaft axis, approximately 2 cm from the knee joint. AP view: C is parallel to A Axial view: C is parallel to B Confirm placement of the central guide wire under image intensification. If it is not parallel to the knee joint axis, insert a new 2.5 mm threaded guide wire. Notes: Because it is designed for use with the DHS / DCS instruments and implants, the 2.5 mm threaded guide wire, and not an alternative wire, must be used. This guide wire remains in place throughout the procedure. If it is inadvertently withdrawn, reinsert it immediately (see “Reinserting the 2.5 mm Threaded Guide Wire,” page 41). 2 cm 2/3 1/3 Synthes 15 Surgical Technique — DCS continued 4 Determine guide wire insertion depth Instrument 338.05 DHS / DCS Direct Measuring Device Slide the direct measuring device over the guide wire, and determine guide wire insertion depth. Calibration on the measuring device provides a direct reading. 80 mm 5 a. Calculate reaming depth and lag screw length To calculate reaming depth, tapping depth and lag screw length, subtract 10 mm from the reading. For example: a b c Direct reading Reamer setting Tapping depth (optional) Lag screw length 80 mm 70 mm 70 mm 70 mm c. If the compression screw will be used, allow for additional compression of the fracture by selecting a lag screw 5 mm shorter (in this case, 65 mm) and inserting it an additional 5 mm. 16 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide b. 6 Ream to predetermined depth Instruments 338.46* DCS Triple Reamer, complete (includes DCS Reaming Head (338.47), 8.0 mm Drill Bit (338.10) and Nut) 532.010* Small Battery Drive 532.015* Large Quick Coupling 532.032* Battery Casing 532.033* 14.4 V Battery Assemble the DCS triple reamer (see “Assembling the Instrumentation,” page 37). Set the reamer to the correct depth. Insert the DCS triple reamer into the small battery drive using the large quick coupling attachment. Slide the reamer over the guide wire to simultaneously drill for the lag screw, ream for the plate barrel, and countersink for the plate/barrel junction to the preset depth. When reaming in dense bone, continuously irrigate the DCS triple reamer to prevent thermal necrosis. 7 Tap to predetermined depth (optional) Instruments 338.08 DHS / DCS T-Handle 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short If necessary, use the tap assembly to tap to the predetermined depth, which can be seen through the window in the short centering sleeve (see “Assembling the Instrumentation,” page 38). * Also available Synthes 17 Surgical Technique — DCS continued 8 Assemble lag screw insertion assembly Instruments 338.06 DHS / DCS Wrench 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw 338.21 DHS / DCS Guide Shaft Select the correct length DHS / DCS lag screw and assemble the lag screw insertion assembly (see “Assembling the Instrumentation,” page 39). Slide the assembly over the guide wire and into the reamed hole. Seat the long centering sleeve in the hole to center and stabilize the assembly. Note: Keep continuous forward pressure on the DHS / DCS wrench while advancing the lag screw. 9 Insert lag screw Insert the lag screw by turning the handle clockwise until the 0 mark on the assembly aligns with the lateral cortex. The threaded tip of the lag screw now lies 10 mm from the medial cortex. The lag screw may be inserted an additional 5 mm in porotic bone, for increased holding power. Note: If a lag screw 5 mm shorter than reaming and tapping depth is used (in this case, 65 mm), insert it an additional 5 mm, until the 5 mark on the assembly aligns with the lateral cortex. 18 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 10 Align handle Before removing the assembly, align the handle so it is parallel with the femoral shaft axis when viewed laterally. This allows proper placement of the DCS plate onto the lag screw. 11 Remove wrench Instruments 532.010* Small Battery Drive 532.022* Quick Coupling for K-Wires Remove the DHS / DCS wrench and long centering sleeve. Slide the appropriate DCS plate onto the guide shaft / lag screw assembly. Loosen and remove the coupling screw and guide shaft. Use the small battery drive in reverse, with the quick coupling for K-wires, to withdraw the guide wire. * Also available Synthes 19 Surgical Technique — DCS continued 12 Seat plate Instrument 338.28 DHS / DCS Impactor Gently seat the plate with the DHS / DCS impactor. The lateral condylar cortex may be chiseled to further seat the plate on bone. 13 Compress distal fragments with compression screw Instrument 314.27 Large Hexagonal Screwdriver If the joint fragments were not previously reduced with independent 6.5 mm cancellous bone screws, the DHS / DCS compression screw may be inserted into the lag screw. In porotic bone, insert the screw very carefully to avoid stripping the lag screw thread. 20 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 14 Insert 6.5 mm cancellous screws Further interfragmentary compression can be achieved by using two 6.5 mm cancellous bone screws through the distal round holes of the DCS plate. 