Category Specification

advertisement

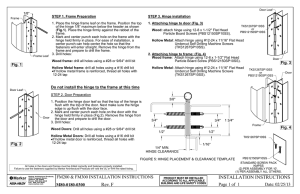

Double Swing 100 Degree Hinge Architectural Specification 1.750 [44] DOOR LEAF 100° 90° DOOR LEAF DOOR LEAF 3.000 [76] 2.750 [70] OPEN 90° 2.500 [64] OPEN 100° FRAME LEAF FRAME LEAF 2.500 [64] DSH Duty Hinge Electrical Modifications Serviceable/Removable (SER) Module - 4 Wire SER4 Size Bearing Maximum Door Weight Serviceable/Removable (SER) Module - 8 Wire SER8 83” & 85” 27 600 lbs Serviceable/Removable (SER) Module - 12 Wire SER12 95” 31 600 lbs 120” 39 600 lbs Electric Modifications Electrically modified hinges are available with concealed current transfer. PEMKO’s exclusive polyurethane-coated 4, 8, or 12 TRI-FLEX titanium copper alloy cables will each carry 16 amps continuous at 24 volts in-rush for 820 milliseconds. When ordering, please use the “shorthand code” shown in the chart. For example, if you require a Clear Anodized standard DSH at 83” with Serviceable Module -- 4 wire, modified 36-1/4” from the top, right hand, you would order DSHP01C-84 with SER4 at 36 -1/4” from top -RH Note: A 4 amp in-line fuse must be used between the hinge thru-wire and the power supply or warranty will be voided. Architectural Specification A. Designed for Safety and Reliability in Healthcare Facilities, Behavioral Health, Hospitals and Food Service B. Standards B.1. BHMA: Meets the requirement for ANSI/BHMA A156.26 Grade 1 for Continuous Geared Hinge B.2. ADA Compliance: DSH meets the barrier free requirements of ICC/ANSI A117.1-2009 and ADAAG-2010 C. CMS Compliant C.1. By eliminating additional ligature points ensures compliance for reimbursement through CMS (Centers for Medicare and Medicaid Services) D. Heavy Duty hinge shall be rated for a maximum door weight of 600 Ibs. E. Construction: Hinges shall consist of three interlocking extrusions in a pinless assembly applied to the full height of the door and frame. Hinges shall be manufactured to template bearing locations. E.1. Heavy duty 6063-T6 Aluminum Alloy/Temper E.2. Two full height, paired and geared leaves E.3. Polymer blended bearings E.4. Full-Length channel cap F. Increased critical stress points of the hinge leaf extrusions providing additional strengths and rigidity to completed product G. Distributes load stress uniformly along the full length of the door and frame H. Thrust type bearings shall carry the vertical loads and be completely concealed on one side by the channel cap over the full length of the hinge I. Inter-meshing gear segments in the hinge which provide 50% more bearing surface resulting in less wear. J. Bearing design eliminates premature wear, guarantees proper alignment and requires fewer bearings to carry more weight. K. Fasteners: All fasteners shall secure the hinge to door and frame using Security Torx Flat Head No. 8 12-24 x 1/2” Machine Screw L. Finishes: The frames leaf and the door leaf shall be anodized after milling and drilling processes are complete. L.1. Clear anodized aluminum (BHMA 628) in accordance with 204-R1 (AA-M12C22A31) clear L.2. Dark Bronze anodize aluminum (BHMA 313) in accordance with HC-II (AA-M12C22A44) dark bronze M. Optional finishes available by request N. 100° swing in either direction O. Ordered with PEMKO Emergency Released Stop (ERS) to improve safety and mitigate risk in Behavioral Health environment P. 1/2 lbs. or less operating force required to operate most doors, regardless of size www.pemko.com Memphis, TN USA P: 800.824.3018 F: 800.243.3656 Ventura, CA USA P: 800.283.9988 F: 800.283.4050 Vancouver, BC CA P: 877.535.7888 F: 877.535.7444 Toronto, ON CA P: 877.535.7888 F: 877.535.7444 Copyright © 2013 Pemko Manufacturing Company, an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Pemko Manufacturing Company is prohibited. November 15, 2013