Fujitsu Inverter AC Troubleshooting Guide: Error Codes & Solutions

advertisement

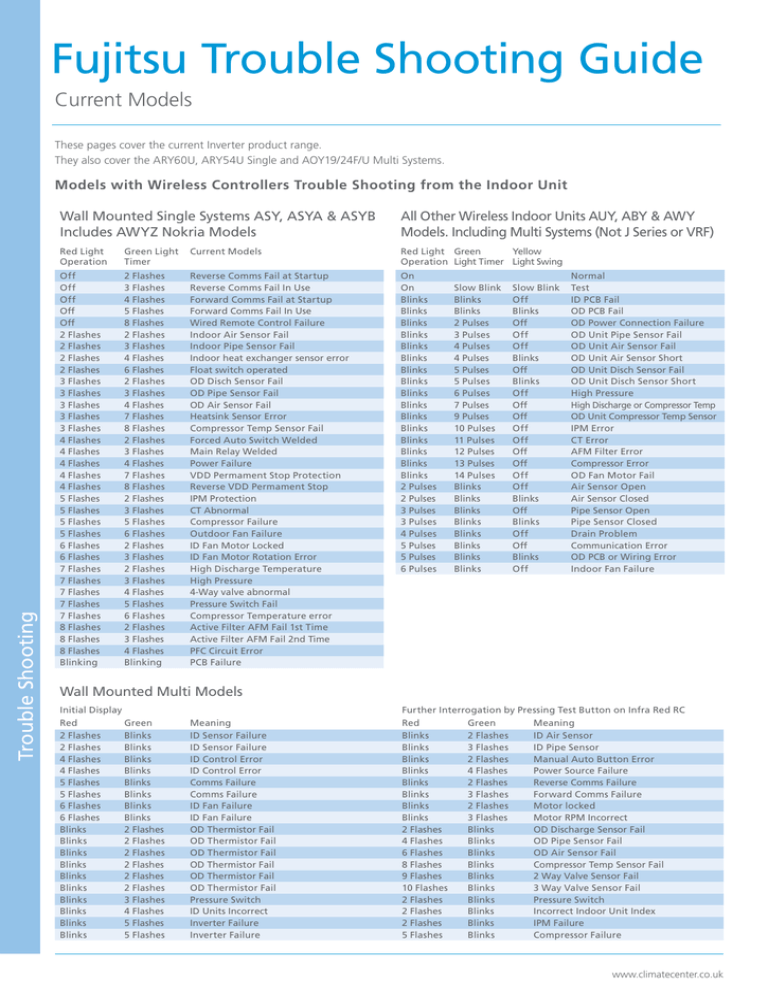

Fujitsu Trouble Shooting Guide Current Models These pages cover the current Inverter product range. They also cover the ARY60U, ARY54U Single and AOY19/24F/U Multi Systems. Trouble Shooting Models with Wireless Controllers Trouble Shooting from the Indoor Unit Wall Mounted Single Systems ASY, ASYA & ASYB Includes AWYZ Nokria Models All Other Wireless Indoor Units AUY, ABY & AWY Models. Including Multi Systems (Not J Series or VRF) Red Light Operation Green Light Timer Current Models Red Light Green Yellow Operation Light Timer Light Swing Off Off Off Off Off 2 Flashes 2 Flashes 2 Flashes 2 Flashes 3 Flashes 3 Flashes 3 Flashes 3 Flashes 3 Flashes 4 Flashes 4 Flashes 4 Flashes 4 Flashes 4 Flashes 5 Flashes 5 Flashes 5 Flashes 5 Flashes 6 Flashes 6 Flashes 7 Flashes 7 Flashes 7 Flashes 7 Flashes 7 Flashes 8 Flashes 8 Flashes 8 Flashes Blinking 2 Flashes 3 Flashes 4 Flashes 5 Flashes 8 Flashes 2 Flashes 3 Flashes 4 Flashes 6 Flashes 2 Flashes 3 Flashes 4 Flashes 7 Flashes 8 Flashes 2 Flashes 3 Flashes 4 Flashes 7 Flashes 8 Flashes 2 Flashes 3 Flashes 5 Flashes 6 Flashes 2 Flashes 3 Flashes 2 Flashes 3 Flashes 4 Flashes 5 Flashes 6 Flashes 2 Flashes 3 Flashes 4 Flashes Blinking Reverse Comms Fail at Startup Reverse Comms Fail In Use Forward Comms Fail at Startup Forward Comms Fail In Use Wired Remote Control Failure Indoor Air Sensor Fail Indoor Pipe Sensor Fail Indoor heat exchanger sensor error Float switch operated OD Disch Sensor Fail OD Pipe Sensor Fail OD Air Sensor Fail Heatsink Sensor Error Compressor Temp Sensor Fail Forced Auto Switch Welded Main Relay Welded Power Failure VDD Permament Stop Protection Reverse VDD Permament Stop IPM Protection CT Abnormal Compressor Failure Outdoor Fan Failure ID Fan Motor Locked ID Fan Motor Rotation Error High Discharge Temperature High Pressure 4-Way valve abnormal Pressure Switch Fail Compressor Temperature error Active Filter AFM Fail 1st Time Active Filter AFM Fail 2nd Time PFC Circuit Error PCB Failure On On Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks 2 Pulses 2 Pulses 3 Pulses 3 Pulses 4 Pulses 5 Pulses 5 Pulses 6 Pulses Slow Blink Blinks Blinks 2 Pulses 3 Pulses 4 Pulses 4 Pulses 5 Pulses 5 Pulses 6 Pulses 7 Pulses 9 Pulses 10 Pulses 11 Pulses 12 Pulses 13 Pulses 14 Pulses Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Slow Blink Off Blinks Off Off Off Blinks Off Blinks Off Off Off Off Off Off Off Off Off Blinks Off Blinks Off Off Blinks Off Normal Test ID PCB Fail OD PCB Fail OD Power Connection Failure OD Unit Pipe Sensor Fail OD Unit Air Sensor Fail OD Unit Air Sensor Short OD Unit Disch Sensor Fail OD Unit Disch Sensor Short High Pressure High Discharge or Compressor Temp OD Unit Compressor Temp Sensor IPM Error CT Error AFM Filter Error Compressor Error OD Fan Motor Fail Air Sensor Open Air Sensor Closed Pipe Sensor Open Pipe Sensor Closed Drain Problem Communication Error OD PCB or Wiring Error Indoor Fan Failure Wall Mounted Multi Models Initial Display Red 2 Flashes 2 Flashes 4 Flashes 4 Flashes 5 Flashes 5 Flashes 6 Flashes 6 