Mass Spectrometer Detectors

advertisement

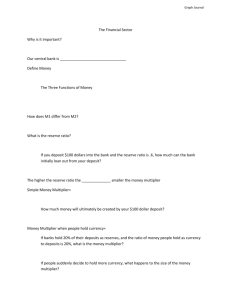

Ion Detectors for Virtually all Mass Spectrometry Applications Electron multipliers are used in a wide range of applications to detect and measure small signals of ions, electrons or photons. One of the main applications for an electron multiplier is for the detection of ions in a mass spectrometer. ACTIVE FILM Multipliers manufactured by ETP ( a division of SGE Group of Companies) are the result of 15 years experience in supplying high performance electron multipliers for use in mass spectrometry applications. The performance of this unique type of ion detector has seen it become widely used in almost all fields of mass spectrometry (including ICP-MS, GC-MS, LC-MS, TOF and SIMS). An electron multiplier is used to detect the presence of ion signals emerging from the mass analyser of a mass spectrometer. It is essentially the "eyes" of the instrument (see Figure 1). The task of the electron multiplier is to detect every ion of the selected mass passed by the mass filter. How efficiently the electron multiplier carries out this task represents a potentially limiting factor on the overall system sensitivity. Consequently the performance of the electron multiplier can have a major influence on the overall performance of the mass spectrometer. Principles of Multiplier Operation The basic physical process that allows an electron multiplier to operate is called secondary electron emission. When a charged particle, an ion or an electron, strikes a surface it can cause electrons associated with the outer layers of atoms to be released. The number of secondary electrons released depends on the type of incident primary particle, its energy and characteristic of the incident surface (see Figure 2). In general there are two basic forms of electron multipliers that are commonly used in mass spectrometry; the discrete-dynode electron multiplier, and the continuous-dynode multiplier Figure 1. Components of Mass Spectrometry Gas Phase Source Ion Sorting Electron Multiplier Analyser Vacuum Data Inlet Sample Introduction Ion Detection Data Output: Mass Spectrum The general layout of a mass spectrometer consists of the following elements; Sample introduction and separation system, Ion source, Mass analyser, Ion detection system, Data processing. Figure 2. Secondary Electron Emission 6 Secondary Electron Emissions www.sge.com TECHNICAL ARTICLE Mass Spectrometer Detectors 5 4 3 2 1 0 0 100 200 300 400 Incident Electron Energy (eV) 500 The average number of secondary electrons emitted from the surface of an ETP electron multiplier plotted against the energy of the incident primary electron. (often referred to as a channel electron multiplier or CEM). The principal difference between these two types of multipliers is the structure used to harness the secondary electron emission process. In the case of the discrete-dynode multiplier electron, amplification is carried out using an array of electron multiplying electrodes, called dynodes. Ions striking the first dynode cause secondary electrons to be emitted from the surface. The optics of the dynodes focuses these secondary electrons onto the next dynode of the array as shown in Figure 3. These in turn emit even more secondary electrons from the surface of the second dynode. In this way a cascade of electrons is developed between successive dynodes, each dynode increasing the number of electrons in the cascade by a factor of 2 to 3, until the cascade of electrons reaches the output electrode where the signal is extracted. In the case of the continuous-dynode multiplier, electron amplification is carried out using a single continuous channel made from extruded lead-silicate glass. The electron gain occurs by the ion striking the channel wall and causing secondary electrons to be emitted. The secondary electrons are then drawn down the channel, by an electrostatic field, until they again impact with the channel wall, emitting even more secondary electrons. This process is illustrated in Figure 4. A typical discrete-dynode electron multiplier has between 12 and 24 dynodes and is used with an operating gain of between 104 and 108, depending on the application. In GC-MS applications, for example, the electron multiplier is typically operated in analog mode with a gain of around 105. For a new electron multiplier this gain is typically achieved with an applied high voltage of ~1400 volts (Figure 5). Noise generated within an ETP electron multiplier is negligible, typically the output equivalent of just a few ions per minute. In applications such as GC-MS the noise on the output signal from the multiplier is influenced by three factors: Figure 3. Discrete Dynode Detector ION First Dynode 1. Noise already existing on the ion signal (produced in the separation column and the ion source). 2. The ability of the input optics of the detector to screen out unwanted radiation (not ions). 3. The statistical noise associated with the number of ions in a measurement (especially for low level ion signals). Figure 6 shows the change in the applied high voltage required to maintain the gain of a typical electron multiplier for GC-MS over the course of its operating life. The electron multiplier power supply in most GC-MS systems is limited to 3000 volts. When the applied high voltage necessary to achieve the required operating gain begins to approach the limit of the power supply, it is necessary to replace the multiplier with a new one. A typical electron multiplier for GC-MS applications lasts 1 to 3 years. Features of ETP Electron Multipliers The electron multipliers manufactured by ETP are called ACTIVE FILM Multipliers. Their name comes from the specialized surface materials used on the dynodes. This proprietary dynode material has a number of properties that make it very suitable for use in an electron multiplier. It has very high secondary electron emission, which allows exceptional gain to be achieved from each dynode. This material is also very stable in air, in fact an ETP multiplier can be stored for years before being used. As a direct result of the high stability of the active materials used in ETP multipliers they come with a 2 year shelf life warranty. Many testing