Crosslinked polyethylene

advertisement

Indian Journal of Chemical Technology

Vol. 11, November 2004, pp. 853-864

Crosslinked polyethylene

S M Tamboli, S T Mhaske & D D Kale*

Institute of Chemical Technology, University of Mumbai, Matunga, Mumbai 400 019, India

Received 12 June 2003: revised received 22 July 2004; accepted 4 August 2004

Properties of polyolefins can be modified by crosslinking process. Different methods of crosslinking and effect of

process parameters, selection of crosslinking agents and applications are briefly discussed.

IPC Code: C 08 F 2/00

Keywords: Crosslinking, polyethylene, crosslinking agents.

Polyethylenes are commodity plastics. They account

for more than 70% of total plastics market.

Polyethylene is easily available, at relatively low cost

and easily processable. It finds applications in

household items, packaging, insulation, net ropes,

fishing rods or medical applications, etc. Polyethylene

is processed at temperature in the range 150-250°C1-3.

Most polyethylene compounds contain reasonably

good amount of fillers. Polyethylenes are

thermoplastic in nature and therefore they can be

reprocessed repeatedly. Polyethylene, however, will

soften and flow, and lose critical physical properties

at

elevated

temperature

thereby

limiting

its applications4,5. Therefore, crosslinking of

polyethylene is carried out to retain desirable

properties at high temperature. Crosslinking will

change the nature of polymer from thermoplastic to

thermoset to yield a non melting, more durable

polymer matrix.

All types of important polyethylenes are

crosslinked, like Linear low density polyethylene

(LLDPE), Low density polyethylene (LDPE), High

density polyethylene (HDPE) and Ethyl vinyl acetate

copolymer (EVA) and Polyolefinic elastomer (POE).

Branched structure is more suitable for crosslinking.

Therefore, crosslinking of LLDPE and HDPE requires

more attention.

Crosslinking leads to the formation of insoluble and

infusible polymers in which polymer chains are

joined together to form three-dimensional network

structure6-8. In thermoset, crosslinking (curing) takes

place through reaction between polymer chains with

_________

*For correspondence (E-mail: ddkale@udct.org)

several functional groups. These functional groups are

capable of forming chemical bonds to convert

thermoplastics into thermosets9,10. McGrins11 has

described various commercially important crosslinked

thermoset materials and their curing reactions. These

are not of much relevance in the present study. For

thermoplastics, crosslinking is a process in which

high molecular weight thermoplastics are converted

into thermosets.

Crosslinked polyethylenes are either extruded or

injection moulded. When degree of crosslinking is

deliberately maintained very low, the resulting

compound is termed as crosslinkable polymer.

Crosslinking can be combined with foaming also.

Crosslinking of biopolymers and foaming is very

common in food industry. Crosslinking for partially

crosslinked extruded profile is commonly employed

in furniture. Although crosslinking of thermoplastics

such as nylon, polypropylene and styrenics has

received attention in literature. Present review is

directed to the crosslinking of polyethylenes only.

Crosslinked polyethylene forms a dense network of

high molecular weight, which improves impact

strength, environmental stress crack resistance

(ESCR), creep and abrasion resistance without

influencing tensile strength and density to any

appreciable extent. Crosslinked polyethylene finds

wide applications in packaging and electrical

insulation

applications

and

rotomoulding

12,13

applications . The degree of crosslinking can

change

considerably

from

applications

to

applications. Some aspects of crosslinking are

reviewed here.

854

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

Crosslinking process

Crosslinking is a process in which carbon atoms of

same or different polyethylene chains are joined

together to form the three-dimensional network

structure14-16. The crosslinking process essentially

forms bonds between the polymer chains, which

could be directly between carbon to carbon or a

chemical bridge linking two or more carbon atoms18.

The main difference between thermoplastic and

crosslinked polymer is that, at temperature above the

crystalline melting point crosslinked polymer behaves

as a soft rubber while thermoplastic has no significant

strength above melting temperature. The changes in

the properties of polyethylene due to crosslinking

have been compared and documented in literature16,17.

Thus, crosslinking reduces the melt index and

elongation at break, while improves the impact

strength, creep resistance, resistance to slow crack

growth and also environmental stress crack resistance

(ESCR). The density and tensile strength of

polyethylene are not influenced by crosslinking.

The crosslinking of polyethylene takes place in four

stages: initiation, propagation, branching and

termination. The principal reaction involved in each

step is discussed below.

Initiation

The first step in crosslinking process is generation

of free radicals, which can be through a chemical

reaction or radiation energy. Decomposition of

initiators which are normally peroxides, or highenergy radiations abstracts hydrogen atom from the

backbone of polymer chain to produce free radicals.

a) Peroxide decomposition

ROOR

RO* + PH

b) High energy radiation

hv

PH

2 RO*

ROH + P*

H* + P*

Propagation and branching

The free radicals react with atmospheric oxygen to

generate peroxide radicals and through series of

reaction crosslinking takes place, these are described

by Peacock19. Crosslinking causes a dense network of

different polymer chains through chemical bonding.

