Multi-Output Flyback Off-Line Power Supply

advertisement

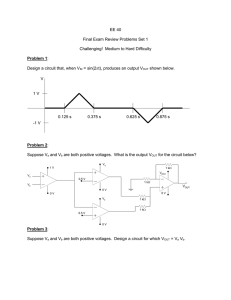

Multi-Output Flyback Off-Line Power Supply Basic Concept • Add additional secondary windings, using the same turns/volt as the original secondary. Vout 1 Vin 1 n Load (R1) Vout 1 = nD Vin D' Vout 2 = mD Vin D' Vout 2 m • • • Outputs can be positive or negative, depending on which side of the output (top or bottom) is grounded. Either output can be the “master” by connecting it to the feedback sensing circuit Formulas are not exact, due to the diode drops not being proportional to the number of turns! www.onsemi.com 2 Load (R2) Example of Adding a Negative Output • There is no theoretical limit to the number of outputs. Vin Vout 1 1 n Load (R1) Vout 1 = nD Vin D' Vout 2 = mD Vin D' Vout 3 = pD Vin D' Vout 2 m Load (R2) Vout 3 p Load (R3) • In this case, the negative output drawn like the positive ones, with the diode reversed and the polarity of the winding as shown. www.onsemi.com 3 Two Outputs with Feedback Regulation • Typical regulated flyback converter – One output is the master (output 2 in this case) – Second output (output 1, in this case) is the “slave” (quasi-regulated). – For output voltages less than 2.5 V, a TLV431 (1.25 V) or other can be used. – Why do we need R3? www.onsemi.com 4 Improvement #1 – Stacked Windings • Regulation of second output is improved, because only part of it is “alone.” – Only the “n” portion is unregulated. (Leakage inductance of n is less.) • Again, one output is the master (output 2 in this case) – Second output (output 1, in this case) will vary with the load on the main output, due to its current flowing through the winding of output 2. www.onsemi.com 5 Improvement #2 Stacked Outputs Vout 1 n Vin Load (R1) Vout 1 = m+n)D Vin D' 1 Vout 2 PWM Controller m Load (R2) Vout 2 = mD Vin D' Optocoupler R3 R4 TL431 2.5 V ref. amplifier R5 • Now, output 1 current flows through output #2’s diode. – Output 1 is less dependent on output 2’s load, because the bottom of its output doesn’t move. www.onsemi.com 6 Improvement #3 No-Load Clamp 12 V n Vin Load (R1) Vout 1 = m+n)D Vin D' 1 9 V Zener 5V PWM Controller Vout 1 m Vout 2 Load (R2) Vout 2 = mD Vin D' Optocoupler R3 R4 TL431 2.5 V ref. amplifier R5 • When output 1 is unloaded, its stray output current flows down through the Zener and into the 5 V output. • In this case, output 1 would be clamped at 14 V. www.onsemi.com 7 Improvement #4 – Combined Feedback Vout 1 n Vin Load (R1) Vout 1 = m+n)D Vin D' 1 Vout 2 PWM Controller m Load (R2) Vout 2 = mD Vin D' Optocoupler R6 R3 R4 TL431 2.5 V ref. amplifier • R5 Now, both outputs are sensed, and the regulator controls the combination of outputs. – Remember: There’s only one feedback point. Neither output will be as tightly regulated as the main one when it had the feedback to itself! www.onsemi.com 8 Weighting the Feedback Vout 2 Vout 1 Optocoupler TL431 2.5 V ref. amplifier i2 = W2 • i0 R2 i0 R0 R1 i1 = W1 • i0 Vref i0 = i1 + i2 = W1 • i0 + W2 • i0 = i0 (W1 + W2) Therefore, W1 + W2 = 1 Wn is the “weight” of the feedback from output n. • If W1 = 0.9 and W2 = 0.1, then output 1 is nine times as important as output 2. – (W1 has a weight of 90%, and W2 has a weight of 10%) www.onsemi.com 9 Designing the Feedback ( i1 + i2 = i0 ) Vout1 − Vref = i1 R1 R1 = R2 = www.onsemi.com 