Medium Voltage Switching Devices Indoor earthing switch 12

advertisement

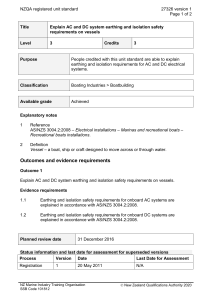

Medium Voltage Switching Devices EI SC Indoor earthing switch 12-36 kV Assembly and Maintenance Instructions No. AGS 531 986-01 Edition 05/2011 www.schneider-electric.com EI SC Contents Remarks on this manual.............................................................................. 4 Purpose and target group............................................................................................ 4 Reference documents................................................................................................. 4 Terms and symbols used............................................................................................. 4 Any questions or suggestions?................................................................................... 5 1 Safety provisions............................................................................... 6 2 Variants and technical data............................................................... 7 3 Transport, delivery, storage............................................................ 16 4 Assembly.......................................................................................... 17 5 Drives for the EI SC series.............................................................. 21 6 High-voltage terminal...................................................................... 24 7 Commissioning................................................................................ 25 8 Maintenance..................................................................................... 26 9 Annex................................................................................................ 28 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 3.1 3.2 3.3 3.4 4.1 4.2 4.3 4.4 4.5 4.6 4.7 7.1 7.2 8.1 8.2 8.3 8.4 8.5 9.1 9.2 9.3 AGS 531 986-01 | Edition 05/2011 Design and function......................................................................................... 7 Special models (optional)................................................................................. 9 Technical data................................................................................................ 10 Standards and regulations applied................................................................. 10 Ambient and operating conditions.................................................................. 10 Technical data for electrical control and operating devices . ..........................11 Nameplate...................................................................................................... 12 Dimensions.................................................................................................... 13 Intended use.................................................................................................. 15 Disposal at the end of service life.................................................................. 15 Shipping units................................................................................................. 16 Transport with forklift truck............................................................................. 16 Delivery.......................................................................................................... 16 Storage........................................................................................................... 16 Safety provisions and instructions for assembly............................................ 17 State as delivered.......................................................................................... 17 Transport by means of a crane...................................................................... 18 Changing the drive side (optional)................................................................. 18 Installation positions....................................................................................... 19 Fastening....................................................................................................... 20 Earth terminal................................................................................................. 20 Checking assembly........................................................................................ 25 Performing switching tests............................................................................. 25 Servicing and maintenance instructions......................................................... 26 Cleaning insulating components.................................................................... 27 Avoiding condensation................................................................................... 27 Corrosion protection....................................................................................... 27 Lubrication instructions.................................................................................. 