O2

P*

POO*

POO*+PH

POOH + P*

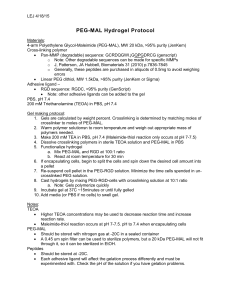

Fig.1⎯Schematic view of crosslinked and

uncrosslinked polyethylene

Branching

POOH

PO* + PH

PO* + OH*

POH + P*

When P* on two sites join, it leads to branching or

network formation.

Termination

Termination takes place by quenching of free

radicals due to presence of additives, impurities etc.

P* + P*

POO* + POO*

PO* + H*

P–P

POOP + O2

POH

Presence of side branches in a polyethylene chain is

a reason for variation in number of important physical

properties such as density, hardness, flexibility and

melt viscosity. Presence of branches is the point in the

molecular network where oxidation may take place.

Crosslinking takes place between carbon atom in

neighboring chains or chain branches joined together

with other branches of chain or with the same chain of

polymer. This is depicted schematically in Fig. 1.

The polyethylenes have different structures

depending upon manufacturing process. Low density

polyethylene is highly branched, while high density

polyethylene and linear low density polyethylene are

linear polymers. In general, branched polymers are

easy to crosslink as compared to linear polymers,

since formation of network is more probable for

branched polymers20.

TAMBOLI et al.: CROSSLINKED POLYETHYLENE

855

Table 2⎯Types of radiation sources

Particulate

Non particulate

α - particles

β - particles

High energy electron

Protons

Deuterons

Neutron

Microwave

Infrared

X-ray

γ-ray

Light energies (UV)

The relative scission to crosslinking ratio is given

by 22

Fig.

β 1 G (S)

=

α 2 G (X)

2⎯Schematic representation of radiation crosslinking

Table 1⎯G(X) and G(S) values of some polymers

Polymers

G(X)

G(S)

LDPE

HDPE

Atactic PP

Isotactic PP

Polyvinyl chloride

Polypropylene oxide

Nylon (6 & 6,6)

Polyvinyl acetate

Polybutadiene

Polystyrene

Polymethyl acrylate

Polymethyl methacrylate

1.4

2.1

0.12 – 0.27

0.07 – 0.14

2.15

0.15

0.5

0.1 – 0.3

3.8

0.045

0.55

-

0.8

1.3

0.10 – 0.24

0.10 – 0.27

0.22

0.6

0.06 – 0.17

< 0.018

0.18

1.22 – 3.5

Crosslinking process is carried out by using (i)

Physical or (ii) Chemical crosslinking methods.

Physical crosslinking

In this method, crosslinking is obtained by free

radical mechanism. The free radical is generated in

polymer chain by using high energy radiations21. This

process is shown schematically in Fig. 2.

Thus, a free radical is generated by the high energy.

Two or more chains, then, join together where the free

radical is generated.

High energy radiation on polymeric material gives

chain scission or crosslinking. The changes in

physical and chemical properties depend upon the

efficiency of crosslinking reaction and its relative

ratio with degradation. Table 1 shows the number of

crosslinking and chain scission per 100eV radiant

energy absorption for different polymers.

… (1)

Where,

α = probability of crosslinking of chains after one

electron volt of energy absorbed.

β = probability of chain scission after one electron

volt of energy absorbed.

G(X) = number of crosslinking per 100eV radiant

energy absorbed.

G(S) = number of scission per 100eV of energy

absorbed.

It is known that bond energy for cleavage of C-H

bond is 364 kJ/mol. The electron beam having energy

sufficient to break C-H bond is suitable for

crosslinking 23.

Crosslinking of polymers by radiation and their

technology involve four main variables.

(i)

(ii)

(iii)

(iv)

Type of radiation and its sources.

The nature of polymer structure to be irradiated.

Mechanism and theories of reactions.

Physical, chemical and mechanical properties of

network formation.

Some of these radiation crosslinking are described

briefly.

Radiation induced crosslinking of thermoplastics

can be carried out using particulate or non-particulate

radiations. These are listed in Table 2.

Particulate radiation sources are not commercially

used. Only non-particulate radiation sources are used

for commercial crosslinking of thermoplastics by

radiation. Crosslinking by radiation mainly depends

upon photon energy of radiation sources. The higher

the photon energy, the more the penetration taking

place and higher crosslinking is obtained. The photon

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

856

energy gained by polymer in UHF field is given by

the following equation31,

Table 3⎯Wavelength and photon energy of

some radiations

Type of

radiation

Wavelength

(nm)

Photon

[MeV]

Infrared

UV

Soft X - ray

1250

125

12.5

1.25

0.125

0.0125

0.001

100

101

102 103

X - ray

γ - rays

energy

… (3)

Where,

104 105

1 2 × 106

energy of radiation is relatively dependent on

wavelength. Table 3 depicts the relationship between

radiation sources, wavelength and photon energies.

Selection of radiation sources mainly depends upon

availability, the radiation penetration rate required,

the dose rate and impact on manufacturing process

(product handling, shielding, safety, equipment cost

and maintenance).

