The Design and Construction of Fire Fighting Monitors

advertisement

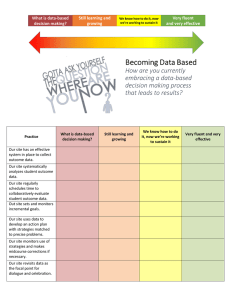

A UTC Fire & Security Company The Design and Construction of Fire Fighting Monitors Fixed and Mobile, Manual and Remote Control, Water and Foam Introduction Monitors spend most of their lives static and lifeless. But when a fire is detected they can often be the only practical way of applying foam or water to the fire. While simple in principle, monitors are sophisticated pieces of engineering made to deliver a specific performance after long periods of inactivity. Like many engineering challenges the design of a monitor can take many forms depending on the specific hazard it is intended to protect and the mechanism and method of operation the designer uses to achieve the final layout. When designing a monitor the manufacturer must balance performance, operational life and ease of use against cost. The installation of fixed monitors, or the provision of mobile or portable monitors, is usually the outcome of a careful analysis of the fire risk and the realisation that without planning in advance fighting any subsequent fire will present difficulties. It is essential therefore, that monitors are robust and will have a long service life, even under adverse conditions. 2 Applications Fixed monitors are found wherever there are substantial Class B fire risks while mobile or portable monitors are often used to protect multiple risks by moving the monitors around the site. Nearly all industrial fire hazards are candidates for monitor protection, but some of the more common applications are: • Refineries • Fuel distribution depots • Chemical plants • Warehouses • Helicopter landing pads • Aircraft hangars • Loading jetties • Process plants • Industrial process areas • Shipping • Vehicle-mounted Fixed or mobile? While many monitors are permanently fixed to pipework and designed to protect specific installations, it is sometimes more convenient to mount monitors on trailers that can be moved from hazard to hazard. In addition, smaller monitors can be designed to be moved by hand and placed on the ground to provide a rapid response in the event of a fire. However, mobile monitors require a water supply, usually provided by hoses or portable pumps. The jet reaction force for a portable monitor can vary from a few kg, for a small ground monitor, to over a tonne for a larger trailer-mounted unit. Any portable monitor must be secured so that it cannot move once the full water flow and pressure is applied. Small, hand-wheel portable monitors are specifically designed to be easy to manoeuvre and carried over rough terrain. To resist the jet reaction forces portable ground monitors are provided with a method of stabilising them on soft ground. Larger monitors are usually mounted on trailers. In addition, the trailer is often fitted with outriggers to provide stability. Water tanks on the trailer can be filled to provide additional weight for stability. Extra tanks can also be specified to provide foam concentrate. Angus monitor with optional foam induction system anchored on soft ground with bipod mechanism Angus trailer-mounted monitors with self-inducing foam cannons Trailer-mounted monitors provide a useful addition to the armoury of equipment a fire service can draw on should a large fire occur. The mobile monitor can be used to protect locations inadequately covered by fixed monitors or provide cooling to equipment adjacent to the fire. 3 Monitor Design Design is always a compromise Bearings The layout of the pipes that make up a monitor must serve several functions. They must contain the water while allowing the jet to be moved in both the horizontal and vertical planes; they must be strong enough to resist the pressure and reaction forces generated by the water; and they must be robust enough to allow the mounting of additional items such levers, gearboxes, hydraulic actuators and nozzles. All of this must be achieved with a design that is cost effective, has an acceptable pressure loss, will resist corrosion and is not too heavy. Like many engineering designs a typical monitor is a compromise between cost, weight and performance. The normal practice is to support the two parts of a monitor, where it moves in the horizontal or vertical plane, using a double ball race. A shaft seal is positioned between the ball races and the waterway to retain the water under pressure. Plugs are machined into the outer casing to allow the ball bearings to be inserted during the manufacturing process and can be fitted with grease nipples to allow lubrication during manufacture or maintenance. Pressure losses If too much water is forced around too many tight bends at too high a speed there will be an unacceptable pressure loss between the monitor inlet flange and the nozzle. The result will be that the water or foam jet will not travel as far as it could. Some designs use a very compact layout forcing water to turn 90° bends and splitting the water into two paths which meet again at the outlet. While the dual path waterway layout is compact its pressure losses can be unacceptable where the supply pressure is limited. Monitor type Pressure loss at 1000 l/min Typical nozzle throw Single waterway fabricated stainless steel 0.2 bar (3.0 psi) 38 m Single waterway cast bronze 0.3 bar (4.5 psi) 37 m Dual path waterway 1.0 bar (15 psi) cast aluminium 33 m In addition, the turbulence created when the two water streams meet usually adversely affects the nozzle performance and limits its range still further. Waterways manufactured from cast bronze usually have tighter bends than those manufactured from steel since it is difficult to fabricate tight bends in steel tube. As a result, stainless steel monitors generally have a lower pressure loss than the equivalent cast bronze monitor while the dual waterway designs have the highest pressure losses of all. Water takes on a spin when negotiating the bends in a single or dual waterway pipe. By the time it has negotiated both the horizontal and vertical joint bends the spin generated can cause a reduction in throw. The spinning water expands the jet stream creating greater friction as it passes through the air. To reduce the spin cast bronze or iron waterway monitors often have vanes or blades cast into the tube to reduce the spin in the water stream. 