15 Compress to femoral shaft Instrument 321.12* Articulated Tension Device Once an approximate anatomic reduction is achieved, use the articulated tension device to produce final compression between the femoral shaft and distal fragments. To facilitate reduction of the diaphyseal fragment, particularly in cases of medial comminution with shortening, the tension device can also be used as a distractor. * Also available Synthes 21 Surgical Technique — DCS continued 16 Fix plate to femur Using AO standard screw insertion technique, fix the DCS plate to the femur with 4.5 mm cortex screws. 22 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Special Techniques — Using the DHS/DCS One-Step Insertion Wrench DHS/DCS One-Step Insertion Wrench Assembly Wrench 338.302 DHS Plate 281.xxx Coupling Screw 338.31 Centering Sleeve 338.32 DHS / DCS One Step Lag Screw 280.2xx 280.3xx 1 Insert guide wire Instruments 338.047 Variable Angle Guide for DHS 338.05 DHS / DCS Direct Measuring Device 900.723 2.5 mm Threaded Guide Wire Set the variable angle guide for DHS to the desired angle. Insert the tip of the 2.5 mm threaded guide wire to the subchondral bone in the femoral head. Use the DHS / DCS direct measuring device to determine the length of the guide wire. To determine reaming depth and lag screw length, subtract 10 mm from the reading. Synthes 23 Special Techniques — Using the DHS/DCS One-Step Insertion Wrench continued 2 Ream for lag screw and plate Instruments 338.13 or 338.43* DHS Triple Reamer DHS Triple Reamer (for short barrel plates) 338.17 DHS / DCS Tap 338.18 Centering Sleeve Ream the hole for the lag screw and plate over the correctly positioned guide wire. (See “Assembling the Instrumentation,” page 37.) Tap using the DHS / DCS tap with centering sleeve. (See “Assembling the Instrumentation,” page 38) *Also available 24 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 3 Assemble wrench Instruments 338.302 One-Step Insertion Wrench 338.31 Coupling Screw 338.32 Centering Sleeve Insert the coupling screw into the one-step insertion wrench and slide the DHS plate onto the shaft of the wrench. Select the appropriate length lag screw and place on the end of the wrench; the flats of the lag screw must be aligned with the flats on the wrench. Thread the coupling screw into the end of the lag screw. Synthes 25 Special Techniques — Using the DHS/DCS One-Step Insertion Wrench continued 3 Assemble wrench continued Place the centering sleeve onto the wrench between the lag screw and the plate. Slide the assembly over the 2.5 mm guide wire and into the reamed hole. 26 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 4 Insert lag screw Turn the wrench clockwise until the back of the lag screw is seated in the lateral cortex (as observed through the window on the centering sleeve). Align the wrench handle with the long axis of the femoral shaft. The tip will be 10 mm from the tip of the guide wire. To remove the centering sleeve from the wrench, twist the inner and outer sleeves in opposite directions. 10 mm 5 Insert plate Instrument 338.28 DHS / DCS Impactor Advance the side plate along the shaft of the wrench and manually insert the barrel into the reamed hole. Seat the plate with the DHS / DCS impactor. Make certain that the wrench shaft lies in the channel of the impactor. Affix the plate to the proximal femur with 4.5 mm cortex screws, using standard AO technique. Synthes 27 Special Techniques — Using the DCS for Subtrochanteric Fractures The design of the DCS plate can enhance fixation of selected, stable subtrochanteric fractures because it permits stable fixation in the proximal fragment.3 The DCS plate has a 95° barrel angle, allowing it to enter the femur more proximally than the DHS plate and allowing insertion of independent screws into the calcar. Further, its two round proximal plate holes permit insertion of 6.5 mm cancellous bone screws, for stable proximal fixation. Stable transverse and short oblique subtrochanteric fractures When using the DCS plate for these fractures, the plate can act as a tension band against normal medial compressive forces.4 Long oblique subtrochanteric fractures When using the 135° DHS plate to treat long oblique subtrochanteric fractures, use of the proximal plate screws can prohibit compression. With the 95° DCS plate, however, stable fixation can be achieved by lagging the fracture through the plate, since controlled collapse is not anticipated. Note: When used in the proximal femur, the DCS plate can only be used to treat stable fractures; i.e., fractures that can be directly reduced and anatomically reassembled to allow restoration of the bony medial buttress. Because the DCS plate has a 95° barrel angle, it does not allow for controlled collapse and compression. 3. Roy Sanders and P. Regazzoni. “Treatment of Subtrochanteric Femur Fractures Using the Dynamic Condylar Screw.” Journal of Orthopaedic Trauma, vol. 3, no. 3. New York: Raven Press, 1989. 211. 4. Ibid., 212. 