Dependence of Minimum Ignition Energy on Ignition Parameters E,ig

advertisement

©

Combust. Sci. and Tech., 1990, Vol. 73. pp. 395-413

Photocopying permitted by license only

Gordon and Breach Science Publishers. Inc.

Printed in Great Britain

Dependence of Minimum Ignition Energy on Ignition

Parameters

ABOELKAOER FRENOI and MERWIN SIBULKIN

Division of Engineering,

Brown University, Providence, R./. 02972

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

(Received January 30,1990; in final form May 14. 1990)

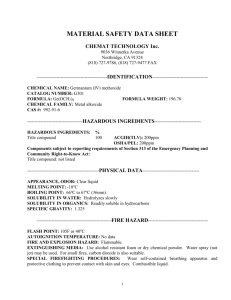

Abstract-Using two mathematical models (one allowing for pressure variations, and the other assuming

the pressure to be uniform), the minimum ignition energies of a stoichiometric methane-air mixture are

calculated. The effect of the initial pressure wave generated by the spark on minimum ignition energy is

studied by comparing the results of the two models. The pressure wave is found to affect the values of

minimum ignition energy for ignition times shorter than 2 us. The dependence of minimum ignition energy

on the kernel radius and ignition time are also investigated. The results show that as the kernel radius is

decreased to small values, the minimum ignition energy reaches a constant value. The ignition times that

give an optimum value of minimum ignition energy are in the range of 3 J.1.S to lOOps. Our results show that

minimum ignition energy is strongly dependent on the ignition parameters, and a minimum value of

0.005 mJ is found for an ignition kernel radius of 0.0635 mm and an ignition time of 27.5I's. This value is

70 times lower than the experimentally reported values. When a kernel radius of 0.5 rnm is used, fair

agreement with experiments is obtained.

NOMENCLATURE

A,

A

Cp

Da

o,

E

E,ig

s;

F

H( ...)

h,

k

K

/,

u,

M

o

P

Pr

p

Frequency factor

Frequency factor (see Eq. (17))

Average specific heat (see Eq. (18))

Non-dimensional number (see Eq. (26))

Binary diffusion coefficient for species k

Activation energy

Ignition energy

Ignition power

Fuel

Heaviside unit function

Heat of combustion per unit mass of fuel

Reaction rate constant

Geometry factor (I, 2n, 4n)

Reference length (/ = (K", r,)'/2)

Molecular weight of species k

Average molecular weight

Oxidiser

Products

Prandtl number

Pressure

Non-dimensional pressure

p

q

R

r

(fJ --

L)

p",

Integer controlling the spatial distribution of ignition energy

Rate of energy

Universal gas constant

Radius

395

A. FRENDI AND M. SIBULKIN

396

Non-dimensional time (I = ~)

r,

Temperature

T

T(O, ei,) Kernel center temperature at completion of energy input

Radial gas veloci ty

II

II,

Non-dimensional enthalpy (

pc;, (T - T",) )

P",cp (1J.uJ - T",)

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

Rate of production (or consumption) of species k per unit volume

Non-dimensional radius (r/I,)

Mass fraction of species k

Greek Symbols

p

Geometry factor (0, I,2)

Gas viscosity

Thermal conductivity

Thermal diffusivity

Mixture equivalence ratio

Stoichiometric coefficient of species k

Gamma function

Gas mixture density

Non-dimensional density (p/p",)

pu

Non-dimensional momentum flux (PII/p",(!c..»

r

r,

Time

Reference time ([p~ y~", A exp ( -

IX

Ii

).

K

</>

Vk

f( ...)

P

r,

PW 1)

Subscripts

f,ad

C

comb

d

f

ig

k

00

Ad iaba tic flame

Critical values

Combustion

Diffusion

Flame

Ignition

Species k (F, 0, P)

Outerflow condition

Superscripts

per unit volume

INTRODUCTION

The knowledge of ignition limits of a combustible gas mixture is of importance in

many combustion systems. In order to successfully ignite a flammable gas mixture, a

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

MINIMUM IGNITION ENERGY

397

sufficient amount of energy is needed. The smallest amount of energy that results in

a successful ignition is known as the minimum ignition energy. The experimental

determination of minimum ignition energy is done using different types of sparks. The

minimum ignition energies of various hydrocarbon fuels were determined by Blanc et

al. (1947, 1948) using a capacitance spark. They found that minimum ignition energy

varied with mixture composition, fuel type, pressure and electrode configuration. A

summary of these results and other experimental results is given in Lewis and von Elbe

(1987). For a stoichiometric methane-air mixture at Too = 298 K and p ; = latm, the

minimum ignition energy was found to be 0.35 mJ; the values of spark gap and spark

duration were not reported.