4 Sharp bends and merging flows cause turbulence Some designs include a second seal to prevent dirt and dust entering the bearing assembly. However, this can cause difficulties since the bearing chamber becomes a sealed space with no room for expansion. Like most engineering designs the layout of the bearings is a compromise. The wider apart they are the lower the forces on each bearing race. However, widening the bearing spacing also increases the overall size of the unit. To resist the loads steel balls are used. These are normally a high grade stainless steel such as SS316. When the monitor body is bronze the steel balls rest in tracks machined into the casting. However, when the monitor is fabricated from stainless steel pipe and the bearing tracks are incorporated into the fabrication it is essential to select a material for the steel balls that does not react with the steel of the bearing races or the balls may “pick up” causing the bearing to seize. INCREASED TURBULENCE NOZZLE NO VEINS VANES TURBULENCE TIGHT BENDS SWEEPING BENDS Flow straightners in pipe reduce water stream turbulence and rotation Ball Bearings Nozzle flow at 7 bar Total reaction force at tip Typical side force on monitor handle with 5° of misalignment in the horizontal plane 2,000 l/min 140 kg 6 kg 4,000 l/min 240 kg 11 kg 6,000 l/min 310 kg 14 kg 8,000 l/min 425 kg 19 kg Shaft Seal Fitting Plugs for Bearing Insertion Misalignment is more common in fabricated monitors. Unless great care is taken during the welding, and special techniques and jigs are used, the welded pipes can easily distort. A worm and wheel gearbox drive is generally used for control in the vertical and horizontal planes for monitors where the flow is 3,000 l/min or more. Gearbox actuation Reaction forces It is important to arrange the layout of a monitor so that the thrust or reaction force caused by the water leaving the nozzle or foam cannon is directed through the pivot point in both the horizontal and vertical planes. Control of the vertical and horizontal movement using a worm and wheel gearbox is recommended for two reasons. Firstly, it is easy for the operator to set the monitor in position. The handle loads are low and control is precise. Secondly, a worm and wheel gearbox, if correctly designed, will resist any out of alignment forces. Provided the worm drive angle is less than 20° it is possible for the worm to drive the wheel, but it is impossible for the wheel to drive the worm due to friction in the gearing. The mechanism is therefore intrinsically safe and any out-of-balance forces in the monitor cannot move it off target. Out-of-balance forces cause the monitor to rotate or move out of alignment If the monitor is distorted and the reaction force does not pass through the pivot there will be a sideways or vertical force on the monitor. If the out-of-line force is not restrained the monitor will tip up or down or spin in the horizontal plane. The consequences of this can be serious. If the monitor is spinning, often the only way to stop it may be to turn off the water at its base. If over 80 kg of monitor body is spinning at 2 or 3 revolutions per second it can be dangerous to climb underneath the spinning body to turn off the water! It could also damage or bend the pipework or other structures. The forces exerted by the jet are considerable and even a minor misalignment can result in a large side load. If at the same time there is a side wind acting on the monitor it is possible for the load on the handle to be too much for the operator to manage. Non-reversible worm drive makes it easy to steer and holds the monitor in position 5 Construction The materials most commonly used are steel in the form of fabricated tube or cast bronze, but aluminium and cast steel or iron are also available. Fabricated steel High quality steel monitors are normally fabricated from grade SS316 stainless steel tube, although some are fabricated from the lower grade SS304 to reduce cost but these suffer corrosion problems in coastal areas and should not be used with seawater. Steel monitors usually have a larger footprint and are physically higher than cast units because of the limits imposed when bending the tube. It is impossible, when bending steel tube, to achieve the tight bend radius possible with a cast unit. However, the larger radius bends have the advantage that the water pressure losses are lower with fabricated stainless steel monitors when compared to cast bronze. Typical performance comparison Material Nominal pipe size Flow at 7 bar Pressure inlet pressure loss Cast bronze 80mm (3”) 4,000 l/min 3.5 bar Stainless steel 80mm (3”) 6,000 l/min 0.9 bar However, when comparing stainless steel with bronze monitors with similar flow rates bronze units are substantially heavier. Typical performance comparison at similar flow rate Material Cast bronze Stainless steel Nominal pipe size Flow at 7 bar inlet pressure Weight 90mm (31/2”) 6,500 l/min 76 kg 80mm (3”) 6,000 l/min 35 kg Low cost monitors or monitors intended for applications where corrosion is not a problem can be fabricated from mild steel tube. The steel is sometimes galvanised to provide some protection against corrosion, although a painted finish is often used to reduce cost. Fabricated steel monitors present additional challenges during manufacture. When the monitor is to be moved using a gearbox, or a geared drive using hydraulic or electric motors, it is necessary to join together thin wall tube and robust cast or machined components of widely differing thicknesses. This can lead to distortion and stresses during the manufacturing process unless the fabricator is experienced or sophisticated jigs are used. Where a monitor is made from mild or stainless steel tube it is important to ensure the ball bearings used in the joints are compatible with the grade of steel used or the bearing may fail under load. Cast bronze While cast bronze monitors are heavier and generate slightly greater pressure losses for a given nominal pipe diameter they are usually more compact and robust than fabricated steel units. However, there is a wide range of materials which are called “bronze” and it is important to determine the specification of