BUS REVISED EPR Booklet

advertisement

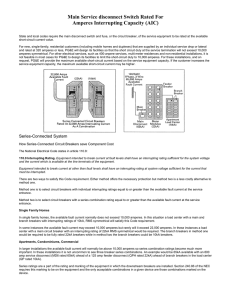

Electrical Plan Review Objectives By reviewing this brochure, the Electrical Inspector, Electrical Contractor, Plan Examiner, Consulting Engineer and others will be able to . . . ■ Understand the importance of overcurrent protection. ■ Understand the meaning and importance of electrical terms commonly used relating to overcurrent protection. ■ Understand and discuss the KEY National Electrical Code® requirements regarding overcurrent protection. ■ Calculate short-circuit currents using the simple POINT-TO-POINT method. ■ Check electrical plans to determine conformance to National Electrical Code® sections that cover shortcircuit currents, interrupting ratings, interrupting capacities, short-circuit ratings, ground faults, grounding electrode conductors, equipment grounding conductors, etc. ■ Verify that circuit, feeder, service, grounding electrode conductors, equipment grounding conductors, and bonding conductors have adequate capacity to conduct safely ANY fault current likely to be imposed on them. ■ Determine let-through current values (peak & RMS) when current-limiting overcurrent devices are used. ■ Apply current-limiting data to protect downstream electrical components that have withstand ratings LESS than the available fault-current at any given point on the system. ■ Realize that whenever overcurrent protection is discussed, the two most important issues are: — HOW MUCH CURRENT WILL FLOW? — HOW LONG WILL THE CURRENT FLOW? ■ Adopt a Form Letter and a Data Required Form that can be used to “log-in” the necessary data relating to available fault currents, interrupting ratings, and let-through currents. ■ Understand that the major sources of short-circuit currents are motors and generators. ■ Understand that transformers are NOT a source of short-circuit current. ■ Know how to ask the right questions. Copyrighted April, 1999 by Cooper Bussmann, Inc., Printed in U.S.A. 1 Electrical Plan Review ® Critical National Electrical Code Sections 250-96(a) General. Metal raceways, cable trays, cable armor, cable sheath, enclosures, frames, fittings, and other metal noncurrent-carrying parts that are to serve as grounding conductors, with or without the use of supplementary equipment grounding conductors, shall be effectively bonded where necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed on them. Any nonconductive paint, enamel, or similar coating shall be removed at threads, contact points, and contact surfaces or be connected by means of fittings designed so as to make such removal unnecessary. 110-3(b) Installation and Use. Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling. 110-9 Interrupting Rating. Equipment intended to interrupt current at fault levels shall have an interrupting rating sufficient for the nominal circuit voltage and the current that is available at the line terminals of the equipment. Equipment intended to interrupt current at other than fault levels shall have an interrupting rating at nominal circuit voltage sufficient for the current that must be interrupted. 110-10 Circuit Impedance and Other Characteristics. The overcurrent protective devices, the total impedance, the component short-circuit current ratings, and other characteristics of the circuit to be protected shall be selected and coordinated to permit the circuit-protective devices used to clear a fault to do so without extensive damage to the electrical components of the circuit. This fault shall be assumed to be either between two or more of the circuit conductors, or between any circuit conductor and the grounding conductor or enclosing metal raceway. Listed products applied in accordance with their listing shall be considered to meet the requirements of this section. 240-1 240-11 Table 250-122 Minimum Size Equipment Grounding Conductors for Grounding Raceway and Equipment. 