Overhead Recloser - City of Palo Alto

advertisement

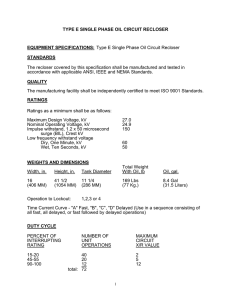

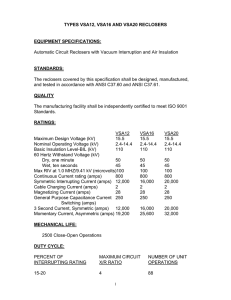

CITY OF PALO ALTO UTILITIES DEPARTMENT SPECIFICATIONS FOR AUTOMATIC CIRCUIT RECLOSERS OVERHEAD TYPE SPECIFICATION NO.: OE-13-08 DATE OF ISSUE: March 12, 2008 Reviewed by: Power Engineer Checked by: Senior Power Engineer Approved by: Electrical Engineering Manager SPECIFICATIONS FOR AUTOMATIC CIRCUIT RECLOSERS OVERHEAD TYPE TABLE OF CONTENTS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. SCOPE......................................................3 STANDARDS..................................................3 RATINGS....................................................3 OPERATING MECHANISM........................................3 LEADS......................................................4 INSULATION.................................................4 GROUNDING..................................................4 PAINT FINISH/RECLOSER TANK.................................4 BUSHINGS AND TERMINALS.....................................5 RECLOSER CONTROL...........................................6 SUBMITTAL REQUIREMENTS.....................................7 DELIVERY...................................................7 Automatic Circuit Reclosers Page 2 March 12, 2008 1. SCOPE These specifications cover electrical characteristics and mechanical features of three phase, 60 hertz, automatic circuit reclosers for pole mounting in a horizontal configuration on the City's high voltage (12470V), 3 phase, 3-wire overhead electric distribution system. Equipment supplied by bidder under this specification shall include: Automatic Circuit Recloser, Electronic Controller, Control Cable, and Pole Mounting Rack. 2. STANDARDS Each recloser shall meet the applicable requirements of the latest edition of all IEEE and NEMA Standards for automatic circuit reclosers and ANSI Standard C37.60, insofar as such standards do not conflict with the requirements of these specifications. In case of conflict, these specifications shall govern. 3. 4. RATINGS a. Maximum Design Voltage 15.5 kV b. Nominal Operating Voltage 12.47 kV c. Basic Impulse Level 110 kV d. Maximum Continuous Current 600 amps e. Symmetric Interrupting Current 10,000 amps OPERATING MECHANISM a. Current interruption shall take place in vacuum interrupters. Oil or SF6 gas shall not be used for current interruption or insulation. b. The recloser shall be mechanically and electrically trip free. c. All three poles of the recloser shall be operated simultaneously by a solenoid controlled spring operating mechanism. The solenoid shall provide energy for closing the main contacts and for storing energy in the opening spring for a tripping operation. c. The operating mechanism shall have a mechanical life of 2000 open/close operations minimum. A mechanical operations counter shall be included, and visible, on the bottom or front of the recloser. d. An operating handle shall be provided to manually trip and lock out the recloser. Automatic Circuit Reclosers Page 3 March 12, 2008 When in the tripped position, the operating handle shall be visible from the ground and electrically disable any closing signal from the recloser control. e. 5. 6. Recloser mechanism open/close times shall perform consistently for control cable lengths from 10 feet to 100 feet. LEADS a. All leads from the interrupters to bushings shall be secured to prevent abrasion of the insulation or weakening of the conductor due to vibration in shipment and in service. b. Terminals, connectors, and current-carrying joints shall have accurately fitted contact and shall be of ample stock for mechanical strength and electrical conductivity. Riveted connections are not acceptable. INSULATION a. The recloser insulation shall consist of a solid dielectric. Oil or SF6 gas are not acceptable. b. The solid dielectric insulation shall provide complete encapsulation of the internal vacuum interrupters. The insulation shall be bonded to the source and load side terminals. c. The solid dielectric shall not contain any environmentally hazardous or toxic materials. 7. GROUNDING The recloser shall be supplied with a grounding connector suitable for connecting to #10 AWG solid - #2 AWG stranded conductors. 8. PAINT FINISH/RECLOSER TANK The recloser shall be capable of meeting the functional specifications shown below and shall meet or exceed EEI Finishing Requirements Latest Revision. a. Tank Color: Unless otherwise specified, the topcoat color shall be ANSI No. 70 sky gray. b. Salt spray (relates to coastal environments and/or presence of snow-melting salts or fertilizers): Scribe to bare metal and test for 1500 hours in a 5% salt Automatic Circuit Reclosers Page 4 March 12, 2008 spray per ASTM B-117. Loss of adhesion from bare metal should not extend more than 1/8 inch from the surface. Underfilm corrosion should not extend more than 1/16 inch from the scribe. 9. c. Crosshatch adhesion (relates to adhesion after scratching of the finish): Scribe to a bare metal a crosshatch pattern and test per ASTM D-3359, latest revision. Use Method A for films thicker than 5 mils, Method B for films between 2-5 mils. There shall be 100% adhesion to the bare metal and between layers. d. Impact (relates to transit and handling damage, and abuse by the public): Impact the test panel with a 160 in-lb falling dart per ASTM D-2794. There should be no cracking or chipping of the paint on the impact side of the test panel. e. Oil resistance (relates to probable contact with mineral oil): Immerse two test panels in mineral oil (or other liquids as specified) for 72 hours, one at room temperature (20 to 25 degrees C) and one at 100 to 105 degrees C. There shall be no apparent changes, such as color shift, blisters, loss of hardness or streaking. f. Exposure (relates