the material used when judging strength and corrosion resistance. Nearly all cast bronze monitors use double race bearings incorporating steel balls for the horizontal and vertical joints. If the bearing is carefully designed to spread the load, and if the bronze is hard enough, it is usual to allow steel balls to run in grooves machined directly into the bronze casting. This layout has the advantage of simplicity and will provide a long life if correctly maintained. A standard published by FM Global calls for monitors to have free movement in their bearings when subjected to a pressure of 35 bar, having previously been subjected to a static pressure of 58 bar. The end load on a bearing in a 150mm (6”) monitor subjected to this pressure is over 10,000 kg or 10 tonnes! To prevent the steel balls denting the bronze bearing face it is usually necessary to incorporate steel bearing surfaces inside the bronze castings to withstand the test load. This can lead to extra cost and corrosion problems in the long-term where the steel meets the bronze. In practice, monitors are rarely subjected to pressures greater than 16 bar. As a result, many manufacturers prefer to design to the UL standard or the new European EU standard. Flanges and material strength While some monitors used in Europe are fitted with PN16 European standard flanges, most monitors are supplied with US ANSI flanges. ANSI flanges come in two basic types, flat faced (FF) and raised face (RF). The full designation also indicates the maximum working pressure for the flange. For example a ANSI 4” 150 RF flange is a raised face flange to fit a 4” (100mm) nominal diameter pipe and designed to be operated at a maximum operating pressure of 150 psi (10 bar). Because a raised face flange, when tightened up, exerts a greater force on the gasket contact area than a flat faced flange, raised face flanges can be used at greater pressures than flat faced. However, if the material used for the flange is not strong enough the flange will distort when bolted up. Therefore, when selecting a material for a monitor the style of flange and the working pressure needed must be taken into account. In general steel monitors use steel flanges. These can always be raised face since steel is strong enough not to distort at pressures used in fire fighting. However, leaded bronze or gunmetal, with its superior corrosion resistance, is relatively soft and cannot always be used for a raised face flange which in turn can limit its pressure rating. Brass tube Brass tube is the weakest of all fabrication materials used for monitors and it is limited in size because it is not strong enough to resist the reaction forces from a large water jet. In addition, it is impractical to operate the monitor using a gearbox because of the difficulties of attaching the gearbox mechanism to the tube. As a result it is only used for small, hand-operated units. 6 Flat Face Raised Face Raised Face (soft material) Soft materials are unsuitable for raised face flanges One solution is to increase the thickness of a bronze flange to give it sufficient strength to be machined as a raised face flange and bolted up to the recommended torque. Materials To resist heat and have sufficient strength monitors are made from different metals. While the basic materials, namely iron, aluminium and copper, can be used in their natural state it is more common to create alloys or variants of the basic metal to improve their strength, corrosion resistance and their ability to be cast or formed. Iron is cheap and easy to cast. However, it is heavy and can be brittle if the carbon content is too high. Corrosion is a problem and it is normal practice to increase the wall thickness of components to allow for corrosion, which adds more weight. Aluminium is light and easy to cast. However, its strength is low. Corrosion is a major problem and components made from aluminium must be protected by anodising (a chemical process which puts a hard layer of Aluminium Oxide on the surface) or painting. Both processes, if applied well, provide a hard coating which separates the water from the metal. However, once the surface coating is scratched corrosion sets in quickly and cannot be reversed. Copper does not have the strength necessary for monitors. It is also soft, which can lead to damage if the monitor is knocked. Copper is also too soft to work as a flange material. Corrosion resistance to salt water is poor. Material Grey cast iron Mild steel strip Stainless steel (SS316) Aluminium (casting grade – with Copper) Copper (annealed) Brass (Copper with Zinc) Bronze (Copper with Tin) Leaded Brass (Copper with Zinc and Lead) Gunmetal or Marine Brass High performance Bronze (Nickel Aluminium Bronze) BS EN 1982 Copper Cu Zinc Zn Brass (Copper & Zinc) is popular for small, low cost, monitors but suffers from many of the same problems as Copper. Bronze comes in many forms and is the most popular material for manufacturing long lasting cast monitors. Simple Bronze is made from a mixture of Copper and Tin. However, while it is easy to cast and machine, it can be weaker and harder than Brass. Nickel Aluminium Bronze is much stronger and an ideal material. However, it is expensive to cast and costly to machine. UK standards AB1-C and AB2-C for Aluminium Bronze (AB2 contains extra Iron and 5% Nickel) have been superseded by European specifications CC331G and CC332G. Nickel Aluminium Bronze is generally used for marine propellers, hubs and valves in permanent contact with sea water and subject to continuous abrasion. These conditions do not generally apply to monitors. Gunmetal, with its added Lead, has excellent corrosion resistance but is not as strong as Aluminium Bronze. It is, however, easy to machine. In the UK two grades of Gunmetal are in common use, LG2 and LG4. Both these designations are now renamed as CC491K and CC492K. Bronze standards in common use European standard BS EN 1982 is the new European standard for Copper alloy and Bronze specifications. It replaces the UK standard BS1400 and other national standards such as UNI in Italy. US specifications for Bronzes do not match European standards. However, for most of the European Bronzes in common use there is a close match with the US ASTM standard bronzes. Symbols Fe + C + Si