HMC 542_BA_EN_V1.0_ehb5057 Tünnissen

advertisement

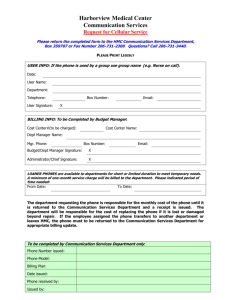

Instructions manual HMC 542 Servicepersonal Version 1.0 Weitergabe und Vervielfältigung dieser Unterlagen, sowie Verwertung und Mitteilung ihres Inhaltes nicht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte für den Fall der Patenterteilung oder Gebrauchsmuster-Eintragung vorbehalten. Manual HMC 542 Short Instruction HMC 542 View SET-Button Display Run LED Function buttons F1 – F2 Fault LED Power supply and connector Abb. 1: HMC 542 , detailled Frontview Function of buttons Button SET Function Display of selected parameters; to quit blinking Fault-LED; to quit settings Green Run-LED; glows if the unit is in use; while preheat the LED is blinking Red Fault-LED; is blinking when an error occurred Function button F1: last display; reduce a number, a value or the engine speed ttertaste Function button F2: next display; increase a number, a value or the engine speed Drehzahl XXXX Upm Display with 16 digits in two lines 1/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual Index Short Instruction ..................................................................................................................... 1 HMC 542 View .................................................................................................................... 1 Function of buttons.............................................................................................................. 1 1. In General ................................................................................................................... 3 1.1. Introduction ............................................................................................................. 3 1.2. Important Advices for using ..................................................................................... 3 1.3. Overhauling of equipment ....................................................................................... 3 2. Use of HMC 542 ......................................................................................................... 5 2.1. Installation ............................................................................................................... 5 2.2. Switch on and off..................................................................................................... 5 2.3. SET-button .............................................................................................................. 5 2.4. Arrow buttons .......................................................................................................... 5 3. Change of settings ...................................................................................................... 5 3.1. Overview ................................................................................................................. 6 3.2. Explanation of parameters ...................................................................................... 7 3.3. Further adjustments and explanations..................................................................... 8 3.3.1. 3.3.2. 3.3.3. 3.3.4. How to reset the total hours counter .................................................................................. 8 Energized to run solenoid (ETR) ........................................................................................ 8 Energized to stop solenoid (ETS)....................................................................................... 8 How to set engine speed values ........................................................................................ 8 4. Display of the operating values ................................................................................... 9 5. Faults .......................................................................................................................... 9 6. Technical Data .......................................................................................................... 10 7. 6.1. Inputs .................................................................................................................... 10 6.2. Hardware .............................................................................................................. 10 6.3. Software ................................................................................................................ 10 6.4. Wiring diagram ...................................................................................................... 11 Dokumentinformationen, Historie .............................................................................. 