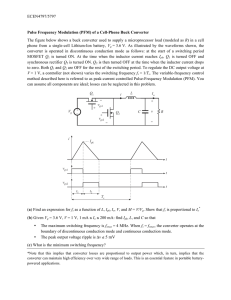

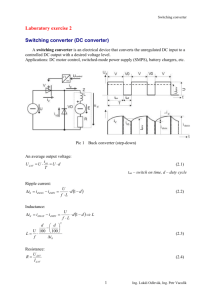

conventional and zvt synchronous buck converter design

advertisement