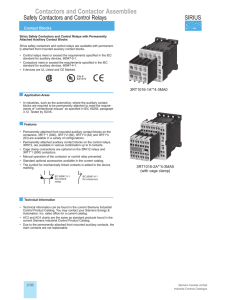

THREE-POLE CONTACTORS • IEC Ith ratings in AC1 duty at ≤40

advertisement