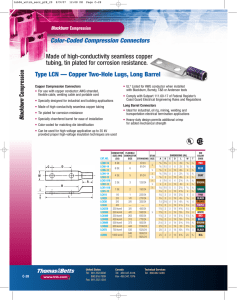

Compression Connectors

advertisement