250-90 Copper Aluminum or Copper-Clad Aluminum 15 20 30 40 60 14 12 10 10 10 12 10 8 8 8 100 200 300 400 500 8 6 4 3 2 6 4 2 1 1/0 600 800 1000 1200 1600 1 1/0 2/0 3/0 4/0 2/0 3/0 4/0 250 350 2000 2500 3000 4000 5000 6000 250 350 400 500 700 800 400 600 600 800 1200 1200 Scope (FPN). Overcurrent protection for conductors and equipment is provided to open the circuit if the current reaches a value that will cause an excessive or dangerous temperature in conductors or conductor insulation. See also Sections 110-9 and 110-10 for requirements for interrupting ratings and protection against fault currents. Definition of Current-Limiting Overcurrent Protection Device. A current-limiting overcurrent protective device is a device that, when interrupting currents in its current-limiting range, will reduce the current flowing in the faulted circuit to a magnitude substantially less than that obtainable in the same circuit if the device were replaced with a solid conductor having comparable impedance. 250-2(d) Performance of Fault Current Path. The fault current path shall be permanent and electrically continuous, shall be capable of safely carrying the maximum fault likely to be imposed on it, and shall have sufficiently low impedance to facilitate the operation of overcurrent devices under fault conditions. Size (AWG or kcmil) Rating or setting of Automatic Overcurrent Device in Circuit Ahead of Equipment, Conduit, etc., Not Exceeding (Amperes) NOTE: Where necessary to comply with Section 250-2(d), the equipment grounding conductor shall be sized larger than this table. 620-62 General. Bonding shall be provided where necessary to ensure electrical continuity and the capacity to conduct safely any fault current likely to be imposed. Selective Coordination. Where more than one driving machine disconnecting means is supplied by a single feeder, the overcurrent protective devices in each disconnecting means shall be selectively coordinated with any other supply side overcurrent protective devices. NOTE: Short-circuit currents may be calculated many ways. A simple method is the Point-To-Point method as presented in Bussmann’s Electrical Protection Handbook, Bulletin SPD. That data is included in this bulletin for ease of use. 2 Electrical Plan Review The Meaning of Short-Circuit Interrupting Rating For a better understanding of interrupting rating, consider the following series of analogies. Normal Current Operation FLOOD GATES ANALOGOUS TO OVERCURRENT PROTECTIVE DEVICE RESERVOIR CAPACITY ANALOGOUS TO AVAILABLE FAULT CURRENT OVERCURRENT PROTECTIVE DEVICE AVAILABLE FAULT CURRENT (e.g., 50,000 AMPS) LOAD CURRENT (100 GALLONS PER MINUTE) Short-Circuit Operation with Inadequate Interrupting Rating FLOOD GATES ARE DESTROYED BECAUSE OF INADEQUATE INTERRUPTING RATING INADEQUATE INTERRUPTING RATING. THEREFORE, OVERCURRENT PROTECTIVE DEVICE IS DESTROYED AVAILABLE FAULT CURRENT (e.g., 50,000 AMPS) SHORT CIRCUIT CURRENT (50,000 GALLONS PER MINUTE) Downstream components may not be able to withstand the amount of let-through current. Short-Circuit Operation with Adequate Interrupting Rating ADEQUATELY RATED OVERCURRENT PROTECTIVE DEVICE IS UNDAMAGED AVAILABLE FAULT CURRENT (e.g., 50,000 AMPS) Downstream components capable of withstanding let-through current. SHORT CIRCUIT CURRENT SAFELY CLEARED FLOOD GATES HAVE ADEQUATE INTERRUPTING RATING. FAULT CURRENT SAFELY INTERRUPTED 3 Electrical Plan Review Ratings of Overcurrent Protective Devices Most overcurrent protective devices are labeled with two current ratings. The Fuse (2) INTERRUPTING RATING (1) NORMAL CURRENT RATING The Circuit Breaker (1) NORMAL CURRENT RATING (2) INTERRUPTING RATINGS 4 Electrical Plan Review Anywh of e er City Data “Log In” Form Letter N , USA SPECTIO N I WHERE Y L A N C A I F CTR CITY O T OF ELE N E M T DEPAR ECTS. , ARCHIT S R E E IN G TORS, EN ICATION. ONTRAC L C P ® L P CTIONS A A IC IT CTR ODE , SE PERM C E L IC A TO: ELE V IC R R CTRIC SE L ELECT 50-90, RE: ELE NATIONA -11, 250-2(d), 2 E H T H NCE WIT 0-1, 240 COMPLIA 10-9, 110-10, 24 2 Note. 1 , 0-12 110-3(b) ABLE 25 T d n a , ) 250-96(a ctrical ent of Ele tm r a l Code. p e ,D Electrica l a n o ti a N IRCUIT SHORT-C the 1996 e e c f th r o fo to y n e it n to stalled. ive The C required will be g s to be in e n is o ic n ti v o e n d e ti c tt t e en Insp ance, a overcurr e compli ent and m ip ached To ensur u q e e, the att