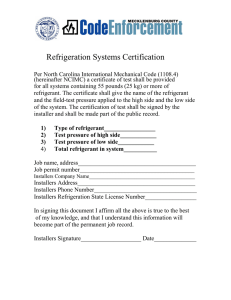

Installers Best Practice Guide

advertisement