Machining Spindles For High-Speed Internal Grinding UHS Style

advertisement

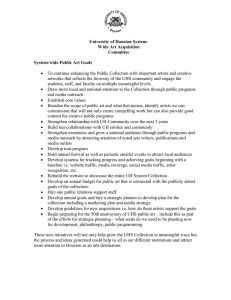

GMN Paul Müller Industrie GmbH & Co. KG Äußere Bayreuther Str. 230 · D-90411 Nürnberg Machining Spindles For High-Speed Internal Grinding UHS Style Phone: +49 911-5691-0 · Fax: +49 911-5691-221 Mail: info@gmn.de www.gmn.de Spindle technology: Phone: +49 911-5691-576 · Fax: +49 911-5691-699 Mail: vertrieb.spi@gmn.de Oficial GMN Representative: 0909 0909 www.gmn.de Machining Spindles UHS Style Made in Germany due to higher speeds, larger grinding quill holders and larger tools HS 80 - 180000/0.4 0.4 ·Higher output 0.001 0.2 0 with the same sleeve diameters and analogous speeds ·Synchronous motor 0 50000 100000 150000 Speed [rpm] 200000 250000 instead of asynchronous motor ·Very high speed values n x dm Displacement at radial load of 10 N due to higher speeds and larger bearing diameters Radial displacement [µm] 6 GMN quality management – tested and approved As a matter of course, we guarantee highest quality on the basis of long-term reliability also for the products of the UHS spindle series. Designation Speed nmax [rpm] UHS 80 - 250000/0.5 250,000 UHS 80 - 200000/1 200,000 UHS 80 - 120000/2 120,000 UHS 100 - 105000/4 105,000 UHS 100 - 90000/5 90,000 Tool: Ø4 x 10 mm 5 M 0.2 A 0.001 Static stiffness cax [N/µm] crad 11 0.05 A 0.001 16 UHS 80 - 250000/0.5 21 18 UHS 80 - 200000/1 32 34 UHS 80 - 120000/2 46 37 UHS 100 - 105000/4 57 58 UHS 100 - 90000/5 4 3 2 UHS 80 - 200000/1 Stiffness +78% 1. Critical speed +42% 1 0 -1 -2 tool 0 spindle 20 Output Frequency Current Inverter PS6-60% [kW] fmax [Hz] IS6 [A] Rated voltage [V] 0.5 Ød 0.6 A 62° ·Higher cutting speeds and thus higher efficiency 0.8 cax 2.8 due to larger bore diameter of the front bearing UHS 80 - 200000/1 Output +150% Torque +128% 1 40 60 Z [mm] motor current HS 80 - 180000/0.4 80 100 oil/air lubrication 120 Bearing-ø W1 [mm] Tool interface Inverter Type Inverter Type 4167 3.5 230 10 U 6.5/10 SD 230-10 SD 230-10 1 3333 8.5 230 10 U 6.5/10 SD 230-20 2 2000 8.5 230 17 U 9/16 SD 230-20 4 1750 9 400 20 U 12/18 SD 480-23 5 1500 11 400 25 U 16/23 SD 480-23 Feeding 1) [V] Rated current at PWM S1 [Aeff] Frequency [kHz] Dimensions H x B x T [mm] 1 x AC 200 ... 230 5 128 SD 230-20 1 x AC 200 ... 230 10 128 250 x 110 x 180 SD 480-23 3 x AC 400 ... 480 17 64 390 x 175 x 180 1) Required line voltage for the operation of the UHS spindles. 250 x 75 x 180 Specifications are subject to change without notice. Last update September 2009. ·Higher rigidity and larger grinding quill holder 1.2 Output S6-60% [kW] This was realized particularly by the following features of the UHS spindles: Output diagram The SD inverter matched optimally to the operation of the UHS spindle and the appropriate lubricator PRELUB PP can be obtained from us. The connection cables and lubricant pipes required for this belong to the standard scope of delivery. crad When designing this spindle type, the demand to offer a product with which our customers can achieve maximum quality and optimum productivity was taken as the basis. Periphery Tool interface U [d]/[W] Taper 1:10 with clamping face 30° Here the comparison between a conventional spindle HS 80 - 180000/0.4 and the new spindle type UHS 80 - 200000/1. ØW The UHS (Ultra High Speed) spindle series is used in high-speed internal grinding with speeds up to 250,000 rpm.