The depth of high energy penetration is given by21,

r = k c1/2 e–1.151εcx

N = E2. 2 f εt tan ζ

… (2)

Where, r: rate of crosslinking reaction, c:

concentration of photoinitiator, ε: extinction

coefficient of photoinitiator, x: thickness of reactive

polymer layer.

Thermoplastic crosslinking by UV radiation is a

very slow process. Thermoplastic is mixed with

photo-initiators, which makes it suitable to use UV

light for crosslinking. UV radiation penetrates the

polymer up to a depth of only a few millimeters24,25.

Therefore UV light is used for crosslinking of thin

parts only26. Ketones such as benzophone, and benzil

dimethyl ketal are suitable photo initiator for

crosslinking of mainly polyethylene27,28.

Electron beams will penetrate up to few centimeters

of thermoplastic polymers. The crosslinking of

moulded parts having thick wall results in variable

crosslink density. Therefore, this process is mainly

used for thin wall products such as films, shrinkable

insulating parts and crosslinking of insulating cables

and foams 29,30.

A microwave represents very high electromagnetic

spectrum [109 to 1012 Hz]. Therefore, it is called as

ultra high frequency (UHF) radiation source.

Microwave crosslinking is independent on the part

thickness. It is applicable to parts of any size. The

N = loss or gain of energy.

E = field intensity.

f = frequency (Hz) of the alternating field.

εt = dielectric coefficient.

tan ζ = dielectric loss factor.

The drawback of microwave field is that, only

components with polar group are excitable in this

field. Thermoplastic such as polyethylene or

polypropylene is non polar compound with very low

tan ζ value. Therefore, crosslinking of polyethylene in

UHF field becomes very difficult. Crosslinking of

polyethylene in microwave field is possible only by

using intensely polar additives such as carbon

black, peroxide, metallic powders and triallyl

oxy-s-triazine32,33.

Most of the applications of radiation crosslinked

polymers are in electrical insulation and packaging

films. These are briefly described in Table 4.

Advantages of radiation induced crosslinking

Advantages of radiation induced crosslinking are

briefed below:

(i)

(ii)

(iii)

(iv)

(v)

crosslinking reaction takes place at room

temperature,

reaction is completed in fraction of seconds,

hence high output is obtained,

reaction can take place without any additives,

highly suitable for relatively thin insulating

layers,

crosslinking takes place in only one step.

Disadvantages of radiation induced crosslinking

Some of the disadvantages of radiation induced

crosslinking are given below:

(i) high capital cost,

(ii) difficult to cross-link article with irregular

shapes,

(iii) Safety precautions are needed to protect

operators from radiation.

TAMBOLI et al.: CROSSLINKED POLYETHYLENE

857

Table 4⎯Commercial uses of radiation-processing techniques

Substrate

Radiation process

Commercial use

Polyolefins and PVC

Cross-linking with high-energy radiation

sources in 0.4-3 Mev range.

Cross-linking with high energy electron

Wire insulation for computers, and

communication application

Improved thermal stability for insulating and

packaging application

Conversions of waste Teflon material into easily

moldable powder or waxes of commercial value

No-wear high performance wood floors for

high traffic areas

Adhesive products for modification of wood,

textiles, paper, film and metal substrates

Polyolefins and PVC foams

Polytetra fluoroethylene (Teflon)

Wood impregnated with acrylic

or methacrylic monomers

Curing of coating and adhesives

Degradation by high energy electron or

cobalt-60 in 0.2-0.4 May

Polymerization with cobalt-60 source

Low energy electron processing equipment in

100-500 Kev range

Chemical crosslinking

Chemical crosslinking is a method, in which

chemicals or initiators are used to generate free

radicals, which in turns leads to crosslinking. In this

method, crosslinking takes place through direct

carbon-to-carbon bonds or through the chemical

bridges which connect different polyethylene

molecules34-36.

Degree of crosslinking in thermoplastic resin varies

according to crosslinking process. Chemical

crosslinking by using peroxide gives highest and

uniform degree of crosslinking as compared to

physical crosslinking method. Kim and White have

reported the difference in degree of crosslinking

between physical and chemical crosslinking

processes37. Accordingly, radiation crosslinking yields

between 34-75% degree of crosslinking. In chemical

crosslinking method, peroxide gives much high

degree of crosslinking (up to 90%), while silane based

crosslinking can be 45-70% degree of crosslinking.

Peroxide initiated crosslinking process depends on

several variables, namely operating temperature, type

and concentration of peroxide, and molecular

characteristics of virgin resin such as, molecular

weight, molecular weight distribution, branch

distribution and concentration of terminal vinyl

groups.

The two main chemical crosslinking methods are,

(i) organic peroxide based and

(ii) silane based (moisture cured).

Crosslinking of thermoplastic by peroxide

Peroxide crosslinking has been in use for more than

40 years and is the most common method for

crosslinking

of

thermoplastics

especially

polyethylenes. In this method, organic peroxide is

used as initiator. Usually, organic peroxide is used in

its original unprocessed structure. Downstream

Fig. 3⎯Schematic representation of crosslinking of polyethylene

processing equipment operates at higher temperature.

