An Internal ALD-Based High Voltage Divider and Signal Circuit for

advertisement

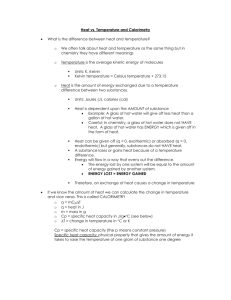

1 2 3 4 5 6 An Internal ALD-Based High Voltage Divider and Signal Circuit for MCP-based Photodetectors Bernhard Adamsb , Andrey Elagina , Jeffrey W. Elamb , Henry J. Frischa , Jean-Francois Genata,1 , Joseph S. Gregarb , Anil U. Maneb , Michael J. Minotc , Richard Northropa , Razib Obaida,2 , Eric Oberlaa , Alexander Vostrikova , Matthew Wetsteina a Enrico Fermi Institute, University of Chicago National Laboratory c Minotech Engineering, Inc and Incom, Inc 7 b Argonne 8 9 10 Abstract We describe a pin-less design for the high voltage (HV) resistive divider of the all-glass LAPPDTM 8”-square thin photodetector module. The divider, which distributes high voltage applied to the photocathode to the two microchannel plates (MCP’s) that constitute the amplification stage, is comprised of the two MCP’s and three glass mechanical spacers, each of which is coated with a resistive layer using Atomic Layer Deposition (ALD). The three glass grid spacers and the two MCP’s form a continuous resistive path between cathode and anode, with the voltages across the MCP’s and the spacers determined by the resistance of each. High voltage is applied on an external tab on the top glass window that connects to the photocathode through the metal seal. The DC ground is supplied by microstrips on the bottom glass plate that form the high-bandwidth anode. The microstrips exit the package through the glassfrit seal of the anode base-plate and the package sidewall. The divider is thus completely internal, with no HV pins penetrating the low-profile flat glass package. Measurements of the performance of the divider are presented for the 8”square MCP and spacer package in a custom test fixture and for an assembled externally-pumped LAPPDTM prototype with an aluminum photocathode. 1 Present 2 Present address, Universités Pierre et Marie Curie; Paris France address, Physics Dept., Univ. of Conn., Storrs, CT 06269 Preprint submitted to NIM December 26, 2014 11 Contents 12 1 Introduction 3 13 2 The HV Resistive Distribution Chain 5 14 2.1 Resistive Components . . . . . . . . . . . . . . . . . . . . . . . . 6 15 2.2 DC Current Path . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 16 2.3 The Signal Path for Fast-Risetime Pulses . . . . . . . . . . . . . 10 17 2.3.1 Normal Anode Configuration . . . . . . . . . . . . . . . . 11 18 2.3.2 The ‘Inside-Out’ Anode . . . . . . . . . . . . . . . . . . . 12 19 20 21 3 Implementation in the LAPPDTM Package 3.1 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . 4 Performance of the HV Divider 14 16 Test Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 23 4.1.1 The Spacer Station (ISS) . . . . . . . . . . . . . . . . . . 17 24 4.1.2 The Demountable Tile . . . . . . . . . . . . . . . . . . . . 17 22 4.1 14 25 4.2 Current-vs-Voltage (I-V) Curves . . . . . . . . . . . . . . . . . . 20 26 4.3 Thermal Coefficient . . . . . . . . . . . . . . . . . . . . . . . . . 20 27 4.4 Pressure Dependence . . . . . . . . . . . . . . . . . . . . . . . . . 21 28 4.5 Long-term Stability . . . . . . . . . . . . . . . . . . . . . . . . . . 22 29 5 Conclusions 23 30 6 Acknowledgments 24 2 31 1. Introduction 32 The LAPPD Collaboration [1] was formed to develop large-area photodetec- 33 tors based on micro-channel plates [2] for precise time-of-flight measurements 34 in large-scale detectors for High Energy Physics. In a number of applications 35 the ability to detect the arrival of multiple photons in a large-area plane, each 36 measured with a time resolution measured in pico-seconds (1 psec = 10−12 sec) 37 and a space resolution measured in millimeters, enables a 3D pattern recon- 38 struction using the 2D position of arrival of each photon and the transit time 39 to determine the remaining orthogonal 3rd component [3]. Additionally, a psec- 40 level measurement of the time coordinate allows a qualitative change in the 41 photodetector area needed to provide a given level of coverage for large diffuse 42 sources such as the large water-Cherenkov or scintillation counters used in par- 43 ticle and nuclear physics, as the addition of the transit drift time of the photon 44 transforms a 2-dimensional phase space into a much larger 3-dimensional space. 45 Optical systems can take advantage of measuring both the position and the time 46 of arrival to minimize expensive photocathode area while still preserving space 47 resolution3 . 48 The amplification in conventional discrete-dynode photomultipliers (PMT’s) 49 and microchannel-based photomultipliers (MCP-PMT’s) is done by electron 50 multiplication, with the electrons accelerated between collisions with a dyn- 51 ode (in a PMT) or the wall of a capillary channel (in an MCP-PMT) to provide 52 energy for secondary electron emission. The multiplication is consequently ex- 53 ponential, and depends on the secondary-emission yield (SEY) of each collision 54 and the number of collisions (equal to the number of dynodes in a PMT). The 55 SEY in turns depends on the accelerating voltage between collisions, which in 56 a PMT is typically set by a resistive voltage divider that supplies each dynode 57 from a high voltage (HV) source at the input to the divider. The principle is the 3 One can think of this as similar to rotations between transverse and longitudinal emit- tances in accelerators. 