Performance Criteria of Systems to Reduce Fire Damage by

advertisement

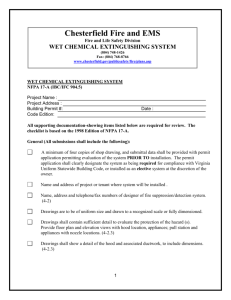

Suppression and Detection Research and Applications - A Technical Working Conference (SUPDET 2008) March 11-13, 2008 Orlando, FL Performance Criteria of Systems to Reduce Fire Damage by Prevention or Suppression Ragnar Wighus, SINTEF NBL as Geir Jensen, COWI AS Performance requirements and approval criteria of fire extinguishing, suppressing and inerting systems are typically based on the benchmark merits of each system category at the time they were introduced, often many decades ago. This conventional way of rating systems has served well for use with prescriptive codes. Performance based code regimes however, require an alternative approach in order to allow optimisation of fire safety designs for actual structures or vital operations. At one end of the scale sprinkler systems are required to control or suppress fire so that it does not exceed the heat release rate at the time of system activation - which may be several megawatts of power or flame heights up to two thirds of the ceiling height. Some are rated as flashover prevention systems. Completely different is a requirement of clean agents to fully extinguish visible flames within a time frame and to prevent re-ignition. In between are systems that prevent rekindling and some that prevent spread by prewetting surroundings. Some new water based systems do not act on the fire itself but close in on it by creating a barrier of water mist around the protected object, while new fire prevention systems prevent or retard combustion. Smoke emissions by non-oxidizing smouldering, overheating or friction are stopped by mitigating actions triggered by early detection. Water mist systems are introduced as an alternative to traditional sprinkler and deluge systems. These systems use less water to obtain a protection, in most cases performing equivalent to or better than the systems they replace. Water mist systems are also used as a replacement of gas systems (Halon replacement). The water mist systems are to be tested in a test setup similar to its application, and some of the existing standards have quantitative measures of the performance of the system. Current performance ratings and code requirements are summarized and their applicability questioned from a fire safety engineering point of view. The possibility is addressed that listing agencies and testing laboratories may in the future, or even in the near term, provide diverse test results that can be applied in performance based fire safety design. The principle of application specific test protocols, as established for water based systems both in US and in Europe, is discussed as a model for gas extinguishing, inerting and fire prevention systems as well. The state of the art of modelling of various systems in order to simulate performance and the potential for use with fire safety engineering is considered. Practical demands emerging from applied performance based engineering design are given. A proposal is given on how code makers, fire engineers and standardization bodies may address performance criteria of systems to reduce fire damage by prevention, suppression, extinguishing and extinction. Introduction Current performance criteria for measures to mitigate ignition and fire development is to be found in the applicable test standards for each kind of system. The criteria are plentiful, extremely varied and set to fit the merits of the respective system at the time standards were made, rather than fit practical demands. Fire safety engineers applying performance based codes ideally ask for mitigating performances that comply with those of their engineered design, which might be “reliability of 85 % to prevent fires attaining more than HRR 100 kW” or “reliability of 90 % to prevent any flame combustion” or “reliability of 90 % to at least control fire at HRR no more than 0,8 MW” or “reliability of 90 % to prevent flashover for minimum 60 min” etc. However, engineers are left to typically choose sprinklers, clean gas extinguishing systems, water mist extinguishing systems, aerosol extinguishing generators23 or inerting systems. The variations of performance criteria of such options literally range from deterministically no flaming for inerting systems and up to a steady HRR at several MWs by sprinklers until intervention by firemen. Harrison2 describes live ad hoc tests to verify performance of extinguishing system alternatives for automated mass storage rooms. Application tests are typically expensive but necessary when standard laboratory tests are insufficient to determine suitability. The article concludes that permanent oxygen reduced