Fe + C Fe + Cr + Ni + Mo Al + Cu Cu Cu + Zn Cu + Sn Cu + Zn + Pb Cu + Zn + Sn + Pb Cu + Al + Fe + Ni Lead Pb Tin Sn Tensile strength 275 MPa 300 – 500 MPa 480 – 600 MPa 250 – 360 MPa 210 MPa 285 – 400 MPa 250 – 310 MPa 215 - 400 MPa 200 – 250 MPa 300 – 750 MPa Aluminium Al Iron Fe Nickel Ni Manganese Mn Alloy Type BS 1400 (old) High Tensile Brass HTB3-C CC762S 63.0% 25.0% 5.0% 3.0% 4.0% High Tensile Brass HTB1-C CC765S 61.0% 35.0% 1.0% 1.0% 2.0% Copper Tin Nickel CT2-C CC484K 86.0% Leaded Gunmetal LG1-C CC490K 84.0% 8.0% 5.0% 12.0% 3.0% 2.0% Leaded Gunmetal LG2-C CC491K 85.0% 5.0% 5.0% 5.0% Leaded Gunmetal LG4-C CC492K 88.0% 2.0% 3.0% 7.0% Leaded Bronze LB4-C CC494K 86.0% 9.0% 5.0% Leaded Bronze LB2-C CC495K 80.0% 10.0% 10.0% Leaded Bronze LB1-C CC496K 78.0% 15.0% 7.0% Leaded Bronze LB5-C CC497K 75.0% 20.0% 5.0% Aluminium Bronze AB1-C CC331G 88.0% 10.0% 2.0% Aluminium Bronze AB2-C CC333G 80.0% 10.0% 5.0% 7 Materials Country Leaded Gunmetal Europe USA Italy Aluminium Bronze USA Europe Designation Copper Cu Zinc Zn Lead Pb Tin Sn CC491K (formerly BS LG2) ASTM B30 C83 600 UNI 7013 85.0% 85.0% 83.0% 5.0% 5.0% 4.0% 5.0% 5.0% 6.0% 5.0% 5.0% 7.0% ASTM B30-C95 800/500 CC333G (formerly BS AB2) 78.2% 80.0% Aluminium Al Iron Fe Nickel Ni Manganese Mn 9.4% 10.0% 5.5% 5.0% 5.5% 5.0% 1.4% Note: the percentages of different materials shown in the table are all subject to tolerances. For example, the quantity of Zinc in the European standard leaded Gunmetal, CC491K, is shown as 5% but can be anywhere between 4% and 6%. This means that materials which are shown as having slightly different compositions can be identical in practice when the tolerance bands are taken into account. When specifying a material for monitor production it is necessary to trade off the excellent corrosion protection of the Lead in Gunmetal against the extra cost and strength of Aluminium Bronze. Steel Mild or ???? steel is used in the form of tube for low cost monitors. Like Aluminium it must be protected against corrosion by painting or galvanising. Like Aluminium, once the coating has been damaged, corrosion spreads quickly. While the material is low cost it presents technical difficulties when being welded as distortion can occur where there are rapid changes in section (typically where the thin wall section joins a bearing housing). International standard Grade SS301 SS302 SS304 SS305 SS309 SS310 SS315 SS316 SS317 SS320 SS321 SS403 SS409 SS410 SS420 430 434 Cr 18% 18% 18% 23% 25% 17% 17% 18% 17% 18% 13% 12% 12% 13% 17% 17% Constituents Ni 17% 9% 10% 12% 14% 20% 10% 12% 13% 12% 10% Mo 7% 1.5% 2.5% 3.5% 2.5% Stainless Steel, next to Bronze, is the most popular material for fabrication of both small and large monitors. SS316 is generally considered the best grade of Stainless Steel for monitors since it combines excellent corrosion resistance with good welding and fabrication features. However, to save cost some manufacturers use SS304. Corrosion resistance Applications * ** ** ** ** ** **** **** ***** **** ** ** ** ** ** *** ** Springs, structural and wear parts Kitchen sinks, water tubing Food processing equipment Spun parts Heat exchangers Heated and electrical parts Sections and dying plant Monitors and process plant Thick section process plant Thick section chemical plant Heater elements and aircraft parts Turbine blades Exhaust parts Gas turbine parts Kitchen knives Decorative houseware Car trim, wiper blades * Low corrosion resistance ***** Extremely high corrosion resistance International material standards Most countries with an industrial base have standards for materials which specify their composition and performance. The most common standards in use are the US ASTM standards and the European EN standards. However, many other countries have standards including Italy, Germany, India and Japan. Comparing materials from one standard to another is often difficult. However, the US ASTM B62 (also known as leaded red brass) is equivalent to EN 1982 CC491K (the old BS1400 alloy LG2) and the Indian specification IS:318 – LTB2. In Europe SS316 stainless steel for sheet and rod is equivalent to the American ASTM A497. Applications in chemically hazardous areas Bronze is preferred by most users, particularly if the monitor is used for sea water or in coastal salt laden atmospheres, but other materials have advantages when other chemicals are present. 8 If Hydrogen Sulphide is present Bronze can blacken and corrode. Hydrogen Sulphide can be a by product of Methane and Propane production. For these applications stainless steel is the preferred material. Salt (Sodium Chloride) and water (H2O) can combine, especially with heat from strong sunlight or processes, to form Hydrogen Chloride. Hydrogen Chloride is also used in chemical plants for pH control and cleaning. Hydrogen Chloride attacks steel, including stainless steels such as SS316. Where Hydrogen Chloride is present Bronze monitors are preferred. Salt also attacks Aluminium or light alloy and while Aluminium is a good material for monitor production, as it is light and low cost its resistance to salt corrosion is poor. Over a period of time salt will turn the metal surface to a white powder if it is not protected and the monitor regularly flushed with clean water after use and kept out of salt laden atmospheres. Remote Actuation In many applications it is necessary to operate a monitor remotely. To do this motors are fitted to move the monitor body in the horizontal and vertical planes. In addition, if the monitor is fitted with an adjustable nozzle this will also need to be moved with a motor or actuator. Remote control monitors will often need to meet the standards for operation in an area subject to explosive gases such as ATEX in Europe or NEC in the USA. Some applications require a master panel and slave panel arrangement, while others require feed back to show the operator where the monitor is pointing so that it can be operated even when smoke obscures the view. Disadvantages: • Can be expensive if explosion proof motors necessary • Secondary panels in an explosion area need to be contained in explosion proof casings MAIN UP RIGHT DOWN NOZZLE VALVE OPEN Hydraulic drive POWER ON FAULT MONITOR LEFT FULL TAG FAULT UP Hydraulic motors have the advantage of low cost, simplicity and