3 58 same in an MCP-PMT, but rather than a divider made of discrete resistive ele- 59 ments, the voltages between collisions are set by a DC current flowing through a 60 resistive layer on the walls of the capillaries. In an MCP-PMT with the typical 61 pair of capillary plates as an amplification section, voltage is usually applied 62 to the top and bottom of each plate by deposition of a conducting electrode 63 surface. 64 The LAPPDTM (Large Area Picosecond Photodetector) is an MCP-based 65 photodetector, capable of imaging at high spatial and temporal resolution, in an 66 ultra-high vacuum (UHV) hermetic package with an active area of 400 square 67 centimeters. The modular detector design is based on a hermetic all-glass vac- 68 uum tube package consisting of a thin window on which a bialkali photocathode 69 has been deposited, two 8”-square micro-channel plates (MCP), and an anode 70 implemented as high-bandwidth RF silver micro-striplines [4]. Amplification is 71 provided by a pair of micro-channel glass substrates [5] coated by Atomic Layer 72 Deposition (ALD) [6], with typical gains of more than 107 . 73 The HV distribution for the LAPPDTM can be implemented in a number of 74 ways, depending on the application and possibly also on parameters of the pro- 75 duction process. In the design described here, the HV distribution and the high 76 frequency signal path are both integral parts of an economical mechanical struc- 77 ture. The hermetic package has only 8 parts, all made of commonly-available 78 sheet glass. The only additional element is a simple getter assembly formed 79 from a strip of getter material and glass bead supports that is situated around 80 the circumference of the channel plate stack assembly. An attractive feature 81 for robustness and fabrication yield is there are no pins penetrating the pack- 82 age; both the HV and the anode signals are brought in through metal layers 83 deposited on the glass prior to assembly. The planar anode signal plane has an 84 analog bandwidth of 1.6 GHz (3 db loss) [4] in this implementation. 85 The organization of the paper is as follows. Section 2 describes the resistive 86 HV distribution chain, with the resistive elements and DC current path de- 87 scribed in Sections 2.1 and 2.2, respectively. The high-speed (radio-frequency, 88 RF) signal circuit, which is electrically and mechanically integrated with the 4 89 HV circuit, is discussed in Section 2.3 for the usual configuration with the an- 90 ode pattern on the inside surface of the vacuum volume (Section 2.3.1), and a 91 capacitively-coupled configuration with pads or microstrips on the outside sur- 92 face (Section 2.3.2). The integration of the HV divider into the LAPPDTM her- 93 metic package is described in Section 3, where the physical dimensions, ALD 94 coating parameters, and electrical values are also summarized. 95 Measurements of the performance of the HV divider are presented in Sec- 96 tion 4. A summary of the test facilities for the HV chain is given in Sec- 97 tion 4.1. Section 4.1.1 describes a custom test facility, the Spacer Station (ISS), 98 used to make DC measurements of current and voltage. A second test facility, 99 the ‘Demountable Tile’, consisting of an LAPPDTM glass-body tile mechanical 100 assembly, but with an O-ring window seal and a permanent connection to a 101 vacuum pump rather than being a hermetically sealed tube, is used to make 102 measurements of fast pulses, including time and space resolutions, as described 103 in Section 4.1.2. Measurements of I-V curves and the dependence of the divider 104 resistance on temperature, pressure, and time are presented in Sections 4.2-4.5. 105 The paper concludes with a summary in Section 5. 106 2. The HV Resistive Distribution Chain 107 The hermetic package, made of readily-available borosilicate glass [7], con- 108 sists of a top window, sidewall, and anode bottom plate. The sidewall is her- 109 metically sealed to the anode plate with glass frit to form a robust base unit. 110 The top window is sealed with indium to the base in vacuum after the photo- 111 cathode is deposited. HV is applied outside the vacuum volume on a window 112 tab that makes contact with the metalized border of the window and the photo- 113 cathode. Resistive grid spacers coated by ALD support the pressure on the top 114 window and bottom anode plate. The three spacers and the two MCP plates, 115 together with the (DC) grounded anode plane, form the resistive HV divider 116 that determines the voltages across the MCP’s and the three gaps. The silver 117 anode strips [8] extend beyond the sidewall bottom seal to complete the electri- 5 Figure 1: The mechanical construction of the LAPPDTM module. All components are glass. The hermetic volume is formed by the top window (1), the side-wall (5), and the bottom plate (7). The photocathode is deposited on the inside of the window, and makes contact with the external HV input through a metalized border (4). The grid spacers (2) and the MCP’s (3) are coated with ALD. The bottom plate (7) has silk-screened silver anode 50Ω microstrips fired on its surface (6) that penetrate a frit seal under the sidewall and connect to the digitizing electronics. 