Ronney (1985) measured minimum ignition energies for methane-air mixtures both

at earth gravity and zero gravity for different pressures. He did not report any

significant difference between the minimum ignition energies except near the zero

gravity flammability limit, where the zero gravity minimum ignition energies were

higher than the earth gravity values. The minimum ignition energy for a stoichiometric methane-air mixture at the same conditions as above was found to be 0.5 mJ

for a spark gap of 3 mm and a spark duration of 6 us. Kono et al. (1976) studied the

effects of electrode configuration, electrode gap and spark duration on the minimum

ignition energy of lean propane-air mixtures. Their results showed the existence of an

optimum spark duration for which the energy is minimum. Decreasing the spark gap

increased the minimum ignition energy, and a similar result was obtained by increasing the electrode diameter. Kravchenko et al. (1973) determined the minimum ignition

energy for a near stoichiometric methane-air mixture as a function of circuit inductance. They found in the cases they studied that there exists a critical ignition time in

the range of 100-120 IlS, for which minimum ignition energy is minimal. This critical

time was found to be independent of the electrical and mechanical conditions of the

spark formation, and they concluded that it was dependent only on the nature and

state of the mixtures.

Even though the physical phenomena involved in ignition are complicated,

theoretical and numerical attempts at modeling the early stages of flame initiation

have been made, and a good understanding of the experimental results has been

reached. A detailed model for a hydrogen-air flame was presented by Dixon-Lewis

and Shepherd (1974). They studied the effects of adding hydrogen atoms to a cornbustible mixture, and found that the thermal energy needed to ignite the mixture was

reduced. This conclusion was also reached by Deshaies et al. (1984) when studying the

effect of molecular diffusion on flame initiation. Using matched asymptotic expansions for large activation energy they showed the existence of a critical radius for

successful flame propagation. When some of the fuel was replaced by hydrogen, the

critical radius became smaller, and if a constant heat source was placed at the center

of the kernel, no critical radius was obtained. Champion et al. (1986) calculated the

critical ignition parameters for premixed lean propane-air mixtures and used them as

the basis for their experiments. The effects of molecular diffusion, activation energy

and unburned gas temperature on minimum ignition energy for methane-air and

propane-air mixtures were examined by Tromans and Furzland (1986). Molecular

diffusion was found to have the greatest effect on minimum ignition energy. Their

results predicted the correct trend, but the values were five times lower than the

experimental ones. Sloane and Schoene (1988) used a detailed chemistry model for the

combustion of methane in air to study the relative importance of the different

reactions on minimum ignition energy. In their model, ignition energy was added

instantaneously into a spherical kernel.

In a recent paper by Maas and Warnatz (1988), an attempt at simulating a spark

A. FRENOI AND M. SIBULKIN

39H

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

ignition experiment was made. They used in their calculations two models; one

allowing the pressure to vary in the gas mixture and the other assuming the pressure

to be uniform. They also studied the effects of spark gap and spark duration on the

minimum ignition energy of a hydrogen-oxygen flame. They concluded that both

models predict the same minimum ignition energy for long ignition times, and that for

small kernel radii the energy became constant.

In this paper, two theoretical models are presented; one allowing the pressure to

vary in the gas mixture and the other assuming the pressure to be uniform. These

models are then used to calculate the minimum ignition energies of a stoichiometric

methane-air mixture for different ignition times and ignition radii. The results of these

two models are compared to existing numerical and experimental results.

MATHEMATICAL FORMULATION

The mathematical models presented in this paper are obtained from the conservation

laws for a chemically reacting gas mixture. The unsteady, one-dimensional models are

derived using the following simplifying assumptions;

• No gravitational force.

• The chemistry is modeled by a one-step, irreversible reaction.

• The gas properties used assume a constant specific heat (chosen to give the correct

adiabatic flame temperature, '0.ad)' constant values for p). and PJ1, and constant

values of p2 D for methane and oxygen.

• No volume heat losses (such as radiation) are included.

Based on these assumptions, the unsteady onedimensional equations written in a

conservation form are:

.

Mass conservation

I a

r' ar

ap

- + - - (ra pu) = 0,

aT

(I)

where ex = 0, I, 2 for planar, cylindrical and spherical geometries, respectively.

Species conservation

a (pYd + .!.. aa (rapYku)

r':l r

ar

la(a

aYk)

a - r pD k r ar

ar

+

(2)

lI'k

Momentum conservation

-a (pu)

aT

+ -I -a

r' ar

+

'

(ra

pu')

=

- ap

- -

ar

2-Ia -a [;

r II -au] + -ex [

r ar

ar

r

-2 -I -a

3 r" ar

[ J1a (ra)]

u

ar

a (r, u)]

- -2J1U

+ -32 -r'J1 -ar

r

(3)

Energy conservation

a - T)

-a (p

T

Cp

I

a

r

r

-

+ -;: -a (rap cp Tu)

.!..r" ~

or [ra A aD

orJ +

q....

com

b

+

q':"

19

(4)

MINIMUM IGNITION ENERGY

399

State equation

For an ideal gas mixture, the equation of state is

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

(5)

In the energy equation written above, the pressure work and the dissipation have

been neglected. The source terms q;;,m; and q;; represent the chemical power per unit

volume released and the ignition power per unit volume input respectively. For the

derivation of these equations, the reader is refered to Toong (1983). For many

combustion systems the pressure change across the combustion wave is neglegible and

therefore the pressure can be considered as uniform. This assumption results in

neglecting the momentum equation. In order to calculate the fluid velocity when the

constant pressure assumption is used, the continuity equation can be integrated to

give

=

pu

I

-r'

f,' r' -dr.

op

or

(6)

constant.

