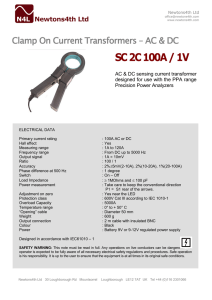

Flexible Cable

advertisement