Vandevier and Gould 1 Application of Electrical Submersible

advertisement

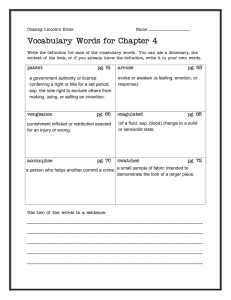

Vandevier and Gould Application of Electrical Submersible Pumping Systems in High Temperature Geothermal Environments Joe Vandevier and Ben Gould Baker Hughes Keywords ESP, electrical submersible pump, artificial lift, submersible motor, multi-stage centrifugal pump, power cable, motor controller, SAGD, EGS, high temperature testing, hot-loop Abstract The need for artificial lift to improve the economics of geothermal fluids production for power generation and direct use applications has been recognized for many years. Electrical submersible pumping (ESP) systems have been used successfully in geothermal and other high temperature applications and show significant promise for future applications. This paper briefly describes the ESP system, its use in geothermal wells and the development of ESPs for applications in excess of 220˚C. In addition, the paper explores future pumping requirements for new geothermal applications such as Enhanced Geothermal Systems (EGS) and outlines recent and future ESP advances for effective operation in increasing well depths, temperatures, and flow rates. Introduction Geothermal resource development is gaining attention due to mounting concerns about hydrocarbon long-term supply, price volatility and carbon emissions. Geothermal production expansion from hydrothermal reservoirs, along with the evolution of EGS, has the potential to significantly impact power generation capabilities from geothermal resources.1 Technology requirements to effectively produce geothermal energy are multi-faceted and require ongoing development and improvement to facilitate rapid growth of geothermal energy. A key need for many geothermal projects is pumping systems capable of delivering the sustained high volumes of geothermal fluids necessary for efficient thermal recovery and electric power generation. Line shaft turbines and ESP systems are used to pump geothermal fluids and remain the most practical solutions. However, ESP operational advantages vs. line shaft turbines include deeper setting depths and higher HP delivery, therefore, ESPs will likely be the pump system of choice for many applications. Development of ESP systems for high temperature applications is accelerating and this paper provides an overview of ESPs and the development status of reliable systems for deployment at extreme temperatures. 1 Vandevier and Gould ESP System ESP systems suitable for a broad range of geothermal applications must be designed for harsh duty environments with high flow rates, high motor horsepower and extreme operating temperatures. Fortunately, ESPs developed for oil and gas production have been used for over 80 years and have been continuously evolving in their capabilities to deliver reliable operation in difficult applications. Although it is not the intent of this paper to provide in-depth details of the anatomy of ESP systems, it is important to understand the basic components. A typical ESP system is shown in Figure 1. The system is installed in a well using a suitable workover rig and during that process the downhole assembly is made up on the rig floor by skilled service technicians. The major components of the completed system are: 1. Surface controller - Starts and stops the ESP by energizing the submersible motor based on control commands programmed into the controller. It can be fixed frequency or variable frequency control. 2. Power cable - provides three phase electric power from the surface to the submersible motor 3. Multi-stage centrifugal pump 4. Seal (protector) - ensures reliable system performance by: a. Isolating the motor internal parts from the well fluid b. Providing for expansion of the motor insulating oil as temperatures rise c. Handling pump thrust d. Transmitting torque from the motor to the pump 5. Motor - a polyphase induction motor with high dielectric windings, multiple rotors in series, and filled with insulating lubricating oil. 6. Downhole Sensor - measures fluid temperature and pressure, motor temperature and motor vibration 2 Vandevier and Gould Figure 1 – ESP system Use of ESP Systems in Geothermal and High Temperature Applications The first use of ESPs in geothermal applications dates back to the 1970s when ESP systems designed for oil production were applied to moderate temperature hydrothermal wells in Europe, U.S. and Japan. These wells typically produced fluid for process heat used for building heating, food processing, and health spas. In the late 1970’s and early 1980’s a significant amount of development on high temperature ESP systems was conducted by ESP manufacturers in conjunction with U.S. Department of Energy funded programs. The DOE objective was to achieve higher temperature requirements to allow for commercial production of electricity. The Raft River project near Boise, Idaho, (Figure 2) was one of the early demonstrations of this technology development. 