27 Auxiliary products........................................................................................... 28 How to treat firmly screw-connected contact surfaces................................... 28 Specifications for screw connections............................................................. 29 3 EI SC Remarks on this manual As our products are subject to continuous further development, we reserve the right to make changes regarding the standards, illustrations and technical data. For reasons of clarity, simplified views are partially used. All dimensions specified in this manual are in millimeters. Purpose and target group This Technical Manual describes design, assembly and maintenance or indoor earthing switches of the EI SC type in indoor medium-voltage switchgear. The work described in this manual may only be performed by specialist electricians with proven experience in conjunction with ■■ the EI SC earthing switch ■■ all relevant safety provisions This Technical Manual is an integral part of the product and must be stored so that it is readily accessible at all times for and can be used by persons who are to work on the earthing switch. If the earthing switch or a panel equipped with this earthing switch is sold to new owners, these must receive this document along with the switch or panel. This Technical Manual cannot describe every imaginable individual case or every customer-specific version of the product. For information which is not included in this manual, please contact the manufacturer. Reference documents The following additional documents must be observed for the handling of this device: ■■ purchase agreement with the stipulations regarding the switch-specific equipment and the legal details ■■ the Assembly and Operating Instructions of the separate drives of the earthing switch: –– ■■ Manual drive mechanism STA 2 (No. AGS 531 992-01) –– Motor-operated drive mechanism GM 3-1 (No. AGS 531 997-01) the technical documentation (Assembly/Operating Instructions) of the switchgear into which the earthing switch is installed or to be installed Terms and symbols used This Technical Manual uses certain terms and symbols. They warn about dangers or provide important information which must be complied with in order to avoid danger to persons and damage to equipment: "Danger!" This danger symbol warns about dangerous electrical voltage. Contact with voltage may result in fatal injury! "Warning!" This danger symbol warns about the risk of injury. Please comply with all the provisions identified by this symbol in order to avoid death or serious injury. "Important:" This instruction symbol is used for information which is important to avoid material damage. 4 AGS 531 986-01 | Edition 05/2011 EI SC Remarks on this manual Any questions or suggestions? Do you have any questions or suggestions regarding this manual, or do you require further information? We always strive to provide you with the best-possible information for optimum, safe use of our products. Thus, do not hesitate to contact us if you have any recommendations, amendments or proposals for improvement. AGS 531 986-01 | Edition 05/2011 5 EI SC 1 Safety provisions The work described in this manual may only be performed by specialist electricians with proven experience in conjunction with the EI SC series and the applicable safety provisions. Read the instructions carefully before you work on the earthing switch. Applicable standards and regulations ■■ Common specifications for high-voltage switchgear and controlgear: IEC 62271-1 ■■ The locally applicable accident prevention, operating and work instructions must be complied with. ■■ Installation: IEC 61936-1/HD 637 S11 ■■ Operation of electrical equipment: EN 50110-11 The national standards applicable in the country where the equipment is to be installed must be complied with. 1 Behaviour in case of incidents or accidents 6 In case of fire or of internal faults, toxic and caustic decomposition products may be produced. Comply with the locally applicable accident and safety provisions. Make sure that first-aid measures are taken in case of injury to persons. AGS 531 986-01 | Edition 05/2011 2 EI SC 2.1 Variants and technical data Design and function 11 10 9 8 1 7 2 3 4 5 Fig. 1 Schematic view of the earthing switch EI SC 1 Frame with fastening bore-holes 7 2 Operating shaft 8 3 High-voltage terminal 9 4 Contact blades 5 Auxiliary switch (optional) 6 Snap-closing mechanism 6 Drive lever QW6 Spring pack Post insulator 10 Earth terminal, screw M12 (Earthing switches with a pole center spacing ≥ 210 mm are equipped with two earth terminals) 11 Nameplate Fig. 2 Earthing switch EI SC with double contact blades AGS 531 986-01 | Edition 05/2011 7 EI SC 2 Variants and technical data 1 75º Switching function Earthing switches of the EI SC series are equipped with a snap-closing mechanism. This ensures that the closing speed required for closing in case of a short-circuit is reached independently of the operating speed. 