to exposure to sunlight and rainfall, loss of gloss, color fading, and chalking): Exposure for 500 hours per ASTM G-53 with a cycle for four hours UV at 55 degrees C followed by four hours of condensation at 40 degrees C. Loss of gloss as a result of this test should not exceed 50% per ASTM D-523. g. Abrasion Test (relates to wear encountered during installation): Test a panel having the minimum dry build thickness (-0, +0.1 mil) using a CS-10 wheel, 1000 gram weight, per ASTM D-4060, latest revision. The number of cycles of abrasion required to wear the coating through to the substrate shall be at least 3000 cycles. h. Recloser shall be fitted with lifting provisions to facilitate installation. i. Recloser shall be fitted with a stainless steel nameplate indicating, at a minimum, serial number, date of manufacture, manufacturer, model, voltage rating, continuous current rating, interrupting current rating, impulse level (BIL) rating, 3line diagram, and dielectric material type. BUSHINGS AND TERMINALS a. The high voltage bushings may be of porcelain or polymer construction. Polymer bushings shall be resistant to UV radiation and tracking. b. High voltage bushings shall have a minimum BIL of 110 kV and a minimum creepage distance of 17 inches. c. High voltage terminals shall be clamp-type, suitable for connecting copper or Automatic Circuit Reclosers Page 5 March 12, 2008 aluminum conductors in the range of 1/0 AWG through 500 MCM. 10. RECLOSER CONTROL The recloser control shall be mounted in a weatherproof cabinet (minimum NEMA 3 rating) which is capable of being padlocked. The cabinet shall be supplied with a grounding connector suitable for connecting to #10 AWG solid through #4 AWG stranded conductors. a. All printed circuit boards shall be conformal coated to prevent control malfunction due to moisture. b. The control shall be fully functional over an ambient temperature range of –40 degrees C to 65 degrees C. c. The control shall be microprocessor based and include overcurrent protection for all three phases and ground. Each phase and ground element shall have user selectable time overcurrent curves including inverse, very inverse, extremely inverse and definite time. The control shall also provide instantaneous or high current trip protection for all three phases and ground. The control shall include sensitive ground fault protection with an overcurrent pickup setting adjustable to 5 amps primary or less, and a definite time delay adjustable to 120 seconds or longer. The control shall include the capability to program up to 3 reclosing operations with reclosing and reset times from 0.2 to 120 seconds. d. The control shall include a digital metering package of Class 1 accuracy which shall provide, at a minimum, the following information: instantaneous values of voltage and current (by phase), load kVA, load kW, load kVAR, and demand values of voltage, current, load kVA, load kW, and load kVAR. Metering data shall be easily accessible from the control panel. The control shall be supplied with inputs for three phase voltage. e. The control shall include a sequence of events recorder. The event recorder shall trigger at fault inception and record time and date stamped fault information in nonvolatile memory. Fault information shall include, at a minimum, voltage, current, protection element status and recloser open/close status for each event. f. The control shall be capable of digital communications with the City’s SCADA system through a communications port located in the control cabinet. The digital communication protocol shall be DNP Version 3.0. g. A self-contained, user replaceable battery with AC charger shall power the control. The battery shall be capable of supplying trip and control power for at least 10 hours after loss of the AC power source. The control shall be capable of monitoring battery health and initiating an alarm if the battery voltage drops below a preset level. Automatic Circuit Reclosers Page 6 March 12, 2008 11. 12. h. The control cabinet shall be fitted with an AC-powered heater and thermostat which are switched off when the control is running on battery power only. i. The supplied control cable shall be 40 feet in length and have separable weatherproof connectors at both ends (recloser and control). SUBMITTAL REQUIREMENTS a. The bidder shall furnish a list of Northern California utilities that have the quoted recloser in service at this time, names of utility references, and contact information. Palo Alto Utilities will only purchase this equipment from vendors who have a history of reliable equipment and responsive customer service, based on a combination of Palo Alto Utilities’ knowledge and reference checks. This assessment is at the sole discretion of Palo Alto Utilities. b. The bidder shall submit drawings and sufficient documentation describing the characteristics of the equipment to be furnished. c. The bidder shall submit a list of any exceptions to these specifications, and that list shall be furnished with the bid submittal. If no exceptions are listed, Palo Alto Utilities will assume the quoted equipment will conform completely to these specifications. d. The bidder shall submit a bid price to include the cost of: Automatic Circuit Recloser, Electronic Controller, 40 foot Control Cable, Recloser Pole Mounting Rack, delivery of the quoted equipment to a designated location in Palo Alto, California, and applicable sales tax (8.25% in Palo Alto). DELIVERY When the best responsive bid has been determined, the manufacturer or Supplier shall provide a one day demo/training session along with a prototype unit at: City of Palo Alto Municipal Service Center 3201 E. Bayshore Road Palo Alto, CA 94303 ATTN: Norm Brown (call 650-496-6902 to schedule) End of Specification Automatic Circuit Reclosers Page 7 March 12, 2008