air, is the ultimate solution. While such systems have been applied for years there is hardly no more than proprietary guidelines and provisional insurance company guidelines to specify performance. A recent improvement beyond oxygen reduced air, termed hypoxic air venting, HAV – a novel and safe way to suppress fire ignition and combusiton11,13 – lacks standard performance criteria as well. HAV allow staff to occupy protected rooms for many hours, as the human breathing mechanism is subjected to the same atmosphere aircraft personnel and inhabitants of high elevation cities at 2400-2800 m. Thus, contrary to inert gases or extinguishing gases which allow 5 min maximum occupation only, at some risk. HAV systems do not require ‘extinguishing’ performance tests as they prevent fire ignition. Incipient smouldering is taken care of by early detection and intervention as with any type of extinguishing system. Despite this, hypoxic air was once questioned for not fully extinguishing smouldering fires or allowing slow rekindling or regrowth of fires3,9. This may at first appear as inferior to clean gas extinguishing performance, but the latter incur initial smoke and heat damages prior to activation of the extinguishing system, and the protected area is unoccupiable as evacuation is required within 120 s. HAV prevention systems are clearly superior to sprinklers controlling or extinguishing fires also. Williamson et al4 elaborates on extinction criteria for vitiated fires. While comprehensive in numerical analysis and experiments the work is less useful for setting practical criteria. Theoretically small flames and virtually no risk of escalation3,4 is considered smouldering or glowing condition by FSE practitioners, i.e. these conditions represent events best catered for by early detection and manual intervention, not by extinguishing systems or hypoxic air fire prevention. Gann5 discusses several specific applications for extinguishing systems. Abbud-Madrid24 reports ultrafine water mist (mean diameter of 8 micron) driven by nitrogen outperforms pure nitrogen and carbon dioxide against realistic spacecraft electrical fires. Bennett25 demonstrates yet another performance quality based on solid propellant inert gas generators exploiting the inherent heat to produce steam by water. Performance requirements for spacecrafts, aircrafts and military fire scenarios call for tailored designs and user-specific test protocols. It has become obvious by numerous cases, as the above sample references, that there is a need to review the way performance criteria are set by standards for extinguishing and suppression/prevention systems. NFPA Standard 200122 refers to the latest cup burner method26 to determine gas concentration required for extinguishing of class B fuels and refers to UL 2127, UL 2166 or equivalent for class A fuels. Proposed European Standard 1500427 relies on the cup burner method as well, for gaseous and liquid fuel. The cup burner method is based on flame extinguishment: It is practical to determine performance of extinguishants. However, performances at other concentrations are not recorded and such data might potentially be useful in FSE or others who does design application specific systems. Challenges to Fire Safety Engineering (1): An example of a specification based on comprehensive testing. The introduction of water mist systems for fire protection is introducing an alternative to the traditional water-based technologies by optimizing the use of water to specific applications. In US, FM released an approval standard Class 5560, which includes a number of test procedures for water mist used in different applications30. In Europe, a technical specification for the design, installation and maintenance of water mist systems is about to be released, CEN TS 149726, 7, 18. It is a standard which requires that all systems shall be designed, installed and maintained by qualified companies. A long list of requirements describes how this is to be obtained. The safe use of a water mist system is limited to applications it has been tested for, unless methods being acceptable to the authorities having jurisdiction to interpolate test results can be applied. This means in practise that manufacturers have to go through thorough test procedures, since no such interpolation methods have been accepted by any authorities. The applications are described by room geometry including volume, ventilation conditions, fire load and other parameters. Water mist systems shall be tested in accordance with Annex A and certified in conformity to this document by a recognized authority. For scenarios where Annex A is not applicable, the water mist systems shall be tested in accordance