The compounding of polyethylene and peroxide must

be carried out at low temperature, below the peroxide

decomposition temperature. Crosslinking is carried

out in the downstream equipment at significantly

higher temperature and pressure. The higher

temperature decomposes the initiator and liberates a

free radical that will abstract a hydrogen atom from

polymer chain. This abstraction site then becomes

reactive radical, forming a crosslinked bond with

another reactive radical of same or different chain.

This reaction occurs until all peroxide is consumed or

the temperature falls below the decomposition

point38,39. Schematic representation of this reaction is

shown in Fig. 3.

Elimination of hydrogen atom converts tertiary

hydrogen atoms of polypropylene and polyethylene to

tertiary radical chain with low reactivity. Tertiary

radical sites are not very reactive and are not

converted easily into more reactive secondary

radicals. The shifting of the radical site along

branched chain is hindered, and dimerization of chain

radical becomes more difficult. Number of peroxides,

which are suitable for crosslinking of thermoplastic

and their dissociation temperatures, are listed in

Table 5.

Dicumyl peroxide (DCP) is widely used for

crosslinking of thermoplastics, and crosslinking

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

858

Table 5⎯Peroxide decomposition rates [kd] and curing temperatures

Initiator

Solvent

Temperature

(°C)

kd ( S-1)

Dicumyl peroxide

Benzene

115

130

145

112

132

154

128

138

148

138

158

100

115

130

108

128

150

125

115

130

145

115

134

156

115

130

145

120

141

164

100

115

130

85

100

115

75

80

100

70

80

91

80

80

2.05* 10-5

1.05* 10-5

6.86* 10-4

1.93* 10-5

1.93* 10-4

1.93* 10-3

8.75* 10-5

2.31* 10-4

5.37* 10-4

2.57* 10-4

1.52* 10-3

8.75* 10-7

5.66* 10-6

3.22* 10-2

1.93* 10-5

1.93* 10-4

1.93* 10-3

2.8* 10-5

1.15* 10-5

6.86* 10-5

4.75* 10-4

1.93* 10-5

1.93* 10-4

1.93* 10-3

3.91* 10-6

2.35* 10-5

1.14* 10-4

1.93* 10-5

1.93* 10-4

1.93* 10-3

5.83* 10-6

3.53* 10-5

2.91* 10-4

6.9* 10-6

5.05* 10-5

2.71* 10-4

2.62* 10-5

2.5* 10-5

2.28* 10-5

1.35* 10-6

4.64* 10-5

1.93* 10-4

2.53* 10-5

6.7* 10-4

Chlorobenzene

Dodecane

Cumene

Di–t–butyl peroxide

Di-t-amyl peroxide

2,5-Dimethyl-2,

5-di (t-butyl-peroxy) hexane

Benzene

Chlorobenzene

Decalin

benzene

Chlorobenzene

2,5-Dimethyl-2,5-di (t-butyl–

peroxy) hexynes

Benzene

Chlorobenzene

n-Butyl-4,4-bis (t-butyl

peroxy) valerate

Dodecane

1,1-Bis (t-butyl peroxy)-3,3,5tri methylcyclohexane

Benzene

Benzoyl peroxide

Benzene

Chlorobenzene

Decane

Dioxane

efficiency of DCP is more than the other peroxides.

During reaction of dicumyl peroxide with

polyethylene, gas generated in reaction contains 98%

methane.

Curing temperature

(°C)

160

175

185

195

160

150

175

Thermal decomposition of peroxide

according to the following equation20,40,41,

r = kd .[c] with kd = ko . e-E/RT

Where,

Kinetics of crosslinking by peroxide

Decomposition of peroxide, that is, generation of

free radical is slowest reaction and it is the ratedetermining step of crosslinking reaction of PE.

r = rate of decomposition

kd = rate constant

ko = rate constant at base temp.[0°C]

proceeds

… (4)

TAMBOLI et al.: CROSSLINKED POLYETHYLENE

859

Table 6⎯Various peroxides used for crosslinking

Name

Dicumyl peroxide

Group

Half Life Data

10H

1H

Dialkyl peroxide

117

137

120

140

131

152

2,5-Dimethyl-2,5-di(t-butylperoxy) hexane

2,5-Dimethyl-2,

5-Di-(t-buytlperoxy)

hexyane-3

Di-t-amyl peroxide

Di-t-butyl peroxide

1,1-Di(t-butyl peroxy)

3,3,5 - trimethyl

cyclohexane

n-butyl 4, 4-bis

(t-butylperoxy) valerate

Peroxy ketals

E = activation energy

[c] = concentration of peroxide

T= absolute temperature

R = universal gas constant.

Table 6 lists the curing parameter for various

peroxides used for crosslinking alongwith their half

life periods and active oxygen content. The crosslinking of PE depends upon the type of peroxide and

the temperature. The reactions are of first order and

depend also on the chemical nature of the polymer to

be cross-linked. For LDPE, the value for the order of

reaction is 0.90-0.99, for HDPE, 1.06 and for

copolymer of ethylene between 0.88 and 1.22. The

decomposition of peroxide is a rate-determining step.

