Airfield Lighting - Canadian Airfield Solutions

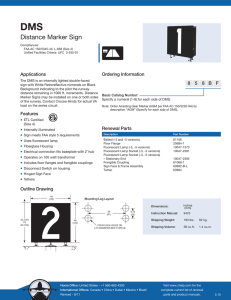

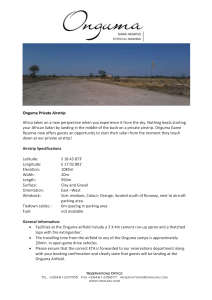

advertisement