INTERNAL CAPACITY CONTROL VALVES FOR 4, 6, AND 8

advertisement

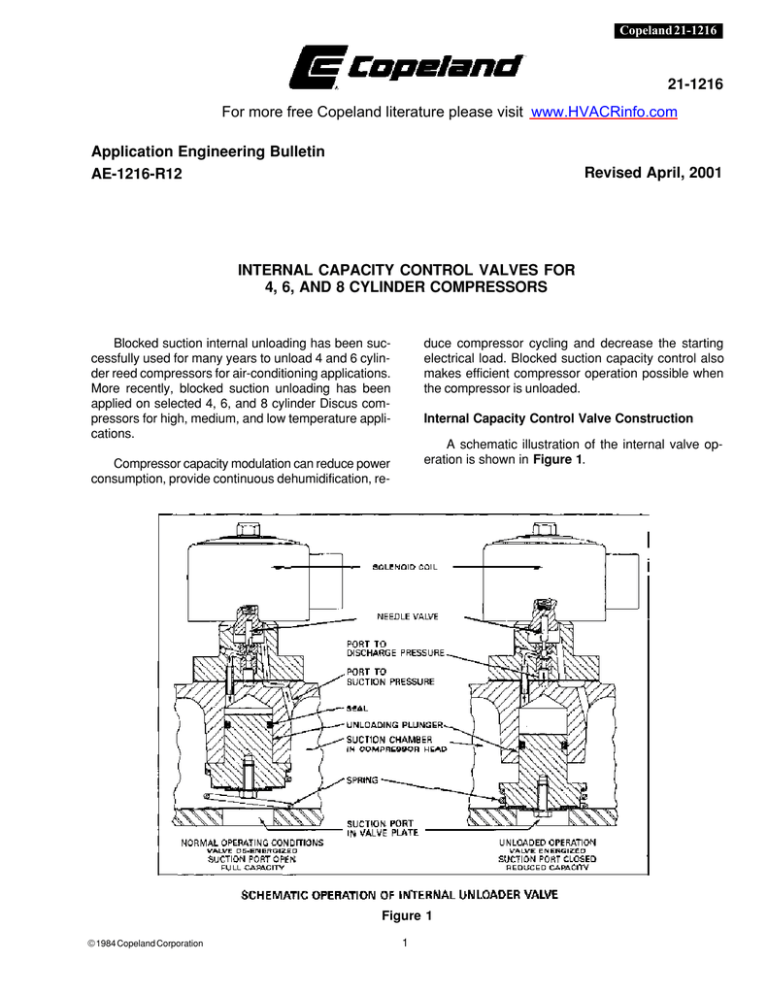

Copeland 21-1216 21-1216 For more free Copeland literature please visit www.HVACRinfo.com Application Engineering Bulletin AE-1216-R12 Revised April, 2001 INTERNAL CAPACITY CONTROL VALVES FOR 4, 6, AND 8 CYLINDER COMPRESSORS Blocked suction internal unloading has been successfully used for many years to unload 4 and 6 cylinder reed compressors for air-conditioning applications. More recently, blocked suction unloading has been applied on selected 4, 6, and 8 cylinder Discus compressors for high, medium, and low temperature applications. duce compressor cycling and decrease the starting electrical load. Blocked suction capacity control also makes efficient compressor operation possible when the compressor is unloaded. Internal Capacity Control Valve Construction A schematic illustration of the internal valve operation is shown in Figure 1. Compressor capacity modulation can reduce power consumption, provide continuous dehumidification, re- Figure 1 © 1984 Copeland Corporation 1 Copeland 21-1216 In the normal (full capacity) operating position with the solenoid valve de-energized, the needle valve is seated on the lower port, and the unloading plunger chamber is exposed to suction pressure through the suction port. Since the face of the plunger is open to the suction chamber, the gas pressures across the plunger are equalized, and the plunger is held in the open position by the spring. When the solenoid valve is energized, the needle valve is seated on the upper port, and the unloading plunger chamber is exposed to discharge pressure through the discharge pressure port. The differential between discharge and suction pressure forces the plunger down, sealing the suction port in the valve plate, thus preventing the entrance of suction vapor into the unloaded cylinders. INTERIOR - HEAD FOR INTERNAL CAPACITY CONTROL REED COMPRESSORS Figure 3 Figures 4 and 5 show the pressure port connections to the unloading solenoid valve. The action of the valve determines which pressure is applied to the unloading valve plunger. The gasket is a universal gasket fitting all 4, 6, and 8 cylinder reed and Discus compressors. The seal on the unloading plunger minimizes any leakage in pressure so that a pumpdown cycle may be used with the valve either energized or de-energized without excessive compressor cycling. 4R-6R Copelametic Compressors A typical capacity control valve plate for conventional Copelametic compressors is shown in Figure 2. Figure 4 Figure 2 An interior view of the internal unloading head is shown in Figure 3. Note that the unloader plunger chamber has been cast in the head, but that the gasketed surfaces of the head are the same as a standard head. A standard head gasket is used with the internal capacity control valve - no special unloading gasket is required. UNIVERSAL GASKET FOR INTERNAL UNLOADING SOLENOID VALVE PART # 020-0783-00 Figure 5 2 Copeland 21-1216 Copelametic Discus Compressors Application The same basic internal unloading mechanism is used on both Discus and conventional compressors. Figures 6, 7, 8 and 9 show typical Discus construction. When an unloading valve in a operating system is switched from the loaded to the unloaded position, a new system balance takes place. In air-cooled systems the suction pressure will rise and the condensing pressure will drop. In water-cooled systems the suction pressure will rise, but the condensing pressure will remain substantially the same. The pressure or temperature control should have as wide a differential as necessary to prevent rapid cycling of the unloading valve. Rapid cycling can lead to wear and premature failure of the solenoid valve and/or internal unloader components. The unloader cycle rates should be limited to no more than 10 to 12 per hour to ensure satisfactory unloader life. A wider differential will be required with the pressure control method than the temperature control method because of the thermal mass (or flywheel effect) of the cooled medium. Figure 6 Application