3 Vandevier and Gould Figure 2 - Geothermal ESP installation Today there is between 100 and 200 ESP systems installed in geothermal wells at moderate temperatures (up to 170˚C) located principally in the U.S., France, Germany and Japan2. Applications include both process heat and power generation. The demand for higher horsepower units to accommodate deeper setting depths and higher produced fluid volumes at higher operating temperatures is on the increase. For example, in the western United States a number of ESP systems have been installed with motors in the range of 600 HP to 1000 HP, producing hydrothermal wells from 140˚C to 170˚C for binary cycle power generation. Over the last five years, the development of ESP equipment for high temperatures (170˚C to 220˚C) has become a high priority for ESP manufacturers serving the oil and gas industry. SAGD (steam assisted gravity drain) applications for unconventional production of viscous crude have grown significantly and thereby accelerated high temperature design improvements. These applications involve drilling parallel horizontal wells approximately 500 to 1000 meters in length with approximately 5 m of separation (Figure 2). Steam is injected into the upper well and contacts the oil, lowering its viscosity. The combined oil / water emulsion then flows to the lower well where it is produced by the ESP3. 4 Vandevier and Gould Figure 3 - SAGD installation To accommodate SAGD applications, ESP systems have been developed to operate at temperatures of up to 220˚C with targeted run life of at least two years. Ongoing developments are aimed at increasing the ESP operating temperature range to 250˚C (extreme temperature). ESP technology currently employed in approximately 200 SAGD wells has direct application to higher temperature geothermal wells. However, to date the largest ESP systems for SAGD applications are limited to around 300 HP while geothermal well requirements can and will be much higher. ESP Design Upgrades for Extreme Temperature Thousands of man-hours and millions of dollars have been invested to develop ESP systems capable of extreme temperature operation. As a part of this investment, and in order to accelerate the learning curve, several high temperature test loops (“hot loops”) have been built to conduct research and test prototypes and production equipment at temperatures up to 340˚C (650˚F) and pressures to 2250 psi. The newest hot loop recently completed by one manufacturer is shown in Figure 4. 5 Vandevier and Gould Figure 4 - High temperature ESP test facility The test loop capabilities include: • • • • • • • • Closed loop system Total well length: 100 ft (30.5 m) Casing size: 12 inch OD and 10 inch ID Flow capability: 580 gpm (1593 m3/d) Maximum pressure: 3500 psi Maximum temperature: 650 F (343˚C) Variable speed control: 500 kVA Test fluid: water The use of the hot loop test facilities, along with experience in high temperature geothermal and SAGD applications, has provided an important learning curve for ESP manufacturers. The ESP system technology used for moderate temperature wells does not provide reliable long-term service at significantly higher temperatures. To achieve the level of reliability and performance required for viable operations at higher temperatures, key engineering design and material changes are required in five key areas of the system4: • • Minimize use of elastomers - Elastomers are commonly used in o-rings, bellows, seals and bushings. However, the high temperature effects of the well, along with damage from absorbed gases, thermal cycling, and hydrolysis, challenge even the most exotic elastomers. The newest ESP systems for ultra-high temperature have reduced or eliminated the use of elastomers. Accommodate increased thermal expansion of mechanical components - The dimensional growth of key mechanical parts is substantial as the equipment transitions from surface temperatures to fully operational well temperatures. In addition, thermal cycling produces changes in running clearances during various 6 • • • Vandevier and Gould phases of operation (such as on / off or variable speed operation). Therefore design changes have been required to create optimum tolerances and clearances. Allow for additional motor oil expansion - The motor is filled with a highly insulating lubricating oil. Its purpose is to insulate, lubricate and balance pressure between the inside of the motor and the outside environment. The motor oil expands significantly with increasing temperature and conventional oils used in standard ESP motors are not sufficient for ultra-high temperature applications. Improve bearing lubricity capacity - An ESP system contains a number of journal and thrust bearings. The