laboratories take advantage of this long shelf life by keeping a replacement ETP multiplier on hand, ready for immediate installation. This keeps the instrument down time to a minimum. A major advantage of the discrete dynode design of ACTIVE FILM Multipliers is increased operating life. This is a consequence of the mechanism of gain loss in an electron multiplier. One of the main mechanisms of multiplier gain loss is the deposition of contamination on the surface of the dynodes. The rate of contamination build-up on the dynode surfaces is influenced by two factors; Ion-optics of an ETP discrete-dynode electron multiplier showing the electron gain at each successive dynode. This electron cascading process results in gains up to 108 being achieved with ~21 dynodes. Figure 4. Continuous Dynode Detector High Voltage Ion-optics of a continuous-dynode, or channel, electron multiplier. The electron gain occurs as each electron strikes the walls of the channel causing secondary electrons to be emitted. Figure 5. Gain vs Voltage 109 108 Typical Gain As a multiplier is used, the surfaces of the dynodes slowly become covered with contaminants from the vacuum system, causing their secondary electron emission to be reduced and the gain of the electron multiplier to decrease. To compensate for this process, the operating high voltage applied to the multiplier must be periodically increased to maintain the required multiplier gain. 107 106 105 104 1200 1400 1600 1800 2000 2200 2400 2600 Applied Voltage A gain curve for an ETP electron multiplier to suit a Hewlett-Packard 5972 MSD. Typical operating gain in this instrument is ~2x105 which is achieved with an applied high voltage of ~1400 volts. The active dynode surfaces of an Active Film Multiplier are composed of stable-in-air materials and can be repeatedly exposed to the air with no loss in performance. The original packaging is designed for long term storage. The multiplier is delivered in two sealed plastic bags, the outer bag containing silica gel to absorb any moisture. If the multiplier is to be stored for long periods it is best left in its original packaging until required. In its original packaging, the shelf life of the Active Film Multiplier is guaranteed for two years from ETP's shipping date. If it is necessary to store the multiplier without its original packaging, it should be kept in a dust free, dry environment. Ideally it should be stored in a glass desiccator containing silica gel. Figure 6. Applied Voltage vs Operating Life 3500 Applied High Voltage 3000 2500 2000 1500 1000 500 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Fraction of Operating Life 0.8 0.9 1.0 Change in the applied high voltage required to maintain the gain of an electron multiplier over the course of its operating life (for a typical GC-MS). The applied high voltage must be periodically increased to maintain the operating gain of the multiplier. 1. Partial pressure of contaminants in the residual gas of the vacuum chamber. This means that a cleaner vacuum environment will allow the multiplier to achieve a longer operating life time. 2. The electron density incident on the surface of the dynode. Because ACTIVE FILM Multipliers use large area dynodes in their construction, the amount of surface contamination per unit dynode area is decreased, resulting in the multiplier having increased operating life and improved gain stability. For a typical ACTIVE FILM Multiplier for GC-MS, the total active dynode surface area is ~1000mm2. This can be compared to a standard (chrome) continuous-dynode multiplier that has a total channel surface area of only around 160mm2 (for a channel with 1mm diameter and 50mm length). This increased surface area spreads out the "work-load" of the electron multiplication process over a larger area, effectively slowing the aging process and improving operating life and gain stability. The electron-optics used in ACTIVE FILM Multipliers were designed using highly specialized CAD software developed by ETP specifically for this task. This has resulted in a performanceoptimized design that efficiently focuses all the ions that enter the input aperture of the multiplier onto the first dynode. This very high ion detection efficiency results in an improved signal to noise ratio on the output spectra. Installation, Storage and Handling Active Film Multipliers are individually designed for each specific mass spectrometer and require no modifications to the instrument. They are designed to be fully compatible with the instrument for which they were designed and can be easily installed. An Active Film Multiplier requires no preconditioning. However, it is recommended that the applied high voltage be limited to 2200 volts for the first day of operation. Any multiplier leads should be positioned to have a minimum clearance of 3 millimeters between the lead and any metal parts of the multiplier mounting or mass spectrometer system. This clearance prevents the risk of noise due to arcing or electrical breakdown. The multiplier should be handled using normal high vacuum methods, keeping the multiplier clean and free of contamination. Powder-free gloves should be used to prevent finger-oils from contaminating the multiplier via direct contact with skin. All tools, mountings and equipment should be cleaned before coming into contact with the multiplier. Care should be taken to minimize the time that the multiplier is exposed to airborne particles of dust or lint which would be expected in a typical laboratory environment. Dust particles within the multiplier can cause increased background noise. Exposure of the multiplier to a high humidity environment should be avoided as it can cause noisy operation. In the event of this situation occurring, the multiplier can be restored by baking for 3 hours in vacuum at 150ºC, or simply by leaving it in vacuum for a day or more. After baking, the multiplier should be allowed to cool in the vacuum chamber to avoid the possibility of damage due to thermal shock. The rugged design of the Active Film Multiplier greatly reduces the chance of damage through rough or careless handling. Nonetheless, an electron multiplier is a precision instrument and all reasonable care should be taken when handling.