Flashes Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Further Interrogation by Pressing Test Button on Infra Red RC Green Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks 2 Flashes 2 Flashes 2 Flashes 2 Flashes 2 Flashes 2 Flashes 3 Flashes 4 Flashes 5 Flashes 5 Flashes Meaning ID Sensor Failure ID Sensor Failure ID Control Error ID Control Error Comms Failure Comms Failure ID Fan Failure ID Fan Failure OD Thermistor Fail OD Thermistor Fail OD Thermistor Fail OD Thermistor Fail OD Thermistor Fail OD Thermistor Fail Pressure Switch ID Units Incorrect Inverter Failure Inverter Failure Red Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks 2 Flashes 4 Flashes 6 Flashes 8 Flashes 9 Flashes 10 Flashes 2 Flashes 2 Flashes 2 Flashes 5 Flashes Green 2 Flashes 3 Flashes 2 Flashes 4 Flashes 2 Flashes 3 Flashes 2 Flashes 3 Flashes Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Blinks Meaning ID Air Sensor ID Pipe Sensor Manual Auto Button Error Power Source Failure Reverse Comms Failure Forward Comms Failure Motor locked Motor RPM Incorrect OD Discharge Sensor Fail OD Pipe Sensor Fail OD Air Sensor Fail Compressor Temp Sensor Fail 2 Way Valve Sensor Fail 3 Way Valve Sensor Fail Pressure Switch Incorrect Indoor Unit Index IPM Failure Compressor Failure www.climatecenter.co.uk Fujitsu Trouble Shooting Guide Current Models Wired Remote Control Models Code Consists of Indoor Unit Address Followed by the Fault Code Below. No E denotes No Fault. OO O1 O2 O3 O4 O5 O6 O8 O9 OA OC OE 11 12 13 14 15 16 17 18 19 1A 1B 1C 1D 1E 1F 20 24 ID to RC Comms Fail ID to OD Comms Fail ID Air Sensor Open ID Air Sensor Close ID Pipe Sensor Open ID Pipe Sensor Close OD Pipe Sensor Fail Power Source Connection Failure Drain Problem Float switch operated OD Air Sensor Fail Discharge sensor Fail Outdoor High Pressure Heatsink error OD PCB Fail ID Fan Fail OD Signal Abnormal ID signal error OD EEPROM Fail Compressor Temp Failure Pressure Switch Error IPM Error CT Error Active Filter Module Error Compressor Failure OD Fan Failure Inverter to PCB Comms Fail 2 Way Valve sensor Fail Expansion Valve Error Connection ID Unit Error Indoor manual switch abnormal Excessive high pressure protection on cooling 25 26 27 28 29 2A 2B 2C PFC circuit error Indoor signal error Indoor signal error Indoor heat exchanger temperature error Outdoor heat exchanger temperature (middle) error Power supply frequency detection error Compressor temperature error Four-way valve abnormal To Interrogate When E:EE is displayed switch unit off and press the temp up and temp down buttons simultaneously for 3 seconds. To Return to Normal Operation Press Temp Up and Temp Down Buttons together for 3 seconds. To Initiate Test Operation Switch Unit Off & Press Master & Fan Buttons together for 3 seconds. Press Start/Stop to Initiate. Changing the Sensor Position The unit can sense the air temperature at the unit or controller Turn Unit Off To change press THERMOSENSOR button for 5 seconds to unlock Toggle the THERMOSENSOR button & controller is displayed Set to desired setting (unit or controller) Press THERMOSENSOR button for 5 seconds to lock Two Handsets/1 Unit – set on RC DIP SWs Single handset DIP SW1 is On & 