28 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Preoperative considerations Plate selection Select the DCS plate so there are four screws (eight cortices) distal to the fracture in hard diaphyseal bone, or five screws (ten cortices) in porotic bone. Insertion of the 2.5 mm threaded guide wire Though the general insertion area of the guide wire is known, the precise insertion point varies with the CCD angle, the angle subtended between the femoral neck and shaft axes. Assessment of the CCD angle will allow subsequent placement of the lag screw in its optimal position — in the center of the femoral neck and in the inferior half of the femoral head (see illustration). This insertion point should be determined preoperatively with the aid of planning templates. Note: The insertion point of the guide wire will vary with CCD angle (angle subtended between the femoral neck and shaft axes), as depicted by the valgus femur in the figure (dotted lines). Example is exaggerated for clarity. Synthes 29 Special Techniques — Using the DCS for Subtrochanteric Fractures continued 1 Reduce fracture Instrument 900.723 2.5 mm Threaded Guide Wire Reduce the fracture. Determine anteversion by placing a 2.5 mm threaded guide wire anteriorly along the femoral neck, gently hammering it into the femoral head. This anteversion wire will ensure correct placement of the central guide wire. 2 Insert guide wire Instruments 310.19 2.0 mm Drill Bit 338.41 95º DCS Drill Guide 900.723 2.5 mm Threaded Guide Wire Place the 95º DCS drill guide along the axis of the femoral shaft so the central guide wire will enter the femur slightly anterior to the midpoint of the greater trochanter, near the vastus ridge. The precise level at which the guide wire enters the femur should be determined preoperatively (see “Preoperative considerations,” page 29). Insert the central guide wire parallel to the anteversion wire in the lateral view. Predrilling of the lateral cortex with the 2.0 mm drill bit is recommended in dense bone. Notes: Because it is designed for use with the DHS / DCS instruments and implants, the 2.5 mm threaded guide wire, and not an alternative wire, must be used. This guide wire remains in place throughout the procedure. If it is inadvertently withdrawn, reinsert it immediately (see “Reinserting the 2.5 mm Threaded Guide Wire,” page 41). 30 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 3 Confirm placement Confirm placement of the central guide wire under image intensification, in two views. In the AP view, the wire should lie in the center of the neck and in the inferior half of the femoral head. In the lateral view, it should lie in the middle of the femoral head. The tip of the guide wire should just engage the subchondral bone. If its position is incorrect, insert a new guide wire. Remove and discard the anteversion wire. 4 95 mm Determine insertion depth Instrument 338.05 DHS / DCS Direct Measuring Device Slide the direct measuring device over the guide wire to determine guide wire insertion depth. Calibration on the measuring device provides a direct reading. 5 Calculate reaming depth and lag screw length a. b. To calculate reaming depth, tapping depth and lag screw length, subtract 10 mm from the reading. For example: a. b. c. Direct reading Reamer setting Tapping depth (optional) Lag screw length 95 mm 85 mm 85 mm 85 mm c. Synthes 31 Special Techniques — Using the DCS for Subtrochanteric Fractures continued 6 Ream to predetermined depth Instruments 338.46* DCS Triple Reamer, complete (includes DCS Reaming Head (338.47), 8.0 mm Drill Bit (338.10) and Nut) 532.010* Small Battery Drive 532.015* Large Quick Coupling 532.032* Battery Casing 532.033* 14.4 V Battery Assemble the DCS triple reamer (see “Assembling the Instrumentation,” page 37). Set the reamer to the correct depth. Insert the DCS triple reamer into the small battery drive using the large quick coupling attachment. Slide the reamer over the guide wire to simultaneously drill for the lag screw, ream for the plate barrel, and countersink for the plate/barrel junction to the preset depth. When reaming in dense bone, continuously irrigate the DCS triple reamer to prevent thermal necrosis. 7 Tap to predetermined depth (optional) Instruments 338.08 DHS / DCS T-Handle 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short Secure the proximal fragment with a bone forceps to prevent rotation in the sagittal plane. If necessary, tap to the predetermined depth using the tap assembly (see “Assembling the Instrumentation,” page 38). Tapping depth can be seen through the window in the short centering sleeve. * Also available 32 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 85 mm 8 Insert lag screw Instruments 338.06 DHS / DCS Wrench 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw 338.21 DHS / DCS Guide Shaft Select the lag screw and assemble the lag screw insertion assembly (see “Assembling the Instrumentation,” page 39). Slide the assembly over the guide wire and into the reamed hole. Seat the centering sleeve in the hole to center and stabilize the assembly, and insert the lag screw by turning the handle clockwise until the 0 mark on the assembly aligns with the lateral cortex. The threaded tip of the lag screw now lies 10 mm from the medial cortex. The lag screw may be inserted an additional 5 mm in porotic bone, until the 5 mm mark aligns with the lateral cortex, for increased holding power. 