Power Transmission Fundamentals

advertisement

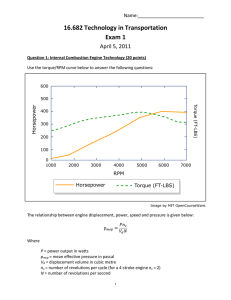

Power Transmission Fundamentals November, 2008 Topics •Measuring Systems •Speed and Velocity •Circumference of a Circle •Service Factors •Force •Ratios •Torque •Power Transmission Terminology •Work •Power •Horsepower •Efficiency 2 Measuring Systems A. British Engineering Units (BEU). The British Engineering Units use the foot (ft), pound (lb.), and second (sec) as the basis of measurement. B. International Standard (SI). The International Standard uses the metric system of measurement, which is based upon the meter (m), kilogram (kg), newton (N), and second (sec). 3 Circles A. Circumference or the measurement around the outside of a circle. B. The Diameter of a circle is a straight line drawn from a point on the circumference through the center to another point on the circumference. C. The Radius of a circle is ½ the diameter. 4 Force A. Force is the push or pull of one body on or against another body, usually measured in ounces, pounds or tons. When the applied force exceeds the resistance of the object, motion is produced. B. Motion is defined as a changing of position or displacement. When a shaft turns, it has motion. C. Types of Motion 1. LINEAR (Straight line) 2. ROTARY (circular) 5 Torque Torque is a twisting or turning force, which “tends” to produce rotation. Torque is determined by multiplying the applied force times the distance from the shaft center. Therefore: Torque = Force x Radius The force can be in either pounds or ounces, and the distance is in inches or feet. Torque is generally expressed in terms of foot-pounds, 6 Work A. The Engineering Definition: Work occurs when a force moves a body a measured distance. If the force does not move the object, no work is being done because no movement takes place. B. The quantity of work done is the amount of the force multiplied by the distance moved. C. FORMULA: Work = F X D 7 Power A. To calculate Power, we must add one more element: Time B. Power is the amount of work done in a given amount of time. Therefore, it can be said that power equals work divided by time. C. FORMULA: Power = Work (Force x Distance) divided by Time. 8 Horsepower The most common unit of measure is horsepower. James Watt developed the steam engine in the 18th century. He needed a way to compare its power with that of a horse. Experiments were conducted with horses lifting weights. It was estimated that a horse could raise 550 lbs. vertically at the rate of one foot in one second. Using these figures, the unit of horsepower was established at 550 ft.- lbs. per second or (550 x 60) 33,000 ft.-lbs. per minute. 9 Horsepower Formulas: Hp (seconds): HP = Work (ft.-lbs.) Time (Sec) x 550 Hp (minutes): HP = Work (ft.–lbs.) Time (min) x 33,000 HP = Torque(lb.ft) x rpm 5250 Torque (lb.ft.) = HP x 5250 rpm 10 Horsepower It is the responsibility of the customer to specify the required motor Hp, Torque, and accelerating time for his application. For estimating purposes only. Rules Of Thumb (Approximation) •At 1800 rpm, a motor develops a 3 lb.ft. per hp •At 460 volts, a 3-phase motor draws 1.25 amp per hp •At 230 volts a 3-phase motor draws 2.5 amp per hp 11 Efficiency Friction, created in the moving components of a machine, causes energy from the power source to be lost as heat; therefore, energy output is always less than energy input and is usually expressed as a percent (%). Efficiency is an important consideration in selecting a motor to drive an application through a speed reducing mechanism. The efficiency will vary depending on the type of reducing element and speed. 12 Efficiencies Typical Efficiencies •Single Stage Cyclo Reducer 95% •Helical gear reducer: Single reduction 98%. Double reduction 96% •Single Worm gear reducer 50% to 90% •Hyponic reducer: 85% Helical Gear Worm Gear Hypoid Gear 13 Double Helical Speed and Velocity The velocity (speed) of an object is the distance it travels in a given unit of time. More often, we are concerned with rotary motion (RPM or Revolutions Per Minute). In many cases (especially in working with conveyors) the customer may ask you to supply components based upon a driven speed given in feet per minute. V (FPM) = P.D. x .262 x RPM 14 Service Factor The service factor could be called appropriately an “experience” factor. The service factor takes into account such things as type of driver (motor or internal combustion engine), type of application, hours of operation, and miscellaneous conditions (abrasive dust, excessive heat or moisture, shock load etc.). It should always be applied in the selection of any power transmission component. Motor Horsepower x Service Factor = Design HP 15 Ratio Ratio is a fixed relation or proportion between two like objects. In power transmission it can be used to express size or speed relationships. Ratio is calculated by dividing the larger number by the smaller number. Ratios are never added or subtracted. They may only be multiplied or divided. 16 PT Terminology A. Mechanical Rating: Maximum HP or Torque a speed reducer can transmit over a continuous period without damage. B. Thermal Horsepower Rating: Actual horsepower a speed reducer will transmit continuously without overheating. C. Demand (or Brake) Horsepower: The amount of HP required to keep an application running at design speed, fully loaded. D. Design (or Equivalent) HP: Application HP times required service factor. A drive or coupling must rate at least design or equivalent HP/kW to be a good selection. 17 Terminology E. Breakaway Torque: The amount of torque that is required to overcome the machines inertia load and friction. F. Overhung Load: A load applied at a right angle to a rotating shaft. V-belts, pinions, chain and sprockets impart overhung loads. G. Thrust: A load applied parallel to a shaft’s axis, either inward or outward. H. Center Distance: Distance between centerlines of input and output shafts of parallel shaft and worm gear speed reducers. I.Bearing L10 Rating: It is calculated life expectancy. Not more than 10% of the bearings will be expected to fail within their design life. 18 Terminology AMBIENT TEMPERATURE Ambient temperature is the temperature of the air surrounding the equipment in question. AUXILIARY DRIVE Belt or chain drives used with a speed reducer to provide additional speed reduction (and torque multiplication) in a drive system. PRIME MOVER Driving member of a drive system; can be an electric motor, internal combustion engine, turbine, etc. 19 Congratulations 20