(7)

0

The equation of state (5) becomes

pT

=

Equations (6) and (7) along with Eqs. (3) and (4) define the constant (or uniform)

pressure model; whereas eqns. (I) through (5) define the variable pressure model .

• The energy source terms

The energy equation given by Eq. (4) is a general one; in order to apply it to a specific

case the source terms need to be defined. The following is the definition of the ignition

and combustion source terms.

The ignition source term

The study we are to perform is that of minimum ignition energy. Most of the recent

experimental work done on this subject used spark discharge systems which delivered

energy at a constant rate. Therefore we choose the ignition source term to be of the

form;

(8)

In this calculation, the spatial distribution used is close to a step function (p

derived in Sibulkin and Siskind (1987), the function g(P) is such that for

g(P)

=

[I ( I

+a -+-I)J/(' +

P

I)

6). As

(9)

the ignition energy is given by;

K

......,+1

- - I Lig'ig riga

+

(10)

A. FRENDI AND M. SIBULKIN

400

where K

=

1, 27': and 47':, for

Cl

=

0, 1 and 2 respectively.

The combustion source term

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

The gas mixture considered in this paper is stoichiometric methane-air. The combustion of methane involves over 100 simultaneous exothermic and endothermic chemical reactions. Depending upon the physical problem being solved, the number of

reactions can be reduced significantly using a sensitivity analysis. However, what is

needed in solving the energy equation is only the net local energy release rate q;~mb'

This is the motivation for the development of "global reaction" models which use

empirical reaction rate constants to model the combustion chemistry.

A single-step irreversible reaction can be represented by

(II)

where V F, "o and Vp are the stoichiometric coefficient for fuel, oxygen and products

respectively. The source terms Wk of the species equations can be written as

WF

= _k

Wo

=

F

M (pYS (PYa)""

F

F

M\'PM\'o

'

F

a

v

-kv M (pYF)"F(pYa)'O

a

0

M'FM'o

F

0

(12)

(13)

The combustion source term of the energy equation is given by

(14)

where h, is the heat of combustion per unit mass of fuel. Taking the rate constant of

the reaction to be of the Arrhenius form

k

=

A, exp (- E/RT),

(15)

leads to an expression for the combustion source term of the form

q;':m'b =

h,(pYp)'F (PYa)"" A exp (- E/RT)

(16)

where

A =

( 17)

The kinetic parameters A and E used in this calculation were determined by Coffee

et al. (1983). In their calculation for a steady, one-dimensional, laminar premixed

flame they tried to match the heat release rate of the global reaction to that of the

detailed chemistry model. After an initial choice of V F and Va, "best fit" values for A

and E were chosen for each mixture to give the correct value of q~"mb' The adiabatic

flame temperature and the heat of combustion h, are also taken from Coffee et al's

data. The specific heat was calculated using the relation

(18)

MINIMUM IGNITION ENERGY

401

• Initial and boundary conditions

The system of partial differential equations defining both the variable pressure and the

constant pressure models are subject to the following initial and boundary conditions;

r

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

r

=

=

0

T

T""

r

0

a;

r",

a;

p

op

Or

ar

OYk

op

Or

ar

Yk

P""

oYk

oT

oT

=

=

=

Yk ,,,, and u

o and u =

0

0,

(19)

(20)

0,

ou

Or

and

=

exu

r",

- -,

(21)

where roo is the outerflow boundary.

METHOD OF SOLUTION

The conservation Eqs. (I )-(7) along with the initial and boundary conditions (19)(21) are then put in a non-dimensional form using an approach developed in Sibulkin

and Siskind (1987) and Sibulkin and Frendi (1989). In the variable pressure model,

the momentum equation is non-dimensionalized as follows

2

op~, +--;,x-.I 0 [ , p~, ]

-a

t

x ox

P

= -

rj)/fJ ax

~3 Pr~x ~

[~~ (x'P~)]

Ox pax

p

(22)

0 [X' 0(PU)]

+

I

2Pr--- x' ax p Ox p

+

Pr -ex [ - ~

x

px

2pu + -32

I

0[x.,PU]]

7--;,

px uX

-e-

p

.

Similarly, the equation of state (5) becomes

...

P =

...

P

U

1

+ -.

y

(23)

The non-dimensional variables of Eqs. (22) and (23) are defined in the nomenclature.

The remaining PDEs were non-dimensionalized in Sibulkin and Frendi (1989). The

non-dimensional parameters rj)p, Pr and yare given by

7J.ad -

Too'

(24)

where Pr is the Prandtl number. The non-dimensional system of equations and

boundary conditions is integrated using a "method of lines" algorithm. The spatial

derivatives are discretized using fourth order finite differences, and the resulting

system of ordinary differential equations in time is integrated using the Gear-Hindmarsh programs for solution of ODEs. The specific package used was developed by

Hyman (1979). The problem is solved on a Cyber205 supercomputer. The average

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

402

A. FRENO I AND M. SIBULKIN

computational cost of a run is 3600 SBUs for a spatial mesh of 150 points (I SBU "" 1

second in CPU time).