actor, of the m S ti G d IN n T a t RA ntr um effor trical co ith minim leted by the elec w RIOR to P is t th n e plish comp partm e e b D conducn to o d ti To accom spec quire showing e In r l m a e a r ic r a g tr ) c ia panels, er d e Ele form(s ts at all e-line ris ted to th n n it e o r m r a b u u e c s d then . Inclu d fault stallation es, distances, an e equipment. actual in iz s v ser ic , conduit e and main , s r tor sizes nce to th te n e onforma ntrol c c o , d c d n e r a k to r e o c m be so ma complian data will wed for e ie v th e r , d e e b v will appro This data sections. When ference. e d future re o r C fo le fi above on be kept and will DATE , Sincerely r specto ctrical In Chief Ele 5 Electrical Plan Review “Log In” Data Required Form DEPARTMENT OF ELECTRICAL INSPECTION CITY OF Date Permit Electrical Contractor Street Address City State Zip The following information is requested to determine that the electrical equipment to be installed at: Name of occupant or owner is in compliance with the National Electrical Code® as it relates to available short-circuit currents and interrupting ratings. See Sections 110-3(b), 110-9, 110-10, 240-1, 240-11, 250-2(d), 250-90, 250-96(a), and Table 250-122 Note. This form is to be completed and returned to the Department of Electrical Inspection for approval prior to installation. THE FOLLOWING INFORMATION IS TO BE SUPPLIED BY THE ELECTRICAL CONTRACTOR OR OTHER RESPONSIBLE PARTY: TRANSFORMER KVA PHASE IMPEDANCE 3 OR 4 WIRE % SECONDARY VOLTAGE LENGTH OF SERVICE CONDUCTORS SIZE & NUMBER OF SERVICE CONDUCTORS PER PHASE TYPE OF CONDUCTORS: COPPER ■ ALUMINUM ■ CONDUIT SIZE STEEL ■ NON-MAGNETIC ■ TYPE, SIZE, AND INTERRUPTING RATING OF OVERCURRENT DEVICES IN SERVICE DISCONNECT (MAIN DISTRIBUTION PANEL) SIZE OF GROUNDING ELECTRODE CONDUCTOR BRACING OF SERVICE EQUIPMENT (page 1 of 2) 6 Electrical Plan Review “Log In” Data Required Form I T E M Location Of Short-Circuit Current 1 AT TRANSFORMER SECONDARY TERMINALS (INFINITE PRIMARY) 2 ON LINE SIDE OF MAIN SERVICE EQUIPMENT 3 AT PANEL 4 AT PANEL 5 AT PANEL 6 AT PANEL 7 AT PANEL 8 AT PANEL 9 AT PANEL 10 AT PANEL 11 AT PANEL 12 AT PANEL ShortCircuit Current Overcurrent Device Ampere Rating Interrupting Rating Apparent RMS Let-Through Current Use back of form or attach separate sheet for data on additional panels. Use back of form or attach separate sheet to show one-line diagram of service, feeders, and all related panels. Attach let-through curves if current-limiting devices are used. All current values in RMS line-to-line unless otherwise noted. The undersigned accepts full responsibility for the values given herein. SIGNED DATE PHONE WHERE YOU CAN BE REACHED Page 2 of 2 7 Peak Let-Through Current Electrical Plan Review Point-To-Point Method Of Short-Circuit Calculation Calculation Of Short-Circuit Currents — Point-To-Point Method. Example Of Short-Circuit Calculation Fault #1 Adequate interrupting rating and protection of electrical components are two essential aspects required by the National Electrical Code in Sections 110-9, 110-10, 240-1, 250-2(d), 250-90, 250-96(a) and Table 250-122 Note. The first step to ensure that system protective devices have the proper interrupting rating and provide component protection is to determine the available short-circuit currents. The application of the Point-To-Point method permits the determination of available shortcircuit currents with a reasonable degree of accuracy at various points for either 3o or 1o electrical distribution systems. This method assumes unlimited primary short-circuit current (infinite bus). MAIN SERVICE PANEL 300 KVA, 2%Z Fault #2 Infinite Primary Available 20', 500 MCM CU Steel conduit 20', #2 CU Steel conduit BRANCH CIRCUIT PANEL Basic Short-Circuit Calculation Procedure. Procedure Step 1 Determine transf. full-load amperes from either: a) Name plate b) Tables 3A & 3B c) Formula Formula Step 2 Find transf. multiplier Step 1 IFLA = KVA x 1000 EL-L Step 2 Multiplier = 3o transf. IFLA 1o transf. IFLA = — Multiplier = Step 3 Determine transf. let-through shortcircuit current (Table 5 or formula). Step 4 Calculate “f” factor. FAULT #1 