9 Align handle Before removing the assembly, align the handle so it is in the same plane as the femoral shaft (parallel with the femoral shaft axis when viewed laterally). This allows correct placement of the DCS plate onto the lag screw. * Also available Synthes 33 Special Techniques — Using the DCS for Subtrochanteric Fractures continued 10 Remove wrench Remove the DHS / DCS wrench and long centering sleeve. Slide the appropriate DCS plate onto the guide shaft / lag screw assembly. 11 Seat plate Instruments 338.28 DHS / DCS Impactor 532.010* Small Battery Drive 532.022* Quick Coupling for K-Wires Loosen and remove the coupling screw and guide shaft. Use the small battery drive in reverse, with the quick coupling for K-wires, to withdraw the guide wire. Gently seat the plate with the DHS / DCS impactor. The vastus ridge can be chiseled to further seat the plate on bone. * Also available 34 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 12 Insert cancellous bone screws Instruments 310.31 3.2 mm Drill Bit, quick coupling 310.44 4.5 mm Drill Bit, quick coupling 312.48 4.5 mm / 3.2 mm Insert Drill Sleeve Insert two 6.5 mm cancellous bone screws through the proximal round holes of the DCS plate, using lag screw technique. To do so, drill a hole through the near cortex with the 4.5 mm drill bit. Fully seat the 4.5 mm / 3.2 mm insert drill sleeve into the hole. Drill through the sleeve and penetrate the far cortex with the 3.2 mm drill bit. Measure, tap and insert the 6.5 mm cancellous bone screw. This technique will prevent the drill bit from gliding along the calcar. 13 Insert compression screw Instrument 314.27 Large Hexagonal Screwdriver Insert the DHS / DCS compression screw into the lag screw. This will prevent disengagement of the lag screw from the plate barrel. Synthes 35 Special Techniques — Using the DCS for Subtrochanteric Fractures continued 14 Compress to femoral shaft Instrument 321.12* Articulated Tension Device Once an approximate anatomic reduction is achieved, the articulated tension device may be used to produce final compression of the fracture. Note: Do not use the tension device if extensive comminution exists. 15 Fix plate to femur Using AO standard screw insertion technique, fix the DCS plate to the femur with 4.5 mm cortex screws. * Also available 36 Synthes DHS/DCS Dynamic Hip and Condylar Screw System Special Techniques — Assembling the Instrumentation Triple reamer assembly Instruments 338.11 DHS Reaming Head, standard 338.13 DHS Triple Reamer, complete (includes 338.11) 338.44 DHS Reaming Head, short 338.47 DCS Reaming Head Caution: The components of the triple reamers are sharp and should be handled carefully. Note: The triple reamers can be assembled preoperatively. Reaming depth is set intraoperatively. 338.13 Select the reaming head that corresponds to the chosen plate (DHS or DCS) and barrel length (DHS standard or DHS short). Align the setscrew on the reaming head with the flat on the drill bit. Slide the cutting end of the reaming head over the coupling end of the drill bit. Setscrew Flat Hold the coupling end of the drill bit with one hand, and continue sliding the reaming head along the drill bit with the other hand. The proper setting is attained when the non-cutting end of the reaming head reaches the calculated depth setting. In this example, the depth setting is 95 mm (see inset). Synthes 37 Special Techniques — Assembling the Instrumentation continued Triple reamer assembly continued Secure the reaming head into the appropriate notch, and lock it in place with the locking nut. Tap assembly Instruments 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short Slide the short centering sleeve over the tap. Simultaneously push the quick coupling fitting on the T-handle and insert the tap into the fitting. 38 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Release the collar, and check to be sure the tap is securely seated in the handle. Lag screw insertion assembly Instruments 338.06 DHS / DCS Wrench 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw, short 338.21 DHS / DCS Guide Shaft Note: The lag screw insertion assembly must be assembled intraoperatively after the proper length lag screw is chosen. Insert the coupling screw into the DHS / DCS guide shaft. Synthes 39 Special Techniques — Assembling the Instrumentation continued Lag screw insertion assembly continued Screw the coupling screw into the end of the lag screw. The tabs of the guide shaft should seat into the slots of the lag screw. Slide the long centering sleeve over the wrench. Firmly insert the guide shaft / lag screw assembly into the wrench until it stops. 