2 is Off Dual Handset Master Both On & Slave both Off Group Control up to 16 Unit from 1 RC Handset Set DIP SW3 on RC to ON Set Each ID Unit Rotary SW to Unit Address (0-15) in series Auto Restart on Power Failure DIP SW2-3 on ID Unit. Off is autorestart (std)/On is Manual Restart Auto Changeover DIP SW5 on RC. On is autochangeover (std)/Off is Manual Memory Retention on Power Failure Dip SW6 on RC. On is Memory/Off is no memory Outdoor PCB Fault Codes Non Inverter OD PCBs (2 red LEDs) OD PCB LED Pulses 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Slow Blink Models 9-30 Comms Failure Disch Sensor Fail Pipe Sensor Fail Air Sensor Fail 2 Way Valve Sensor 3 Way Valve Sensor Compressor Thermistor Pressure Switch Indoor Comms Error Current Trip CT Fail Compressor Position Fail Compressor Start Fail Timer Failure Models 36-54 Comms Failure Disch Sensor Fail Pipe Sensor Fail Air Sensor Fail Compressor Thermistor Heatsink Sensor Fail Pressure Switch LED 1 LED 2 Blinks 1 Pulse 2 Pulses 3 Pulses 4 Pulses 5 Pulses 6 Pulses 7 Pulses 8 Pulses 9 Pulses 10 Pulses Blinks Lift Lift Lit Lit Lit Lit Lit Lit Lit Lit OD PCB Fail Power Source Failure OD Disch Temp Sensor OD Pipe Sensor OD Air Sensor Comms Failure Indoor Unit Error High Discharge Temp High Pressure Compressor Temp Abnormal Compressor Temp Sensor Fail IPM Error Compressor Position Fail Compressor Start Fail OD Upper Fan Fail OD Lower Fan Fail Protect Operation Inverter Multi AOY30 Interconnecting Wiring This has 4 LEDs A,B, C & D to denote which circuit has the fault Up to 8 flashes - faults are identical to above 9-30 Single System This has 4 LEDs A,B, C & D to denote which circuit has the fault Up to 8 flashes - faults are identical to above 9-30 Single System 9 10 11 12 13 14 15 16 17 Pressure Switch A Pressure Switch B Indoor Unit Indexing Problem IPM Fail Compressor Position Fail Compressor Fail OD Fan Upper Fail OD Fan Lower Fail PCB Fail www.climatecenter.co.uk CO Multis HP Multis AOY90T ALL OTHERS Live 2 1 3 1 or L Neutral 1 2 2 2 or N Comms 3 3 1 3 We recommend external pumps have their own power supply. Taking Power for a pump from the unit is a major source of Errors. Trouble Shooting Inverter OD Unit PCBs (1 red LED) Fujitsu Trouble Shooting Guide A General Guide Pipework Outdoor Unit • Pipe sizes and lengths should be as the relevant Technical Guide • Discharge temperature should be between 50 & 70°C • Both lines should be insulated • Suction temperature should be between -3 & 4°C • No line accessories or oil traps should be fitted • If fan switches off check for high discharge temperature • In cooling mode both pipes should be between 0 and 10°C - the suction line should sweat, but not freeze • Check Suction Line is sweating – problem if not! • Hot Recip. Compressor = PROBLEM! • In heating moded both pipes should be between 30 and 60°C • Sweating/Frost on expansion line – undercharged • Pipework should be refrigeration quality • Refrigerant should be R22, unless stated on the outdoor unit • Look for restrictions. They could cause compressor failures. Indoor Unit Controller Wiring • Is it level? Have we adequate drainage? • EE:EE on LCD handset – fault diagnostics – see over • In general interconnecting wiring is 240 Volt, but see chart for details • Is the handset too far away? • With LCD wired handset models, Terminal 3 is the Live Not Terminal 1 • Smells are always due to site conditions or drains • Flashing lights? = Fault Diagnostics – see over • When were the batteries changed last? • When were the filters last cleaned? • Heat Pump models 7-14 – NOT auto changeover • Is the unit too large/small (between 5/20 air circs / hr) NEVER apply mains voltage to Terminal 1 on these models • Timer is one shot, unless it has ‘repeat’ mode • Is it on Timer/ Test Mode Trouble Shooting • With wired handset, check for interference. Cable should be screened • Is it on Timer/ Test Mode • With LCD wired handset models wiring should be screened • Check Voltage drops! Check it isn’t down to Earth! • Has it got a timeclock/BMS interface? • Interconnecting cables MUST be circular crimped What the separate wires do in the interconnecting cables Note – Wires are 240V Live except where marked neutral or Earth or signal. Cables marked Signal are digital pulses and you should not attempt to measure these with a meter. E N L 1 2 3 4 5 6 ASY7-12A Wire Earth Neutral Comp+Fan Unused Unused Unused Unused Unused Unused ASY7-12R Earth Neutral Comp Unused Unused Rev Valve OD Fan Unused Unused ASY13PS Earth Neutral Line to OD Unused Unused Signal Unused Unused Unused ASY14A & ABY14-24A Earth Unused Unused Neutral Comp+Fan Unused Unused Unused Unused ASY17-30A Earth Unused Unused Live to In Neutral Comp+Fan Unused Unused Unused ASY14-17R & ABY14R Earth Unused Unused Neutral Comp Rev Valve OD Fan Unused Unused ASY20-30R & ABY18-24R Earth Unused Unused Neutral Comp Fan Hi Rev Valve Fan Low Unused AUY12-18AG Earth Unused Unused Neutral Comp Fan Hi Fan Low Unused Unused AUY12-18RG Earth Unused Unused Neutral Comp Fan Hi Rev Valve Fan Low Unused AUY18-54A, ABY30-54A & ARY24-60A Earth Unused Unused Comp Neutral Live to In Unused Unused Unused AUY18-54R, ABY30-54R & ARY24-60R Earth Unused Unused Signal Neutral Live to In Unused Unused Unused Technical Support: 08705 218218 www.climatecenter.co.uk Fujitsu Trouble Shooting Guide Current Models Wired Controllers – Fault diagnostics A Fault Condition is signalled by EE:EE appearing on the LCD panel. The unit should be interrogated by switching it off on the handset then pressing either the down arrows on the SET TIME and TEMP/DAY buttons together for 3 seconds for 7 day models or the ENERGY SAVE & ZONE CONTROL buttons for other models. The Failure code is in 2 parts – Fault and Address. The Fault Code is an E code. The second is the unit address for multi linked systems – with single units this is always 00. 7 day models have the fault code as shown in the table below above the address. Other models have the codes below, minus the 0, followed by the address – e.g. E9:00 denoting Float Switch on Unit 0. Code Fault Diagnosis E:0 E:01 E:02 E:03 E:04 E:05 E:06 E:07 E:08 E:09 E:0A E:0C E:0D E:0F I/U - R/C Comms I/U - O/U Comms Room Sensor Open Room Sensor Short I/U Pipe Sensor Open I/U Pipe Sensor Short O/U Pipe Sensor Open O/U Pipe Sensor Short Power Source Error Float Switch O/U Air Sensor Open Disch Sensor