2 Contact blades and drive levers have an operating angle of 90°. On switching "on", the drive lever performs an idle movement of approx. 75° (Fig. 3). Subsequently, the shaft is taken along. Once the dead centre has been passed, the spring pack actuates the snap-closing mechanism (Fig. 4). On switching "off", the contact blades are taken along immediately and the spring pack is recharged simultaneously. 1 75º 2 8 Fig. 3 Drive lever (1), turned up to 75º; contact blades (2) have not tripped yet Fig. 4 Snap-closing mechanism actuated Fig. 5 Earthing switch OFF Fig. 6 Earthing switch ON AGS 531 986-01 | Edition 05/2011 EI SC 2 2.2 Variants and technical data Special models (optional) Optional attachments 1 2 3 Fig. 7 1 Pole partitions (optional depending on the ratings) 2 Blocking coil Capacitive divider-insulator The HV terminals are checked for zero voltage and/or phase coincidence acc. to IEC 61243-5 with integrated (e. g. IVIS, Fig. 9) or non-integrated voltage detecting systems. The electrical properties and dielectric strengths of the capacitive divider-insulators (Fig. 8) correspond to those of conventional post insulators; they have a short, screw-fastened connection cable and are suitable for connection to both high-resistance and low-resistance systems according to the relevant standard. For detailed information regarding the voltage detecting system IVIS, please contact the manufacturer. Fig. 8 Capacitive divider-insulator AGS 531 986-01 | Edition 05/2011 Fig. 9 Integrated Voltage Detecting System IVIS 9 EI SC 2 Variants and technical data 2.3 Technical data Rated voltage Ur [kV] 12 17,5 24 36 Rated lightning impulse withstand voltage Up [kV 75 95 125 170 Rated short-time power frequency withstand voltage Ud [kV] 28 38 50 70 Rated short-time current Ik [kA] Rated short-circuit duration tk Rated peak withstand current Ip Rated short-circuit making current Ima Rated frequency fr 251/31,52 [s] 1 [kA] 631/802 [Hz] Weight (without drives; see Chapter 5) 1 2 The earthing switch EI SC is: 501/632 50 Electrical endurance class Phase spacing 201/252 E1 165 175 210 215 250 [mm] [kg] 210 165 210 215 250 275 300 ≤ 30 350 370 400 460 ≤ 40 with single contact blade with double contact blade 2.4 Standards and regulations applied ■■ type-tested ■■ designed for indoor switchgear units Series EI SC earthing switches comply with the following standards and regulations: Switching devices Standard Common specification for high-voltage switching devices IEC 62271-1 Earthing switch IEC 62271-102 2.5 Ambient and operating conditions The EI SC series switches are indoor switching devices and may only be operated under normal operating conditions acc. to IEC 62271-1. Operation under conditions deviating from these is only admissible upon consultation with and with the written approval of the manufacturer. Ambient conditions (in accordance with IEC 62271-1) "minus 25 indoors"1 Temperature class 1 10 Ambient temperature min./max. °C –25/+401 Average value over 24 hours °C ≤ 351 mean rel. air humidity: 24 hours/1 month % ≤ 95/≤90 Installation altitude above sea level m ≤ 10001 other values available on request AGS 531 986-01 | Edition 05/2011 EI SC 2 Variants and technical data 2.6 Technical data for electrical control and operating devices On principle, the earthing switch is designed for manual operation. The drive mechanisms can be equipped with electrical control and operating devices, depending on the specific customer's model . Auxiliary switch (HS 3) Permit direct control of releases, blocking coils and motor-operated drives. Auxiliary switches are always actuated directly by the switch shaft via an intermediate linkage. Their position always corresponds to that of the main contacts. VDC [V] 24 48 60 110 220 Switching capacity [A] 8 4 3 2 1 Rated short-time current 120 230 10 100 A/30 ms Time factor T = L/R [ms] Rated continuous current Variants available for the auxiliary switch HS 3 VAC Rated supply voltage ≤ 20 [A] – 10 11 23 31 43 51 63 71 83 91 103 111 123 12 24 32 44 52 64 72 84 92 104 112 124 HS 3/2 HS 3/4 HS 3/6 HS 3/10 HS 3/12 Fig. 10 Circuit diagram and item of apparatus designation of the auxiliary switches HS 3/2 to HS 3/12 (2-/4-/6-/10-/12-pole) Blocking coil (Y1) Prevents actuation of the earthing switch. Only after the armature has been actuated is manual actuation enabled and the ON or OFF operations can be performed. In case of failure of the power supply, all blocking coils are in their "locked" position. Power consumption: approx. 