40 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Special Techniques — Reinserting the 2.5 mm Threaded Guide Wire If the guide wire is inadvertently withdrawn at any time during the procedure, reinsert it immediately. To reinsert guide wire if withdrawn upon removal of triple reamer Instruments 338.19 DHS / DCS Centering Sleeve, long 399.42* Hammer, 500 grams 900.723 2.5 mm Threaded Guide Wire Insert a lag screw backwards into the short centering sleeve. Place this assembly into the bone, and use it as a guide for reinsertion of the threaded guide wire. Cannulation in the DHS / DCS lag screw centers the threaded guide wire in the hole. Use a hammer to gently reseat the threaded guide wire. Caution: Do not continue the procedure without the threaded guide wire, as the risk of misdirecting the triple reamer, tap assembly, or DHS / DCS lag screw is too great. * Also available Synthes 41 Implant Removal Implant removal Instrument 338.06 DHS / DCS Wrench Remove the plate. Assemble the insertion wrench, using the long coupling screw. The long coupling screw allows the surgeon to exert traction while unscrewing the lag screw. Align the flats inside the wrench with the flats of the lag screw. Slide the wrench over the lag screw until it is well over the end of the screw. Pull on the wrench while turning it counterclockwise. Instrument options for removal System Will remove: DHS – Wrench (338.06) – Long Coupling Screw (338.22) DHS DHS DHS One-Step – Insertion Wrench (338.302) – Coupling Screw (338.31) DHHS – Solid Coupling Screw with internal threads (338.313) – Hammer Guide (03.010.059) – Side / Fixed Hammer, 400 grams (03.010.058) DHS One-Step DHS One-Step DHHS DHHS DHS One-Step DHS One-Step DHHS DHHS DHHS DHHS DHHS Note: If the DHHS solid coupling screw has external threads on the back-end, use the Inserter Extractor (356.49) and Slotted Hammer (332.20) for removal. 42 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Implants DHS Plates, standard barrel (38 mm barrel) ◊ Holes Shaft Length (mm) 130° 135° 2 46 281.021 281.102 3 62 281.031 281.131 4 78 281.040 281.140 5 94 281.050 281.150 6 110 281.060 281.160 8 142 281.081 281.180 10 174 281.010 281.100 12 206 281.012 281.110 14 238 281.014 281.130 16 270 — 281.170 18 302 — 281.190 20 333 — 281.020 Barrel Angle 140° 281.220 281.230 281.240 281.250 281.260 281.280 281.200 281.212 281.214 281.216 — — 145° 281.320 281.330 281.340 281.350 281.360 281.308 281.310 281.312 281.314 281.316 — — 150° 281.402 281.430 281.440 281.450 281.460 281.480 281.400 281.410 281.414 281.416 281.418 281.421 DHS Plates, short barrel (25 mm barrel)◊ Holes Shaft Length (mm) 130° 135° 2 46 281.502 281.520 3 62 281.503 281.530 4 78 281.504 281.540 5 94 281.505 281.550 6 110 281.506 281.560 Barrel Angle 140° 281.620 281.630 281.640 281.650 281.660 145° 281.720 281.730 281.740 281.750 281.760 150° 281.820 281.830 281.840 281.850 281.860 DCS Plates◊ Holes Shaft Length (mm) 6 114 8 146 10 178 12 210 14 242 16 274 18 306 20 338 22 370 Barrel Angle 95° 281.960 281.980 281.900 281.925 281.930 281.940 281.950 281.970 281.990 ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. Synthes 43 Implants continued DHS/DCS Lag Screws, 12.7 mm diameter thread◊ – Thread length: 22 mm – Shaft diameter: 8 mm – Pitch: 3.0 mm – Diameter of cannulation: 2.7 mm 280.501 280.550 280.600 280.650 280.700 280.750 280.800 280.850 280.900 280.950 Length (mm) 50 55 60 65 70 75 80 85 90 95 280.000 280.050 280.100 280.150 280.200 280.250 280.300 280.350 280.400 280.451 Length (mm) 100 105 110 115 120 125 130 135 140 145 DHS/DCS Lag Screws, 14.0 mm diameter thread ◊ – Thread length: 22 mm – Shaft diameter: 8 mm – Pitch: 3.0 mm – Diameter of cannulation: 2.7 mm Length (mm) Length (mm) 280.454 50 280.504 100 280.455 55 280.505 105 280.460 60 280.510 110 280.465 65 280.515 115 280.470 70 280.520 120 280.475 75 280.525 125 280.480 80 280.530 130 280.485 85 280.535 135 280.490 90 280.540 140 280.495 95 280.545 145 DHS/DCS Compression Screw ◊ 280.990 36 mm ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. 44 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide DHS/DCS One-Step Lag Screws, 12.7 mm dia. thread ◊ Length (mm) Length (mm) 280.251 50 280.301 100 280.255 55 280.305 105 280.260 60 280.310 110 280.265 65 280.315 115 280.270 70 280.320 120 280.275 75 280.325 125 280.280 80 280.330 130 280.285 85 280.335 135 280.290 90 280.340 140 280.295 95 280.345 145 DHS/DCS One-Step Lag Screws, 14.0 mm dia. thread Length (mm) Length (mm) 280.651S 50 280.701S 100 280.655S 55 280.705S 105 280.660◊ 60 280.710◊ 110 280.665S 65 280.715S 115 280.670◊ 70 280.720◊ 120 280.675S 75 280.725S 125 280.680◊ 80 280.730◊ 130 280.685S 85 280.735S 135 280.690◊ 90 280.740◊ 140 280.695S 95 280.745S 145 02.102.001* 281.869* 281.870* Universal Locking Trochanter Stabilization Plate, 131 mm Trochanter Stabilization Plate, 138 mm◊ Trochanter Stabilization Plate, 148 mm◊ 02.102.001 281.869 ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. * For