118 cal circuits for both signals and DC current. Atmospheric pressure transmitted 119 through the top window and bottom anode plane compresses the ’stack’ of grid 120 spacers and microchannel plates into a rigid thin package. 121 122 A diagram of the layers of the HV divider is shown in Figure 1. 2.1. Resistive Components 123 Amplification in the tile is provided by a pair of microchannel-plates with 124 20 µm -diameter pores, arranged in a chevron configuration. The pores have a 125 length-to-diameter ratio (L/D) of 60, making the thickness of each plate 1.2 mm. 126 The plates are coated with a resistive layer by ALD with a target resistance of 127 between 10 and 40 MΩ [9]. The plates are chosen within a pair to be matched 128 in resistance within ±10%. 129 To provide structural rigidity and the ability to support atmospheric pressure 130 on the top and bottom of the package, the gaps in the vacuum volume from the 131 cathode to the first MCP, from the first to the second MCP, and from the 6 Figure 2: The equivalent electrical circuit of the tile assembly.The upper diagram shows the DC circuit. The HV voltage divider is implemented by resistive ALD coatings of the grid spacers and the MCP’s. (see Figure 1). 132 second MCP to the anode, are formed by spacers consisting of thin flat glass 133 grids. The HV resistive divider chain is completed by coating the grid spacers 134 with a resistive layer, also by ALD, as shown in Fig. 2. 135 The parameters of the layers that make up the tile are given in Table 1 [10]. 136 A 2-mm grid spacer, shown in Figure 4, sets the height and voltage across the 137 photocathode-MCP gap and the gap between the two MCP’s. A 6.5 -mm grid 138 spacer similarly sets the height and voltage across the gap between the bottom of 139 the second MCP and the anode plane. The grid spacers are aligned to minimize 140 the occluded area and to transfer the force of atmospheric pressure in columnar 141 fashion between the top and bottom plates. 142 A 2.3 cm by 0.076 cm cut-away indentation in each crossbar in one direction 143 in the bottom spacer allows the vacuum volumes defined by the spacer grid to 144 communicate with each other for pumping, as shown in Figure 3. 145 We have made tests with a Nichrome coating on the grid spacers and without. 146 Because the MCP’s are metalized with Nichrome top and bottom there is no 147 need to metalize the grid spacers at those interfaces. However metalization of 7 148 the top surface of the top spacer can provide a convenient method of distributing 149 HV and current across the face of the (resistive) photocathode. The silver anode 150 microstrips distribute the DC ground potential under the bottom spacer, which 151 cannot be metalized without shorting the strips. 152 2.2. DC Current Path 153 The DC electrical circuit of the photodetector is shown in Figure 2. High 154 voltage is applied to a Nichrome border on the underside of the window via a 155 tab that extends beyond the sidewall. The Nichrome makes contact with the 156 top grid spacer to supply current to the resistive divider through the spacers 157 and MCP’s. Figure 3: A partial assembly showing the ‘bottom’ spacer grid, the getter strip and its supporting glass beads, and the sidewall as they would be in the assembled tile base. The 2.3 cm by 0.076 indentations that allow the separate vacuum volumes in the tile to communicate with each other are visible as channels running from left to right on the top edges of the spacer. 8 158 Figure 5 shows the window, including the external tabs and Nichrome bor- 159 der that supply the input HV to the photocathode and the divider. The HV 160 is applied to the underside of two of the tabs, and connects to the cathode 161 through the metalization for the seal. The four metalized lines that extend into 162 the cathode provide HV distribution to the cathode plane, complementing the 163 distribution from the top spacer. 164 The internal five layers, consisting of three grid spacers and two MCP’s, form 165 a resistive voltage divider [11] that passes a nominal 100 µA divider current from 166 the cathode to the anode. Table 2 gives the nominal resistance and voltage drops 167 across the divider. 