12 W/VA Motor-operated drive (GM 3-1) Overview of rated supply voltages AGS 531 986-01 | Edition 05/2011 see separate Manual AGS 531997-01. Overview of rated supply voltages Direct voltage DC [V] Alternating voltage AC [V] 24 48 120 60 110 220 230 11 EI SC 2 Variants and technical data 2.7 Nameplate The type designation of the earthing switch on the nameplate (Fig. 11) specifies essential technical data. It is explained using the following example: 1 2 3 4 Fig. 11 Nameplate of the earthing switch EI SC 1 Type designation 2 Serial number 3 Year of construction 4 Technical data EI SC1 / 24 / 63 / 275 Earthing switch EI SC Rated voltage 24 kV Peak withstand current 63 kA Phase spacing 275 mm (T = with partition attachment) When submitting enquiries to the manufacturer or when ordering spare parts, the following information is required: ■■ Type designation 12 ■■ Serial number ■■ Year of construction AGS 531 986-01 | Edition 05/2011 2 EI SC 2.8 Variants and technical data Dimensions (further dimensional diagrams available on request) 28 150 e 205 74 120 40 14 39 d c I1* º 90 a b I c 60 Fig. 12 Dimensions of earthing switch EI SC with single contact blades and rated peak withstand current 63 or 50 kA Type EI SC (without capacitive post insulators) 12/63/1651 a b c d e 440 490 165 281 340 12/63/2101 12/63/2151 12/63/2501 17,5/63/210 24/63/165 24/63/2101 24/63/2501 24/63/2751 24/63/3001 36/50/370 36/50/4001 460 590 590 690 590 440 590 690 750 740 940 1000 510 640 640 740 640 490 640 740 800 790 990 1050 175 210 215 250 210 165 210 250 275 300 370 400 281 281 281 281 326 361 361 361 361 361 476 476 340 340 340 340 386 421 421 421 421 421 534 534 36/50/460 1120 1170 460 476 534 a b c d e 12/63/1751 Type EI SC (with capacitive post insulators) 12/63/150 12/63/1651 12/63/2102 12/63/2151 24/63/2101 24/63/250 24/63/275 24/63/300 1 I1 short medium long short medium long 283 333 365 539 593 623 483 483 483 483 365 483 533 550 743 743 743 743 539 743 850 850 383 383 383 383 283 383 433 483 also available with red blades AGS 531 986-01 | Edition 05/2011 490 490 490 640 640 740 800 790 2 165 165 165 215 210 250 275 300 281 281 281 281 361 361 361 361 340 340 340 340 421 421 421 421 333 433 433 433 333 433 483 533 533 550 750 750 593 743 743 743 593 743 850 955 955 1100 750 medium 433 483 1495 1495 I long 288 383 850 850 850 850 623 850 955 955 1495 I1 short 440 440 440 590 590 690 750 740 I short medium long 556 333 433 433 433 533 533 483 483 533 743 850 850 593 743 743 743 850 850 955 955 955 only available with red blades 13 2 EI SC Variants and technical data 28 e 150 205 74 120 14 40 39 d c c I1* º 90 a b I 60 Fig. 13 Dimensions earthing switch EI SC with double contact blades and rated peak withstand current 80 or 63 kA Type EI SC (without capacitive post insulators) 12/80/165 12/80/210 12/80/250 17,5/80/210 24/80/275 24/80/300 36/63/350 36/63/370 36/63/400 36/63/425 Type EI SC (with capacitive post insulators) 12/80/210 12/80/250 24/80/275 14 a b c d e 520 590 690 590 750 740 940 940 1000 1050 560 640 740 640 800 790 990 990 1050 1100 165 210 250 210 275 300 350 370 400 460 281 281 281 326 361 361 476 476 476 476 340 340 340 386 421 421 534 534 534 534 a b c d e I1* short medium 383 383 383 483 433 433 433 533 550 640 740 800 210 250 275 281 281 361 340 340 421 long 383 483 483 483 short medium 743 743 743 850 743 850 743 955 550 1100 750 750 750 483 long 743 850 850 850 1100 1495 1495 1495 I1* short 590 690 750 I I medium long 433 433 533 483 short 850 medium long 743 850 955 850 AGS 531 986-01 | Edition 05/2011 EI SC 2 Variants and technical data Motor-operated drive GM 3-1 (optional) attached 40,5 789 674 100 m Fig. 14 Dimensions, attachment of motor drive mechanism GM 3-1 Rated voltage Ur [kV] Dimension m mm 2.9 12 17,5 171 24 36 206 Intended use EI SC series earthing switches are exclusively designed for earthing and short-circuiting of parts of a circuit in indoor switchgear units. They may only be used in the scope of the specified standards, of the switchgear-specific technical data and of the application types specified in this manual. Any other utilization constitutes improper use and may result in danger and damage. Disclaimer of liability The manufacturer shall not be held responsible for damage which occurs if ■■ instructions in this Technical Manual are not complied with; ■■ the earthing switch EI SC is not operated according to its intended use (see above); ■■ the earthing switch EI SC is assembled, connected or operated improperly; ■■ accessories or spare parts are used which have not been approved by the manufacturer; ■■ the earthing switch EI SC is converted without the manufacturer’s approval, or if inadmissible parts are added. 2.10 Disposal at the end of service life Disposal is performed as a service by the manufacturer’s Service Center and is subject to a fee. For further information, please contact the manufacturer. AGS 531 986-01 | Edition 05/2011 15 EI SC 3 Transport, delivery, storage 3.1 Shipping units The conditions and types of transport have been stipulated in the contract details. The type of packaging depends on the type of transport and the storage conditions. The earthing switches are delivered ready for connection. The accessories are included. Packaging ■■ If earthing switches are exclusively transported by truck, they are delivered on a pallet, packaged in cardboard boxes or PE protective film, depending on their outside dimensions. ■■ For sea transport, the units are packed in sealed aluminium foil with desiccant and in a wooden case or cardboard box (also for container