trochanter stabilization plate techniques, please refer to the Universal Locking Trochanter Stabilization Plate and Trochanter Stabilization Plate for DHS Technique Guides Synthes 45 Instruments 292.20 2.0 mm Kirschner Wire, 150 mm, trocar point 310.19 2.0 mm Drill Bit, 100 mm, quick coupling 310.31 3.2 mm Drill Bit, 145 mm, quick coupling 310.44 4.5 mm Drill Bit, 145 mm, quick coupling 311.44 T-Handle, with quick coupling 311.46 Tap for 4.5 mm Cortex and 4.5 mm Shaft Screws 312.46 4.5 mm / 3.2 mm Double Drill Sleeve 46 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 312.48 4.5 mm / 3.2 mm Insert Drill Sleeve 314.11 Holding Sleeve 314.15 Large Hexagonal Screwdriver Shaft 314.27 Large Hexagonal Screwdriver 319.10 Depth Gauge, for large screws 319.97 Screw Forceps 322.43 4.5 mm DCP Hip Drill Guide Synthes 47 Instruments continued 338.01 – 338.04 DHS Angle Guides (135°, 140°, 145° and 150°) 338.05 DHS / DCS Direct Measuring Device 338.06 DHS / DCS Wrench 338.08 DHS / DCS T-Handle 338.11 DHS Reaming head 338.13 DHS Triple Reamer, complete (includes DHS Reaming Head, standard (338.11), 8.0 mm Drill Bit (338.10) and Nut) 338.17 Tap for DHS / DCS, 12.5 mm diameter 48 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide 338.18 DHS / DCS Centering Sleeve, short 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw, short 338.21 DHS / DCS Guide Shaft 338.22 DHS / DCS Coupling Screw, long 338.28 DHS / DCS Impactor 338.41 95° DCS Drill Guide Synthes 49 Instruments continued 338.44 DHS Reaming Head, short 338.47 DCS Reaming Head 900.723 2.5 mm Threaded Guide Wire, spade point, 230 mm 50 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide One-Step Instruments 338.047 Variable Angle Guide 338.25 Small Impactor Tip 338.302 DHS / DCS One-Step Insertion Wrench 338.31 DHS / DCS Coupling Screw 338.32 DHS / DCS Centering Sleeve for One-Step Insertion Wrench 338.730 4.5 mm / 3.2 mm Insert Drill Sleeve Synthes 51 One-Step Instruments continued 338.740 6.0 mm / 4.5 mm Drill Sleeve 338.750 DHS Parallel Drill Guide 52 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide DHS/DCS Basic Set, with self-tapping screws (105.831) and DHS/DCS Basic Set (105.31) Graphic Cases 304.250 DHS / DCS Basic Set with self-tapping screws Graphic Case (for set 105.831) 304.257 DHS / DCS Basic Set Graphic Case (for set 105.31) Instruments (in both sets) 292.20 2.0 mm Kirschner Wire, 150 mm, trocar point, 1 pkg. of 10 310.19 2.0 mm Drill Bit, quick coupling, 100 mm, 2 ea. 310.31 3.2 mm Drill Bit, quick coupling, 145 mm, 2 ea. 310.44 4.5 mm Drill Bit, quick coupling, 145 mm, 2 ea. 311.44 T-Handle, with quick coupling 311.46 Tap for 4.5 mm Cortex and 4.5 mm Shaft Screws, 2 ea. 312.46 4.5 mm /3.2 mm Double Drill Sleeve 312.48 4.5 mm /3.2 mm Insert Drill Sleeve 314.11 Holding Sleeve 314.15 Large Hexagonal Screwdriver Shaft 314.27 Large Hexagonal Screwdriver 319.10 Depth Gauge, for large screws 319.97 Screw Forceps 322.43 4.5 mm DCP Hip Drill Guide 338.01 135° DHS Angle Guide 338.02 140° DHS Angle Guide 338.03 145° DHS Angle Guide 338.04 150° DHS Angle Guide 338.05 DHS / DCS Direct Measuring Device 338.06 DHS / DCS Wrench 338.08 DHS / DCS T-Handle 338.13 DHS Triple Reamer, complete 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw, short 338.21 DHS / DCS Guide Shaft 338.22 DHS / DCS Coupling Screw, long 338.28 DHS / DCS Impactor Note: For additional information, please refer to package insert. 338.41 95° DCS Drill Guide For detailed cleaning and sterilization instructions, please refer to 338.44 DHS Reaming Head, short http://www.synthes.com/sites/NA/MedicalCommunity/Pages/Cleaning_and_Sterilization.aspx or to the below listed inserts which will be included in the shipping container: 338.47 DCS Reaming Head —Processing Synthes Reusable Medical Devices—Instruments, Instrument Trays and Graphic Cases—DJ1305 —Processing Non-sterile Synthes Implants—DJ1304 Synthes 53 DHS/DCS Basic Set, with self-tapping screws (105.831) and DHS/DCS Basic Set (105.31) continued Instruments (in both sets) continued 900.723 2.5 mm Threaded Guide Wire, spade point, 230 mm, 10 ea. 900.723LBL Graphic Case Labels for 2.5 mm Threaded Guide Wire (900.723) Implants in set 105.831 4.5 mm Cortex Screws, self-tapping Length (mm) Qty. 214.828 28 3 214.830 30 3 214.832 32 8 214.834 34 8 214.836 36 8 214.838 38 8 214.840 40 10 214.842 42 8 214.844 44 6 214.846 46 6 214.848 48 3 214.850 50 3 214.852 52 3 214.854 54 3 Implants in set 105.31 4.5 mm Cortex Screws Length (mm) 214.028 28 214.030 30 214.032 32 214.034 34 214.036 36 214.038 38 214.040 40 214.042 42 214.044 44 214.046 46 214.048 48 214.050 50 214.052 52 214.054 54 54 Qty. 3 3 8 8 8 8 10 8 6 6 3 3 3 3 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide DHS Basic Set, with self-tapping screws (105.837) and DHS Basic Set (105.37) Graphic Cases 304.250 DHS / DCS Basic Set with self-tapping screws Graphic Case (for set 105.837) 304.257 DHS / DCS Basic Set Graphic Case (for set 105.37) Instruments (in both sets) 310.19 2.0 mm Drill