How New Transformer Energy Efficiency Levels Benefit You

advertisement

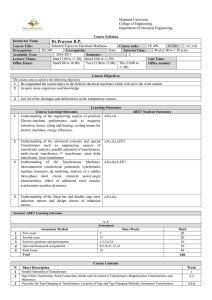

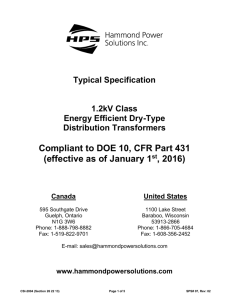

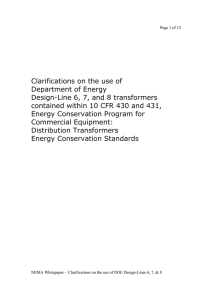

How The New DOE Transformer Energy Efficiency Levels Will Benefit You Here’s what you need to know about the new energy efficiency levels for transformers the U.S. Department of Energy will require starting January 1, 2016. By Les Heidrich, Marketing Product Manager, Hammond Power Solutions In the past decades, greenhouse gas (GHG) emissions and their effects on our planet have become the focus of many governments, agencies, companies and individuals. Energy generation is a major contributor to GHG emissions. In addition to widespread efforts to make energy generation more environmentally friendly, lowering energy consumption within most industrial and commercial facilities also is a goal. As a result, achieving increased energy efficiency levels for electrical equipment, including transformers, has become a priority for many industry participants. Improving the energy efficiency of new transformers is a primary objective of the U.S. Department of Energy (DOE), which has the legal authority to define minimum efficiency levels and enforce compliance. In April 2013, the DOE amended the current energy efficiency standards, also known as TP1, for distribution transformers. The new, more stringent standard, known as DOE 10 CFR p431, will come into effect on January 1, 2016. The improved efficiency levels affect both dry-type and liquid insulated transformers. Benefits of Higher Efficiency in Transformers According to the DOE, the new efficiency levels are expected to reduce energy losses by an average of 18% in low-voltage dry-type distribution transformers and by 13% in medium-voltage dry-type transformers, compared to the current TP1 efficiency levels (www1.eere.energy.gov). The environmental impact and savings for consumers resulting from the DOE changes are positive and significant. The DOE estimates that higher energy efficiency levels will result in an estimated $12.9 billion in total costs savings for consumers and 3.63 quadrillion BTU of energy savings over a 30-year period. As a result, about 265 million metric tons of CO2 emissions will be avoided, equivalent to the annual GHG emissions of about 52 million automobiles. What you Need to Know Energy efficiency for transformers raises two main considerations: 1. Under normal operation, a transformer is always on (typically at 35% average loading), making any energy efficiency improvements more significant over an extended period of time. This means users will be rewarded in two ways: reduced GHGs and an economic payback through reduced energy costs. Considering the life expectancy of a transformer and that the transformer will be on 24/7 for the next 25 to 30 years, even small energy-efficiency improvements will pay dividends for decades. More efficient transformers also generate less heat; in many cases this translates into lower costs to cool the environment in which they are used. 2. Currently mandated energy-efficiency levels already are reaching as high as the 98 to 99% mark, depending on the type of transformer and its kVA rating. This means any further efficiency improvements become more challenging to achieve, typically requiring more — and/or better — core and conductor materials. As a result, the efficiency increase will directly impact the cost of the transformer in most cases. However, as noted previously, the economic benefits offset the higher initial transformer costs. The DOE 2016-compliant transformers also will be somewhat heavier than the current TP1- efficiency-level transformers. What are the Effects of this Change? New transformers will be 30 to 35% more efficient than current TP1 levels. As stated, more efficient designs will cost more. Specifications must be updated. Long lead-time projects might require updated specifications to the DOE 2016 levels in the second half of 2015. It’s estimated that most transformer manufacturers will begin production of DOE 2016 products in the last quarter of 2015, but limited inventory may be available sooner. Depending on market demand, TP1 product inventory may deplete earlier than expected — in later 2015 or very early in 2016. Therefore, customers might be required to adopt the DOE 2016-compliant products earlier than planned. Modern electrical loads produce more harmonics and heat in transformers, lowering their efficiency and operating life. To prevent this, the use of K-rated or harmonic mitigating transformers is recommended. These product designswill also be affected by DOE 2016. When updating your specifications, consider requiring a K4 rating as the minimum K factor for this type of application. How Much Will You Save? Today, for applications that require energy efficiency higher than the currently DOE-regulated TP1 levels, the industry is using Premium Efficiency transformers defined by the NEMA Premium Efficiency Guidelines that stipulate approximately 30% lower losses than the TP1 levels. NEMA Premium products are optional within the market today — not everyone takes advantage of their benefits. DOE 2016 energy efficiency levels are equal to or slightly higher than NEMA Premium. Let’s look at the environmental benefits and electricity savings resulting from upgrading a 3-phase 75 kVA transformer to a DOE 2016 transformer (compared to a TP1-rated transformer): • 1.19 metric tons of CO2. • 121 gallons of gasoline. • Planting 28 trees. • Recycling 0.34 metric tons of waste. • Savings of $166 per year at $0.12 per kW-hr (see Table). Upgrading a 75 kVA transformer nearing its end of life with a DOE 2016 transformer can save more than $23,000 over its 30-year lifetime at $0.12/kW-hr (see table). The change in transformer efficiency levels mandated by DOE beginning January 1, 2016, applies to any distribution transformer intended to be connected to the U.S. power grid. As a result, the benefits of premium efficiency will apply to most power distribution applications that are connected to the power system in United States.