transport). ■■ In case of air transport, the units are either packed in cardboard boxes on a pallet or in wooden crates with PE film. 3.2 Transport with forklift truck The packing units may only be transported complete with pallet. Move the forks completely under the whole pallet. The earthing switch must be fixed safely on the pallet. Fig. 15 Transport with forklift truck 3.3 Delivery ■■ Handle shipping units carefully when unloading and unpacking them. ■■ Shipping units must be checked upon receipt. Any damage which may have occurred in transit must be recorded and reported to the manufacturer immediately. ■■ The consignment must be checked for completeness based on the shipping documents. The manufacturer must be notified in writing without delay about any possible deviations. 3.4 Storage Warning! Risk of injury due to sliding or tilting of transport units. Sufficient stability and evenness of the supporting area (floor) must be ensured. The transport packaging is not intended for storage. If earthing switches are not commissioned immediately after delivery, they can be stored under the following conditions: ■■ Storage only admissible indoors ■■ 16 Earthing switches must be sealed with desiccant in aluminium foil and be packed in a wooden crate (storage for max. two years after the date of packaging). + 40 ºC – 25 ºC Fig. 16 Schematic diagram of storage conditions for earthing switch EI SC AGS 531 986-01 | Edition 05/2011 EI SC 4 4.1 Assembly Safety provisions and instructions for assembly Danger! Prior to performing work in the high-voltage area, de-energize the system, verify it for zero voltage and earth the system according to the applicable safety rules in acc. with EN 50110-1. Danger! Prior to performing work on the drive mechanism or on the earthing switch, switch off the supply voltage and prevent the system from reclosing. Warning! Risk of injury from movable parts in mechanical drives: - isolate the system from the supply voltage, - Always switch ON the earthing switch and do not charge the earthing switch drive mechanism during assembly. Fitters The earthing switch may only be assembled and connected by the manufacturer’s staff or by persons with proven experience in conjunction with the EI SC series and the applicable safety provisions. Important: ■■ The tightening torques in Chapter 9.3 on page 29 must be used for all screw connections which are not directly defined in the assembly description. ■■ Check technical data on the nameplate (see page 12). 4.2 State as delivered The earthing switch EI SC is delivered in ON position (closing spring released) (Fig. Fig. 17). Fig. 17 State as delivered AGS 531 986-01 | Edition 05/2011 17 EI SC 4 Assembly 4.3 Transport by means of a crane Warning! Risk of injury during crane transport. The appropriate regulations for hoisting equipment must be complied with. Make sure the crane mounting harness is sufficiently strong. Never lift the switch by grasping it by the post insulators or conductor bars. The earthing switch can be lifted by grasping it on the frame or on the operating shaft. To this effect, a crane mounting harness with rope Ø 12–15 mm (not a metallic steel rope) or a strap is used. Fig. 18 Crane transport 4.4 Changing the drive side (optional) Prior to changing the drive side, a new return spring (Fig. 19, no. 3) must be ordered from the manufacturer's: Return spring, right-hand: AGSI09329-01 Return spring, left-hand: AGSI09347-01 Conversion from right-hand drive to left-hand drive: 1. Remove collar (Fig. 19, no. 4) and drive lever (5) from the shaft (1). Release clamping piece with free wheeling (2). Pull clamping piece and return spring (3) from the shaft. Do not re-use return spring. 2. Mount clamping piece, new return spring, drive lever and collar onto the other end of the operating shaft analogously (Fig. 19). 1 3 2 5 Fig. 19 Removal on the right-hand side 1 Operating shaft 2 Clamping piece 3 Return spring AGSI09329-01 4 Collar 5 Drive lever 18 4 4 3 2 1 5 Fig. 20 Mounting on the right-hand side 1 Operating shaft 2 Clamping piece 3 Return spring AGSI09347-01 4 Collar 5 Drive lever AGS 531 986-01 | Edition 05/2011 EI SC 4 Assembly 4.5 Installation positions The installation position for the series EI SC earthing switch can be selected freely, in acc. with Fig. 21. To this effect, the operating shaft must always be in horizontal position. Important: For different installation positions, please enquire at the manufacturer's. 4 1 3 2 Fig. 21 Possible installation positions for earthing switch EI SC 1 Wall mounting 2 Floor installation 3 Wall mounting, upside down 4 Ceiling mounting AGS 531 986-01 | Edition 05/2011 19 EI SC 4 Assembly 4.6 Fastening Important: The switch frame must not be distorted during assembly. In case of an uneven mounting surface, place washers below the unit. Fasteners are not included in the scope of supplies. The fastening material and the support must be suitable to bear the weight of the earthing switch EI SC and for operation thereof. Providing