168 The final step in the DC return path to HV ground is at each end of the 169 anode microstrips, where individual 10KΩ resistors terminate each strip to the 170 copper substrate sheet that forms the signal ground-plane of the microstrips Layer Thickness Material Resistive Coating Metalization (side) Window 2.75 mm B33 Photocathode Nichrome border (bottom) (bottom) Grid Spacer 1 2.0 mm B33 ALD-GS None MCP 1 1.2 mm Micropore ALD-MCP Nichrome (both) Grid Spacer 2 2.0 mm B33 ALD-GS None MCP 2 1.2 mm Micropore ALD-MCP Nichrome (both) Grid Spacer 3 6.5 mm B33 ALD-GS None Anode 2.75 mm B33 N/A Silver strips (top) Table 1: A tabulation of the layers in the tile assembly, starting with the top window and ending with the bottom anode layer. Mechanical stability against atmospheric pressure is provided by a glass grid spacer in each of the three gaps, as listed. All components except the microchannel plates are made from B33 borosilicate glass plate [7]. 9 171 and the HV DC return, as shown in Fig. 2. 172 2.3. The Signal Path for Fast-Risetime Pulses 173 The pulses from photons incident on the photocathode have sub-nsec rise- 174 times, with typical bandwidths for the present 20-micron pores in the 1-2 GHz 175 range. The DC HV path and the path of the fast signal pulses share the same 176 HV distribution and ground. For the signal path, however, there are two con- 177 figurations we have considered, a ‘normal’ one in which the charge of the fast 178 signals is collected and recorded from the anode microstrips inside the vacuum 179 volume, and an ‘inside-out’ geometry in which the anode is a thin metal layer 180 that serves as a DC ground, but is thin enough so that the fast signal pulses 181 capacitively couple through to strips or pads on the external side of the bottom 182 plate. These are described in turn below. Figure 4: Two of the glass grid spacers after the resistive ALD coating has been applied. The grid spacers are cut from easily available B33 glass [7]. Mechanically, the spacers serve to transmit the compressive force of atmospheric pressure from the top to the bottom of the tube; electrically the resistive coating provides the voltage drop across each gap. Metalization of the top surface of the top spacer can serve to provide distribution of HV across the (resistive) photocathode. 10 183 2.3.1. Normal Anode Configuration 184 The signal path maintains the 50Ω impedance of the strip onto the printed 185 circuit card containing the waveform sampling 6-channel PSEC4 ASICs [12] 186 that digitize the signals. The thickness of the anode glass plate and the width 187 of the strips determine the impedance of the microstrip lines [4, 13]. While 188 the choice of impedance depends on a number of considerations, we chose a 189 50Ω impedance for convenience in testing to match cabling and oscilloscope 190 impedances. The choice of the anode plate thickness is application specific, 191 with impedance, strip parameters, occupancy, weight, cost, amount of inactive Figure 5: The glass window, showing the Nichrome border that is the ‘tie layer’ supporting the indium seal to the glass sidewall. The external tabs and the metalized border also supply the input HV to the cathode and resistive divider. The view is from the air-side (top); the Nichrome metalization for the seal and the HV distribution is visible on the vacuum-side (underneath) along the perimeter and on the four lands extending into the interior of the cathode. 11 Layer Resistance Voltage Drop Grid Spacer 1 2 MΩ 200 V MCP 1 10 MΩ 1000 V Grid Spacer 2 2 MΩ 200 V MCP 2 10 MΩ 1000 V Grid Spacer 3 6.5 MΩ 650 V Total 28.5 MΩ 3050 V Table 2: The target resistances and nominal voltage drops in the internal HV divider. The divider current is set at 100 µA, corresponding to a limit of approximately 1 µA of current draw from signal pulses [11]. 192 material in the path of charged particles being some of the considerations. After 193 the plate thickness is chosen the width of the anode strips can be set so to 194 determine the characteristic impedance. A further parameter is the gap between 195 strips, which is vulnerable to charging in high-rate applications if electric field 196 lines terminate on the dielectric. 197 Each 50Ω stripline is impedance-matched to the PC cards that digitize the 198 signals and that mate with the edge of the end tiles of a tile row, as shown in 199 Fig. 6. The DC return for the divider current through the 10KΩ resistor has 200 a much higher impedance than the 50Ω signal path. For flexibility in testing, 201 an easily removable connection was made using low profile Electro-Magnetic 202 Interference (EMI) shielding gaskets [14]. Each EMI gasket strip was cut at 203 the pitch interval into separate RF fingers and mounted on a 1/2” G10 bar to 204 match the anode spacing. Figure 6 shows the connections between the strips on 205 the tile and the strips on the PC card used for testing the tiles. 206 2.3.2. The ‘Inside-Out’ Anode 207 There are a number of applications, such as large collider detectors in HEP 208 and some medical imaging cameras, that would have many particles arriving in a 209 narrow time window and consequently high occupancies in a strip-line readout. 