are usually explosion proof. FULL POWER ON MONITOR DOWN LEFT RIGHT NOZZLE FOG CLOSE Optional secondary control station housed in explosion proof enclosure FOG Advantages: • No need to use limit switches on the motors. When they reach the limit of travel they will simply circulate the hydraulic fluid without damage • Reliable, low cost and easy to maintain • Option of a water driven hydraulic power pack means the system does not need an electrical supply 1500m Hydraulic/electric systems For some applications hydraulic/electric systems are preferred. In these the monitor is moved using hydraulic motors but the hydraulic power is provided by individual hydraulic power packs mounted at the base of the monitor. The power packs are generally explosion proof. Hydraulic control panel with electric driven hydraulic power pack Hydraulic control panel with water driven hydraulic power pack MAIN UP OPEN TAG UP 200m FULL Disadvantages: • No facility for a secondary panel • No facility for position indicators POWER ON MONITOR DOWN LEFT • General limited to 300 m maximum distance between the monitor and control panel RIGHT DOWN FAULT Water POWER ON FAULT MONITOR LEFT FULL RIGHT NOZZLE NOZZLE VALVE FOG CLOSE Optional secondary control station housed in explosion proof enclosure FOG 1500m The advantages of this arrangement are that it combines the benefits of using hydraulic motors with the benefits of electrical control panels, retaining the option of a slave panel and no distance limitations between the master panel and the monitor. Electric drive Distance limitations Electric motors must have a mechanism to stop the current when they reach the limit of travel or they may burn out. Modern positioning encoders and electronic controls are replacing the more traditional overload protection devices. There is a limit to the distance it is practical to run hydraulic pipes. If the distance is too long there can be problems with friction in the pipes. If the pipe size is increased in diameter to reduce friction the cost increases, and there can be problems with air in the pipes. Both air and friction will cause the movement of the monitor to be sluggish or erratic. Advantages: • Possible to have a master and slave panel arrangement • Built in encoders will show monitor position if required • Distance between the monitor and master panel is not limited Alternatively an electrical supply can be run almost any distance. Generally a Zone 1 explosion rated multi core electrical cable is cheaper than the equivalent multi tube hydraulic pipe. Hydraulic pipe Electric cable Maximum practical distance 300 to 400 m between panel and monitor 1,500 m 9 Remote Actuation Nozzle and Cannon Design Explosion proof panels Two types of nozzle are generally fitted to monitors. Fog/Jet nozzles which can be adjusted to give either a straight jet or a wide spray water or non-aspirated foam fan, and foam cannons or nozzles specifically designed for throwing aspirated foam by entraining a quantity of air into the stream. It is normal to mount the master electrical panel in a safe area with the secondary panel, near the monitor, contained in a explosion proof enclosure. Where the panel is hydraulic it is necessary, if it is positioned in the risk area, to ensure both the hydraulic power pack and the panel are explosion rated. TAG FAULT UP DOWN LEFT FULL POWER ON MONITOR RIGHT NOZZLE FOG Where it is not considered good practice to have an electrical supply to the monitor it is possible to use water pressure to power a Pelton wheel driven hydraulic pump. In this way it is possible to install a remotely controlled monitor which is totally independent of an electrical supply and intrinsically safe for zone 1 areas. Position indicators Some systems require the position of the monitor, its direction and elevation to be indicated on the master control panel. This can be useful when the area is obscured by smoke as they allow the operator to point the monitor at a specific target even though it cannot be seen. Most electrically driven monitor designs can be fitted with encoders on the horizontal and vertical movements which send a low voltage signal (intrinsically safe) back to the control panel where the position is shown on a dial. X Manual override Many specifications require the ability to manually operate the monitor in both the horizontal and vertical planes in the event of a complete power failure. However, the addition of hand wheels also adds to the cost and complexity of the system. 10 Fog/Jet Nozzles are generally manufactured from brass, bronze or aluminium. The simplest designs are adjusted by hand while hydraulic or electrical actuation is employed for remote control monitors. The design is simple in principle and uses a plunger in the nozzle stream to force the water into a straight stream when the outer casing is extended, and into a wide jet when retracted. It is normal to use either water or foam solution in a Fog/Jet nozzle. However, the degree of air entrapment in a foam stream is limited to the small amount of air that is trapped in the stream once it leaves the nozzle, which limits the foam expansion that can be achieved and reduces the stability of the foam once loaded. Throw Calculations Foam cannons are usually not adjustable and will only provide a straight jet. To generate expanded foam an orifice in the pipe entrance is used to generate a low pressure area and draw air into the foam stream. Foam expansion ratios of up to 8:1 are common. Cannons are traditionally manufactured from stainless steel (SS316) for the expansion tube and bronze for the tube base. The design and shape of pipe end is critical for generating a coherent and tightly packed foam stream. If the foam stream diverges, not only does it pick up more air and expand, but its range will be less. CURVED LIP CAUSES JET SPREAD SHARP LIP MAINTAINS JET LINEARITY Self-inducing nozzles and cannons For some applications it is convenient to fit the nozzle or branchpipe with an orifice and pick up tube which, when the water is flowing through the nozzle, will suck up foam concentrate from a container. Foam pick-up tubes should not be placed more than 4 to 6m from the nozzle or the efficiency of the inductor mechanism will be impaired and the foam mix may be affected. The energy