ability of these bearing surfaces to operate reliably at both low temperature and ultra-high temperature require newly developed innovative design and material changes. Increase temperature capabilities of electrical insulation - The life of an ESP system is mostly controlled by mechanical wear or insulation deterioration of the electrical system. High temperatures are detrimental to insulation systems in the power cable, motor connectors and motor insulation. Significant materials improvement for insulation systems is driving higher temperature capabilities. Emerging Opportunities and Future Advances Commercial ESP systems rated to 220˚C have evolved from over 80 years of experience in high temperature oil wells and several hundred geothermal and SAGD applications. However, the quest for higher flow rates and deeper depths at greater temperatures in hydrothermal wells remains a clear objective of both the geothermal industry and key ESP manufacturers. These systems are commercially available today. Expanding hydrothermal energy production and the evolution of EGS applications will require further increases in operating temperature, system horsepower, and ultimate ESP system life. Table I summarizes the existing general capabilities of current ESP systems in three contrasting applications and forecasts future requirements for both extreme temperature hydrothermal applications and EGS. Well Temp (˚C) Setting Depth (m) Flow (GPM) Horsepower Conventional Oil & Gas 30 to 140 150 to 3700 3 to 1200 20 to 1250 SAGD 125 to 220 300 to 1000 15 to 350 60 to 350 Hydrothermal 60 to 190 50 to 1000 40 to 3000 30 to 1500 Future 150 to 250 750 to 3700 40 to 4000 50 to 2500 Table I - ESP operating range by application As outlined in the DOE / MIT report entitled “The Future of Geothermal Energy,” the impact of EGS on future U.S. electric power production can be significant.5 What makes EGS applications particularly challenging are the deeper depths required to reach hot dry rock structures with commercially viable geothermal temperatures. Developing higher horsepower ESP systems that operate at 200˚C to 250˚C will be required to provide the lifting needs of EGS. Significant engineering, development and testing is ongoing to meet these needs. Programs are planned to expand the ESP system operating range to 250˚C 7 Vandevier and Gould with a minimum three year run life target. In the meantime, new high horsepower motor frames that can deliver up to 2800 HP in wells with 10 3/4 inch casing or larger will be commercialized soon (figure 5). This will significantly expand existing motor capabilities of 1600 HP for 9 5/8 inch casing. Conclusion Currently, ESP systems play an important role in pumping fluid from a broad range of geothermal wells up to 200˚C. Working together, ESP manufacturers, geothermal producers and governmental agencies around the world can expand ESP use in newly drilled moderate temperature hydrothermal wells and invest in needed enhancements for reliable future ultra-high temperature applications. Acknowledgements The authors would like to thank Baker Hughes Centrilift for permission to write this paper. Also, special thanks to John Bearden, Steve Tetzlaff, Lawrence Burleigh, Kelvin Wonitoy, Hans Sjerps and David Patti who provided important technical and operational information. Finally, we would like to thank John Thompson for assisting with graphics and editorial support. Figure 5 - New high HP motor Footnotes 1 MIT Summary Report, “The Future of Geothermal Energy,” prepared for DOE and Idaho National Laboratory under contracted-AC07-05ID14517, 2006, p.3. 2 Author’s estimate 3 Steve Tetzlaff, Kevin Wonitoy, Brad Ward, Lawrence Burleigh, and Adrian Dodds, “Extreme Temperature ESP Development,” SPE Annual Conference and Technical Exhibit (Anaheim, 2007) Paper #110701. 4 ibid., p4. 5 Op. cit., MIT Summary Report, p.3 References Tetzlaff, Steve, K. Wonitoy, B. Ward, L. Burleigh, and A. Dodds, 2007. “Extreme Temperature ESP Development,” SPE Annual Conference and Technical Exhibition, Anaheim, California, paper # 110701. 8 Vandevier and Gould Price, William and Burleigh, Lawrence, 2001. “Electrical Submersible Pumps for Geothermal Resources.” Geothermal Resource Council Transactions, Vol. 25, August 26- 29, pages 27 – 31. Burleigh, Lawrence and Miller, M., 2002. “An Electrical Submersible System Efficiency Study.” Geothermal Resource Council Transactions, Vol 26, September 22-25, pages 125 – 131. DOE / MIT Report, 2006. “The Future of Goethermal Energy, Summary Report.” Massachusetts Institute of Technology and Idaho National Laboratory, ISBN: 0-61513438-6. Noonan, Shauna, J. Sukianto M. Dowling, W. Klaczek and K. Piers, 2009. “The Quest to Understand ESP Performance and Reliability at 220˚C Ambient and Beyond,” SPE Gulf Coast Section Electric Submersible Pump Workshop, April 29 – May 1, 2009. 9