12 Figure 6: A picture showing the interface between the tile anodes and the readout system at the end of a row of tiles. The DC path to HV ground at the end of the microstrips is through individual 10KΩ resistors on each strip to HV ground on the analog card that holds the waveform sampling ASICs. To allow easy disconnection for testing, a bar of FR4 with RF-fingers is used to bridge the gap between each of the 30 strips on the tile to the corresponding strip on the PC card. 13 210 These applications would benefit from a 2-dimensional ‘pad’ readout rather than 211 a 1-dimensional stripline geometry. 212 The fast risetime of the signal pulses from the MCP amplification chain 213 provides a mechanism to extract the signals from the vacuum volume by ca- 214 pacitively coupling through the glass anode bottom plane. In this ‘inside-out’ 215 implementation, a uniform metal layer thinner than a skin-depth at frequencies 216 characteristic of the MCP risetime is deposited on the inner (vacuum-side) side 217 of the anode bottom glass plate, replacing the microstrips. This layer provides 218 the ground return for the DC HV current. The outer (air-side) side of the anode 219 plate supports the readout pattern deposited by metalization, typically in pads 220 or strips. This layer can then be connected to the electronics and additional 221 grounds as necessary. 222 3. Implementation in the LAPPDTM Package 223 The LAPPDTM design integrates the mechanical structure with both the 224 high frequency signal path and the HV DC current path into a single economical 225 structure. The advantage of the integrated design is the construction is planar, 226 with all electrical connections lying in the same plane as the thin form-factor 227 detector module itself. This allows a ‘tiling’ of large areas with a higher filling 228 factor than would be possible with individual modules with edge-readout. We 229 give details of the implementation below. 230 3.1. Mechanical Dimensions 231 The tile assembly is a flat glass package with transverse dimensions of 229.1 232 mm in the strip direction by 220 mm transverse. The active area is 203 mm 233 by 203 mm (8” by 8”). The current prototype grid spacers occlude 16% of the 234 active area; this will be reduced in future designs after more experience with 235 this first-generation simple implementation. 236 A mockup of an assembled glass module, made with prototype glass parts 237 but without a photocathode or vacuum seal, is shown in Figure 7. Multi- 238 ple modules can be integrated into a ‘supermodule’, sharing the RF-strip-line 14 239 readout mounted on the ‘Tray’ that also supports the electronics, as shown in 240 Figure 8 [4]. Figure 7: An 8”-square (20 cm-by-20 cm) LAPPDTM module (‘tile’). The tiles are hermetically sealed vacuum tubes that provide the photocathode and MCPbased amplification chain. The upper layer of the micro-strip RF transmission lines that form the anode are on the internal surface of the bottom plate of the tile; the ground plane of the transmission line is the upper surface of the supporting ‘Tray’, shown in Figure 8. The thin format and modular nature of the photodetector allow application-specific optimization. 241 The tile is made from glass layers stacked to form a rigid structure when 242 compressed by atmospheric pressure. The vacuum volume is enclosed by the 243 2.75 mm-thick top window, a standard plate glass thickness. The photocathode 244 is on the bottom surface of the window, facing the top of the upper MCP (see 245 Fig. 1). The anode plate with silver microstrips on its top surface, serves as the 246 bottom of the vacuum volume, and is also 2.75 mm-thick. A rectangular border 247 of 5.08 mm (0.200”) width, cut from a standard thickness glass plate, forms the 15 Figure 8: A ‘supermodule’ consisting of twelve 8”-square LAPPDTM modules (‘tiles’) mounted on a ‘tray’ that provides the ground plane for the anode microstrips and the support for the digitizing electronics at each end. Each row of 4 tiles shares the same anode strips in series, as described in Ref. [4]. 248 sidewall of the volume. 249 The sidewall is sealed to the anode plate over the microstrips with a glass 250 frit seal. The metal microstrips extend beyond the sidewall so that contact can 251 be made with neighboring tiles [4] or the digitization printed circuit cards at 252 the end of a tile-row [12]. 253 4. Performance of the HV Divider 254 The proposal to use ALD coatings on the grid spacers and MCP’s to deter- 255 mine the amplification and transport voltages had unknown risks at the outset 256 of the LAPPD program. In particular we are relying on the stability of the 257 coatings under a large mechanical pressure. Atmospheric pressure corresponds 258 to almost 1200 lbs on the top and bottom plates. The pressure on the MCP 16 259 surfaces is magnified by the ratio of areas of the grid spacer to the total area, 260 approximately a factor of 10. The surfaces of the MCP’s consist of glass capil- 261 laries with ∼ 65% open area, and have both metal electrode material and ALD 262 secondary-emitting material; the surfaces of the grid spacers have a grid-specific 263 ALD resistive coating. How these interfaces behave under pressure, with tem- 264 perature, and over time is not tractable to calculation; we have consequently 265 embarked on a series of measurements of the stability of the HV divider assem- 266 bly under HV and pressure. Several of the test facilities are described in turn 267 below. 