Requirements Because of the decreased volume of suction vapor returning to the compressor from the system and available for motor cooling, the operating range of unloaded compressors must be restricted. Reed style compressors should be limited to a minimum evaporating temperature of 25°F when operating unloaded. Discus compressors can be operated unloaded below 25°F with the addition of head cooling fans and oil coolers. See Tables 1 and 2 for specific requirements for Discus. The capacity control valve is in the normal discharge position (loaded) when de-energized, and in the unloaded position when energized. The solenoid valve may be energized either by means of a reverse acting low pressure control or a temperature control thermostat. On six cylinder compressors with two unloaders, two step thermostats may be employed, but if sequence control of unloaders from compressor suction pressure is desired, two separate controls are necessary. Figure 7 MOUNTING PAD ON SHORT COMPRESSOR HEAD FOR INTERNAL UNLOADING SOLENOID VALVE COPELAMETIC 4D*1 AND 6D*1 DISCUS COMPRESSORS MOUNTING PAD ON TALL COMPRESSOR HEAD FOR INTERNAL UNLOADING SOLENOID VALVE COPELAMETIC 4D*3 AND 6D*3 DISCUS COMPRESSORS Figure 8 Figure 9 3 Copeland 21-1216 Although the leak back rate when the coil is energized during a compressor off cycle is minimal, to prolong the solenoid coil life it is recommended that the capacity control solenoid valve be de-energized when the compressor is not operating. supply. In such cases the unloading solenoid valve and control may be connected as shown in Figure 10, or they may be connected in parallel with the compressor contactor coil as in Figure 11. Booster Compressors In control circuits operating at line voltage, the solenoid valve and control can be connected to the load side of the contactor as in Figure 9. The unloader solenoid valve will then be de-energized and closed when the compressor is not operating. See Application Bulletin 4-1288 for requirements. Demand Cooling Applications Demand Cooling is not approved for compressors with modulation. See AE 4-1287 for additional information. On large installations, the control circuit may have a power source independent of the compressor power Figure 10 Figure 11 4 Copeland 21-1216 Piping IMPORTANT - Unloader Valve Location One very important factor to be considered in the design of any system equipped with an unloading type compressor is the gas velocity. It must be maintained at a sufficiently high level to insure oil return to the compressor when it is unloaded. When an unloading type compressor is employed on a single evaporator with a single suction line, it may be necessary to employ double risers constructed as shown to insure oil return. (See Copeland Refrigeration Manual AE104). 4R: right bank 4D: right bank 6R, 33%: right bank 6R, 67%: right & left bank 6D*1, 33%: right bank 6D*1, 67%: right & left bank 6D*3, 33%: right bank 6D*3, 67%: right & top bank 8D: lower right & upper left banks The right bank is the terminal box side. While unloaders could be physically mounted on the other banks, to do so would interfere with the internal crankcase pressure suppression and prevent proper oil return. If the unloading type compressor is to be installed on a system employing multiple evaporators with solenoid valves to control the flow of refrigerant to the evaporators, a separate suction line should be run from each evaporator to the machine room and there connected into a common line, which must slope downward toward the compressor. See Figure 12. Capacity Control Variations (6D*1-vs-6D*3) There are two styles of unloader heads presently used by Copeland. To identify the two styles see Figures 8 & 9. The hole configuration is different depending on what model compressor you have. Expansion valves for systems with unloading compressors must be able to control the refrigerant flow while the compressor is unloaded as well as when loaded. They generally cannot maintain stable control below 25-35% of their rated capacity and, therefore must not be oversized for the fully loaded condition. Prior