When the variable pressure model is used, the instantaneous ignition energy addition by the spark generates a pressure wave which travels at the speed of sound. As

the wave reaches the outer boundary it gets reflected and therefore causes oscillations

in the density, velocity and pressure profiles. In order to overcome this difficulty, a

method is devised to convect the pressure wave out of the domain of integration. It

is observed that the decay of the pressure wave is fast, and behind the pressure front

the ambient condition is recovered quickly; therefore a two-stage calculation is used.

In the first stage, the calculation is done on a domain three times larger than the

desired domain. The integration is then stopped at a known time which corresponds

to the time it takes the pressure wave to reach the outer boundary. The data corresponding to the desired domain is stored. By the end of this stage the pressure in the

desired domain has come back to the ambient value. In the second stage, the calculation is continued using the stored results as input. The combustion wave is now the

only propagating wave in the domain. The details of this method are given in Frendi

( 1990).

Besides the built-in accuracy checks on the time integration required by the GearHindmarsh programs; an additional check on the accuracy of the calculation was

monitored by applying conservation of energy to the entire computational domain.

The thermal energy stored in the computational domain at a given time is compared

to the algebraic total of the ignition and combustion inputs to the system up to that

time. As an initial check, a calculation of the burning velocity for a stoichiometric

methane-air mixture in a planar geometry is performed. A burning velocity of 40 cm/s

is obtained, which is in good agreement with the detailed chemistry value of 39.6 cm/s

(Coffee et al., 1983) and with experimental values.

RESULTS AND DISCUSSION

The results reported in this paper are for a stoichiometric methane-air mixture at

Poo = I atm and Too = 298 K and for a spherical geometry (0: = 2). The method of

finding the minimum ignition energl' is as follows. For a given set of ignition parameters (r,g, r,g), the power input E'K is increased (or decreased) until the relative

difference in energy between ignition and non-ignition with respect to non-ignition is

approximately 10%.

Effect oj spark-induced pressure wave on minimum ignition energy

We first compare the results obtained using the constant pressure assumption to that

obtained through the variable pressure model. Figure I shows that for a fixed kernel

radius of r'g = 0.167 mm the two models predict the same minimum ignition energies

for long ignition times (r,g > 2 liS). However; for short ignition times (r,g < 2ps), the

variable pressure model predicts higher minimum ignition energies. This result is

explained by the generation of a strong pressure wave (Kono et al. (1988); Bradley et

al. (1987) and Lim et al. (1987)) which leads to lower temperatures in the ignition

kernel and therefore non-ignition. The minimum ignition energy predicted by the

constant pressure model remains constant for short ignition times.

Effect oj ignition parameters on minimum ignition energy

The effect of changing the kernel radius on minimum ignition energy is shown on

Figure 2 for different ignition times. For kernel radii larger than 0.3 mm, the minimum

MINIMUM IGNITION ENERGY

403

10-'--,---------------,

Ignition

o Non-ignition

--,

E

riG; 0.167 mm

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

_ _ _ Variable pressure

........... Constant pressure

10-7

10-6

T. (S)

'9

FIGURE I Comparison of minimum ignition energies obtained by the variable pressure and constant

pressure models. Stoichiometric methane-air mixture, spherical geometry.

ignition energy increases in proportion to the volume (r!g) of the ignition kernel. As

the kernel radius is decreased below r;g = 0.1 mm, the minimum ignition energy

reaches a constant value for !;g = 2.75 Ji,S and 27.5 us. For !;g = 100/ls and 500 Ji,S

asymptotic behavior is approached, but due to the computational cost for small

ld - = r - - - - - - - - - - - - - ,

_ _ _ 2.75

____________ .27.5

----100.0

_ _._500.0

FIGURE 2

Variation of minimum ignition energy with kernel radius for different ignition times.

Stoichiometric methane-air mixture, spherical geometry.

404

A. FRENDI AND M. SIBULKIN

108 =

------------,

:

-

-

\

2.75

\

27.5

\\

-.

\,

~

100.0

500.0

"-

<,

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

". ' 't ; ~

0.1

"-----. - " " - ' "

,

,

0.2

0.3

0.4

r. (mm)

'9

FIGURE 3 Variation of minimum ignition energydensity with kernel radius for different ignition times.

Stoichiometric methane-air mixture, spherical geometry.

values of rig the calculation was stopped at rig = 0.04 mm. The variation of the

ignition energy density (E;;) with kernel radius for different ignition times is shown

on Figure 3. For rig > 0.2 rnm, the ignition energy density is a constant for values of

rig ,;:; 100ps, and tends to a constant value for larger ignition times. For kernel radii

smaller than 0.2 mm, the ignition energy density increases rapidly for all ignition

times.