Bit, quick coupling, 100 mm, 2 ea. 310.31 3.2 mm Drill Bit, quick coupling, 145 mm, 2 ea. 310.44 4.5 mm Drill Bit, quick coupling, 145 mm, 2 ea. 311.44 T-Handle, with quick coupling 311.46 Tap for 4.5 mm Cortex and 4.5 mm Shaft Screws, 2 ea. 312.46 4.5 mm / 3.2 mm Double Drill Sleeve 312.48 4.5 mm / 3.2 mm Insert Drill Sleeve 314.11 Holding Sleeve 314.15 Large Hexagonal Screwdriver Shaft 314.27 Large Hexagonal Screwdriver 319.10 Depth Gauge, for large screws 319.97 Screw Forceps 322.43 4.5 mm DCP Hip Drill Guide 338.01 135° DHS Angle Guide 338.02 140° DHS Angle Guide 338.03 145° DHS Angle Guide 338.04 150° DHS Angle Guide 338.05 DHS / DCS Direct Measuring Device 338.06 DHS / DCS Wrench 338.08 DHS / DCS T-Handle 338.13 DHS Triple Reamer, complete 338.17 Tap for DHS / DCS, 12.5 mm diameter 338.18 DHS / DCS Centering Sleeve, short 338.19 DHS / DCS Centering Sleeve, long 338.20 DHS / DCS Coupling Screw, short 338.21 DHS / DCS Guide Shaft 338.22 DHS / DCS Coupling Screw, long 338.28 DHS / DCS Impactor 338.44 DHS Reaming Head, short 900.723 2.5 mm Threaded Guide Wire, spade point, 230 mm, 10 ea. 900.723LBL Graphic Case Labels for 2.5 mm Threaded Guide Wire (900.723) Note: For additional information, please refer to package insert. Synthes 55 DHS Basic Set, with self-tapping screws (105.837) and DHS Basic Set (105.37) continued Implants in set 105.837 4.5 mm Cortex Screws, self-tapping Length (mm) Qty. 214.828 28 3 214.830 30 3 214.832 32 8 214.834 34 8 214.836 36 8 214.838 38 8 214.840 40 10 214.842 42 8 214.844 44 6 214.846 46 6 214.848 48 3 214.850 50 3 214.852 52 3 214.854 54 3 Implants in set 105.37 4.5 mm Cortex Screws Length (mm) 214.028 28 214.030 30 214.032 32 214.034 34 214.036 36 214.038 38 214.040 40 214.042 42 214.044 44 214.046 46 214.048 48 214.050 50 214.052 52 214.054 54 56 Qty. 3 3 8 8 8 8 10 8 6 6 3 3 3 3 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide DHS Universal Implant Set (105.35) Graphic Case 305.36 DHS Universal Implant Set Graphic Case Implants DHS / DCS Lag Screws, 12.7 mm diameter thread ◊ Length (mm) Length (mm) 280.000 100 280.451 145 280.050 105 280.650 65 280.100 110 280.700 70 280.150 115 280.750 75 280.200 120 280.800 80 280.250 125 280.850 85 280.300 130 280.900 90 280.350 135 280.950 95 280.400 140 DHS / DCS Compression Screw, 3 ea.◊ Length (mm) 280.990 36 DHS Plates, standard barrel (38 mm) ◊ Angle Holes Length (mm) 281.140 135° 4 78 281.150 135° 5 94 281.160 135° 6 110 281.240 140° 4 78 281.250 140° 5 94 281.260 140° 6 110 281.340 145° 4 78 281.350 145° 5 94 281.360 145° 6 110 281.440 150° 4 78 281.450 150° 5 94 281.460 150° 6 110 DHS Plates, short barrel (25 mm) ◊ Angle Holes 281.540 135° 4 281.840 150° 4 Length (mm) 78 78 ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. Note: For additional information, please refer to package insert. Synthes 57 DCS Universal Implant Set (105.32) Graphic Case 304.270 DCS Implant Set Graphic Case Implants DHS / DCS Lag Screws, 12.7 mm diameter thread ◊, 2 ea. Length (mm) 280.501 50 280.550 55 280.600 60 280.650 65 280.700 70 280.750 75 DHS / DCS Compression Screws ◊, 6 ea. Length (mm) 280.990 36 95° DCS Plates ◊ 281.900 281.925 281.930 281.940 281.960 281.980 Holes 10 12 14 16 6 8 Length (mm) 178 210 242 274 114 146 Qty. 2 1 1 1 2 2 ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. Note: For additional information, please refer to package insert. 58 Synthes DHS/DCS Dynamic Hip and Condylar Screw System DHS One-Step Basic Set (105.839) and DHS/DCS One-Step Basic Set (105.833) DHS One-Step Basic Set (105.839) Graphic Case 690.348 DHS / DCS One-Step Basic Set Graphic Case Instruments 292.20 2.0 mm Kirschner Wire, 150 mm, trocar point, (10 / pkg.),1 pkg. 310.31 3.2 mm Drill Bit, quick coupling, 145 mm, 2 ea. 310.44 4.5 mm Drill Bit, quick coupling, 145 mm, 2 ea. 311.44 T-Handle with quick coupling 311.46 Tap for 4.5 mm Cortex and 4.5 mm Shaft Screws, 130 mm, 57 mm tap depth, 2 ea. 312.46 4.5 mm / 3.2 mm Double Drill Sleeve 314.11 Holding Sleeve 314.15 Large Hexagonal Screwdriver Shaft 314.27 Large Hexagonal Screwdriver 319.10 Depth Gauge for large screws 319.97 Screw Forceps 322.43 4.5 mm DCP Hip Drill Guide, neutral and load, 60 mm 338.047 Variable Angle Guide for DHS 338.05 DHS / DCS Direct Measuring Device, 200 mm length 338.08 DHS / DCS T-Handle, with quick coupling 338.13 DHS Triple Reamer, complete 338.17 Tap for DHS / DCS, 12.5 mm diameter, 220 mm 338.18 DHS / DCS Centering Sleeve, short 338.25 Small Impactor Tip 338.28 DHS / DCS Impactor 338.302 DHS / DCS One-Step Insertion Wrench 338.31 DHS / DCS Coupling Screw (for One-Step Insertion Wrench) 338.32 DHS / DCS Centering Sleeve (for One-Step Insertion Wrench) 338.44 DHS Reaming Head, for DHS Triple Reamer (for short barrel plates) 338.730 4.5 mm / 3.2 mm Insert Drill Sleeve 338.740 6.0 mm / 4.5 mm Drill Sleeve 338.750 DHS Parallel Drill Guide 900.723 2.5 mm Threaded Guide Wire, 230 mm, 10 ea. Note: For additional information, please refer to package insert. Synthes 59 DHS One-Step Basic Set (105.839) and