with Annex B by a recognized third party laboratory. In this case the results of the test protocol shall be acceptable to the authority having jurisdiction, responsible for the acceptance of the system. In CEN TS14972 the basic requirement for test results are well defined, both as a general requirement in Guidelines for test protocols and in the individual test protocols. Two test protocols which are highly relevant for the sprinkler industry are: Test protocol for flammable liquids (control and suppression systems) and Fire test protocol for office occupancies of Ordinary Hazard Group 1.The general part of the Guidelines is shown below. Guidelines for developing representative fire test procedures for water mist systems General Current understanding of the performance of water mist systems does not warrant the design of systems from first principles. The basic design and installation parameters of all water mist systems shall therefore be obtained from performance tests. Performance test procedures may be generic to a certain fire hazard class, as defined in EN 12845, or they may be particular to an application within a fire hazard class. Where possible, an application specific test procedure should be preferred to a generic procedure. These guidelines provide information on developing, carrying out, and documenting a fire performance test procedure for a representative application. The design of a test procedure shall be in accordance with the established scientific and engineering principles of fire protection that incorporate widely accepted methods, empirical data, calculations, correlations and computer models, as exemplified by the standard ISO/TR 13387-1 to ISO/TR 13387-8, "Fire safety engineering", and as contained in engineering textbooks and technical literature. The intent of these guidelines is to encourage the development of fire test procedures that 1.are based on a fire protection engineering evaluation of the fire hazard, the compartment conditions, and the performance objectives for the water mist system 2.are developed, carried out, and interpreted by qualified fire testing laboratories Figure B.1 shows the process as a simple flowchart. The chart identifies the steps of the process, as well as the main output from each step. Below, the steps are discussed in more detail. Figure B1 of CEN TS 14972 This guidance for developing a test procedure might be universal, since it requires quantitative pass/fail criteria. Such pass/fail criteria can be specific with regard to the objective of protection. Challenges to Fire Safety Engineering (2): A Need for Extended Application Options Extended application is a term dubbed by the European passive fire protection standardization community to describe conditional allowances to apply tested structures or products larger or smaller than tested. In the field of passive fire protection the extended application principle has been introduced and points further to even more FSE-adaptable practice of testing16. The fire detection industry has evolved to provide a broad array of performance classes and detector categories: Standards include performance based guides to determine required sensitivity for a given application (NFPA 72). G-JET14, 20 is a simple e-tool to handle nominal and effective smoke detector sensitivity in designs by FSE practitioners. Within the fire extinguishing industry most success criteria of standard tests largely remain fixed, governed by early benchmarks by systems of respective categories rather than by practical demands. Equivalency versus Performance Based Design Equivalency by NFPA and SOLAS terms is understood to basically mean specific parts only of a safety system providing an equal or improved performance to prescriptive solutions, such as fire resistance to a specific test condition, pump output flow, water application rate, time to extinguish etc. Alternative solutions to functional requirements, however – fundamental in performance based design (PBD) and fire safety engineering (FSE) – are other means to meet the goals and objectives and they may become widely different. Even organizational measures may substitute for active fire protection hardware systems if the objective is served and measures properly proven. Challenges to Fire Safety Engineering (3): Heritage Fire Protection Flashover Suppression Some fire prevention measures are based on flashover suppression. Smoke venting systems are basically such measures, intended to prevent a severe fire situation in a later state of the fire development. Originally this was used to assure safe entry of the fire brigade, to aid their rescue of persons and intervention with water sprayers. Flashover suppression may also