12 Imprint .................................................................................................................................. 12 © ehb Errors excepted 2/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen Manual HMC 542 1. In General 1.1. Introduction HMC 542 has a lot of features to control an engine and a woodchipper. The features can be adapted for different types of engines. • automatic control of feed by engine speed • monitoring of alternator, temperature, oil pressure, engine bonnet, chute and clutch • programmable preheat and after glow time • suitable for ETS or ETR solenoids • all inputs can be programmed as normally open or normally closed • programmable service intervals • resettable hour meter for daily hours • hour meter for total hours • four languages 1.2. Important Advices for using Usage Safety The unit has only to be operated with the delivered accessories. Protect the unit against humidity and dust. Clean the unit only with a light humid drapery. While operating the unit take care of the requirements and regulations of the local authorities and employer’s liability insurance associations! Do not operate the HMC 542 in the proximity of electromagnetic fields. Take care of the temperature advices to 6.2. Your HMC 542 contain important operating data, protect against burglary. Stockage If you do not use the HMC 542, stock it only in between the temperature range that is written in 6.2. Shipping If you have to ship the HMC 542, you have to use the original packaging or something similar. In case of using a packaging material that is not adequate the HMC 542 can be damaged. In this case you lose the warranty of the product. Maintenance The HMC 542 needs no maintenance during its whole operating life. Opening the HMC 542 The HMC 542 contains no exchangeable or fixable parts for the customer or external maintenance staff. 1.3. Overhauling of equipment If there is a repair needed, then please send the unit to: ehb electronics gmbh Hans-Böckler-Str. 20 30851 Langenhagen Please describe the failure as detailed as possible and put the written paper into the box. This enables our service department to find the failure easier and we can send you the unit back as quick as possible. 3/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual Warning When replacement parts are required, ehb electronics recommends using replacement parts supplied only by ehb electronics. Failure to heed this warning can lead to premature failure, product damage, personal injury or death. ehb electronics GmbH is exclusively responsible for the professional execution of the works as well as for the normal condition of the assigned material. Claims of compensation, e.g. substitution of lost of profit or the substitution of direct or indirect consequential loss, e.g. the loss of data are excluded. NOTE! Damage by improper packing of the equipment with the dispatch and/or foreign interferences lets the warranty expire! © ehb Errors excepted 4/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen Manual HMC 542 2. Use of HMC 542 2.1. Installation HMC542 is to be connected according to the wiring diagram to the power supply, sensors and actuators of the chipper 2.2. Switch on and off The HMC 542 is switched on with the key start (turn to position 1). The chipper can be started after the preheat time (turn to position 2). After start of the engine, the chipper speed is displayed (see at 3.1). To stop the and the chipper and switch off the HMC542 turn the HMC542 into the Position “0” HMC542 has to be connected permanent to the battery + to enable the storage of parameters like running hours after the engine was stopped. 2.3. SET-button If you want to change settings on the device, hold the SET button pressed, while the ignition key is turned into position 1, until the field of code entry appears. Each digit of the code has to be confirmed by pushing the SET button. In addition, you need the button to get in the sub-menus of programming or display mode and to quit your entry . 2.4. Arrow buttons In normal operation, the arrow buttons are used to increase and to decrease the engine speed (RUN and IDLE. In the parameterization mode, use the arrow keys to navigate the various settings in the main and submenu and in the "selection / input" (see table in paragraph 3.2). In addition, use the arrow keys to enter the digits in the code and for reducing or increasing a value of the parameters. 