The cross-linking reaction is exothermic. The value of

activation energy for various crosslinking reaction of

different polymers such as LDPE, HDPE or

copolymer is practically same if same peroxide is

used. It has been shown that the order of reaction

depends on the temperature and it increases at high

temperatures.

Number of bonds between PE chains as a function

of peroxide content may be stoichiometrically

calculated by assuming that one peroxide molecule

independently is responsible only for one bond

between two PE chains. The calculation is based on

the following equation42,

X .M pe

… (5)

A=

M pr

% Active O2

Description

2.13- 5.92

Powder or flake

Solid or liquid

5-10

10 – 10.6

5 – 5.36

123

143

129

149

96

115

92% liquid

45% solid on inert

filler

8.8-9

96% liquid

10.8

9.73

4.1-4.34

98.5% liquid

92% liquid

40% solid on inert

filler

40% solid on inert

filler

109

129

Where,

A = number of peroxide molecules per two PE chains,

Mpe, Mpr = molecular weight of PE and peroxide

respectively,

X= thickness of reactive polymer layer OR the mass

concentration of peroxide per one gram of PE.

The decrease of XLPE density is due to additional

branching introduced by peroxide and the maximum

density can be obtained at 0.5% peroxide

concentration. The drop in crystallinity as a function

of peroxide concentration and increase in crosslinking

impose some restraint on mobility of polymer chains

in molten state preventing them from arranging into

lamellae fold43.

Relative degree of crosslinking and degradation of

polymers is discussed by Kwei42 with the help of

following equation,

S + S0.5 = {P0 / Q0} + {1 / Q0 Yn D}

… (6)

Where,

P0/Q0 = ratio of degradation to crosslinking

D = radiation dose (Mrad)

S = percent of soluble molecule in network

Yn = initial number average molecular weight of

polymer.

Crosslinking of copolymers

Crosslinking of PE-PP has been studied by Braun44.

They observed that PP did not crosslink and grafting

860

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

of PP onto PE could take place45. They have reported

that as PP content increased, the heat resistance of

crosslinked compound decreased.

Ethylene vinyl acetate (EVA) is blended with

polyethylene quite widely. Ethylene vinyl acetate

copolymer is more rapidly crosslinked and accepts

high filler loading, without significant loss of physical

properties, making them well suited for lower voltage

applications and in automobile etc.

Peroxide coagent crosslinking method

Coagents are low molecular weight molecules with

two or more reactive double bonds. Coagents work in

a free radical cure system. Free radicals are generated

by using peroxide or high energy radiation sources,

coagent reacts with these free radicals to increase the

efficiency of cure i.e. to give more crosslinks. The

presence or addition of a coagent in crosslinking

provides more reactive sites where the crosslinking

reaction can occur46. Addition of coagents reduces

cure time, improves resistance to oils and fuels,

improves heat aging, improves peroxide efficiency,

improves flexibility and gives higher tensile strength

and hardness47,48.

Advantages of peroxide-coagent system

when exposed to excessive heat or light. Therefore,

polyethylene compounds used for coating wire and

cable application may contain anti-oxidants. Cables

exposed to ultraviolet rays in sunlight must also

contain carbon black or other UV inhibitors. Such

additives also assure that the electrical and

mechanical properties of the resin are preserved under

the high temperatures prevailing in the extruder50,51.

Carbon black of fine particle size can be used as a

thermal antioxidant. Carbon black is used as a

conducting filler for elastomer and plastics.

Incorporation of carbon black increases brittle point

and yields stress with concentration, without affecting

tensile strength52.

Crosslinking by silane

There are two types of processes for crosslinking of

polyethylene by silane grafting: two-step process and

one-step process.

In two-step process, silane molecule such as vinyl

trimethoxysilane (VTO) is grafted on polyethylene

chain. For grafting, the peroxide such as dicumyl

peroxide is mixed with the polyethylene in small

percentage. The peroxide initially generates free

radical on polyethylene chain. Grafting of silane takes

The advantages of peroxide-coagent system are:

(i) excellent heat stability

(ii) simple compounding

(iii) better hot tear

(iv) good shelf life stability.

Disadvantages of peroxide-coagent system

The disadvantages of peroxide-coagent system are:

(i) higher cost

(ii) surface tackiness in presence of oxygen.

Applications

Peroxide-coagent systems are widely used in

automotive seals, automotive hoses, oil well packers,

swab cups, golf balls, butterfly valves, belts, mats,

shock absorber, cable, coating and foam packing.

Some of the coagents used in crosslinking

Some of the coagents used in crosslinking are49,

ethylene glycol dimethylacrylate, 1,3–butylene glycol

dimethylacrylate, poly (ethylene glycol) dimethylacrylate and trially cyanurate dimethylacrylate.