Open Disch Sensor Short High Disch Temp Check R/C wiring. Interference? Check intercon. wiring. Interference Sensor Missing Sensor Faulty Sensor Missing Sensor Faulty Sensor Missing Sensor Faulty Incorrect Power Supply Check Drains - High Water Level Sensor Missing Sensor Missing Sensor Faulty Contamination In Pipework/ Gas Shortage E:11 E:12 E:13 E:14 Model Abnormal Indoor Fan Failure O/D Signal Abnormal Outdoor PCB Fail Check PCB compatability Check Fan and Motor Communications? PCB Failure Fault Outdoor Unit with A fault condition is signified by flashing red LED’s on the the outdoor PCB if it is equipped with one. Except for multisplits and 2 LED models, the diagnostics are shown in the table on the right. For 2 LED models flashing signifies sensor failure and constantly lit indicates high discharge temperature. LED1 Signal Failure Indoor Unit Failure Discharge Sensor Fail O/D Pipe Sensor Fail O/D Air Sensor Fail Power Source Error PCB PCB Failure High Pressure Trip Discharge Temp Trip LED2 LED3 LED4 LED5 LED6 Flash Flash Flash Flash Flash Flash Flash Flash Flash Flash All Flashing Very Rapidly Flash Flash Flash Flash Flash Models with wireless handsets have three LED’s on the units which light up to show operational, or fault conditions. In general the codes are as right, but there are other codes available. Model References are A=ASY7A /R B=ASY9/12A/R C=ASY14/17A /R D=ASY20/30/A /R ABY14-24A /R & AUY12/18AG/RG E=ABY36/45A F=ABY36/45R G=AUY18/45A Unit Code Means:- Red Green Yellow All All All All All D,E,F All G A,B,G D,E,F E,F C D,E,F E,F D,E,F F G B,E,F F C F OD F OD F OD F OD F F F F Power On Timer Mode Louvre On HP Defrost Cont. Test Power Fail PCB Failure Room Sensor Fault Sensor Fault Room Sensor Open/Fail Room Sensor Short Room Sensor Fault Pipe Sensor Open Pipe Sensor Short High Water Comms Failure High Water Fan Failure 3ph Reversal Pipe Sensor Fault Pipe Sensor Open Pipe Sensor Short Temp Sensor Open Temp Sensor Short Discharge Sensor Open Discharge Sensor Short High/Low Pressure High Discharge Temp On On On Long pulses Cont. Pulse On Cont. Short Pulse 1 Short Pulse 2 Short Pulses 2 Short Pulses 2 Short Pulses 3 Short Pulses 3 Short Pulses 3 Short Pulses 4 Short Pulses 5 Short Pulses 6 Short Pulses 6 Short Pulses Rapid Pulse Long Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse 7 Off On On or Off Off Cont. Pulse Cont Long Cont. Short Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Long Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse Rapid Pulse 2 Short Pulses 3 Short Pulses 3 Short Pulses 3 Short Pulses 4 Short 4 Short Pulses 5 Short Pulses 5 Short Pulses 6 Short Pulses Short Pulses Off Off On Off Off Pulses Off Off Off Off Off Rapid Pulse Off Off Rapid Pulse Off Off Off Off Off Off Off Rapid Pulse Pulses Off Rapid Pulse Off Rapid Pulse Off Off Sensor Resistances – Use to Check Thermistors across the range Sensor Air Temperature Sensors Indoor Pipe Sensor Outdoor Pipe Sensor Discharge Sensor www.climatecenter.co.uk At 10°C At 20°C At 30°C 20K Ohms 103K Ohms 10K Ohms 646K Ohms 13K Ohms 63K Ohms 6K Ohms 395K Ohms 8K Ohms 40K Ohms 4K Ohms 250K Ohms Trouble Shooting Wireless Remote Control Models – Diagnostics