be obtained by water mist systems, utilizing small flow rates of water. However, this is not well documented, and is not widely included in the tool-box of fire suppression. In Norway, the historic town Røros is protected by pre-installed dry pipe water mist system covering areas that are difficult to enter by the fire brigade18, 21. The purpose is to prevent flashover in the house with a fire, subsequently preventing a devastating deflagration. Fire Suppression to Avoid Damage to Decorations and Paintings As water mist systems were designed to fit the Norwegian stave churches, 1:1 scale mock up tests were made12. One performance requirement was to avoid damage to medieval water soluble paintings on walls and ceilings. Conventional sprinkler would cause damage; any gas would leak out and allow reignition etc. The best system turned out to be flashover suppression plus strategically located water mist nozzles for direct hit extinguishing. The assumption could be made that fires would not start at or involve decorations at an early stage so no nozzles need be directed towards such. It was found that fine, low-impulse water mist does not harm the paint. A specific, thorough experimental study of water spray impact on similar decorations were made in Sweden recently19, see Figure 1. Such special application designs can be engineered based on test reports by laboratories if they are dedicated to provide FSE practitioners with the detailed performance rather than success/no success ratings as currently provided. Figure 1: Test samples of authentic decorations before (left) and after (right) being subjected to sprinkler at 1.5 m and 5.0 bar (upper row). Middle row show samples before and after being subjected to water mist nozzle at 1.6 m and 15.0 bar. Bottom row show samples before and after being subjected to water mist nozzle at 1.3 m and 120.0 bar (a repeat of the latter test made an apparently better result) Extinguishing Criteria set by Performance Based Standards NFPA Standard 914 describes performance based design (PBD). The standard leave the success criteria of extinguishing systems unaltered (as is by current standards). However, to complement the PBD context of 914 future test reports by testing laboratories and agencies on extinguishing and fire prevention systems ought to be improved to allow flexibility of FSE design for historical buildings. Fire Prevention and Extinguishing Methods by Strategic Performance Criteria in Heritage Applications A qualitative comparison of fire protection options in heritage environments is shown in Figure 2. It is useful for a qualitative discussion of parameters and for overview, but not intended for decision making. The figure shows a favourable ranking of inert air venting based on the lack of secondary damage risks, and on the simplicity, related to the concept. Figure 2: A qualitative comparison of two vital properties of fire protection systems for heritage13. The illustration does not apply to any single object, and is based on evaluation of risk of secondary damage and robustness/reliability (aesthetics, cost, maintenance, space requirements etc are not considered in this evaluation). Challenges to Fire Safety Engineering (4): Fire Preventive Air vs Extinguishing of Established Fires Hypoxic air venting represents an ultimate method of fire suppression. Generator plants on site ensure continuous air, conditioned as inert to prevent ignition, flaming and retard smouldering of most common materials. Being clean air with oxygen concentration equivalent to partial pressure of oxygen in aircraft cabins or elevated cities, typically 15 %, compensated by increased concentration of nitrogen, it allows prolonged occupation without protective gear. As the patented fire suppression method was submitted to standard testing agencies it became apparent that current success criteria for ‘clean agent’ as per NFPA22 did not fit. Neither did it fit a NFPA standard covering inerting gas systems9. Many suggested a separate standard. A new standard has been declined by some on rationale that hypoxic air does not ‘extinguish’, referencing the FM article by Xin of Factory Mutual3. The article, however, basically explores extinguishing performance of hypoxic air in concentrations used for preventing ignition and is irrelevant. The bewilderedness of the standardization committees when confronted with new, superior performance emphasises the need to review current success criteria of standards. Hypoxic air venting is an inherently robust, simple hardware system compared to those for inert gas or gas extinguishing and would easily be covered by relevant parts of existing standards. The mere obstacle appears to be current performance