Effect of anti-oxidants and carbon black fillers

The power factor of polyethylene may be

unfavorably affected by oxidation of the insulator

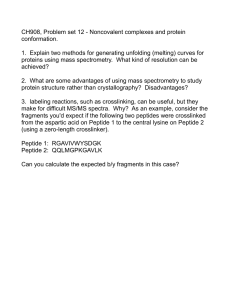

Fig. 4⎯Schematic representation of two-step crosslinking

process of polyethylene by using silane

TAMBOLI et al.: CROSSLINKED POLYETHYLENE

place at the site where free radical is generated. The

grafted polyethylene is mixed with silanol

condensation catalyst such as dibutyltin dilauarate,

and extruded or injection moulded profile is

produced. Up to this stage the polyethylene retains the

thermoplastic nature. Extruded or injection moulded

article is crosslinked with the help of water or at

elevated temperature or at room temperature53,54. The

two-step silane crosslinking process is schematically

represented in Fig. 4.

In one-step process, a copolymer of silane and

polyethylene may be formed or free radical generating

and grafting take place in single step only. The

chemical reaction of silane crosslinking is shown in

Fig. 5. The reaction continues until all grafted

copolymer is converted into crosslink chains. In the

peroxide and irradiation cross-linking processes, the

links between macromolecule consist of carboncarbon bond. The silane process gives -Si-O-Sicrosslinks. These siloxane bridges are weaker than

carbon-carbon bond, and this will have effect on the

attainable strength and long term chemical

stability55,56.

Silane grafting of polyethylene

The most common silane used for cross-linking of

polyethylene is vinyl trimethoxysilane (VTO). The

silane is introduced into polyethylene by melt grafting

using peroxide as an initiator. The silane-grafted

polyethylene

is

then

crosslinked

through

hydrolyzation of the methoxysilane group with water

followed by condensation of the hydroxyl group57,58.

Various types of silanes used in crosslinking are listed

in Table 7.

Crosslinking of grafted polyethylene is completed

only in presence of moisture. A catalyst is used to

activate and speed up the crosslinking process. The

crosslinking is also enhanced by high temperature, but

silane crosslinking is usually performed at 50 to 80oC

and at atmospheric pressure.

Polypropylene is degraded due to peroxide and

therefore, it cannot be crosslinked similar to

861

polyethylene. The degradation is mainly due to βchain scission. Crosslinking of polypropylene is

possible only by silane grafting method.

Advantages of silane-grafted crosslinking

Various advantages of silane-grafted crosslinking

are:

(i) crosslinking can be done at room temperature

(ii) low cost

(iii) higher gel percentage obtained as compared to

physical crosslinking.

Disadvantage of silane-grafted crosslinking

Some disadvantages of silane-grafted crosslinking

are given below:

(i)

curing time is very high as compared to peroxide

crosslinking

(ii) extra downstream equipments are required (for

condensation)

(iii) bond strength of crosslinking is weaker than

bond strength in peroxide crosslinking system.

Effects of crosslinking

Polyethylene is crosslinked to improve its

dimensional stability at elevated temperature, to

Fig. 5⎯Silane grafted polyethylene crosslinking reaction

Table 7⎯Various types of silane used for crosslinking

Silane

Tetramethoxysilane

Tetraethoxysilane

Methyltriethoxysilane

Methyl tris methyltriethoxysilane

MolecularWeight

Colour

Boiling Point (°C)

Flash Point (°C)

152.2

208.3

136.3

Colourless

Colourless

Colourless

Yellowish

liquid

122

168

101

26

46

5

110

105

301.46

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

862

Table 8⎯Comparison between crosslinking processes

Crosslinking process

Peroxide

Silane

Radiation

No. of steps

Crosslinking mechanism

Gel %

Curing mechanism

Two step

Grafting

> 65

Condensation reaction

One step

Free radical

>60

Curing temperature

Curing time

Additives

Equipment cost

Bond strength

One step

Free radical

> 75

Homolysis temperature of

peroxide

150-160 °C

Less

No

Medium

Strong

Room temperature

Very low

Peroxide for initiating

High

Strong

Degree of crosslinking

Constant throughout the article

80-90 °C

Very high

Peroxide for grafting

Low

Weak as compared to

peroxide

Varies with residence

time in water bath and

temperature of bath

improve its impact resistance or to reduce its

propensity to stress crack. Due to crosslinking

polyethylene changes from ductile semi-crystalline

solid to a non-crystalline elastomer59.

As crosslinked density increases, a degree of

crystallinity and crystallite thickness decreases. This

was studied by Badar60. Reduction in crystallinity

occurs because of crosslinking taking place in

amorphous phase. There is also some breakdown of

crystallinity. Decrease in degree of crystallinity and

crystalline thickness, decreases Young’s modulus,

yield stress, elongation at break and peak melting

temperature of polyethylene61.

Harper62 studied the effect of crosslinking on melt

index and concluded that the melt flow index

decreases uniformly with increase in degree of

crosslinking.

Crosslinking increases the impact strength,

environmental stress crack resistance, creep resistance

without affecting tensile strength and flexural

modulus. Comparison of different crosslinking

methods is presented in Table 8.