needed to pick up the foam will have a small but noticeable negative effect on the maximum throw. Distance travelled The distance a jet of water or foam solution will travel is, in theory, simple to calculate. If the flow of water through the monitor, typically in litres/minute, is known and this is divided by the cross sectional area of the nozzle, the speed of the jet can be calculated. If it is assumed that there is no atmospheric drag then the optimal angle for the jet is 45°. This is easier to understand by taking the two extremes. If the jet were to be pointed straight up (90º) it would not travel any distance horizontally and would fall back to ground where it started. If the jet were fired horizontally (0º) it would hit the ground almost immediately and once again travel no distance. Half way between 90º and 0º, or 45º, gives the maximum distance that can, in theory, be travelled horizontally before gravity pulls the jet down to the ground. For a monitor flow of 6,000 l/min with an effective nozzle orifice diameter of 6 cm, the exit velocity from the nozzle is 35 m/sec. If the nozzle is at an angle of 45º the vertical and horizontal components of the velocity are 25 m/sec. Gravity will slow the jet by 9.8 m/sec for every second the jet is in the air. Therefore, the time that will elapse before the vertical jet stream hits the ground is just under 5 seconds (2.5 seconds upwards and 2.5 seconds downwards). During this time the jet will travel horizontally for 5 seconds at 25 m/sec or a theoretical distance of 125 m before hitting the ground. However, in real-life air resistance and other dynamic effects make the actual distance much shorter, typically 80 m, or 50% to 60% of the theoretical distance achievable. theoretical throw actual throw 50% 60% 100% Air resistance The major influence on jet travel is air resistance. As the water jet leaves the nozzle it breaks up into droplets, each one of which behaves as a small ball travelling through the air. The smaller the droplets, the wider the spread of the jet, the greater the air resistance and the shorter the throw. Not only is there resistance through the air but the jet is subject to wind, either from the side or head on. Even a small air movement will make a significant difference to the spread of the jet and the throw of a nozzle. Air resistance increases as a square of the water droplet speed. Therefore, the jet slows at a greater rate when it first leaves the nozzle than when it is close to hitting the ground at the end of its travel. Because of this effect the optimum angle for achieving the maximum throw or distance is not 45° but nearer 32°. Water jet and self-inducing foam cannon mounted on a single monitor body. Linked change over valves direct the water flow to the jet or the cannon 11 Throw Calculations Water, Foam & Powder Foam in the jet stream Water Foam, especially aerated foam from an aspirating cannon increases the area of the jet stream and therefore the theoretical air resistance. However, in practice it can have the opposite effect. Modern protein-based foam (FP or AR-FFFP), is cohesive and sticks to itself, increases the droplet size. This has the effect of binding or coalescing the foam stream into a “rope” helping the jet to punch through the air with reduced surface area and therefore reduced resistance. As a general rule a modern FP or ARFFFP protein-based foam in the jet stream, provided it is not expanded above 10:1, can increase the maximum jet throw by around 5%. Where the primary function of a monitor is cooling, dust control or water jetting the only considerations are whether the water is potable, brackish or seawater. If salt is present then a bronze or SS316 stainless steel monitor is required. Mild steel and light alloy will be quickly attacked by salt, severely reducing the working life of the product, leading to high maintenance and unreliable operation. However, synthetic based foam like AFFFS can have the opposite effect. The detergent bubbles slip and slide over one another and have no cohesive effect on the jet. This results in a jet more likely to spread out, increasing wind resistance. In addition, synthetic foam is often seen falling short with wider levels of dropout between the monitor and the target, resulting in less foam reaching its destination. High performance ARAFFFS with their polymer additives help detergent foams behave more like protein based products. Depending on the application either a fog/jet nozzle or a simple water cannon for maximum throw is adequate for water alone. Distance or foam quality? It is possible to design a foam cannon that will maximise the distance the jet will travel. However, it is important to ensure that the foam quality generated is good enough to extinguish a fire. Unfortunately cannons that generate foam with the best expansion ratios and drainage times are not the same designs that will throw the longest distances. It is essential when comparing cannons and monitors to ensure that distance claims are backed up with foam quality tests. Distance alone is almost always achieved at the expense of foam quality, in some cases to the point where the foam delivered will be inadequate for effective fire fighting. How far will the jet travel? Unfortunately there are so many conflicting effects that come into play that it is difficult to predict with any degree of accuracy how far a given combination of monitor, nozzle and foam will throw or what height the jet will clear. Not only are there the effects of nozzle design but wind, foam type, self-inducing pressure losses and the general condition of the equipment will all affect the distance travelled. Figures given in data sheets must of necessity be taken as an approximate guide to the best that can be achieved under ideal circumstances. Where cooling is the objective it is important to ensure that the correct quantity of water can reach the hazard after taking into account obstructions. Foam The majority of monitors are used to place foam on to a fire or fire hazard. The monitor design, its throw and jet height are critical to ensure the foam can reach its target while still maintaining adequate quality in terms of drainage time and expansion ratio. Modern FP, ARFFFP or ARFFF foams are preferred since they enhance