requirements which are based on benchmark performances of conventional techniques. Figure 3: Shredded paper in cardboard box after 180 minutes of being subjected to hot electrical nichrome wire in 15 % oxygen hypoxic atmosphere. In normal air the wire caused flaming in 60 seconds10. If in an aircraft there would be a risk that alternate methods like gas or aerosol extinguishing would suppress fire only for the cargo room gas holding time which is likely shorter than time to emergency decent, and initial smoke before extinguishment could be corrosive/toxic. Figure 4: Class B fire prevention by hypoxic air: An electrically heated probe of 982 oC being immersed into N-heptane, isopropyl alcohol, methyl ethyl ketone fuel without ignition10. Challenges to Fire Safety Engineering (5): Loss Development versus Fire Development in Real Fires Current success criteria for extinguishing systems do not recognize need for flexible criteria/system performances to cater for real life challenges. Development of fire versus loss is often not concurrent. For the same fire exposure (fire development graph, Figure 5) loss developments at 4 different locations may simply not compare at all. In fact, four distinct type of extinguishing systems, one for each scenario, may be required for adequate performances despite fires valuables are exposed to being identical. HEAT SENSITIVE GOODS IN STORAGE EXPENSIVE ELECTRONIC COMMODITIES TELECOM FACILITY CONTROL ROOM MULTIPLE ROOMS SEPARATED BY GLAZING Figure 5: Sample scenarios of varying loss developments versus a fixed fire development. The guide on FSE provided by the British Standard PS 797415 elaborate on sprinkler systems, while less on other fire suppression systems. It does, however, make the point that the FSE practitioner should take into account many more factors than mere success criteria of standard tests for extinguishing systems, in order to optimize design and reduce loss consequences. Based on a figure by this reference15, figure 6 illustrate basic choices facing an FSE practitioner: water based gas/aerosol, inerting, and preventive systems. The expected loss consequences of applying systems of various categories are conventionally illustrated by the marked areas which clearly demonstrate the importance of selecting the optimum system. To further assess expected loss in a specific FSE design one may compare loss versus fire developments as illustrated in Figure 6. Thus, by taking into account accumulated loss and total loss events related to specific valuables one specifically illustrate realistic losses, which is most useful while doing FSE. UNCONTROLLED FIRE FLASHOVER SUPPRESSION CONTROLLED BY SPRINKLER EXTINGUISHED BY SPRINKLER EXTINGUISHED BY GAS SYSTEM HYPOXIC AIR PREVENTION Figure 6: By an FSE ‘expected loss concept’ point of view, selecting the optimum system category is more important than small variations in performance within a single category. Most current test standards yield ‘yes/no” results only. The message calls for a common handling of performance criteria, such as by a separate standard for the criteria only. New Standard Proposal: Performance Criteria of Methods to reduce Fire Loss by Prevention/Suppression/Extinguishing Based on the challenges facing fire safety engineering and on implications by retaining exclusive performance requirements in every standard for the various categories of systems, the authors propose to consider a new international standard of performance criteria that system specific standards may refer to. This standard should include quantification of performance to evaluate equivalency and compensating measures. Such a move may bring the fire suppression/extinguishing community in line with similar approaches adopted by fire safety engineering and passive fire protection communities. Effectively, future test results should be presented to users, such as FSE practitioners, by quantifiable criteria yet not in terms of yes or no to one single criterion but rather graphs and other detailed performance. The user may select systems that comply with requirements of fire safety designs based on loss prevention etc, and with improved confidence and documentation. New Approach Proposal: Future Editions of Test Standards to serve Specific Criteria of FSE Users An expected loss consequence of successfully operating systems is the key to a new approach to make sense in FSE. The loss refers to the sum of all secondary damages and initial fire damages prior to activation. In order to determine expected loss consequence if a given fire extinguishing system the FSE practitioner need to know the time of activation and the effect of activation upon the protected systems, stored items or structures. Current