sufficient fastening is the responsibility of the operating company. The earthing switch EI SC is equipped with 4 oblong holes of 28 x 14 mm (Fig. 22) for fastening. Fasten the earthing switch to a metal frame or to a concrete wall by means of 4 bolts M12. Fig. 22 Securing boreholes of the earthing switch EI SC 4.7 Earth terminal Earthing devices are not included in the scope of supplies. Design and dimensioning of the earth terminal for the switch disconnector acc. to ■■ IEC 62271-100 and ■■ national design specification (Germany: DIN VDE 0101) The mechanical fastening of the switch disconnector to a steel frame can be used simultaneously for earthing the switch disconnector. Additional earth terminal Moreover, the frame cross beam features an earth terminal (bolt M12) which is identified by an earthing symbol (Fig. 23). Its position depends on the variant of the earthing switch: at the top or front. Important: Coat contact surfaces and comply with specified tightening torques (see Chapter 9.3 as of page 29). Fig. 23 Earth terminals (position - at the top or front - depending on the design) 20 AGS 531 986-01 | Edition 05/2011 EI SC 5 Drives for the EI SC series Drives are not included in the scope of supplies and must be ordered separately. Available drive variants Mounting drives The following drives can be used for actuation of the earthing switch EI SC: ■■ Manual linkage drive mechanism STA 2 (Fig. 24) ■■ Manual articulated drive mechanism STAD 2 (Fig. 25) ■■ Motor-operated drive mechanism GM 3-1 (Fig. 26) ■■ Lever QW6 with extensions QV1 (Fig. 27) The actuation angle of the contact blades is approx. 90°. Attachment of the drives is dependent on the installation position of the earthing switch, on the operator side and the type of drive as such. Assembly of the illustrated drives, as far as specified, is described in separate manuals. Please refer to the separate manuals for the manual linkage drive mechanism STA 2 and for the motor-operated drive GM 3-1. Warning! Mortal danger due to high voltage! When attaching the drives, make sure that parts of the drive linkage do not get too close to live parts. In case of doubt, please contact the manufacturer. Manual drive mechanism STA 2 For mechanical actuation of the earthing switch EI SC, the manual linkage drive mechanism STA 2 (Fig. 24) is available. The design of the drive depends on the installation position and on the operator side of the earthing switch. ON Fig. 24 Manual linkage drive mechanism STA 2 AGS 531 986-01 | Edition 05/2011 21 5 EI SC Drives for the EI SC series Manual articulated drive mechanism STAD 2 OFF 135-433 90º 90º 46,7 OFF 45,5 63 ON ON 63 Ø 10 7 90º 1 9 1 2 7 8 Ø 55 4 6 Ø 30 5 135-433 3 10 10 11 12 L Fig. 25 Manual articulated drive mechanism STAD 2 1 Cell frame 2 Drive lever for the earthing switch 3 Drive shaft of earthing switch 4 Coupling rod 5 Rear bearing 6 Stop 7 Steel shaft (optional plastic shaft) 22 8 9 10 11 12 Front bearing Swivel lever Steel ring with clampscrew for axial blocking of the shaft Roll pin for taking the shaft along ON/OFF indicator dial AGS 531 986-01 | Edition 05/2011 EI SC 5 Drives for the EI SC series Motor-operated drive mechanism GM 3-1 For electrical actuation of the earthing switch EI SC, motor-operated drives of type GM 3-1 are available (Fig. 26). They are mounted directly to the frame of the earthing switch so as to create a complete unit. Optionally, the motor-operated drive can also be delivered separately as an accessory and be installed in a different place in the cell. Important: For attachment dimensions and dimensional diagrams for the motoroperated drive GM3-1, please contact the manufacturer. Fig. 26 Motor-operated drive mechanism GM 3-1 Lever QW6 with extension QV1 Optionally, the earthing switch can be delivered with the actuating lever QW6 and the extension QV1 (in red or metallic) (Fig. 27). The earthing switch is actuated by means of a commercially available operating rod (1), which is not included in the scope of supplies. 2 1 3 Fig. 27 Drive mechanism with lever QW6 (2), extension QV1 (3) and commercially available operating rod (1) AGS 531 986-01 | Edition 05/2011 23 EI SC 6 Safety provisions and instructions for assembly High-voltage terminal Warning! The earthing switch can be damaged by inadmissible mechanical stress. Conductor bars must be fastened additionally to prevent mechanical forces from being exercised on the earthing switch after screw-fastening. Important: Note for connection of the coductor bars: ■■ Conductor bars must be dimensioned sufficiently according to the specifications for rated and short-circuit current. National regulations must be observed. ■■ In case of short-circuit current, make sure that the earthing switch is not exposed to higher electrodynamic forces. The connecting bars must be provided with sufficient support in the vicinity of the connecting points. ■■ The conductor bars must be positioned flat and so as to cover the holes. When tightening the connection bolts, make sure the switch connecting elements are not turned. Make sure to use a second wrench to block the bolts. Connecting conductor bars 1. Pre-coat connecting surfaces (see page 28). 