268 4.1. Test Facilities 269 Section 4.1.1 describes a custom test facility, the Spacer Station (ISS) used 270 to make DC measurements of current and voltage. A second test facility, the 271 ‘Demountable Tile’, consisting of an actively-pumped glass-body tile mechanical 272 assembly with an O-ring top seal, is used to make measurements of fast pulses 273 at resolutions down to 5 psec, as described in Section 4.1.2. 274 4.1.1. The Spacer Station (ISS) 275 To measure the resistance of the grid spacers and MCP plates versus pres- 276 sure, temperature, and over time, a simple flat square vacuum vessel with a 277 flexible lid consisting of an aluminum foil incapable of withstanding atmospheric 278 pressure was constructed. The window provides the same (atmospheric) pres- 279 sure on the component stack as the glass window of the sealed tile. Figure 9 280 shows the ISS open to air with a single grid spacer inside. The copper plate 281 to the right of the ISS provides HV contact to the layers being measured; the 282 ISS frame is the DC ground. Single, multiple, or a full stack of the component 283 layers (grid spacer and MCP) can be measured using suitable non-conducting 284 spacers above the copper plate. 285 4.1.2. The Demountable Tile 286 In order to test the time and position response of the photodetectors as a 287 system we have constructed a facility [15] of which the key components are a 17 Figure 9: The spacer station (ISS) used to measure resistances of individual grid spacers, MCP’s, and the complete divider. A grid spacer is shown in the vacuum volume; the copper plate being held on the right is an electrode that supplies the HV to the piece being measured. A thin insulating layer separates the copper HV electrode from the 2.75-mm-thick top window, which is thin enough that atmospheric pressure deflects it until stopped by the internal stack of MCP’s and grid spacers, compressing the divider. 288 pulsed Ti:Sapphire laser with a pulse width ∼100 fsec, and a data-acquisition 289 system with 60 channels of 10-15 GS/sec waveform sampling readout, shown 290 in Figure 10. The Demountable Tile is constructed with the anode frit-sealed 291 to the sidewall and the internal HV divider as in the LAPPDTM , but has 292 a removable window sealed with an O-ring so that MCP plates can be easily 293 inserted and removed for rapid testing. The tile consequently has to be actively 294 pumped, and has an air-stable aluminum cathode. 18 295 The HV control system for the Demountable Tile Test Facility allows for 296 measuring voltage and current under computer control [15], and similarly mea- 297 suring the stability of the gain and spatial response over the face of the tile [16]. 298 Figure 10: The Demountable Tile test setup, consisting of glass tile of the LAPPDTM design constructed with the LAPPDTM hermetic package and internal divider, but with a removable window sealed with an O-ring. The tile consequently has to be actively pumped, and, as a bialkali anode cannot survive in air, has an aluminum cathode. However the HV divider and signal circuit are the same as in the sealed tile. The tile is shown sitting on a 4-tile anode readout ‘Tray’, which is equipped with 60 channels (30 strips on each end) of 10-15 GS/sec waveform sampling PSEC-4 ASICs. 19 299 4.2. Current-vs-Voltage (I-V) Curves 300 One concern about using ALD-coated elements as a HV divider is the possi- 301 ble non-linear or non-reproducible behavior as a function of voltage. Figure 11 302 shows the measured I-V curve using the ISS facility. The behavior is linear, and 303 demonstrates little hysteresis. Figure 11: The current-vs-voltage (I-V) data for the ALD-based HV divider, as measured in the ISS test facility. The voltage is measured both ramping up and ramping down increased (red, squares) vs decreased (blue, circles). The slope gives the effective resistance of the multi-layer divider. 304 4.3. Thermal Coefficient 305 The temperature dependence of the divider resistance is of concern due to 306 the vulnerability of MCP-based photodetectors to thermal run-away [17]. The 307 divider resistance depends on the thermal coefficients of the ALD-coatings of 308 the grid-spacers and MCP’s. The resistivity of the coatings on the grid spacers 309 is different from that for the MCP’s, as the effective conducting areas are so 310 different. At present the three grid spacers are coated in the same batch, so the 20 311 difference in resistance is determined solely by the difference in the conduction 312 path length of the thicker grid spacer from that of the other two (see Table 1). 