KVA x 1000 = EL-L x 1.73 †I SCA f= 100 Transf. % Z 1.73 x L x lL-L-L C x EL-L 1o line-to-line (L-L) faults on 1o, center-tapped transformers f = 2 x L x l L-L C x EL-L 1o line-to-neutral (L-N) faults on 1o, center-tapped transformers f = 2 x L x l L-N* C x EL-N Step 6 Compute the available shortcircuit current (symmetrical) at the fault. M= 1 1+f = 833A 100 100 = 55.55 = .9x Transf. % Z Step 3 ** I SCA = 833 X 55.55 = 46,273 Step 4 f= Step 5 M= Step 6 At Transformer Secondary 1.73 x L x lL-L-L 1.73 x 20 x 46,273 = = .347 C x EL-L 22,185 x 208 1 1 = 1 + .347 = .742 (See Table 4) 1+f I SCA = 46,273 x .742 = 34,343A Fault #1 1.73 x 20 x 34,343 = .968 5,906 x 208 Step 4 f= Step 5 M= Step 6 I SCA = 34,343 x .508 = 17,447A 1 1 = 1 + .968 = .508 (See Table 4) 1+f Fault # 2 ** For simplicity, the motor contribution and voltage variance was not included. See Notes 1 and 4. †† Transformer % Z is multiplied by .9 to establish a worst case condition. See Note 3. Note 3: The marked impedance values on transformers may vary ±10% from the actual values determined by ANSI / IEEE test. See U.L. Standard 1561. Therefore, multiply transformer % Z by .9. I SCA = I SCA x M at fault 300 x 1000 FAULT #2 (Use I SCA @ Fault #1 to calculate) L = length (feet) of conduit to the fault. C = constant from Tables 1, 2. For parallel runs, multiply C values by the number of conductors per phase. I = available short-circuit current in amperes at beginning of circuit. Step 5 Calculate “M” (multiplier) or take from Table 4. = †† = Transf.FLA x multiplier 3o faults KVA x 1000 at beginning of circuit. † Note 1. Motor short-circuit contribution, if significant, may be added to the transformer secondary short-circuit current value as determined in Step 3. Proceed with this adjusted figure through Steps 4, 5, and 6. A practical estimate of motor short-circuit contribution is to multiply the total load current in amperes by 4. * Note 2. The L-N fault current is higher than the L-L fault current at the secondary terminals of a single-phase center-tapped transformer. The short-circuit current available (I) for this case in Step 4 should be adjusted at the transformer terminals as follows: At L-N center tapped transformer terminals I L-N = 1.5 x I L-L at Transformer Terminals At some distance from the terminals, depending upon wire size, the L-N fault current is lower than the L-L fault current. The 1.5 multiplier is an approximation and will theoretically vary from 1.33 to 1.67. These figures are based on change in turns ratio between primary and secondary, infinite source available, zero feet from terminals of transformer, and 1.2 x %X and 1.5 x %R for L-N vs. L-L resistance and reactance values. Begin L-N calculations at transformer secondary terminals, then proceed point-to-point. 8 Note 4. Utility voltages may vary ±10% for power, and ±5.8% for 120-volt lighting services. Therefore, for worst case conditions, multiply values as calculated in Step 3 by 1.1 and/or 1.058 respectively. Note 5: Bolted fault approximations: L-L-L 100% of Step 6. L-L 87% of Step 6. L-G, L-N 25-125% of Step 6. (Use 50% as typical) Note 6: Arcing fault approximation for sustained arcs (percentages of L-L-L bolted fault values) 480 Volts 208 Volts L-L-L 89% 12% L-L 74% 2% L-G 38% — L-L-L with one primary open 80% — Electrical Plan Review Point-To-Point Method Of Short-Circuit Calculation Calculation Of Short-Circuit Currents At Second Transformer In System. Procedure For Second Transformer in System Procedure Formula Use the following procedure to calculate the level of fault current at the secondary of a second, downstream transformer in a system when the level of fault current at the transformer primary is known. Step 1 3o transformer (I P(SCA) and I S(SCA) are 3o fault values). KNOWN FAULT CURRENT Calculate “f” (IP(SCA), known). H.V. UTILITY CONNECTION Step 2 Calculate “M” (multiplier) or take from Table 4. Calculate short-circuit current at secondary of transformer. (See Note 1 under “Basic Procedure”) 1 1+f IS(SCA) = — VP x M x IP(SCA) VS KVATRANS = KVA rating of transformer. %Z = Percent impedance of transformer. Note: To calculate fault level at