The variation of minimum ignition energy with ignition time for different kernel

radii is shown on Figure 4. The vertical dotted line separates the regions where the

two models predict the same values (r i, > 2ps) and different values (r iK < 2ps) of

minimum ignition energy. For rig < 2 us, only the constant pressure results are

plotted, and, as the figure shows, the minimum ignition energy is constant (the

minimum ignition energies predicted by the variable pressure model would be higher

in this region). For 2 us < rig < 100 JiS the minimum ignition energy is nearly constant; however for rig > 100 JiS it increases in proportion with ignition time (E i• o: rig)'

The increase in minimum ignition energy at long ignition times is caused by the larger

diffusional heat losses. Figure 5 shows the variation of the ignition energy density with

ignition time for different kernel radii. The general trend of the curves is similar to that

of the minimum ignition energy, the only difference is that the ignition energy density

is higher for smaller kernel radii.

To summarize these results, Figure 6 shows a three dimensional plot of the minimum ignition energy surface, Eig = Eig(rig, rig)' It is important to observe that for

small kernel radii and short ignition times, the minimum ignition energy surface

shows a plateau; therefore supporting the conclusion of constant minimum ignition

energy for this range of parameters. This result is in agreement with the conclusions

of Maas and Warnatz (1988), and disagrees with that of Kailasanath et al. (1982) who

found an increase in minimum ignition energy as the kernel radius is decreased to

smaller values.

MINIMUM IGNITION ENERGY

405

10-'-::r----------,--------,

rig (mm)

_ _ 0.0635

........... 0.1100

___ .0.1253

_ _ .0.1670

/.

j(/ ~/

If"

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

----------//:

=. -.=.:.:-::::::-.:.:t::--::".:.~;./

Constant pressure

iVoriable pressure

:

and

jConstont pressure

-3

10 , '"

10-9

FIGURE 4

Variation of minimum ignition energy with ignition time for different kernel radii. Stoichio-

metric methane-air mixture, spherical geometry.

108 - = r - - - - - - - - - - - - , - - - - - , - - - - ,

_ _ 0.0635

7

10

~

-€.

...,

........... 0.1100

___ .0.1253

_ . _ .. 0.1670

.~

W

6

10

'vcrlobte pressure

Constant pressure

~

and

iConstant pressure

I 1,111

10-4

I

10-3

FIGURE 5 Variation of minimum ignition energy density with ignition time for different kernel radii.

Stoichiometric methane-air mixture, spherical geometry.

ROLE OF HEAT DIFFUSION

The nondimensional enthalpy profiles (u,) at the end of ignition are shown on Figure

7. These profiles correspond to the successfully ignited cases, and to an ignition kernel

radius of rig = 0.0635 mm. As the ignition time is increased, more energy is needed

for successful ignition (except for rig = 27.5 J1S where less energy is used). This

406

A. FRENDI AND M. SIBULKIN

Minimum Ignition Energy Surface

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

0.0_------1------,

FIGURE 6

Dependence of minimum ignition energy on ignition time and kernel radius. Stoichiometric

methane-air mixture. spherical geometry.

0.20 - , - - - - - - - - - - - - - - - - - - - - ,

T" (ILS ) E" ( ILJ )

_ _ _ 2.75

6.05

............ 27.5

5.5

0.16 ____ 100.0

7.0

_. _ _ 500.0

18.0

0.12-

~

"".

..... '.~

\'\\

'\\

: \

\ ' \

\ \\

\ ' \

0.08-

r .,

. = 0.0635 mm

\.

0.04

,

0.0

0.2

'.

\

<,

,

0.6

0.8

FIGURE 7 Non-dimensional enthalpy profiles (u,) at the end of ignition for different ignition times.

Stoichiometric methane-air mixture, spherical geometry. (Successful ignitions only)

407

MINIMUM IGNITION ENERGY

10.0,..------------------,

8.0

rill

= 0.0635 mm

EIIl

= 5.S pJ

T"

"

2.75 fl.S

6.0

~

27.5 fl.S

I

~

>-

4.0

T

=

T

ig

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

2.0

0.0

--I------,---..::.:;===:::;:::==::,::==:::j

I

0.0

0.1

0.2

0.3

0.4

r (mm)

FIGURE 8a Temperature profiles at the end of ignition for two different ignition times. Stoichiometric

methane-air mixture, spherical geometry.

increase in energy is explained by the higher diffusional heat losses at longer ignition

times (the energy spreads over a larger volume). However, the value of UI at the center

becomes smaller as the ignition time is increased which corresponds to lower kernel

temperatures.

Figures (Sa) and (Sb) show an example of ignition and non-ignition cases for two

ignition times (r,g = 2.751ls and 27.5Ils), a kernel radius of r,g = 0.0635 mm and

using the same ignition energy E,g = 5.5IlJ. Figure Sa shows the temperature profiles

at the end of ignition. For rig = 2.751ls the temperatures near the kernel center are

higher than that for rig = 27.5Ils; however, more energy has diffused out of the

ignition kernel in the latter case. The kernel trajectories for the two cases are shown

on Figure Sb. Both kernels expand initially to nearly the same kernel size

(rj = 0.17 mm). For rig = 2.75 IlS the kernel decayed, and for rig = 27.5 Ils a combustion wave is propagated. Notice that in the latter case the kernel radius remains

constant for some time (0.03 ms < r < 0.12 ms) before it propagates. This example

shows that for small kernel radii (rig < 0.17 mm), in order to obtain a successful

ignition a critical size and temperature need to be reached during the decay phase. For

this particular case, the size and temperature are 0.17 mm and 1700 K respectively.