313 Figure 12 shows the resistance of the HV divider as a function of temperature, 314 measured in the ISS. Figure 12: The resistance of the HV divider as a function of temperature. The measurements between room temperature and the temperature of ice were measured by necessity ‘on the fly’, rather than in thermal equilibrium, a possible explanation of the apparent offset from the curve. 315 4.4. Pressure Dependence 316 The contacts between the grid spacers and the MCP’s are complex electri- 317 cally and mechanically [18]. The Spacer Station (ISS) was constructed with 318 a thin foil top ‘window’ specifically to measure the contact resistances versus 319 pressure. The pressure is varied by control of the vacuum inside the ISS through 320 a needle valve to the pump. A curve of resistance vs the pressure on the layers 321 of the HV divider (lbs/in2 ) is shown in Figure 13. The drop in resistance of 322 approximately 20% at low pressure is presumably due to changes in contact. A 21 323 small amount of hysteresis is observed; however in an operating evacuated tile 324 the pressure on the stack is stable, with only minor variations due to changes 325 in atmospheric pressure or temperature. Figure 13: The resistance of the HV divider as a function of the pressure compressing the divider stack. The pressure is varied by using the differential between atmospheric pressure on one side of the thin foil window at the top of the ISS and the partial vacuum inside the volume. The pressure in the ISS is controlled by pumping through a needle valve. Note the suppressed zero on the ordinate. 326 4.5. Long-term Stability 327 The large pressure (> 1000 lbs) on the HV divider transmitted through the 328 thin glass top window and bottom plate is also cause for concern about the 329 long-term stability of the electrical contacts between the layers that constitute 330 the divider. The mechanical and electrical stability of the interface are subject 331 to changes due to pressure, electro-chemistry, and temperature, as well as a 332 possible slow creep of a component or layer under the pressure. Over the course 22 333 of 11 months under vacuum, a stack of two MCP’s and 3 grid spacers the 334 Demountable Tile has remained stable in resistance, gain, and uniformity, giving 335 us confidence in the mechanical design. 336 5. Conclusions 337 The use of ALD for functionalizing glass capillaries and glass grid spacers 338 enables a modular compact design of a thin planar photodetector with an in- 339 ternal HV divider. The LAPPDTM module is simple, consisting of eight parts, 340 all made of glass, and a simple getter assembly. The amplification section con- 341 sists of two 203 mm-by-203 mm MCP’s. The HV divider is formed by applying 342 resistive coatings to the grid spacer in each of the three gaps: between the pho- 343 tocathode and MCP1, between MCP1 and MCP2, and between MCP2 and the 344 anode microstrip transmission lines. 345 The sealed module sits flat on a ground plane that is shared with neighboring 346 modules; there are no connecting pins on the back side. The HV is applied to an 347 external metalized tab that connects to the metal top seal between the window 348 and the glass sidewall. The DC ground is provided by the anode ground plane 349 of microstrips, which are deposited on the top surface of the glass bottom plate 350 of the hermetic package, and extend through the seal to outside the vacuum 351 volume. The anode microstrips can be connected in series to form a continuous 352 anode up to 90 cm long, with the DC ground return and ASIC readout on the 353 ends of the outer-most modules [4]. 354 Measurements of current vs voltage in the HV divider have been made in 355 a custom test setup and in the module glass body on a 90-cm anode. The 356 measurements in the test setup have been made as a function of the pressure on 357 the divider, controlled by varying the vacuum in the module. Measurements of 358 the temperature dependence and stability are also presented. An 11-month test 359 under vacuum gives us confidence in the long-term stability of this relatively 360 simple integrated electro-mechanical design. 23 361 6. Acknowledgments 362 We thank our colleagues in the Large Area Psec Photodetector (LAPPD) 363 Collaboration for their contributions and support. Special thanks are due to A. 364 O’Mahony (Incom) and Neal Sullivan (Arradiance) for their essential work on 365 ALD coatings for the components of the internal stack. Thanks are due to R. 366 G. Wagner (ANL) for technical support; D. Walters, and J. Williams (ANL) for 367 metalization of the windows and vacuum expertise; and H. Wen and H. Gibson 368 (ANL) for laser and electronics support at the APS testing lab. We are deeply 369 grateful to E. Hahn (Fermilab) for meticulous metalization of the MCP’s, and P. 370 Murat (Fermilab) for support. R. Metz (UC) provided expert machining of test 371 setups and glass parts. M. Heintz (UC) supplied crucial technical and computer 372 systems support. We thank Q. Guo (UC), Chian Liu (ANL) and H. Clausing 373 (H. Clausing, Inc) for expert advice and large amounts of time teaching us about 374 cleaning and metalization of glass. We also thank our superb glass vendors P. 375 Jaynes (CatI Glass, Inc) and P. Seegebrecht (Webcorr) for metalization and 376 glass 377 The activities at Argonne National Laboratory were supported by the U. S. 378 Department of Energy, Office of Science, Office of Basic Energy Sciences and 379 Office of High Energy Physics under contract DE-AC02-06CH11357, and at 380 the University of Chicago by the Department of Energy under DE-SC-0008172, 381 the National Science Foundation under grant PHY-1066014, and the Driskill 382 Foundation. 