the end of a conductor run, follow Steps 4, 5, and 6 of Basic Procedure. Table 3A. Three-Phase Transformer—Full-Load Current Rating (In Amperes). Ampacity Busway Plug-In Feeder High Impedance Copper Aluminum Copper Aluminum Copper 225 28700 23000 18700 12000 — 400 38900 34700 23900 21300 — 600 41000 38300 36500 31300 — 800 46100 57500 49300 44100 — 1000 69400 89300 62900 56200 15600 1200 94300 97100 76900 69900 16100 1350 119000 104200 90100 84000 17500 1600 129900 120500 101000 90900 19200 2000 142900 135100 134200 125000 20400 2500 143800 156300 180500 166700 21700 3000 144900 175400 204100 188700 23800 4000 — — 277800 256400 — Note: These values are equal to one over the impedance per foot for impedance in a survey of industry. Copper AWG Three Single Conductors or Conduit kcmil Steel 600V 5KV 15KV 14 389 389 389 12 617 617 617 10 981 981 981 8 1557 1551 1557 6 2425 2406 2389 4 3806 3750 3695 3 4760 4760 4760 2 5906 5736 5574 1 7292 7029 6758 1/0 8924 8543 7973 2/0 10755 10061 9389 3/0 12843 11804 11021 4/0 15082 13605 12542 250 16483 14924 13643 300 18176 16292 14768 350 19703 17385 15678 400 20565 18235 16365 500 22185 19172 17492 600 22965 20567 17962 750 24136 21386 18888 1000 25278 22539 19923 M= — IP(SCA) = Available fault current at transformer primary. IS(SCA) = Available fault current at transformer secondary. VP = Primary voltage L-L. VS = Secondary voltage L-L. Table 1. “C” Values for Busway. Table 2. “C” Values for Conductors IP(SCA) x VP x 1.73 (%Z) 100,000 x KVATRANS. 1o transformer (I P(SCA) and I x VP x (%Z) I S(SCA) are 1o fault values; f= P(SCA) 100,000 x KVATRANS. I S(SCA is L-L.) Step 3 KNOWN FAULT CURRENT f= Voltage (Line-toLine) 208 220 240 440 460 480 600 Transformer KVA Rating 150 167 225 300 417 464 625 834 394 439 592 788 362 402 542 722 197 219 296 394 189 209 284 378 181 201 271 361 144 161 216 289 500 1388 1315 1203 657 630 601 481 750 2080 1970 1804 985 945 902 722 1000 2776 2630 2406 1315 1260 1203 962 1500 4164 3940 3609 1970 1890 1804 1444 Table 3B. Single-Phase Transformer—Full-Load Current Rating (In Amperes). Voltage 115/230 120/240 230/460 240/480 Transformer KVA Rating 25 50 75 100 109 217 326 435 104 208 313 416 54 109 163 217 52 104 156 208 150 652 625 326 313 167 726 696 363 348 200 870 833 435 416 250 1087 1042 544 521 333 1448 1388 724 694 (Note: These values are equal to one over the impedance per foot for impedances found in IEEE Std. 241-1990, IEEE Recommended Practice for Commercial Building Power Systems.) Nonmagnetic 600V 5KV 389 389 617 617 981 981 1558 1555 2430 2417 3825 3789 4802 4802 6044 5926 7493 7306 9317 9033 11423 10877 13923 13048 16673 15351 18593 17120 20867 18975 22736 20526 24296 21786 26706 23277 28033 25203 28303 25430 31490 28083 2000 5552 5260 4812 2630 2520 2406 1924 Three-Conductor Cable Conduit Steel 600V 5KV 389 389 617 617 981 981 1559 1557 2431 2424 3830 3811 4760 4790 5989 5929 7454 7364 9209 9086 11244 11045 13656 13333 16391 15890 18310 17850 20617 20051 22646 21914 24253 23371 26980 25449 28752 27974 31050 30024 33864 32688 15KV 389 617 981 1558 2406 3752 4802 5809 7108 8590 10318 12360 14347 15865 17408 18672 19731 21329 22097 22690 24887 9 15KV 389 617 981 1559 2414 3778 4760 5827 7188 8707 10500 12613 14813 16465 18318 19821 21042 23125 24896 26932 29320 Nonmagnetic 600V 5KV 389 389 617 617 981 981 1559 1558 2433 2428 3837 3823 4802 4802 6087 6022 7579 7507 9472 9372 11703 11528 14410 14118 17482 17019 19779 19352 22524 21938 24904 24126 26915 26044 30028 28712 32236 31258 32404 31338 37197 35748 15KV 389 617 981 1559 2420 3798 4802 5957 7364 9052 11052 13461 16012 18001 20163 21982 23517 25916 27766 28303 31959 500 2174 2083 1087 1042 Electrical Plan Review Point-To-Point Method Of Short-Circuit Calculation Table 4. “M” (Multiplier).* f 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.20 *M= M 0.99 0.98 0.97 0.96 0.95 0.94 0.93 0.93 0.92 0.91 0.87 0.83 0.80 0.77 0.74 0.71 0.67 0.63 0.59 0.55 0.53 0.50 0.45 Table 5. Short-Circuit Currents Available from Various Size Transformers f 1.50 1.75 2.00 2.50 3.00 3.50 4.00 5.00 6.00 7.00 8.00 9.00 10.00 15.00 20.00 30.00 40.00 50.00 60.00 70.00 80.00 90.00 100.00 M 0.40 0.36 0.33 0.29 0.25 0.22 0.20 0.17 0.14 0.13 0.11 0.10 0.09 0.06 0.05 0.03 0.02 0.02 0.02 0.01 0.01 0.01 0.01 1 1+f Voltage And Phase KVA Full % Short Load Impedance†† Circuit Amps (Nameplate) Amps† 25 104 1.58 11,574 371/ 2 156 1.56 17,351 120/240 50 209 1.54 23,122 1 ph.