Variations of the kernel center temperature

Figure 9 shows the kernel center temperature at the completion of energy input

(r = rig) as a function of kernel radius for different ignition times. For r,g = 2.75,

27.5 and IOOIlS the curves show the existence of two regions; one in which the kernel

center temperature is constant and equal to approximately 1000 K (for r,g > 0.2 mm),

and the other where the temperature rapidly increases to high values (rig < 0.2 mm).

This region of rapid increase is followed by another constant temperature region

above the adiabatic value for r'g = 27.5 and IDOllS. For rig = 500 us, only two regions

are shown by the figure; the constant temperature region above the adiabatic value

which extends over a wide range of r'g values and a region of rapid change in kernel

408

A. FRENDI AND M. SIBULKIN

0.50

,---~-------------,

T

0.45

0.40

0.35

'.

2.75 1'5

_ _ _ 27.5 f1S

rig

= 0.0635 mm

E" = 5.5 j.LJ

0.30

E

E

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

...-

0.25

0.20

0.15

0.10

0.05

0.00 +--,-----,,..-----,----,--------1

0.00 0.06

0.12

0.18

0.24

0.30

T (

ms )

FIGURE 8b Kernel trajectories for ignition and non-ignition cases. Stoichiometric methane-air mixture,

spherical geometry.

center temperature (r;K > 0.3 mm). This figure illustrates the role of heat diffusion and

chemical reaction on the kernel center temperature. For short ignition times there is

less diffusion and therefore the kernel center temperature is high for small kernel radii.

At longer ignition times both heat diffusion and chemical reaction contribute to the

final value of the kernel center temperature. Notice that the temperatures plotted on

Figure 9 are those that give successful ignition.

The change in kernel center temperature with ignition times for different kernel

radii is shown on Figure 10. As mentioned previously, the combination of heat

diffusion and chemical reaction contribute to the value of the kernel center temperature. The constant temperature region for short ignition times corresponds to

neglegible diffusional heat losses and chemical energy production. As the kernel

radius becomes smaller. this constant temperature region becomes smaller. For

r;K = 0.0635 mm no results are obtained at short ignition times due to numerical

instabilities.

In the absence of diffusional heat losses and chemical reaction, the energy equation

reduces to a simple form and the temperature distribution can be found analytically

when the ignition source given in the mathematical model is used (see Frendi (1990)

for details). In particular the kernel center temperature is given by

(25)

MINIMUM IGNITION ENERGY

409

10.0,-------------_

,-..

'::L

2.75

27.5

100.0

500.0

8.0

~

,

9

~

6.0

x

.'"

t-

o

00'9:::::

1.0

4.0 -

)=:"

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

2.0

,

,

0.0 +----;r----,--,.------,---I

0.0

0.1

0.2

0.3

0.4

0.5

';9 ( mm )

FIGURE 9

Variation of kernel center temperature with kernel radius for different ignition times.

Stoichiometric methane-air mixture, spherical geometry. (Successful ignitions only)

Using the energy densities corresponding to the successfully ignited cases for kernel

radii of 0.167 mm, 0.1253 mm and 0.11 mm, the kernel center temperature is calculated and the results are shown on Figure I I. For short ignition times, Figures II

and 10 predict the same values of kernel center temperatures, implying the absence of

10.0.,-----------------,

Tr,ad

'" (mm)

_ _ 0.0635

8.0

........... 0.1100

•

_ _ .. 0.1253

6.0

= 1.0

Do

"

_ _ .0.1670

4.0

2.0

0.0

I

I I

10- 9

10- 7

10- 6

T,

'9

(s)

FIGURE to Variation of kernel center temperature with ignition time for different kernel radii. Stoichiometric methane-air mixture, spherical geometry. (Successful ignitions only)

410

A. FRENDI AND M. SIBULKIN

10.0

"Y:

.......,

",

~

x

~

fIg

1

(mm)

Ii

0.1100

___ .0.1253

•••• C••••••

8.0

f

_:'-.0.1670

6.0

-'I'

1-.

,..:'1

0

):::'

. . .:.. . . j

4.0

T,.,;·················

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

2.0

0.0

•

::=::-:="'::.=-:---=.:::::::- _911111111

10

_611111111

10

_1711111111

10

.==-_.--./

_1611111111

10

T.

'0

..-I/-:

-5

10

11111

111111

4

10.

10"

(s)

FIGURE II Kernel center temperatures obtained using Eq. (25), for three different kernel radii.