3. Change of settings If you want settings different than the factory defaults settings, the HMC 542 can be programmed after the initial installation. If you want to make such a change, please contact the manufacturer of your chipper To enter the parameterization mode, press the SET button while the ignition key is turned into position1, until the field for entering the codes appears. ehb electronics Hannover MC 542 Version x.x Code 0000 Now please select with the arrow keys the code 1234 and confirm this with the SET button. Next, go to the box “function <<select>> ", as shown from the schedule below. Use the arrow keys to navigate in the main and sub-menu and in the “selection/input” of the various options. With the SET button you confirm the offered or selected option. You leave the sub-menu by confirming "back next <<OK>>" with the SET button. 5/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual 3.1. Overview Main menu arrow SET Minimum speed Left arrow Right arrow FUNCTION Rated speed SET in decimal steps 0-4000 rpm SET input Maximum speed SET in decimal steps 0-4000 rpm SET input Return speed SET in decimal steps 0-4000 rpm SET input Pulses per Rev SET in steps of 0,1 0-510,0 SET input N/S solenoid SET ETR; ETS SET choice back SET back to „FUNCTION“ SET ETR; ETS SET choice Pre-Heat Time SET in seconds 0-999 SET input Post-Heat Time SET in seconds 0-999 SET input Start glow SET yes; no SET choice back SET back to „MOTOR PARAMETER“ SET Aux. 3; extern Stop SET choice SET normally close; normally open SET choice Temperature NoNc SET normally open; normally close SET choice Clutch NoNc SET normally open; normally close SET choice Bonnet NoNc SET normally close; normally open SET choice Chute NoNc SET normally open; normally close SET choice Alternator stop SET yes; no SET choice Clutch sw fitted SET yes; no SET choice Bonnet stop SET yes; no SET choice Chute stop SET no; yes SET choice back SET back to „INPUTS“ arrow left right left right arrow Oilpressure NoNc arrow SET Total hours left right remark SET input SET Aux. 3 / Ext. Stop SERVICE Pfeiltaste SET in decimal steps 0-4000 rpm MOTOR PARAMETER SET Fuel solenoid INPUTS choose/ input Sub menu SET No input possible, only display SET display Day hours SET 0-99:59 hours:min. SET input Reset day hours SET yes SET choice Next oil change SET No input possible, only display SET display Next service 1 SET No input possible, only display SET display Next service 2 SET No input possible, only display SET display Oil change intrv SET in hours, 0-990 Std. SET input Service 1 intrv SET in hours, 0-990 Std. SET input Service 2 intrv SET in hours, 0-990 Std. SET input back SET back to „SERVICE“ © ehb Errors excepted 6/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen Manual left right SET Deutsch; Englisch; Español, Francais SET choice Standard display SET engine speed; daily hour meter; total hours; failures SET choice Backgroundlight SET on; off SET choice Contrast SET 0-999, illegible over 20 SET input back SET back to „DISPLAY“ SET Language arrow DISPLAY EXIT HMC 542 SET You get back to the display mode 3.2. Explanation of parameters Parameter Explanation FUNCTION Minimum speed If the engine speed falls below this limit, the feeder switches off. Rated speed If the feeder switches off because of over speed, the roll will turn on again when the speed falls below this value. Maximum speed If the speed gets over this value the feeder will be switched off. Return speed If the speed gets over this value the feeder will be switched on. Pulses per Revolution Numbers of pulses, the proximity switch sends per revolution of cutter spindle. N/S solenoid Choose the required type of solenoid. You find an explanation on 3.3.2 and 3.3.3 MOTOR PARAMETER Fuel solenoid Choose the required type of solenoid. You find an explanation on 3.3.2 and 3.3.3 Pre-Heat Time Fix a preheat time from 0 to 999 seconds. Post-Heat Time 0-999 seconds Start glow To glow while the starter is activated INPUTS Aux 3, Chute/ External Stop Choose if you use Auxiliary 3 (Chute switch) or external stop Oilpressure NoNc up to You have to choose for each switch normally open or normally closed. Chute NoNc Alternator stop If there is detected an error on the alternator input, the unit stops (Yes) or there will only be a warning by blinking Fault-LED (No) Aux1/Clutch sw fitted If the clutch will be opened, the Fault-LED blinks (No) or the unit stops (Yes) A clutch switch can be used to activate or lock the IDLE-RUN buttons for speed changes Aux 2/Bonnet stop If the bonnet will be opened the Fault-LED blinks (No) or the unit stops (Yes) Aux. 3/Chute stop If the chute will be moved the Fault-LED blinks (No) or the unit stops (Yes) 7/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual SERVICE Total hours There is no input possible. Day hours No input, only display of the hours from 0-99:59 hrs. Reset day hours Choose „Yes“ if you wish to reset the counter of daily hours. Next oil change / Next service 1/ Next service 2 No input, only display. At the given time the message appears on the display. Oil change interval Enter the interval for oil service (0 to 999hrs.). At the given time the message appears on the display. Service 1 interval/ Service 2 interval You have the possibility to determine any service interval. At the given time the message appears on the display. DISPLAY Language German, English, Spanish or French language of the menu Standard display Choose the value that shall appear first on the display. Backgroundlight Yes or No Contrast Enter the intensity of the display contrast. 