Heavy Duty Alternator Charging System Troubleshooting

advertisement

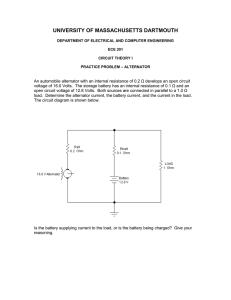

Heavy Duty Alternator Charging System Troubleshooting Alternator Charging System Troubleshooting Squealing noises under the hood? Headlight bulbs blow out repeatedly or dim? Is the dash voltmeter gauge out of range - either too high or too low? These are common indicators that something may be wrong with the charging system. If any of these symptoms are evident, then follow these five steps to pinpoint the issue. Helpful Hint: If you find something wrong at any step, it’s wise to complete the remaining steps anyway to ensure you’ve given the charging system a thorough review. Visit http://tinyurl.com/delcoremyvideos to watch our Tech Tip videos Technical Assistance 800-372-0222 1 2 3 4 5 Perform Visual Inspection Inspect Battery Battery Voltage Test Battery Load Test Measure Voltage at Battery Test Alternator Output Troubleshoot per Service Manual Troubleshooting Complete 1 Perform Visual Inspection Perform a visual inspection under the hood Look at the belt tension and condition. Next, check electrical connections and cables for corrosion and proper tightness. Finally, make sure the alternator is mounted properly. Belt Tension and Condition OK? No Perform Repairs Yes Electrical Connections OK? No Perform Repairs Yes Alternator Mounted OK? No Perform Repairs Yes Visual Inspections Complete Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video 2.A Inspect Batteries Visually inspect and test the batteries Inspect the batteries for any signs of physical damage, cracks in the casing, loose terminals or leaking fluid. Clean, repair connection and replace any damaged batteries found. Ensure that all batteries used in the same circuit are of the same manufacturer, CCA rating type and age. Then test the batteries using a standard battery test. Remember that realistic testing, as well as successful operation, requires a fully charged battery, capable of supplying the starting system’s current needs. Corrosion or Loose Connections? Yes Perform Repairs No Battery Damaged? No Perform Battery Voltage Test Visual Inspection Complete Technical Assistance 800-372-0222 Yes Replace Battery 2.B Battery Voltage Test Test the batteries using a standard battery test. Remember that realistic testing, as well as successful operation, requires a fully charged battery, capable of supplying the starting system’s current needs. 12.4 DC AMP DC VOLTS Connect Voltmeter to Battery With Engine Off, Remove Surface Charge and Wait Two Minutes Measure Voltage Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video < 12.4 Volts Recharge Battery ≥ 12.4 Volts Perform Battery Load Test Battery Voltage Test Complete Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video 2.C Battery Load Test Connect Carbon Pile and Voltmeter to Battery 12.5 Adjust Carbon Pile to One-half the Cold Cranking Amp Rating for 15 Seconds Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video Record Lowest Voltage < Minimum Loaded Voltage ≥ Minimum Loaded Voltage Battery Passes Battery Load Test Complete Technical Assistance 800-372-0222 Replace Battery 3.A Measure Voltage at Battery Fig 1. With the engine running, use a voltmeter to measure voltage at the battery. If voltage is greater than or equal to 13.8 volts, you can move on to Step 4. 12.4 DC AMP DC VOLTS Fig 1 Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video Fig 2. However, if it is less than 13.8 volts, then you should measure voltage at Alternator B+ and the alternator case. (Note: If the model is insulated, you have to use a ground stud to get a reading.) 13.0 DC AMP DC VOLTS At that point, if the voltage falls between 12.6 and 13.7 volts, you need to replace your alternator. If it’s greater than or equal to 13.8 volts, a voltage drop test needs to be performed. Learn how to perform a voltage drop test by visiting our YouTube page and watching our Tech Tip - Voltage Drop Test video. Link: tinyurl.com/delcoremyvideos. Fig 2 Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video 3.B Measure Voltage at Battery Connect Voltmeter to Battery Turn Engine On Measure Battery Voltage < 13.8 Volts Connect Voltmeter to Alternator B+ and Ground Post ≥ 13.8 Volts Measure Voltage ≥ 13.8 Volts Perform Voltage Drop Test Voltage at Battery Measured Technical Assistance 800-372-0222 12.6 to 13.7 Volts Replace Alternator 4 Test Alternator Output You can use either an automated tester or a manual process to determine the output of the alternator. If the alternator doesn’t pass this test, then it needs to be replaced. Connect Carbon Pile, Ammeter and Amp Clamp Engine Running at Governor Speed and Electrical Loads Off Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video Load Carbon Pile until Ammeter Reads Highest Value Record Output < 90% of Rated Capacity Replace Alternator ≥ 90% of Rated Capacity Alternator Output Test Complete Visit http://tinyurl.com/delcoremyvideos to watch the Alternator Charging System Tech Tip video 5 Troubleshoot Using the Service Manual If you’ve passed through the first four steps, then the alternator is working as designed and your problem is likely caused by something external to the alternator. 1 2 3 4 5 Perform Visual Inspection Inspect Battery Battery Voltage Test Battery Load Test Measure Voltage at Battery Test Alternator Output Troubleshoot per Service Manual Troubleshooting Complete Remy International, Inc. 600 Corporation Drive Pendleton, IN 46064 USA For Technical Assistance call 1-800-372-0222 Technical Assistance 800-372-0222 delcoremy.com Delco Remy is a registered trademark of General Motors Corporation, icensed to Remy Inc., Pendleton, IN 46064 ©2013 Remy International, Inc.