Stoichiometric methane-air mixture, spherical geometry. (Successful ignitions only)

heat losses by diffusion or gains by chemical reaction. However, as the ignition time

is increased Eq. (25) predicts higher temperatures. When the chemical source term in

the energy equation is dropped we obtain the diffusion equation. A comparison of

kernel center temperatures given by the total energy equation, the diffusion equation

and Eq. (25) is shown on Figure 12. These results are obtained using the same ignition

parameters. At short ignition times rig < 10- 7 s, all three equations predict the same

temperatures (this means neglegible diffusion and chemical energy production). For

10- 7 s < rig < 2 x 10- 6 s, the diffusion equation and the thermodynamic equation

(Eq. (25» predict the same temperatures; however the energy equation gives higher

temperatures. This means that diffusion is still neglegible but there is some chemical

energy production. As the ignition time is increased above 2 x 10- 65 , the three

equations predict different values of kernel center temperature. This is because for

these values of ignition times both diffusion and chemical reaction are important. The

lowest temperatures are those predicted by the diffusion equation.

Comparison of time scales

Consider the nondimensional parameter defined by;

(26)

where Da ig is similar to the so-called 'Darnkohler number' and the subscript "ig"

means ignition. In Eq. (26), rdis the diffusional time scale (r~/Kig) and rig is the ignition

time, Equation (26) expresses the relative importance of diffusion time to ignition

time, therefore;

Da, <

I

--+

Diffusion is important

411

MINIMUM IGNITION ENERGY

10.0

........... Energy eq.

~

8.0

",

\

- - - - Diffusion eq.

I

- . -.. Thermodynamic eq.

I

9

x

.,

.

I-

r lt

6.0

• DOIIl = 1.0

a

)::'

4.0

0.0

/

.......

/

/

"./

/

TL:--"='~<:"'.

<,

2.0

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

= 0.11 mm

---- -

10- '9 ' "';'O-'B'

"';'0-7' "';'0- 6 "';'0- ;'05

4

10-3

T '9 ( S )

FIGURE 12 Kernel center temperatures obtained using three different equations; energy equation,

diffusion equation and Eq. (25). Stoichiometric methane-air mixture, spherical geometry. (Successful

ignitions only)

Da, >

I

---+

Diffusion is not important.

The value Da.; = I can be regarded as the boundary between the region of high

diffusional losses and the region of low diffusional losses. This point is clearly marked

on Figures 9,10 and 12. In particular, Figure 12 shows that this point is indeed located

at the time when the diffusion equation starts to predict different values from those

of Eq. (25).

COMPARISONS AND CONCLUSIONS

We have shown in this paper that in order to make any meaningful comparison to

available experimental data, one needs to know the ignition parameters used. However, a large number of published works on minimum ignition energy fail to give those

parameters. The value of minimum ignition energy given in Lewis and von Elbe (1987)

for stoichiometric methane-air mixtures at p = I atm and T = 298 K is 0.35 mJ for

a spark gap of the order of the quenching distance (2.1 mm) and using a fast spark.

For the same conditions of temperature and pressure, and for a spark gap of 3 mm

and spark duration of6'/S, Ronney (1985) found a minimum ignition energy of 0.5 mJ

at zero gravity. The minimum ignition energy found in our calculation is 0.005 mJ for

a kernel radius of 0.0635 mm and an ignition time of27.5/1s. This value of minimum

ignition energy is 70 times lower than the experimental one. In making these comparisons it is important to recall that spark ignition is a complex sequence of chemical

and fluid dynamic processes. The presence of the relatively cold electrodes leads to

both heat extraction from the ignition kernel and the development of convective

motion (Kono et al. 1988), and the high temperatures during spark initiation result

in additional chemical reactions. However, the authors believe that a major cause of

the difference between experimental and calculated minimum ignition energies is the

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

412

A. FRENDI AND M. SIBULKIN

use of electrode spacings based on quenching distance in these experiments. When a

kernel radius of rig = 0.5 mm and an ignition time 2/ls < rig < 500/ls are used, our

model predicts an ignition energy of 0.3 mJ as shown by Figure 2, which is in fair

agreement with the experimental values. (Complete agreement could be obtained by

adjusting rig')

Kono et al. (1976) studied the effects of electrode configuration, electrode gap and

spark duration on the minimum ignition energy of near stoichiometric propane-air

mixtures. As they varied the spark gap from 0.5 mm to 2.0 mm, the minimum ignition

energy decreased, which is in disagreement with our calculations (Figure 2). This may

be due to the heat losses to the electrodes; since by varying the electrode configuration

the minimum ignition energy varied in a similar way. Their results showed that there

exits an optimum ignition time for which the minimum ignition energy has the

smallest value. This result is reproduced by our calculation using the two models

(Figure I). The increase in minimum ignition energy obtained by Kono et al. for short

ignition times may be explained by the strong pressure wave generated by the spark.

The increase in minimum ignition energy at long ignition times is due to heat losses

by diffusion as found using both models (Figure 4). The critical ignition time obtained

in our calculation (Figure 4) is in good agreement with that measured by Kravchenko

et al. (1973).