3.3. Further adjustments and explanations 3.3.1. How to reset the total hours counter To reset the total hour meter push the SET-button while turning the key start in position 1. Afterwards enter the code 9191. If you confirm the code with the SET-button the total hours are deleted. 3.3.2. Energized to run solenoid (ETR) This solenoid releases the fuel supply and has to be triggered while the engine is running. 3.3.3. Energized to stop solenoid (ETS) This solenoid has to be triggered to stop the engine. If you turn the key start in position “0”, the solenoid will be triggered for 20 seconds. After the engine is stopped, the HMC 542 is disconnected from power supply. 3.3.4. How to set engine speed values The setting of the speed values with the help of four parameters, guarantees the stable operation of the engine. The following overview of the scheme should serve faster understanding: The rated speed is the speed at which the feeder is switched on. If during the operation speed gets below the minimum speed, the feeder is stopped. The engine will increase the speed because the load is reduced. When the return speed is reached, the feeder will start again. If during the operation the speed exceeds the maximum speed, the feeder is stopped also. When the rated speed is reached, the feeder will start again. © ehb Errors excepted 8/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen Manual HMC 542 4. Display of the operating values When the HMC 542 is ready for use, the unit diplays the operating values as follows. The vertical arrows stands for the SET-button, the horizontal arrows stands for the arrow-button In 3.1 choosen standard display SET automatically Chipper speed Error: Total hours <<display>> <<display>> <<display>> Arrow-button Arrow-button Daily hours <<display>> Arrow-button 5. Faults A warning fault will be shown by a flashing Fault-LED. You can read out the fault by scrolling through the menu. A Fault that cause an engine switch off is shown in the display. Example: Error Oil pressure 9/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual 6. Technical Data 6.1. Inputs On ground switching inputs a failure is detected if the voltage level falls below 10% of the operating voltage. On plus switching inputs a signal is detected if the voltage level gets over 90% of the operating voltage. 6.2. Hardware Parameter Conditions Voltage UB Interference voltage UB Voltage peak UB Current consumption at UB 8-24V 6Vss, 50Hz Limits Notes Min. Typ Max. 10V 12...24V 32V 14V 28V 2ms 200V <1mA 200 mA Operating temperature -25°C +85°C Temperature at stock -40°C +85°C Humidity (not condense) Ignition off/ on Static t > 50°C temporary discoloration of the display 48h 95% SAE J1378 Vibration 6h, 10-80Hz 20g SAE J1378 Shock 72x, 9-13ms 44g LC-Display 55g 2x16 digits Size housing SAE J1378 Alpha numeric 80 x 120 x 100 mm Mounting with shock mount Protection category IP54 Frontside 6.3. Software While starting the unit the software number is shown in the display. HMC 542 Version x.x If you have any questions concerning this unit, please note the software number. © ehb Errors excepted 10/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen Manual HMC 542 6.4. Wiring diagram 11/12 © ehb Errors excepted Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen HMC 542 Manual 7. Dokumentinformationen, Historie Projekt: HMC 542 Dokumentenart: Technische Dokumentation Version: 1.0 Erstellt am: 30.07.2008 Autor: Mühlhausen/ Klages ehb electronics gmbh, Hannover Änderungen: Version: 1.0 Bearbeitung: Übersetzung der Version 1.0 DE am: von: 30.07.2008 Mü Imprint Messen – Steuern – Regeln Industrie Hard- und Software Dieselmotorüberwachungen Service Tel. Fax. eMail +49-511-123 207-0 +49-511-123207-77 info@ehb-electronics.de Hans-Böckler-Str. 20 D – 30851 Langenhagen www.ehb-electronics.de © ehb Errors excepted 12/12 Y:\Vertrieb\1 - Produkte\a - Produktinformationen Vertrieb\HMC 542\Bedienungsanleitung\HMC 542_BA_EN_V1.0_ehb5057 (Tünnissen).doc Bedienungsanleitung.doc • Stand/Version: 25.02.2005/00 • Layout: Gottschalk • \\Ehelec-nts-000\EHELEC\Iso 9001\Formblätter\Vorlagen