24 383 References 384 [1] The original LAPPD institutions include ANL, Arradiance Inc., the 385 Univ. of Chicago, Fermilab, the Univ. of Hawaii, Muons,Inc, SLAC, 386 SSL/UCB, and Synkera Corporation. More detail can be found at 387 http://psec.uchicago.edu/. 388 389 [2] J.L. Wiza, Micro-channel Plate Detectors. Nucl. Instr. Meth. 162, p567; 1979 390 [3] E. Oberla, Ph.D thesis, in preparation. We thank H. Nicholson for the 391 original suggestion of using large-area planar detectors for water Cherenkov 392 neutrino detectors, and for the OTPC name. 393 [4] H. Grabas, R. Obaid, E. Oberla, H. Frisch, J.-F. Genat, R. Northrop, F. 394 Tang,D. McGinnis, B. Adams, M. Wetstein, RF Strip-Line Anodes for Psec 395 Large-Area MCP-based Photodetectors. Nucl. Instr. Meth. A71, p124; 2013 396 [5] The glass capillary substrates are produced by Incom Inc. Charlton Mass. 397 398 See http://www.incomusa.com/. [6] S. M. George, Atomic Layer Deposition: An Overview; Chemical Reviews 399 2010, 110, (1), 111-131; 400 J. W. Elam, D. Routkevitch, and S. M. George, Properties of ZnO/Al2O3 401 Alloy Films Grown Using Atomic Layer Deposition Techniques; Journal of 402 the Electrochemical Society 2003, 150, (6), G339-G347; 403 D. R. Beaulieu, D. Gorelikov, H. Klotzsch, P. de Rouffignac, K. Saadat- 404 mand, K. Stenton, N. Sullivan, and A. S. Tremsin, Plastic microchannel 405 plates with nano-engineered films; Nucl. Instr. Meth. A633, S59-S61 (2011); 406 O.H.W. Siegmund, J.B. McPhate, S.R. Jelinsky, J.V. Vallerga, A.S. Trem- 407 sin, R. Hemphill, H.J. Frisch, R.G. Wagner, J. Elam, and A. Mane, 408 Development of Large Area Photon Counting Detectors Optimized for 409 Cherenkov Light Imaging with High Temporal and sub-mm Spatial Reso- 410 lution; NSS/MIC 2011 IEEE, p2063 (Oct., 2011). 25 411 [7] http://psec.uchicago.edu/glass/borofloat 33 e.pdf#page=28; The dielec- 412 tric constant is 4.6 and the loss tangent is 37 × 10−4 , both measured at 413 25C and 1 MHz. 414 [8] Ferro Corp., 251 Wylie Ave., Washington PA 15301. We are grateful to E. 415 Axtel for extensive assistance with selecting the silver ink for silk-screening 416 the anode microstrips. 417 [9] A. U. Mane, W. M. Tong, A. D. Brodie, M. A. McCord, and J. W. Elam, 418 Atomic Layer Deposition of Nanostructured Tunable Resistance Coatings: 419 Growth, Characterization, and Electrical Properties, ECS Transactions, 64 420 (9) 3-14 (2014); 421 A. U. Mane and J. W. Elam, Atomic Layer Deposition of W:Al2O3 422 Nanocomposite Films with Tunable Resistivity, Chem. Vap. Deposition, 19, 423 186-193, (2013) 424 [10] The tabulated values are those in current use. They can be changed to 425 optimize the voltages across the respective gaps for specific performance 426 goals. The total thickness depends on the height of the sidewall, which also 427 can be optimized for different applications. 428 429 [11] Photomultiplier Tubes: Principles and Applications, S-O Flyckt and C. Marmonier; Photonis Brive, France, Sept. 2002 430 [12] E. Oberla, H. Grabas, J.-F. Genat, H. Frisch, K. Nishimura, G. S. 431 Varner, A 15 GSa/s, 1.5 GHz Bandwidth Waveform Digitizing ASIC, 432 Nucl.Instrum.Meth. A735 (2014) 452-461. 433 [13] For an excellent discussion of transmission lines, see E. Bogatin, Signal 434 Integrity Simplified, Prentice Hall Professional Technical Reference, 2004. 435 Chapter 10 is especially clear on cross-talk in striplines. 436 437 [14] Leader Tech part number 12-60LPAH-BD-16; Laird Technologies, Item 97115 26 438 [15] B. Adams, M. Chollet, A. Elagin, R. Obaid, E. Oberla, A. Vostrikov, 439 P.Webster, M. Wetstein; A Test-Facility for Large-area Microchannel Plate 440 Detector Assemblies Using a Pulsed sub-Picosecond Laser, Rev. Sci. In- 441 strum. 84, 061301 (2013) 442 [16] B. Adams, A. Elagin, M. Wetstein et al.; Measurements of the Gain, Time 443 Resolution, and Spatial Resolution of a 2020 cm2 MCP-based Picosecond 444 Photo-detector, Nucl. Instrum. Meth. A732 (2013) 445 [17] C. W. Carlson and J. P. McFadden Design and Application of Imaging 446 Plasma Instruments, in Measurement Techniques in Space Plasmas: Parti- 447 cles, R. F. Pfaff, J.E. Borovsky, and D. T. Young eds.; American Geophys- 448 ical Union pub. (1998) 449 [18] The measurements presented here are made with MCP’s that have the 450 electrode surface ‘under’ the ALD resistive and emissive coatings. The other 451 option, ‘over’, has the electrode on top of the ALD coatings. Both options 452 have their merits and drawbacks. 27