Disadvantages of crosslinking

As mentioned earlier, crosslinking of polyethylene

changes its nature from thermoplastic to thermoset.

This enhances the viscosity to a very high value. To

control the degree of crosslinking in a continuous

process is very tricky. During extrusion of a profile, if

excessive crosslinking takes place stresses are

developed and, these do not get relaxed due to dense

network of polyethylene. Selection of proper

crosslinking agent is very critical. Blending uniformly

crosslinking agents with polyethylene beds can lead to

uneven distribution of crosslinking agent. Melting of

Varies with thickness of

article

polyethylene prior to crosslinking is therefore, key

function in processing.

Due to its thermoset nature recycling of crosslinked

polyethylene cannot carried out by melting it with

virgin polyethylene, since crosslinked polyethylene

does not melt. The crosslinking process decreased the

crystallinity.

Application of crosslinked polymers 63,64

Cable insulation

The most advanced area of application for

crosslinked polyethylene is in the electrical cable

industry. Crosslinking, whilst not interfering with the

dielectric properties of polyethylene, introduces

resistance to flow and permanent deformation above

the softening point. This permits higher conductor

operating temperature and reduces the level of short

circuit and overload protection required.

Flame retardant properties of pipe are also

improved by irradiation (60% gel) by introducing

double layer structure to the jacket, in which inner

layer is adjacent to polyethylene insulation which is

crosslinked more densely than the outer layer. The

wire exhibits markedly improved resistance to flame

and heat deformation.

Crosslinked polyethylene pipes

The main applications for crosslinked polyethylene

hot water pipe are:

a) under floor or central heating

b) domestic or portable water piping system.

The benefits of crosslinking become obvious above

ambient temperatures where a reduction in the rate of

creep for the corresponding hoop stress is observed.

TAMBOLI et al.: CROSSLINKED POLYETHYLENE

Injection and blow moulded articles

Specially moulded articles such as containers with

significant improvement in ESCR and chemical

resistance characteristics can be made using

crosslinked polyethylene. Increasing the molecular

weight by crosslinking increases its solvent and creep

resistance. The increased dimensional stability at

evaluated temperatures allows the article to come in

contact with heated fluids.

Crosslinked film

Crosslinked polyethylene in packaging applications

is confined to multi-layer film constructions, in which

the cross linked layer provides a number of specific

effects including: increased temperature resistance

especially for hot filled or heat sterilization

applications; increased heat seal strength where a

thermoplastic seal is subsequently crosslinked;

increased impact, tear and abuse resistance capability

especially for packing irregular shaped items to

impart heat shrinking properties to the film.

Conclusions

Crosslinking of polyethylene and polypropylene is

practiced industrially for very interesting applications.

Polyethylene can be crosslinked by radiation energy

as well as by organic peroxide. Polypropylene can be

crosslinked by silane method. Very little information

exists on crosslinking of PVC. Various aspects of

crosslinking process have been studied earlier and are

reviewed in this article.

References

1

2

3

4

5

6

7

8

9

10

Crosslinked polyethylene foam

Crosslinked polyethylene (XLPE) foams have

various kinds of applications, such as thermal

insulation, floatation, automotive trim, and sports

goods.

The advantages of crosslinking, prior to foaming

are that high quality closed cell structure can be

achieved which gives the following benefits a)

increased mechanical properties, b) increased

resistance and recovery from deformation, c)

increased thermal resistivity, d) reduced vapour and

liquid transport, e) to improve elevated temperature

and load bearing characteristics of the foam, f) to

permit secondary moulding and foaming without

collapse of the cell structure.

11

12

13

14

15

16

17

18

19

20

21

Special application

High pressure crosslinked polyethylene tube shows

water clear transparency on high heat, while lower

heat produces translucency, but this effect of

temperature is not obtained with untreated PE.

High pressure crosslinked PE makes it feasible to

use the material for applications such as automobile

muffler tail pipe.

Crosslinked polyethylene fibre used as a filler in

denture base resin poly [methyl methacrylates],

improves impact strength without adverse aesthetic

effects.

863

22

23

24

25

26

27

28

Krupa & Luyt A S, Polymer Degradation and Stability, 70,

111 (2000).

Engel T, Modern Plastic, 44 (1967) 175.

Narkis M, Modern Plastic, 10 (1980) 68.

Samburski G & Narkis M, J Macromol Sci Phys B35(5)

(1996) 843.

Dakin Y I, J Appl Poly Sci, 59 (1996) 1355.

Narkis M, Modern Plastic, 47, 1982.

Sawatari Chie & Mastuo M, Polym J, 19 (12) (1987) 1365.

Houde M & Schreiber H P, J Appl Polym Sci, 46 (1992)

2049.

Stepto R F T, in Crosslinked Polymers, edited by Dickie Ray

A & Baver R S (ACS, Washington), 1988.

Shultz Allen R, Encyclopedia of Polymer Science, Vol.4,

edited by Mark H F & Gaylord N G (John Wiley & Sons,

NY), 1986, 350.

McGinnis V D, Encyclopedia, Vol. 4 (1972) 419.