test methods and corresponding success criteria are limited in this respect. Sprinklers are effectively judged by the water application rate rather than the impact on the fire. Clean agents are effectively judged by the time to quench flames by a minimum time after activation. Consequences of effective nozzle spray patterns or other activation times may not have been tested. Life safety of occupants in a building relies on early warning and possibility to evacuate in a fire situation. Alternatively, an early extinguishing or suppression of a developing fire may secure the occupants without evacuation. The criteria for acceptance of the safety level are used in recent publications and work of standardisation comittees1, 17. The latter acceptance criteria, especially those based on the dose of exposure of toxic gases, is not widely used. Recently, the Norwegian and Swedish Authorities published guidelines for the installation of easily installed automatic extinguishing systems for occupancies for people with reduced mobility8. These guidelines include a set of acceptance criteria of this type. The system requirements read as follows: The system shall minimally meet the following requirements as results of the fire tests using this method: • The average temperature for the two thermo-element trees in the room, over a period of one minute, at a time five minutes after the first activation of the extinguishing system, must not exceed 100°C. • The CO dosage measured in the tests must not exceed 15,000 ppm-minute over a period of 20 minutes following the first activation of the extinguishing system. • The oxygen concentration in the room must not be less than 15% for longer than five minutes following the first activation of the extinguishing system. These requirements are based on an evaluation of normal use threshold values for that particular category of occupant with regard to the possibility of survival in a room exposed to an equivalent fire. These criteria do not apply to people that are directly affected by the actual fire in the immediate vicinity of the starting point of the fire. Some test methods requiring equivalency base the quantification on fire damage to a specified commodity. This comparison requires a similar test enclosure to be representative, at least in case of water-based fire suppression media. IMO A800 test protocol for cabins has plastic mattresses and combustible wood lining in the test compartment29. UL 1626 for residential sprinkler tests has an assembly of plastic pads, a wood crib and an ignition source, simulating a piece of furniture28. An example of a damage seen after a fire test is shown in Figure 7. IMO A 800 also includes tests of fire scenarios in public spaces The commodities range from free-standing sofas or sofas located towards combustible linings, and the tests of the water mist systems are to be compared to the damage obtained by a typical sprinkler system. For scenarios of shopping areas of passenger ships, the commodity consists of cardboard boxes filled with plastic cups. In both situations the tests have to be carried out for the ceiling height it is approved for. The acceptance criteria is that the damage measured after the 10 minutes of water mist action is to be less or equal to the damage measured after 10 minutes in the typical sprinkler test. This equivalency requirement is based on quantification of performance of the fire protection system. Figure 7. Interior of a fire room with sufficient water application for fire suppression. A large portion of the sofa backrest has been burnt. The wall lining shows some damage, but there is no significant damage to the ceiling lining. Conclusions Since most of the standards for fire protection systems still are descriptive in their approach, quantitative basis for Fire Safety Design with these systems is missing. The key to obtain a better basis is to introduce quantification of damage or hazard to life safety as a part of test protocols. Quantification of damage may be direct, as in test protocols issued by IMO, as a percentage fire damage of commodities, or indirect, as measured by suppression of fire load or by enclosure temperature. Fire safety engineering by performance based codes has brought about a need to review the way performance criteria are set by standards for extinguishing and suppression/prevention systems. Ideally, laboratories ought to issue test reports on performance in broad scope conditions in quantifiable or controlled ways so that the FSE practitioner may design and specify systems for practical demands. To meet the future need results should be presented to users, such as FSE practitioners, by quantifiable criteria. This will exclude the conventional ‘yes or no’ to one single criterion in favour of graphs and detailed performance. The user may select protection systems that comply with requirements of the fire safety design based on loss prevention etc, and with improved confidence and documentation. A proposal is given to consider a new international standard of performance criteria that system specific standards may refer to. References 1. Huczek, Jason P.: ”Demonstration Testing: Extinguishment of Kitchen Fires and the Effect of Sprinklers in a Residential Setting”. Orlando, SUPDET 2007. 