(*) Application of Sweep Frequency

advertisement

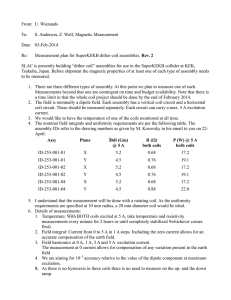

A1-205 21, rue d’Artois, F-75008 PARIS http : //www.cigre.org CIGRE 2012 Application of Sweep Frequency Response Analysis (SFRA) for inter-turn detection of in medium-voltage coils manufacturing. C.A.PLATERO (*), F.BLÁZQUEZ, F. R. BLÁNQUEZ, E. REBOLLO Universidad Politécnica de Madrid Spain B. BATLLE OMICRON Spain E. FERNANDEZ-SANCHEZ ABB Spain SUMMARY It is known that for some years it has been developed a technique based on the sweep frequency response analysis (SFRA) for the diagnosis of power transformer windings [1]-[6]. Since the first works to nowadays many developments and improvements have been made. The relevance of this method has resulted in the creation of new standards for applying the method, such as CIGRE and IEEE. Since its appearance, the industrial interest of this technique lies in the possibility of identifying small strains that could appear in the coils of power transformers, as a result of forces that occur during a short circuit or any possible shock during transport. Basically, this technique is based on the analysis of the impedance of the windings in the frequency domain. Given that the winding can be modeled as an equivalent circuit with a complex network of capacities, inductances and resistances, its frequency response is unique. Thus, any alteration in the winding results in a variation of the equivalent circuit and therefore its frequency response changes too. However, despite its apparent advantages in power transformers, the SFRA technique has been practically unused in the diagnosis of rotating machines. This is because the high frequency equivalent circuit of the windings rotating machines is more complex than the transformers: the stator winding is divided into slots, and there is a rotor winding. Moreover, in some cases the relative position between rotor and stator can significantly influence the (*) carlosantonio.platero@upm.es measurements. The authors of this paper conducted a preliminary study using the SFRA for detecting and locating faults in the stator windings of synchronous machines. This study concluded the high potential of SFRA to locate and identify a fault in salient poles rotating machine, maintaining the position of the rotor to avoid variations in the magnetic circuit structure [7]. The complete and correct interpretation of the results is difficult. It will be necessary to carry out many tests on different machines, in order to have a large database and interpret the results of SFRA correctly. A first step in this verification process would be to use the SFRA to test form coils during the manufacturing phase. Thus, the purpose of the present studies has been the detection of deformations and inter-turn faults within the coils. Using real medium-voltage coils, the first stage of this project has been the study of the grounding connections. Given that the coil is normally inside the stator of the machine, the grounding conditions of the individual coil in study could be relevant. In this paper the results of the tests that have been carried out related to this topic are described. Once the grounding conditions were fixed, the coil under test has been modified, as it will be described, in order to perform inter-turn faults. After conducting several tests, the results have been analyzed and the conclusions allow corroborating that the inter-turn faults in motor medium voltage coils can be detected and, in further studies, the faults could be located. KEYWORDS Fault diagnosis, fault location, frequency response analysis. 1 Ground connection The normal operation of the coil in the slots is electrically equivalent to insert the coil under test in a tailor made structure connected to earth. This tailor made structure would be specific for the test and only useful for one type of coil. Thus, the tests would be rather costly. On the other hand, it would be the best to perform the tests without any additional devices or elements, and even without any additional earth connection in the coil, just placing the coil on an insulated surface. The coils under test in the laboratory are shown in Figure 1. The main points of the coils have been named as shown in the figure, and they are used in the paper figures to identify each test result. These coils have eleven turns, and the inter-turn faults (with or without resistance) have been performed between contiguous turns. Figure 1: Coils under test Several tests have been carried out with different earth connection, trying to cover all the possible layouts. The results obtained connecting each point to ground are shown in Figure 2, where the meaning of each color is described at the bottom of the figure. As it is shown, the frequency responses of the coils are independent of the grounding point and are similar to the reference (source1), ungrounded coil. Figure 2 Results of the SFRA connecting multiple points to ground 2 In order to perform the SFRA test of the coil in a more realistic scenario, the second coil has been wrapped with foil, so the capacitance to ground of the coil is higher than in insulated condition (reference case). The results, as it is shown in Figure 3, are similar to the results without foil. Figure 3 Results of the SFRA connecting multiple points to ground and wrapped with foil. After analyzing the tests results, we conclude that the main influence