* 75 313 1.6 32,637 100 417 1.6 42,478 167 695 1.8 60,255 25 69 1.6 4,791 50 139 1.6 9,652 75 208 1.11 20,821 100 278 1.11 27,828 150 416 1.07 43,198 120/208 225 625 1.12 62,004 3 ph.** 300 833 1.11 83,383 500 1388 1.24 124,373 750 2082 3.5 66,095 1000 2776 3.5 88,167 1500 4164 3.5 132,190 2000 5552 5.0 123,377 2500 6950 5.0 154,444 1121/ 2 135 1.0 15,000 150 181 1.2 16,759 225 271 1.2 25,082 300 361 1.2 33,426 277/480 500 601 1.3 51,362 3 ph.** 750 902 3.5 28,410 1000 1203 3.5 38,180 1500 1804 3.5 57,261 2000 2406 5.0 53,461 2500 3007 5.0 66,822 * Single phase values are L-N values at transformer terminals. These figures are based on change in turns ratio between primary and secondary, 100,000 KVA primary, zero feet from terminals of transformer, 1.2 (%X) and 1.5 (%R) multipliers for L-N vs. L-L reactance and resistance values and transformer X/R ratio = 3. ** Three-phase short-circuit currents based on “infinite” primary. †† U.L. listed transformers 25 KVA or greater have a ±10% impedance toler- ance. Short-circuit amps reflect a “worst case” condition. † Fluctuations in system voltage will affect the available short-circuit current. For example, a 10% increase in system voltage will result in a 10% increase in the available short-circuit currents shown in the table. Aluminum AWG Three Single Conductors or Conduit kcmil Steel 600V 5KV 15KV 14 236 236 236 12 375 375 375 10 598 598 598 8 951 950 951 6 1480 1476 1472 4 2345 2332 2319 3 2948 2948 2948 2 3713 3669 3626 1 4645 4574 4497 1/0 5777 5669 5493 2/0 7186 6968 6733 3/0 8826 8466 8163 4/0 10740 10167 9700 250 12122 11460 10848 300 13909 13009 12192 350 15484 14280 13288 400 16670 15355 14188 500 18755 16827 15657 600 20093 18427 16484 750 21766 19685 17686 1000 23477 21235 19005 Nonmagnetic 600V 5KV 236 236 375 375 598 598 951 950 1481 1478 2350 2341 2958 2958 3729 3701 4678 4631 5838 5766 7301 7152 9110 8851 11174 10749 12862 12343 14922 14182 16812 15857 18505 17321 21390 19503 23451 21718 25976 23701 28778 26109 Three-Conductor Cable Conduit Steel 600V 5KV 236 236 375 375 598 598 951 951 1481 1480 2351 2347 2948 2956 3733 3719 4686 4663 5852 5820 7327 7271 9077 8980 11184 11021 12796 12636 14916 14698 15413 16490 18461 18063 21394 20606 23633 23195 26431 25789 29864 29049 15KV 236 375 598 951 1476 2333 2958 3672 4580 5645 6986 8627 10386 11847 13491 14954 16233 18314 19635 20934 23482 10 15KV 236 375 598 951 1478 2339 2948 3693 4617 5717 7109 8750 10642 12115 13973 15540 16921 19314 21348 23750 26608 Nonmagnetic 600V 5KV 236 236 375 375 598 598 951 951 1482 1481 2353 2349 2958 2958 3739 3724 4699 4681 5875 5851 7372 7328 9242 9164 11408 11277 13236 13105 15494 15299 17635 17351 19587 19243 22987 22381 25750 25243 29036 28262 32938 31919 15KV 236 375 598 951 1479 2344 2958 3709 4646 5771 7201 8977 10968 12661 14658 16500 18154 20978 23294 25976 29135 Electrical Plan Review Peak Let-Through Charts Peak let-through charts let you determine both the peak let-through current and the apparent prospective RMS symmetrical let-through current. (These charts are commonly referred to as Current-Limitation Curves.) LOW-PEAK® KRP-C Fuses LOW-PEAK® LPJ Fuses 1000000 900000 800000 700000 600000 B 100000 90000 80000 70000 60000 B 600A 50000 500000 400A 40000 400000 100000 90000 80000 70000 60000 800A 601A 50000 AMPERE RATING 40000 30000 20000 10000 9000 8000 7000 6000 5000 4000 200A 20000 100A 60A 10000 9000 8000 7000 6000 30A 5000 15A 4000 3000 AMPERE RATING 2500A 2000A 1600A 1200A 2000 1000 900 800 700 600 500 400 300 3000 A A 200 2000 PROSPECTIVE SHORT-CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES PROSPECTIVE SHORT CIRCUIT CURRENT - SYMMETRICAL RMS AMPERES 11 200000 300000 60000 70000 80000 90000 100000 50000 40000 30000 20000 6000 7000 8000 9000 10000 4000 5000 3000 2000 600 700 800 900 1000 500 400 300 100 200000 300000 60000 70000 80000 90000 100000 50000 