Miltz J & Narkis M, Polymer, 9 (1968) 173.

Narkis M & Mitz J, J Appl Polym Sci,12 (1968) 1030.

Ghosh P, Polymer Science and Technology of Plastic and

Rubber (Tata McGraw Hill), 1993, 266.

Labana S S, Encyclopedia of Polymer Science and

Engineering,Vol.4, edited by Mark Herman (John Wiley &

Sons, New York), 1986, 350.

Syncure, Technical Service Report, Polyone Corp., No 66

1999.

Stepto R F T, in Crosslinked Polymers, edited by Dickie Ray

A, Labana S S & Baver R S (ACS, Washington), 1988.

Tal Horng-Jer, Polym Eng Sci, 39(9) (1999) 1577.

Peacock Andrew J, Handbook of Polyethylene (MarcelDekker Inc., New York), 2000.

Kresser O J, Polyethylene (Reinhold Corp., New York),

1957.

Pedernera N, Sarmoria C & Brandolin A, Polym Eng Sci,

39(10) (1999) 2085.

Nabio S V & Rangwalla I J, Radiation Curing of Polymeric

Materials, edited by Hole Charles E & Kinstie J F (ACS,

Washington), 1990, 534.

Sangester D F, The Effect of Radiation on High-Technology

Polymers, edited by Reichnanis E & O’Donnell J H (ACS,

Washington), 1989, 15.

Chapiro A, Radiation Chemistry of Polymeric Systems (John

Wiley & Sons), 1962, 1.

US-PS,3.219.566, Dow Chemical Co.

US-PS,2.484.529, DuPont.

Wu Quianghua & Qu Baogun, Polym Eng Sci, 41 (2001)

1220.

Mitsui H F & Ushairokawa Hosoi M, J Appl Polym Sci, 19

(1975) 361.

864

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

INDIAN J. CHEM. TECHNOL., NOVEMBER 2004

Ali Zl & Zahran Ah, Polym International, 49 (2000) 1555.

Amrhein E & Kolloid Z, J Polym Sci, (1967) 216.

Thomas Engel, Modern Plastics, (1967) 175.

Narkis M & Miltz J, J Appl Polym Sci, 13 (1969) 713.

Salyer I O & Davsion J E, J Appl Polym Sci, 28 (1983) 2903.

Sperling L H, Introduction to Physical Polymer Science

(John Wiley, New York), 2001, 363.

Bueche F, J Appl Phys, 44 (1973) 532.

Narkis M, Raiter I & Eyerer P, J Macromol Sci – Phys,

B26(1), 37 (1987).

Kim B & White J L, Polym Eng Sci, 37 (1997) 576.

Narkis M & Toboisky A V, J Appl Polym Sci, 14 (1970) 65.

Kumar Sen, De P P & Bhowmick A K, J Appl Polym Sci, 44

(1992) 183.

Berzin F & Veanes B, Polym Eng Sci, 40 (2) (2000) 344.

Kunert K A, Soszynska H & Pislewski N, Polymer, 22

(1981) 1355.

Wei K, J Appl Polym Sci, 42 (1991) 1939.

Stoyanov O V & Deberdeev R Ya, International Polym Sci

Technol, 14(7) (1987) 83.

Braun D, Ricter S & Hellmann G P, J Appl Polym Sci, 68

(1998) 2019.

Sherman R D & Jacobs S M, Polym Eng Sci, 23 (1983) 36.

Smoluk G, Mod Plast Int,12 (9) (1982) 46.

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

Bonotto Sergio, J Appl Polym Sci, 9 (1965).

U S Patent, 6.231.978 (2001).

Biggs B S & Hawkins W L, Modern Plastics, 31 (1953) 121.

Brandrup J & Immergut E H, in Polymer Handbook, 2nd edn

(John Wiley & Sons, New York), II-12 (1975).

Mayer J, Polym Eng Sci, 14 (1974) 705.

Hawkins W L, Hansen R H, Mareyek W & Winsow F H, J

Appl Polym Sci, I (1959) 37.

Narkis M, J Appl Polym Sci, 25 (1980) 1515.

Dennberg E M, Jordan M E & Cole H M, J Appl Polym Sci,

31 (1958) 127.

Befran M & Mijangos C, Polym Engg Sci, 40 (2000) 1534.

Yeong-tarang sheigh & Tsai T H, J Appl Polym Sci, 1 (1998)

255.

Hjerterberge T T, Palmof M M & Swatan A, J Appl Polym

Sci, 42 (1991) 1185.

Shieh Y T & Hsiao Kuo, J Appl Polym Sci, 70 (1998) 1075.

Marin J & Paul B, J Appl Polym Sci, 7 (1968) 133.

Badar Y & Ali Zl, Polym Int, 49 (2000) 1555.

Brody H, J Appl Polym Sci, 15 (1971) 987.

Harper B G, J Appl Polym Sci, 2 (1959) 363.

Hagiwara M, J Appl Polym Sci, 25 (1980) 1541.

Kumar Suresh & Pandya M V, J Appl Polym Sci, 64 (1997).