2. Harrison, Neil: “Safe Storage. Warehouse Fire Safety”. Fire Safety Engineering November 2007. 3. Xin and Khan: ”Flammability of combustible materials in reduced oxygen environment”. FM Global. Published by Fire Safety Journal – accepted 3 April 2007. 4. Williamson, Marshall and Trouvé: ”Developing Extinction Criteria for Fires”. Interflam 2007. 5. Gann, Richard G: ”Technology for fire Suppression in Aircraft: Findings of the Next Generation Fire suppression Technology Program”. Interflam 2007. 6. prCEN/TS 14972 Fixed Firefighting Systems – Water Mist Systems - Design and Installation 7. Wighus, Ragnar: ”Equivalency – the principle for acceptance of firefighting systems”. SINTEF NBL as, Norway. IWMA Conference October 2007. 8. ’Easily installed automatic extinguishing system - A Guide. June 2007. Norwegian Directorate for Civil Protection and Emergency Planning (DSB) and Swedish Rescue Services Agency (SRSA). 9. NFPA 2001-2008. Proceedings of Hearing. TIA Log No 886 SC 07-10-6 Series. 10. Brooks, John: Aircraft Cargo Fire Suppression using Low Pressure Dual Fluid Water Mist and Hypoxic Air. International Aero Technologies LLC. Website of NIST. 11. Jensen, Geir: Clearing the Air - Hypoxic Air Venting for Fire Protection. Fire Engineers Journal. 2007. 12. Jensen, Geir: Water Mist for Protection of Heritage. Norwegian Directorate for Cultural Heritage. COWI. 2004. 13. Jensen, Geir: Hypoxic Air Venting for Protection of Heritage. For COST. Historic Scotland and Norwegian Directorate for Cultural Heritage. COWI. 2006. 14. Jensen, Geir: Minimum Invasive Fire Detection for Protection of Heritage. For COST. Historic Scotland and Norwegian Directorate for Cultural Heritage. COWI. 2006. 15. PD 7974-4:2003 Application of fire safety engineering principles to the design of buildings. Part 4: Detection of fire and activation of fire protection systems. BSI. 16. ISO/TR 22898: Review of outputs for fire containment tests for buildings in the context of fire safety engineering. 17. ISO TC92/SC3 WG2 N Sprinklers and Fire Effluents - Methods forAssessing Life Threat from Sprinklered Fires. (Dave Purser 11/7/01). 18. R.Wighus Progress in European Standardisation Work on land-based use of Water Mist. International Water Mist Conference 2006, Budapest, Hungary. 19. Arvidson, Magnus: ”The influence of water from sprinkler sprays on invaluable wall- and ceiling paintings in heritage buildings”. SP Swedish National Testing and Research Institute. 2007:25. Also, a paper of same title, based on this report presented at the IWMA Conference October 2007. 20. G-JET: Smoke Detection Model. Design tool for smoke detectors to predict response to performance requirements in applications. COWI. http://www.interconsult.com/G-Jet/. Model databases: http://www.firemodelsurvey.com/pdf/GJET_2001.pdf , http://www.interconsult.com/G-Jet/GJET%20i%20CIB%20Printing%20Format.pdf 21. 22. 23. 24. 25. 26. 27. 28. NFPA 555 Guide on Methods for Evaluating Potential for Room Flashover. 2004 Edition. NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems. 2008 Edition. NFPA Standard 2010. Fixed Aerosol Fire Extingushing Systems”. 2005 Edition. Abbud-Maddrid, Watson and McKinnon: ”On the Effectiveness of Carbon Dioxide, Nitrogen and Water Mist for the Suppression and Extinction of Spacecraft Fires”. Interflam 2007. Bennett, Mike: ”Recent Findngs in the Development of Solid Propellant Inert Gas Generator Fire Extinguishing Systems for Occupied Space Use. Interflam 2007. Senecal, Joseph A: ”Standardizing the Measurement of Minimum Extinguishing Concentration of Gaseous Agents. Orlando, SUPDET 2007. prEN 15004-1 ”Fixed firefighting systems – Gas extinguishing systems – Part 1. Design, installation and maintenance” (ISO 14520-1, modified). Also: Parts 7, 8, 9 and 10 of the 15004 series. UL 1626. Residential Sprinkler for Fire Protection Service, Revision December 8. 2003. Underwriters Laboratories Inc, USA. 29. IMO Res. A. 800(19), Appendix 2, “Fire test procedures for equivalent sprinkler systems in accomodation, public space and service areas on passenger ships”. 30. Approval Standard for Water Mist Systems. Class Number 5560. FM Approvals LLC, May 2005.