40000 30000 20000 5000 6000 7000 8000 9000 10000 4000 3000 2000 200 100 1000 1000 INSTANTANEOUS PEAK LET THRU CURRENT IN AMPERES 200000 INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES 6000A 5000A 4000A 3000A 300000 30000 Electrical Plan Review Peak Let-Through Charts FUSETRON® FRS-R Fuses FUSETRON® FRN-R Fuses B 200000 200000 AMPERE RATING 300000 600A 400A 50000 40000 200A 30000 100A 20000 60A 10000 9000 8000 7000 6000 PEAK CURRENT IN AMPERES 100000 90000 80000 70000 60000 50000 30A 5000 200A 40000 30000 100A 20000 60A 10000 9000 8000 7000 6000 5000 4000 4000 3000 3000 30A LOW-PEAK® LPS-RK Fuses 200000 50000 60000 70000 80000 90000 100000 40000 30000 20000 LOW-PEAK® LPN-RK Fuses B B 100,000 600 400 200 100 60 10,000 30 A AMPERE RATING INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES 400,000 AMPERE RATING 400,000 100,000 600A 400A 200A 100A 60A 10,000 30A A RMS SYMMETRICAL CURRENTS IN AMPERES A-B=ASYMMETRICAL AVAILABLE PEAK (2.3 x SYMM RMS AMPS) RMS SYMMETRICAL CURRENTS IN AMPERES A-B=ASYMMETRICAL AVAILABLE PEAK (2.3 x SYMM RMS AMPS) 12 300,000 200,000 100,000 10,000 1,000 300,000 100,000 10,000 1,000 1,000 INSTANTANEOUS PEAK LET-THROUGH CURRENT IN AMPERES 4000 AVAILABLE RMS CURRENT IN AMPERES AVAILABLE RMS CURRENT IN AMPERES 1,000 5000 6000 7000 8000 9000 10000 1000 200000 60000 70000 80000 90000 100000 50000 30000 40000 20000 6000 7000 8000 9000 10000 4000 5000 1000 3000 1000 2000 2000 3000 A A 2000 1000 600A 400A 2000 PEAK CURRENT IN AMPERES 100000 90000 80000 70000 60000 B 400000 300000 AMPERE RATING 400000 Electrical Plan Review Work Sheet Short-Circuit Calculations (Transformer) Short-Circuit at Secondary Terminals of Transformer (Infinite Primary) A) FROM TABLES B) CALCULATED Amperes STEP 1 Find Transformer Full-Load Amperes (3 Phase) KVA x 1000 = IFLA = EL-L x 1.73 x 1000 = x 1.73 Amperes x 1000 = Amperes = Amperes (1 Phase) KVA x 1000 = IFLA = EL-L STEP 2 Find Multiplier: M= 100 = TRANS %Z 100 STEP 3 Find Short-Circuit Current: ISCA = Transformer F.L.A. x M = Short-Circuit Amperes = x Short-Circuit at Secondary Terminals of Transformer (Infinite Primary) Amperes A) FROM TABLES B) CALCULATED STEP 1 Find Transformer Full-Load Amperes (3 Phase) KVA x 1000 = EL-L x 1.73 x 1000 = x 1.73 Amperes (1 Phase) KVA x 1000 = IFLA = EL-L x 1000 = Amperes = Amperes IFLA = STEP 2 Find Multiplier: M= 100 = TRANS %Z 100 STEP 3 Find Short-Circuit Current: ISCA = Transformer F.L.A. x M = x Short-Circuit Amperes = 13 Electrical Plan Review Work Sheet Short-Circuit Calculations (Three o) Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x C) Multiplier “M” = 1 = 1+ 1+f = 1 D) SCA = M x lL-L-L = = x = Amperes = Amperes Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x C) Multiplier “M” = 1 = 1+f 1+ = 1 D) SCA = M x lL-L-L = = x Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x C) Multiplier “M” = 1 = 1+ 1+f D) SCA = M x lL-L-L = = 1 = = x 14 Amperes Electrical Plan Review Work Sheet Short-Circuit Calculations (Three o) Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x 1 = 1+f 1+ C) Multiplier “M” = = 1 D) SCA = M x lL-L-L = = x = Amperes = Amperes = Amperes Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x C) Multiplier “M” = 1 = 1+f 1+ = 1 D) SCA = M x lL-L-L = = x Short-Circuit Current at 1.73 x L x IL-L-L A) f = C x EL-L B) f = 1.73 x x x C) Multiplier “M” = 1 = 1+f 1+ D) SCA = M x lL-L-L = = 1 = x 15 Electrical Plan Review Work Sheet Short-Circuit Calculations (Single o, Line-To-Line) Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = 1 = 1+ 1+f = 1 D) SCA = M x lL-L = = x = Amperes = Amperes = Amperes Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = 1 = 1+f 1+ = 1 D) SCA = M x lL-L = = x Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = D) SCA = M x lL-L = 1 = 1+f 1+ = 1 = x 16 Electrical Plan Review Work Sheet Short-Circuit Calculations (Single o, Line-To-Line) Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = 1 = 1+ 1+f = 1 D) SCA = M x lL-L = = = x Amperes Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = 1 = 1+f 1+ D) SCA = M x lL-L = = 1 = Amperes = x Short-Circuit Current at 2 x L x lL-L A) f = C x EL-L B) f = 2 x x x C) Multiplier “M” = D) SCA = M x lL-L = 1 = 1+f 1+ = 1 = x = 17 Amperes Electrical Plan Review Work Sheet Short-Circuit Calculations (Single o, Line-To-Neutral) Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+ 1+f 1 D) SCA = M x lL-N = = x = Amperes = Amperes Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+f 1+ 1 D) SCA = M x lL-N = = x Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+f 1+ D) SCA = M x lL-N = 1 x = Amperes = *See Note 2 on Page 8 18 Electrical Plan Review Work Sheet Short-Circuit Calculations (Single o, Line-To-Neutral) Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+ 1+f D) SCA = M x lL-N = 1 = x = Amperes = Amperes = Amperes Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+ 1+f D) SCA = M x lL-N = 1 = x Short-Circuit Current at 2 x L x lL-N* A) f = C x EL-N B) f = 2 x x = x C) Multiplier “M” = 1 = 1+f 1+ D) SCA = M x lL-N = 1 x = *See Note 2 on Page 8 19 Electrical Plan Review Grounding & Bonding of Service Equipment Bonding Why? Section 250-90 What? Section 250-92 How? Section 250-94 Material: Section 250-102(a) Size: Section 250-102(c) MAIN DISTRIBUTION PANEL METER BASE NEUTRAL Equipment Grounding Conductor Material: Section 250-118 Install: Section 250-120 800/800 Grounded Neutral Service Entrance Conductors to Pad Mount Transformer Neutral Grounded Conductor Size: Sections 230-42, 220-22 When Serving As Grounding Conductor: What? Section 250-24(a) Size: Section 250-24(b) Section 250-66 IMPORTANT: Effective Bonding and Grounding Required: Section 250-2(d) Section 250-90 Section 250-96(a) Must have capacity to conduct safely any fault current likely to be imposed on it. Supplemental Ground (If Required) Section 250-50(a) Neutral Disconnecting Means Section 230-96 Main Bonding Jumper: Section 250-28, 250-96 Material: Section 250-28(a) Size: Section 250-28(d) Connect: Section 250-28(c) Grounding Electrode Conductor Size: Section 250-66 Material: Section 250-62 Install: Section 250-64 Enclosure: Section 250-64(e) What: Section 250-24 Grounding Electrode System Section 250-50 Connection to Electrode Sections 250-68, 8, 70 Bonding of Metal Water Pipes Section 250-104 20 Electrical Plan Review Typical Component—Short Circuit Current Ratings Component Short-circuit current rating, kA Clock-Operated Switch 5,000 HVAC Equipment 110-120V 9.8 or less 9.9-16.0 16.1-34.0 34.1-80.0 Over 80.0 Single-Phase-Amps 200-208V 5.4 or less 5.5-8.8 8.9-18.6 18.7-44.0 Over 44.0 3-Phase-Amps 220-240V 2.0 or less 2.1-3.5 3.6-9.0 9.1-22.0 Over 22.0 200-208V 2.12 or less 2.13-3.7 3.8-9.5 9.6-23.3 Over 23.3 Meter Socket Base Motor Controller, Rated in Horsepower (kW) a. 0-50 (0-37.3) b. 51-200 (38-149) c. 201-400 (150-298) d. 401-600 (299-447) e. 601-900 (448-671) f. 901-1600 (672-1193) Photoelectric Switches Receptacle (GFCI Type) Receptacle (Other Than GFCI Type) Snap Switch Terminal Block Thermostat 220-240V 4.9 or less 5.0-8.0 8.1-17.0 17.1-40.0 Over 40.0 254-277V — 6.65 or less — — Over 6.65 440-480V — 1.8 or less — — Over 1.8 550-600V — 1.4 or less — — Over 1.4 200 1,000 2,000 3,500 5,000 200 1,000 2,000 3,500 5,000 10,000 5,000 10,000 18,000 30,000 42,000 85,000 5,000 10,000 2,000 5,000 10,000 5,000 Wire Copper, 75° Thermoplastic Insulated Cable Copper Wire Size 75° Thermoplastic #14 #12 #10 #8 #6 #4 Maximum Short-Circuit Withstand Current in Amperes For 1/2 Cycle For 1 Cycle For 2 Cycles For 3 Cycles 2,400 3,800 6,020 9,600 15,200 24,200 1,700 2,700 4,300 6,800 10,800 17,100 1,200 1,900 3,000 4,800 7,600 12,100 1,000 1,550 2,450 3,900 6,200 9,900 21 Electrical Plan Review Work Sheet Problem—Main Distribution Panel PRIMARY FUSE 1 300 KVA Transformer by Utility 120/208 Volt 3 Phase, 4-Wire 2% Impedance 1 METER (2) 3" C. each with 4-500 kcmils/XHHW - 20 Feet 4 - #8 THHN, 3/4" C. - 10 Feet 8 EMP 800/800 3 200/200 4 - #3/0 THHN, 2" C. - 60 Feet 1/2" C. - 30' FLUOR. 3 - #12 THHN 2 Ground Buss FIXTURE 2 MAIN SWITCH 9 LPA 3 4 200/150 4 - #1/0 THHN, 1-1/2" C. - 15 Feet LPC 4 100/100 4 - #3 THHN, 1-1/4" C. - 20 Feet LPB 5 6 100/90 AC-1 3 - #3 THHN, 1" C. - 35 Feet 6 7 100/70 3 - #4 THHN, 1" C. - 35 Feet AC-2 7 8 9 3 - #8 THHN, 3/4" C.- 4 Feet 5 10 100/ 200/ 7-1/2 Combination Motor Controller 22