in regards to SFRA test for detecting inter-turn faults is the capacitance between turns. The influence of the capacitances to earth is not significant. Considering these results, the ungrounded configuration has been chosen, because its simplicity. Despite of the capacitance to earth of the winding is lower and the frequency response of the coils should be different to their response when they are inserted in the stator core, this should not be a problem as this is a comparative test, based on a reference and successive test performed in the same conditions. Thus, the reference test should be done on an insulated surface. This is an advantage because of its simplicity, and the detection of interturns faults could be performed by SFRA, as it will be explained in the following section. Inter-turn SFRA tests In order to carry out the inter-turn faults, the isolation of the coils has been removed in multiple points as shown in Figure 4. The way these tests have been performed in the laboratory is described in Figure 5. 3 Figure 4 Coil sector for inter-turn faults tests Figure 5 Test procedure layout Numerous tests have been carried out in after artificially short-circuited different turns of the coil. To differentiate between real short-circuits and incipient ones, the tests have been performed with and without a fault resistance, and using different resistance values to simulate the faults. In order to summarize, only the non-resistance tests results are shown in the Figure 6. As expected the SFRA results are different when testing with an inter-turn fault. Just looking at the lower frequency range (in this case around 2MHz), we observe a similar behavior to the effect of the core when we talk about power transformers. This is a parallel resonance due to the change from inductive to capacitive behavior. As an inter-turn fault will affect the inductance and the capacitance, it's expectable to see these differences in the frequency response. Additionally, when the inter-turn fault changes, the ratio between inductance and capacitance also changes, and the frequency of resonance also changes, increasing when short-circuit is taken away from the voltage source. 4 Figure 6 Results of the FRA in multiple inter-turn fault tests An inter-turn fault can then be clearly detected, comparing the frequency response of the faulty coil to the reference test. This is then an easy way to find out the existence of a manufacturing defect or inter-turn fault before inserting the coil in the stator core, and a cheapest and saver alternative to the more standard surge test, where high voltage is applied. The exact location of the fault inside the coil will remain a major goal for further studies, using a higher number of different coils in order to obtain a relevant tests results database. Conclusions In this paper, the results of tests using the SFRA in motor medium-voltage coils are presented. These tests have been carried out in MV form coils in order to detect turn to turn faults during the manufacturing process in the factory. The number of turns and the fault position has been chosen in each test, so numerous tests have been performed in fully controlled conditions, which is essential for proper interpretation of results. After the analysis of the results, it appears that SFRA can easily and reliably be used to detect inter-turn faults in medium voltage coils. This method can be used during the motor manufacturing process, and one of the advantages of this method compared to those currently used, is that it should be possible to indicate the exact location of the fault and, possibly, at what manufacturing stage it happened. This is particularly interesting in the manufacture of medium voltage windings. In a future research, the behavior patterns for each type of defect in the coil should be investigated, making this test very useful in the diagnosis of stator windings, mounted on the stator core of the machine. 5 BIBLIOGRAPHY [1] [2] [3] [4] [5] [6] [7] Wilk, A.; Adamczyk, D.; , "Investigations on sensitivity of FRA method in diagnosis of interturn faults in transformer winding," Industrial Electronics (ISIE), 2011 IEEE International Symposium on , vol., no., pp.631-636, 27-30 June 2011. P.T.M. Vaessen, E. Hanique, “A new frequency response analysis method for power transformers,” IEEE Trans. Power Delivery, vol. 7, no. 1, pp. 384 – 391, 1992. M. Kraetge1, P. Krüger1, Fong. “Frequency Response Analysis – Status of the worldwide standardization activities”, International Conference on Condition Monitoring and Diagnosis, April 21-24, 2008 Beijing, China M. Wang, A.J. Vandermaar, K.D. Srivastava, “Improved detection of power transformer winding movement by extending the FRA high frequency range,” IEEE Trans. Power Delivery, vol. 20, no. 3, pp. 1930–1938, 2005. W. Zhongdong, Jie Li, D.M. Sofian, “Interpretation of Transformer FRA Responses - Part I: Influence of Winding Structure,” IEEE Trans. Power Delivery, vol. 24, no. 2, pp. 703–710, 2009. Pleite J., Olías E., Barrado A. Lázaro A. and Vázquez J. “Transformer Modeling for FRA Tecniques” IEEE-PES Asia & Pacific. Transmission and Distribution. 2002. Yokohama, Japón. 2002 Platero, C.A.; Blázquez, F.; Frías, P.; Ramírez, D.; , "Influence of Rotor Position in FRA Response for Detection of Insulation Failures in Salient-Pole Synchronous Machines," Energy Conversion, IEEE Transactions on , vol.26, no.2, pp.671-676, June 2011 6