to 1991 all 4D & 6D compressors were the *1 version (see Figure 8). This style unloader used gasket 020-0690-00. The new *3 model (see Figure 9) has different hole configurations and requires a different style unloader gasket. The new gasket (see Figure 5) was made to fit both the *1 & *3 models. Field Service and Conversion 4-6 Compressors Standard 4 and 6 compressors may be converted to internal capacity control models by means of the appropriate conversion kit. See Table 1 for Part Numbers. When changing from the *1 to the *3 type head you must do the following: To convert a standard reed compressor to unloading, it is only necessary to remove the existing head, install a new head gasket, install the new head and unloader assembly, and install the solenoid valve. A new valve plate is also required on Discus compressors. Torque head bolts to 375 inch pounds on reed compressors and 550 inch pounds on Discus compressors. • Use gasket (Figure 5) on all 4D/6D unloader type heads. Make sure the tab of the gasket is aligned with the tab of the head. • The unloader valve pin fits in the small hole on the *1 style head. For the *3 style head the unloader valve must be turned 180 degrees and the valve pin fits into a much larger hole. If the old style gasket is used on a *3 head, the port to the plunger will be covered up and the unloader will not work. Figure 12 5 Copeland 21-1216 Non unloading Operation The 4, 6, and 8 cylinder capacity control models are shipped from the factory with a shipping plate and gasket on the unloading pad, and the unloading valve and coils as a “ship remote” item. These compressors can be operated continuously full loaded without the valve and coil installed if desired for any reason. The gasket needs to be replaced when mounting the valve and coil for unloading. See Figure 14. Installation 020-0783-00 Figure 14 The unloading valve and coil assembly (240 volt) is included in the capacity control model standard bill of material as a “ship remote” item. The capacity control model can be operated without the unloading valve and coil installed, if desired for any reason. If mounting the valve and coil for unloading, use the correct gasket per the following instructions. Unloading Valve Gasket. Use this gasket when installing the unloading valve and coil on all 4, 6, and 8 cylinder models. It is supplied in the gasket kit. 020-0931-00 Figure 13 Shipping Gasket / Full Load Gasket. This gasket is under the shipping plate covering the unloader mounting pad on the cylinder head. There is no need to remove the plate or change gaskets if the compressor is to be operated without a valve and coil. If a compressor was previously operated with valve and coil installed, but is to be converted back to non-unloading (without valve), this gasket should be used under a shipping plate. 6 Copeland 21-1216 Table 1 Medium Temperature Discus Models - Unloaded Operation Criteria Evaporator Range +25°F. To -5°F. • • • Head cooling fan required. Maximum condensing temperature............................................................140°F. Minimum evaporating temperature........................................................... -5°F. Table 2 Low Temperature Discus Models - Unloaded Operation Criteria Evaporator Range -5°F. to -40°F. • • • • • Head cooling fan required. Oil cooler required. Maximum condensing temperature..........................................................130°F. Minimum evaporating temperature for 4D and 6D (33% unloaded)............-40°F. Minimum evaporating temperature for 6D (66% unloaded)........................-25°F. NOTE: Minimum evaporating temperature for 4R, 6R, 8R models is +25°F when unloading. __________________________________________________________________________________________ CAUTION: Because of lower suction gas velocity when unloading low and medium temperature compressors, adequate oil return must be assured through piping design or defrost control. __________________________________________________________________________________________ Copeland Corporation Sidney, OH 45365-0669 Printed in U.S.A. 7