the throw of the jet and minimise dropout and wastage. They also minimise fuel pick up from forceful plunging and provide superior burnback resistance with longer post-fire security. Most monitors are designed to produce their optimum performance using only one manufacturer’s foam. Where the monitor producer does not manufacture foam then it can be difficult to determine performance in the field. Powder The use of fire fighting powders is particularly useful where pressurised gas and liquid leaks may occur. Because of the nature of these hazards it is essential to choose the correct powder. For powder applications specialist assistance is recommended from the manufacturer at an early stage in the specification of the monitor and powder cannon but Monex is the discerning choice by many leading class B, C, E fire professionals. Allowances need to be made for prevailing conditions during use that can reduce the distance travelled through no fault of the monitor, nozzle, induction system or foam concentrate being used. Fluorprotein-Based Foam Synthetic-Based Foam Angus Colossus large-capacity aspirating foam monitor 12 Explosion Proof Rating Many monitors are sited in areas where flammable liquids or gases are processed, stored or transported. While there is little risk of explosion when the liquids and gases are contained, it must be assumed that there is a risk of explosion if there is a breakdown, an emergency release or sudden ignition. To allow for this, specifications normally call for monitor and monitor control systems to be manufactured to international explosion proof standards such as ATEX (ATmosphères EXplosibles) or NEC (National Electrical Code) in the USA. Therefore, for a monitor used to protect a Zone 1 area, for example a hydrocarbon loading jetty, the ATEX approval should read: CE Ex II 2 II EEx d T4. Note: The ATEX classification system only applies to equipment containing electrical components or apparatus which could cause a spark or become hot and can cause ignition and a subsequent explosion. Equipment which is only mechanical and cannot cause a spark or produce sufficient heat to ignite gas cannot be ATEX approved. Most fire fighting equipment will be sited in: “A place in which an explosive atmosphere is likely to occur in normal operation occasionally.” These are classed as Zone 1 or Class 1 areas. ATEX Directive For gases (and vapours given off by flammable liquids) this represents a Zone 1 area. (Zone 0 is the continual presence of flammable gas, Zone 2 is where flammable gas is not likely to occur). Equipment for use in these areas is classified into Groups and Categories. Zone 1 requires monitors and control equipment to be Group II approved. (Group I is reserved for mining equipment). USA – Hazardous area classifications Under the US NEC system areas are firstly given a “Class” location for specific applications. Class 1 covers flammable gases, vapours or liquids. (Class 2 is dust and 3 fibres). Classes are further subdivided into “Divisions”. Division 2 is defined as “Where ignitable concentrations of flammable gases, vapours or liquids are not likely to exist under normal operating conditions”. (Division 1 is for flammable gases present some or all of the time during normal operating conditions). There is a further classification for the type of gas or vapour that may be present and their ignition temperatures. Most industrial systems fall under Groups C and D. Equipment is given a Category depending on the Zone in which it is intended to operate. A Zone 1 environment requires equipment classified as Category 2G, where G stands for gas. (There are separate categories for dust hazards - D). A typical monitor installed under the US classification system may be required to operate in a Class 1, Division 1, area in which gases in Groups C and D may be present. The type of protection applied is defined by the CENELEC (Comité Européen de Normalisation Electrotechnique) code. Ratings are defined by a letter preceded by EEx. An explosive or flame proof enclosure for a control panel intended for a Zone 1 area would be classed as EEx d. In addition, the maximum surface temperature the equipment can generate is also added to ensure it cannot form the source of ignition for any gases present. The code “T4” indicates a maximum temperature of 135°C which caters for most fire fighting requirements in industrial areas. Comparison of ATEX and NEC The ATEX system was made mandatory in Europe in July 2003 and reflects a more up to date method of working. It also takes into account a wider range of parameters than the US system. As a result, ATEX is a more comprehensive system and is therefore the preferred system for most international fire fighting specifications. Comparison of ATEX and NEC zone classifications: ATEX NEC (USA) Zone 0 Division 1 Where ignitable concentrations of flammable gases, vapours or liquids are present continuously or for long periods of time under normal operating conditions Where ignitable concentrations of flammable gases, vapours or liquids can exist all of the time or some of the time under normal operating conditions Zone 1 Where ignitable concentrations of flammable gases, vapours or liquids are likely to exist under normal operating conditions Zone 2 Division 2 Where ignitable concentrations of flammable gases, vapours or liquids are not likely to exist under normal operating conditions Where ignitable concentrations of flammable gases, vapours or liquids are not likely to exist under normal operating conditions 13 Titan Range Angus Fire has been manufacturing fixed and portable monitors for over 40 years. The range includes light alloy, stainless steel and bronze models ranging in nominal flow from 1000 to 40,000 l/min. The trailer mounted fixed range of monitors is supplemented by a wide range of fog/jet nozzles and foam cannons. Selfinducing nozzles and cannons are also available. Titan Angus Fire, the manufacturer of the unique Monnex® powder, manufacture specialist powder nozzles for selected models. 