2. Fasten busbars with the bolts M12 supplied with the unit as shown in Fig. 28 (tightening torque, see page 29). 1 2 Fig. 28 Conductor bar terminal 1 Conductor bars 2 M12 screw fastening 24 AGS 531 986-01 | Edition 05/2011 EI SC 7 Commissioning Danger! Mortal danger due to high voltage. The high-voltage supply must not be connected. All active parts must be earthed. 7.1 Checking assembly If damage has been detected, it must be repaired or the appropriate components be replaced immediately. In case of ambiguities or irregularities, please contact the manufacturer’s Service Center. 1. Check securing bolts. 2. Check the conductor bars’ screw connections using a torque wrench. 3. Check wiring laid on the site. 4. Check the earthing switch for damage which might be due to transport or assembly work. 5. Compare the data on the nameplate (see Chapter 2.7, page 12) to the required rating specifications. 6. Check supply voltage of the control and operating devices. 7. Check surfaces of insulating components for impurities. Clean if necessary (see page 27). 7.2 Performing switching tests Warning! Risk of injury due to the precharged drive mechanism and the quickly rotating contact blades. Perform switching tests only via the attached drive mechanisms and keep a sufficient distance from the earthing switch. Do not reach into the area of movement of the contact blades. Important: In case of failure of the power supply, the blocking coils (optional) are in "locked" position; thus, manual switching operations are blocked. Action: switch power supply ON. AGS 531 986-01 | Edition 05/2011 1. Apply supply voltage. 2. Switch the earthing switch ON and OFF manually several times. Check position indicators of auxiliary switches. 3. Check electrical functions of control and operating devices: –– optional interlock with blocking coil –– optional motor-operated drive GM 3-1 for earthing switch 25 EI SC 8 8.1 Maintenance Servicing and maintenance instructions Danger! Prior to performing work in the high-voltage area, de-energize the system, verify it for zero voltage and earth the system according to the applicable safety rules in acc. with EN 50110-1. Danger! Prior to performing work on the drive mechanism or on the earthing switch, switch off the supply voltage and prevent reclosure. Warning! Risk of injury from movable parts in mechanical drives: - isolate the system from the supply voltage, - Always switch ON the earthing switch and do not charge the drive of the earthing switch during assembly. - Do not disassemble the earthing switch for maintenance work. Maintenance work on the earthing switch may only be performed by the manufacturer’s staff or by persons with proven experience in conjunction with the EI SC series and the applicable safety provisions. Series EI SC earthing switches are indoor switching devices designed for normal operating conditions acc. to IEC 62271-1. Inspection It is recommended to check the earthing switch visually on a regular basis and according to the applicable national regulations, depending on the strain to which it is subjected. A visual inspection includes a complete check of the earthing switch for contamination, condensation and damage, to be performed by certified staff. Important: In case of frequent condensation or air pollution (dust, smoke or corrosive gases), the maintenance intervals must be adapted to the actual conditions. Maintenance If there are signs of impurities or condensation, the earthing switch must be cleaned in an expert fashion (see Chapters 8.2 and 8.3, page 27) and subsequently checked for proper functioning (see Chapter 7.2 on page 25). Servicing If damage has been detected, it must be repaired without delay or components be replaced. In case of ambiguities or irregularities, please contact the manufacturer’s Service Center. Servicing interval Servicing work Qualification / Work performed by after 2 closing operations with rated short-circuit making current after exposure to major stress by rated short-time current Inspection of the earthing switch certified staff after 1000 mechanical operations without electrical load 26 AGS 531 986-01 | Edition 05/2011 EI SC 8 Maintenance 8.2 Cleaning insulating components To ensure the specified insulating level, the insulating components must be clean. On principle, general cleanliness of the switch and of its external parts should be ensured. Slight contamination Clean using a dry, lint-free cloth. Depending on the degree of soiling, replace cloth as often as necessary. Severe soiling Use cleaning agent, 1 litre can (see Chapter 9.1, page 28). The use of other cleaning agents is not admissible. ■■ Wear protective gloves ■■ Use cleaning agents according to manufacturer's instructions ■■ Soak the cloth thoroughly and wipe the insulating components. Keep duration of exposure as short as possible. ■■ Expose the cleaned surface to the air for at least two hours. When cleaning, make sure that the lubrication in the drive mechanisms is not removed. If the drive mechanisms are no longer sufficiently lubricated, new lubrication must be applied. 