DHS/DCS One-Step Basic Set (105.833) continued DHS One-Step Basic Set (105.839) continued Implants 4.5 mm Cortex Screws, self-tapping: Length (mm) Qty. 214.828 28 3 214.830 30 3 214.832 32 8 214.834 34 8 214.836 36 8 214.838 38 8 214.840 40 10 214.842 42 8 214.844 44 6 214.846 46 6 214.848 48 3 214.850 50 3 214.852 52 3 214.854 54 3 DHS/DCS One-Step Basic Set (105.833) Includes all components of DHS One-Step Basic Set (105.839), plus: 338.41 95° DCS Drill Guide 338.47 DCS Reaming Head 60 Synthes DHS/DCS Dynamic Hip and Condylar Screw System DHS One-Step Implant Set (105.352) Graphic Case 690.344 DHS One-Step Implant Set Graphic Case Implants DHS / DCS One-Step Lag Screws, 12.7 mm thread Length (mm) Length (mm) 280.265 65 280.301 100 280.270 70 280.305 105 280.275 75 280.310 110 280.280 80 280.315 115 280.285 85 280.320 120 280.290 90 280.325 125 280.295 95 130° DHS Plates, standard barrel Holes 281.040 4 281.050 5 281.060 6 135° DHS Plates, standard barrel Holes 281.140 4 281.150 5 281.160 6 140° DHS Plates, standard barrel Holes 281.240 4 281.250 5 281.260 6 145° DHS Plates, standard barrel Holes 281.340 4 holes 281.350 5 holes 281.360 6 holes 280.990 281.440 281.540 281.869 281.870 DHS / DCS Compression Screw, 36 mm, 3 ea. 150° DHS Plate, standard barrel, 4 holes 135° DHS Plate, short barrel, 4 holes Trochanter Stabilization Plate, 138 mm, 2 ea. Trochanter Stabilization Plate, 148 mm, 2 ea. Note: For additional information, please refer to package insert. Synthes 61 DCS One-Step Implant Set (105.321) Graphic Case 304.295 DCS One-Step Universal Implant Set Graphic Case Implants DHS / DCS One-Step Lag Screws, 12.7 mm thread, 2 ea. Length (mm) 280.251 50 280.255 55 280.260 60 280.265 65 280.270 70 280.275 75 280.990 DHS / DCS Compression Screw, 36 mm, 6 ea. 95° DCS Plates 281.960 281.980 281.900 281.925 281.930 281.940 Holes 6 8 10 12 14 16 Qty. 2 2 2 1 1 1 Note: For additional information, please refer to package insert. 62 Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Also Available Sets 01.102.001 105.12 105.35S 105.352S 105.355 105.812 105.831J and 105.31J 105.837J and 105.37J 105.839J 105.954 Universal Locking Trochanter Stabilization Plate Set DHS / DCS Basic Screw Rack with screws (not self-tapping) DHS Universal Implant Set, sterile (without graphic case) DHS One-Step Implant Set, sterile, without graphic case DHS Supplemental Implant Set DHS / DCS Basic Screw Rack with self-tapping screws DHS / DCS Basic Set with self-tapping screws DHS / DCS Basic Set (with standard drill bits 310.20, 310.32 and 310.45 to fit Jacobs chuck) DHS Basic Set with self-tapping screws DHS Basic Set (with standard drill bits 310.20, 310.32 and 310.45 to fit Jacobs chuck) DHS One-Step Basic Set with self-tapping screws (with standard drill bits 310.32 and 310.45 to fit Jacobs chuck) Small Battery Drive with 14.4 V Battery Pack Set Implants 02.102.001 Universal Locking Trochanter Stabilization Plate, 131 mm DHS / DCS Lag Screws, 14.0 mm diameter thread ◊ Length (mm) Length (mm) 280.454 50 280.504 100 280.455 55 280.505 105 280.460 60 280.510 110 280.465 65 280.515 115 280.470 70 280.520 120 280.475 75 280.525 125 280.480 80 280.530 130 280.485 85 280.535 135 280.490 90 280.540 140 280.495 95 280.545 145 ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. Synthes 63 Also Available continued Implants continued DHS / DCS One-Step Lag Screws, 12.7 mm dia. thread Length (mm) 280.330 130 280.335 135 280.340 140 280.345 145 DHS / DCS One-Step Lag Screws, 14.0 mm dia. thread Length (mm) Length (mm) 280.651S 50 280.701S 100 280.655S 55 280.705S 105 ◊ ◊ 280.660 60 280.710 110 280.665S 65 280.715S 115 280.670◊ 70 280.720◊ 120 280.675S 75 280.725S 125 280.680◊ 80 280.730◊ 130 280.685S 85 280.735S 135 280.690◊ 90 280.740◊ 140 280.695S 95 280.745S 145 Instruments 310.20 321.12 338.005 338.43 338.720 338.731 399.42 532.010 532.013 532.015 532.022 532.032 532.033 Graphic Case 690.371 DHS Supplemental Implant Set Graphic Case ◊ Available nonsterile and sterile-packed. Add “S” to catalog number to order sterile product. 64 2.0 mm Drill Bit, 85 mm, Jacobs chuck Articulated Tension Device 130° DHS Angle Guide DHS Triple Reamer, complete (for short barrel plates) 4.5 mm / 2.0 mm Insert Wire Sleeve (for Parallel Drill Guide) 4.5 mm / 2.8 mm Insert Wire Sleeve (for Parallel Drill Guide) Hammer, 500 grams Small Battery Drive Quick Coupling for Drill Bits Large Quick Coupling Quick Coupling for K-Wires Battery Casing for 14.4 V Battery 14.4 V Battery Synthes DHS / DCS Dynamic Hip and Condylar Screw System Technique Guide Synthes (USA) 1302 Wrights Lane East West Chester, PA 19380 Telephone: (610) 719-5000 To order: (800) 523-0322 Fax: (610) 251-9056 © 1990 Synthes, Inc. or its affiliates. All rights reserved. Synthes (Canada) Ltd. 2566 Meadowpine Boulevard Mississauga, Ontario L5N 6P9 Telephone: (905) 567-0440 To order: (800) 668-1119 Fax: (905) 567-3185 DCS, DCP, DHS, LCP and Synthes are trademarks of Synthes, Inc. or its affiliates. www.synthes.com Printed in U.S.A. 3/12 J3045-G