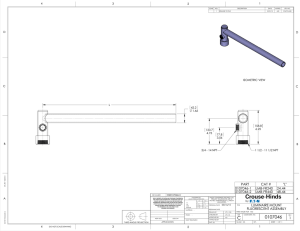

Unions, Couplings and Seals: Explosionproof, Dust

advertisement