4,000 - 5,900 l/min Max throw 80m Max throw 90m 6,000 Max Portable / mobile PMA 18 PMS 27-37 PMB 40 PMB 65 1,800 l/min 2,700 - 3,700 l/min 4,000 l/min 6,500 l/min Hand lever with friction locks LMB/A 30 LMS 30 LMB 40 LMS 45 LMS 60 3,000 l/min 3,000 l/min 4,000 l/min 4,500 l/min 6,000 l/min GMA 30 GMS 30 GMB 50 GMS 45 GMS 60 3,000 l/min 3,000 l/min 5,000 l/min 4,500 l/min 6,000 l/min 560 SSM AR-AFFF is increasingly popular by those committed to synthetic detergent based products on the basis of exceptional Last Fire test performance. Hand wheel* with worm and wheel gearbox Hydraulic, electrical and hydro/electric remote control options are available on all monitors together with a wide range of single and multi way control panels. Remote control panels for use in areas where explosive regulations apply are also available. *Chain drive optional Angus Fire is the worlds leading manufacturer of fire fighting foam concentrates. Angus Fire monitors are designed to optimise the performance of Angus Fire foams, maximising throw and flow without reducing foam quality. Modern FP or AR-FFFP protein-based foams, such as Angus Fire Tankmaster, are preferred since they enhance the throw of the jet and minimise dropout and wastage. They also minimise fuel pick up from forceful plunging and provide superior burnback resistance with longer post fire security. 14 1,800 - 3,900 l/min Automatic oscillating gearbox OMB 36 OMB 40 3,600 l/min 4,000 l/min Hydraulic drive (EExd rated) RHMA 30 Hydraulic drive with electro/ hydro power packs (EExd rated) Electric drive (EExd rated) RHMB 50 RHMS 60 5,000 l/min 6,000 l/min RHEMA 30 RHEMB 50 RHEMS 60 3,000 l/min 5,000 l/min 6,000 l/min REMA 30 REHMB 50 REMS 60 3,000 l/min 5,000 l/min 6,000 l/min 3,000 l/min A Light alloy body L Hand lever and locks B Bronze body M Monitor C Continuous rotation O Oscillating movement CG Chain drive Gearbox P Portable E Electrical motors R Remote control G Worm and wheel gearbox S Stainless steel 316 body H Hydraulic motors INCREASED TURBULENCE NO VEINS TURBULENCE TIGHT BENDS Double row stainless steel bearings Jig welded stainless steel minimises offset forces Computer a reduce flo n Monitor Range - 7,900 l/min throw 95m 8,000 - 9,000 l/min 15,000 - 30,000 l/min 50,000+ l/min Max throw 100m Max throw 115m Max throw 130m PMS 80 PMS 100 - 300 8,000 l/min 10,000 - 30,000 l/min LMB 65 LMS 80 LMB 85 6,500 l/min 8,000 l/min 8,500 l/min GMB 65 GMS 80 GMB 85 GMS 200 GMS 300 6,500 l/min 8,000 l/min 8,500 l/min 20,000 l/min 30,000 l/min OMB 65 OMB 85 6,500 l/min 8,500 l/min RHMB 65 RHMS 80 RHMB 85 RHMS 200 RHMS 300 RHMS 500 6,500 l/min 8,000 l/min 8,500 l/min 20,000 l/min 30,000 l/min 50,000 l/min RHEMB/C 65 RHEMS 80 RHEMB/C 85 RHEMS 200 RHEMS 300 RHEMS 500 6,500 l/min 8,000 l/min 8,500 l/min 20,000 l/min 30,000 l/min 50,000 l/min REMB 65 REMS 80 REMB 85 REMS 200 REMS 300 6,500 l/min 8,000 l/min 8,500 l/min 20,000 l/min 30,000 l/min LEO + HYD 80 Alloy NOZZLE VANES TAG FAULT UP aided bends ow losses Electro-hydraulic, waterhydraulic and electrical panels Bronze Nominal flows and throws shown at 7 bar inlet pressure with foam and no wind conditions POWER ON MONITOR DOWN LEFT FULL SWEEPING BENDS Stainless Steel 316 © Angus Fire. Angus Fire reserves the right to modify any specification without prior notice RIGHT NOZZLE FOG Panels for hazardous areas Wide range of fog jet nozzles and foam cannons Angus Fire, Thame Park Road, Thame, Oxon, OX9 3RT, UK Telephone +44 (0)1844 265000 Fax +44 (0)1844 265156 E-mail general.enquirie@kiddeuk.co.uk Web www.angusfire.co.uk 15 Approvals In common with most fire fighting equipment, monitors can be approved by third party national and international accreditation bodies. While some bodies verify the manufacturers’ specifications, others test the equipment to their own, clearly defined standards. The two most common test standards for fixed fire protection equipment are FM Global and UL (Underwriters Laboratories Inc) based in the USA. Others in common use are Lloyd’s Register/MCA (Lloyd’s Register plus UK Maritime and Coastguard Agency), Bureau Veritas (France), ABS (American Bureau of Shipping), DNV (Det Norsk Veritas – Norway) and RINA (Registro Italiano Navale). The latter are approvals based on codes for the protection of ships but are also often accepted for land-based systems. It is expected in the future that fire fighting equipment that generates foam will need to be tested by an independent third party test house for compliance with the EEC Construction Equipment Directive. The test standards and scope of this section of the Directive are in the process of being formulated. FM standard FM Global specifies that monitors should to be tested for movement of the monitor after high and low temperature and salt spray tests. In addition the standard calls for a 58 bar static pressure test (monitors are not normally exposed to pressures greater than 16 bar in operation) and a 35 bar dynamic test. FM Global also require the “K” factor of the monitor to be logged at various flows and the straight water jet throw distance (using an FM standard jet) to be measured at a variety of inlet pressures. This is useful for water jets but has little relevance for foam applications. UL standard Underwriters Laboratories Inc. follows a similar system to FM with one important addition. For UL Listing the quality of the foam generated by the monitor is measured under various conditions and must conform to set criteria. Where monitors are installed for spraying foam the quality of the foam generated is paramount and often critical to the successful control and extinction of a fire. In this respect UL Listing is generally more comprehensive and relevant to the practical application than other monitor standards. Lloyd’s Register, Bureau Veritas, ABS and RINA Unlike FM Global and UL these approvals are, in the main, verifications that the manufacturers’ specifications are accurate and that the equipment performs as stated in their specification and will meet the minimum marine equipment performance criteria. Technical datasheets containing further information are available on request from your local Angus Fire representative or from our website www.angusfire.co.uk Angus Fire reserves the right to modify any specification without prior notice. REF: 6445/1-01/07 © Angus Fire Printed in England A UTC Fire & Security Company THAME PARK ROAD, THAME, OXFORDSHIRE, OX9 3RT, ENGLAND Tel: +44 (0)1844 265000 Fax: +44 (0)1844 265156 e-mail: general.enquiries@kiddeuk.co.uk Web site: www.angusfire.co.uk