8.3 Avoiding condensation To ensure the specified insulating level, the device – especially its insulating components – must not be exposed to condensation. Measures in case of condensation ■■ If there are signs of condensation: clean the earthing switch (see Chapter 8.2). ■■ Check heating system or install a heating. It must provide a sufficient heating performance to prevent condensation on the earthing switch. ■■ Condensation can also be prevented by ensuring suitable ventilation and heating of the station or by using de-humidification devices. 8.4 Corrosion protection Earthing switches and drive mechanisms have a long-term protection against corrosion. Any scratches and other damage must be repaired immediately to avoid corrosion. Contact the manufacturer’s Service Center. 8.5 Lubrication instructions For regreasing of bearings, latches and main circuit contacts, only the auxiliary products listed in Chapter 9.1 may be used. Apply a very thin film of lubricant on live parts. Group of compoPoint of lubrication nents ■■ Parts subject to ■■ mechanical stress Contact areas 1 AGS 531 986-01 | Edition 05/2011 Lubricant Application Low-temperature grease1 apply a uniform coat Contact grease1 apply a thin coat Shaft bearing Springs for instantaneous-switching mechanism ■■ Contact rivet ■■ Suspension elements ■■ Contact tab See Table "Auxiliary products" on page 28. 27 EI SC 9 Annex 9.1 Auxiliary products The auxiliary products are available from the manufacturer. The use of other auxiliary products is not admissible. Warning! Risk of injury if these products are handled improperly. Observe the safety data sheets of the manufacturers of the auxiliary products. Designation Ref. no. Cleaning agent, 1-l can S 008 152 Aseol Sylitea 3 Synthetic low-temperature grease with graphite S 008 163 Berulub FK 60 Contact grease AGSI89210-01 9.2 How to treat firmly screw-connected contact surfaces Important: ■■ Caution when handling bars insulated by heat-shrinkable sleeves. The heat-shrinkable sleeve must not get into contact with contact grease (swelling). ■■ Contact areas coated with contact grease should not be touched, if possible. 1. Contact surfaces must be subjected to preliminary treatment before screwfastening (see Table below) 2. Immediately after pre-treatment, coat contact surfaces with contact grease so that the space between the contact surfaces is filled once the screws have been connected. 1 2 3 28 Material of contact surfaces Pre-treatment silver-plated Clean1 Copper or copper alloy Clean1, expose metallic surface2 Galvanized steel Remove passivation, not, however, the zinc layer3 by means of lint-free cloth; use cleaning agent in case of serious contamination – by treating the entire surface with emery cloth or a rotating grinding tool (grain size 100 or finer) or – with a wire brush specifically marked for use exclusively for copper, aluminium, or steel with brass or steel brush AGS 531 986-01 | Edition 05/2011 EI SC 9 Annex 9.3 Specifications for screw connections Important: ■■ The threads of screws and bolts must generally not be pre-treated. ■■ Max. tolerance for the effective tightening torques: ±15 % ■■ The nut must correspond in strength to the grade of the screw/bolt used or be of better quality. General screw connections Grade or material Screw/bolt Thread Ø Screw connections for current transmission AGS 531 986-01 | Edition 05/2011 Plastic ≥ 8.8 ≤ 10.9 Self-locking screw ≥ 8.8 Tightening torques [Nm] M4 0,25 2,6 M5 0,5 5,0 7,0 M6 0,8 8,8 12,3 M8 1,8 21,0 30,0 M 10 3,5 42,0 59,0 M 12 6,0 70,0 97 Screws and bolts: Grade ≥ 8.8 Conductor material: copper Thread Ø Tightening torques [Nm] M6 6,5 M8 17 M 10 35 M 12 68 M 16 135 29 Notes: © Schneider Electric 2011 – All rights reserved to this technical manual. Reproduction and making available of this technical manual, or extracts, to third parties are prohibited. Only integral reproduction of this technical manual is permitted with the written permission from Schneider Electric. Electronic copies in e.g. PDF-format or scanned version have the status “for information only” . The only valid version of this technical manual is always enclosed directly to the product in question by the factory. Schneider Electric 35, rue Joseph Monier CS 30323 92506 Rueil-Malmaison Cedex, France As our products are subject to continuous development, we reserve the right to make changes regarding the standards, illustrations and technical data described in this Technical Manual. For any requests, please contact the address given below. RCS Nanterre 954 503 439 Capital social 896 313 776 € www.schneider-electric.com Schneider Electric Sachsenwerk GmbH Rathenaustrasse 2 D-93055 Regensburg, Germany ( +49 (0) 9 41 46 20-0 7 +49 (0) 9 41 46 20-418 AGS 531 986-01 | 05-2011