Using an overall reaction model, Tromans and Furzland (1986) calculated minimum ignition energies for propane and methane. Their study was directed towards the

effects of initial temperature, pressure and activation energy on minimum ignition

energy. For stoichiometric methane-air, the minimum ignition energy they reported

was 0.1 mJ for an ignition time of 10- 3 s, but there is nothing directly comparable to

our ignition radius in their calculation. This result is 20 times higher than our

minimum ignition energy value. Sloane and Schoene (1988) using a detailed chemistry

model and an instantaneous heat addition, found a minimum ignition energy of

0.16 mJ for a stoichiometric methane-air mixture. The size of their ignition kernel was

not reported. In a recent paper, Maas and Warnatz used a variable pressure model

and a constant pressure model to calculate the minimum ignition energy of hydrogenoxygen mixtures. They concluded that as the ignition radius was decreased the

minimum ignition energy reached a constant value, which agrees with our results and

disagrees with Kailasanath et al. (1982). The same result was obtained by Sibulkin and

Siskind (1987) in their study of ignition of solid fuels. Maas and Warnatz found that

at long ignition times (10- 3 s), both the variable pressure and constant pressure

models predict the same results. However, no calculation was done for short ignition

times. In this paper, the same conclusion is reached for long ignition times; however,

the pressure wave effect is found to be important for short ignition times (Figure I).

It was shown in Figures 8a and 8b that there exists a set of critical parameters,

kernel size and temperature, for a successful ignition to occur. Such parameters were

also predicted by Champion et al. (1986), who used large activation energy asyrnptotics to study the existence of steady state flame propagation. The calculated critical

parameters (r,., r" E,) obtained from their expressions are in good agreement with our

numerical results. The role of heat diffusion in flame initiation is found both to

contribute to successful ignition for small kernel radii (rig < rJ, and to increase the

minimum ignition energy at long ignition times.

ACKNOWLEDGEMENTS

Computational support for this work was provided by the John von Neumann National Supercomputer

Center under NAC grant 13031.A scholarship was awarded to the first author by the Algerian government.

~IN!~V~ !CiNITION ENERGY

413

His current address is Mech. Eng. Dept., 334 Snell Engineering Center, Northeastern University. Boston,

MA 02115. and correspondence should be directed to this address.

Downloaded By: [University of Southern California] At: 22:09 18 January 2011

REFERENCES

Blanc. M.V .. Guest. P.G .. Von Elbe. G .• and Lewis. B. (1947). Journal of Chemical Physics. 15, 798.

Blanc. M.V .. Guest. P.G .• Von Elbe, G .• and Lewis. B. (1948). Third Symposium [International] 011

Combustion, The Williams and Wilkins Company, Baltimore. p. 363.

Bradley, D. and Lung. F.K-K .• (1987). Combustion and Flame 69,71.

Champion. M .. Deshaies, B.; Joulin. G .• and Kinoshita. K. (1986). Combustion and Flame 65. 319.

Coffee, T.P.. Kotlar, AJ .. and Miller, M.S. (1983). Combustion and Flame 54, 169.

Deshaies. B. and Joulin. G. (1984). Combustion Science and Technology 37, 99.

Dixon-Lewis. G. and Shepherd. I.J. (1974). Fifteemli Syposium [lnternationul] on Combustion, The

Combustion Institute. Pittsburgh. p. 1483.

Frcndi, A. (1990). PhD thesis. Division of Engineering Brown University. Providence.

Hyman. J.M .. (1979). Los Alamos Scientific Laboratory LA-7595. UC-32.

Kailasanath. K; Oran. E.S .. Boris, J.P. and Young. T.R.. (1982). in: Peters. N. and Warnatz, J. (eds).

Numerical Methods in Laminar Flame Propagation Viewg, p. 152.

Keno, M., Kumagai, S.. and Sakai, T., (1976). Sixteenth Symposium (International) on Combustion, The

Combustion Institute. Pittsburgh. p.757.

Kono, M., Niu. K.. Tsukamoto, T .. and Ujiie. Y., (1988). Twenty-Second Symposium (International) all

Combustion, The Combustion Institute. Pittsburgh, p. 1643.

Kravchenko. V.S.. Erygin. AT. and Yokovlev, V.A.. (1973). Combustion. Explosion and Shock Waves. 9,

No.4. pp.603-604.

Lewis, B. and Von Elbe. G .. (1987). Combustion. Flumesand Explosions of Gases. Third edition, Academic

Press. New York. p.333lf.

Lim. MT.• Anderson, R.W. and Arpaci. V.S .. (1987), Combustion and Flame 69.303.

Maas, U. and Warnatz, 1.. (1988). Combustion and Flame 74.53.

Ronney. P.O.. (1985). Combustion and Flame 62, 121.

Sibulkin, M. and Siskind. K.S .. (1987). Combustion and Flame 69. 49.

Sibulkin. M. and Frendi. A. (1989). in "Prediction of a flammability limit in an unconfined premixed gas

in the absence of gravity", Combustion and Flame in press.

Sloane. T.M. and Schoene, A.Y .. (1988), Twenty-Second Symposium (International) on Combustion. The

Combustion Institute. Pittsburgh. p. 1669.

Toorig. T.Y .. (1983), Combustion Dynamics: The Dynamics of Ctiemicatty Reacting Fluids, McGraw-Hill,

New York.

Tromans. P.S. and Furzland. R.M .. (1986), Twenty-First Symposium (International) on Combustion, The

Combustion Institute, Pittsburgh. p. 1891.