10 Vout1 − Vref i1 Vout 2 − Vref i2 = = Vout1 − Vref W1i0 Vout 2 − Vref W2i0 Example Procedure: – Given: Vout 1 = 5, Vout 2 = 12, Vref = 2.5 – Choose i0 = 1 mA – Choose W1 = 0.7 and W2 = 0.3 Calculating the values: Vref 2.5 R0 = = = 2.5 kΩ i0 1 mA R1 = R2 = www.onsemi.com 11 Vout1 − Vref W1i0 Vout 2 − Vref W2i0 5 − 2.5 = = 3.57 kΩ 0.7 ⋅1 mA = 12 − 2.5 = 31.7 kΩ 0.3 ⋅1 mA More Outputs? No Problem Vout 2 Vout 1 Vout n Optocoupler TL431 2.5 V ref. amplifier • • i2 = W2 • i0 R2 i0 R0 www.onsemi.com i1 = W1 • i0 Rn Vref Feedback can be from any number of outputs. Provided that: W1 + W2 + ……..+Wn = 1 Rn = 12 R1 Vout n − Vref Wn ⋅ i0 in = Wn • i0 The “Magic” Capacitor With cap: Clean pulse; improved regulation at low-current load Vout 1 Vout 1 = n nD Vin D' Low-current load (R1 = large) Vin 1 Vout 2 m=n PWM Controller Vout 2 = Vout 1 = Load (R2) Optocoupler R3 R4 TL431 2.5 V ref. amplifier www.onsemi.com 13 R5 nD Vin D' Another Version of the “Magic” Capacitor n Load (R1) Vout 1 = Vin D' m Vin 2m+n)D Example: 12 V 1 Vout 2 PWM Controller mD Vin D' Example: 5 V Load (R2) Vout 2 = m Optocoupler R3 R4 TL431 2.5 V ref. amplifier • • Here, since the bottom of upper secondary is tied to Vout 2 (which is dc), waveforms at each end of the capacitor are identical. Overshoot & ringing at light load on Vout 1 is reduced by 5/7, since 5 of the 7 added turns are tightly coupled via the capacitor. (m = 5, n = 2, m+n = 7). www.onsemi.com 14 R5 Adding an Output to a Buck Converter • • • During the “off” time of the switch, the output voltage across the inductor is coupled to a new output via an added winding! No free lunch. There must be enough energy stored in the choke to feed the new output. Ampere-turns are preserved, so current drawn from the new output causes discontinuous current in the main output. – Ripple current in the main output capacitor increases. www.onsemi.com 15 Design Example, Built and Tested 65 Watt, 8 Output Set Top Box Power Supply Frank Cathell, Senior Applications Engineer www.onsemi.com 16 General Specifications • Input: 90 to 135 Vac, 47 – 63 Hz • Inrush current: 30 A cold start; 60 A warm start • Efficiency: > 80% at nominal loading • Output Voltages/Regulation/Ripple: Channel 1 2 3 4 5 6 7 8 Vout 2.6 V 3.3 V 5V 6.2 V 9V 12 V 30 V -5 V Output type Buck reg. Buck reg. Main output Quasi-reg. 3-T reg. Main output Quasi-reg. 3-T reg. Regulation +/-1% +/-1% +/-2% +/-6% +/-1% +/-2% +/-8% +/-1% Max Ripple 40 mVp/p 40 mVp/p 50 mVp/p 50 mVp/p 30 mVp/p 50 mVp/p 100 mVp/p 30 mVp/p Current 3A 4A 3A 1.5 A 100 mA 1A 20 mA 30 mA Surge 4A 5A 4A 2A 200 mA 3A 40 mA 60 mA • Output overshoot: 5% max; typically <1% • Overcurrent/short circuit protection: Protected against accidental overloads via reduced duty cycle, burst mode operation • No load: Output voltages are controlled and stable under no load conditions • Hold-up time/power fail detection: Output will hold up for 20 ms following drop out at 100 V ac and nominal load; power fail warning following holdup period with 5 ms minimum delay to output voltage dropout. • Temperature: Operation from 0 to 50O C (no over temp protection included) www.onsemi.com 17 Circuit Features • Critical conduction mode flyback converter ¾NCP1207 • 2.6 V and 3.3 V outputs derived from 12 V output ¾NCP1580 synchronous buck controllers • Low current outputs on -5 V and +9 V allowed use of conventional 3-T regulators • Control loop closed via sum of 5 V & 12 V outputs; all other outputs quasiregulated • Transformer main secondary made from foil winding for low leakage inductance • “Stacked” secondary windings utilized for improved cross-regulation • Simple but effective power fail detection circuit utilizing TL431 and 2N2222 • Overcurrent protection implemented by initiating burst mode of NCP1207A • 2-wire ac input with dual common mode EMI filter inductors • Single-sided printed circuit board www.onsemi.com 18 Set-Top Box Test Results Regulation Data (120VAC input) Parameter 2.6V 3.3V 5V Outputs 6V Output type Buck Buck Main Quasi-reg 3-T reg Main Quasi-reg 3-T reg Vout setpoint at typical loads 2.53V 3.4V 4.89V 6.27V 8.94V 12.54V 31.0V 4.96V Vout setpoint at minimum loads 2.55V 3.42V 4.96V 6.38V 8.94V 12.33V 32.70V 4.98V Vout setpoint at maximum loads 2.54V 3.34V 4.90V 6.29V 8.94V 12.53V 30.10V 4.95V Vout setpoint at no output loading 2.56V 3.43V 5.02V 6.54V 8.93V 12.13V 29.60V 4.97V Note: Vout setpoints measured at PC board www.onsemi.com 19 9V 12V 30V neg 5V More Test Results E ffic ie n c y M e a s u re m e n ts (1 2 0 V A C in p u t) P a ra m e te r 2.6V 3.3V 5V O u tp u ts 6V 9V 12V 30V n e g 5V O u tp u t V o lta g e 2 .5 4 3.42 4.91 6.31 8.94 12.48 30.06 4.96 O u tp u t C u rre n t 3 .8 A 2.9A 1.56A 1.3A 91m A 1.0A 30m A 73m A O u tp u t P o w e r (W ) 9 .6 5 9.92 7.66 8.2 0.81 12.48 0.9 0.36 9V 12V 30V neg 5V (4 9 . 9 8 W t o t a l) T o ta l P o u t = 4 9 . 9 8 W P in a t 1 2 0 V A C = 6 1 . 4 W E ffic ie n c y = 8 1 .4 % Parameter 2.6V 3.3V 5V Outputs 6V Output Ripple (@ max loads) 27mV 45mV 50mV 50mV 40mV 30mV 100mV 20mV Output Overshoot (turn-on) none none none none none none none none Holdup Time (prior to PF warning) at 100 Vac in, maximum output loads: 25ms Power Fail warning time (Vout decay to 90%): 15ms Line Regulation: Minimal on all outputs; +/- 20mV max www.onsemi.com 20 (10:1 scope probe) Schematic R40 10 T1 8 560pf 1KV C5 FIGURE 1: Schematic 30V D13 16 1 Stacked windings MUR120 C11 330/50V R21 30K C13 0.1uf R2 P1 D4 1N5406 L1 15 AC INPUT Q1 IRF740 1 C2 0.22/250V BU10-1311R6B R1 1M .5W MBR1645 + + C3 470/250V BU16-4021R5B D2 t 3 C1 0.22/250V TH1 1 2 12V-BUCKS D12 1N5406 L2 3A 1 2 Before diode After diode 6 2 D1 F1 15, 1W C14 680/16V 560pf 1KV C6 12V 1 L3 1N5406 R5 4.7 1N5406 R4 4.7K R3 0.33 1W + + C15 680/16V C16 680/16V C17 0.1uf U3 MC78M09 3 I O 1 9V G 1 D11 R19 10K + C18 270/25V 2 C4 Y -CAP L4 1N5820 4.7uH 6V 1 + + C20 680/16V + C21 680/16V MBR1635 C23 C22 680/16V L5 0.1uf 4.7uH 5V 1 D10 NCP1207A 1 2 3 2 2 4 4 3 C28 270/25V 9 JUMPER U5 R9 1K 4 C8 22/25V D9 MUR110 + C10 470 pf + C51 270/25V I O 3 3 2 H11A817A D8 R11 270 COM C30 1K 1N4148 0.1uf R10 1 R17 10K Combined, weighted feedback C29 0.1uf -5V 1 10 R14 30K 3 R13 C27 0.1uf 1 U4 MC79L05 1 R12 1K C9 Not installed C26 1200/6.3V 1 JP3 1 + C25 1200/6.3V + R8 22K 1 C24 1200/6.3V 14 13 3 G 7 R7 100 D6 1N4148 6 6 + 1 8 + 8 5 C7 1nf 1 U1 2 2 1 R18 1K 10 NC 7 1 C19 0.1uf 12 11 Not installed 5 1 4.7uH D3 10 Ohm 4A R6 3.6K 1 + 1 U6 TL-431 R25 47K 12V-BUCKS C31 10nf U7 TL-431 1 R28 4.7K 1 R16 3.6K C32 0.1uf 3 R27 1K PF Q2 PN2222A D7 1 1 1N5226B R24 4.7K R23 4.7K R22 1K 2 2 R26 6.2K R15 6.8K JP5 2 JUMPER 1200/6.3V C34 + 2 JUMPERD15 1N5818 Q3 NTD60N02R 8 5 C39 1nf 7 C40 10nf 4 6 4 C42 1nf 7 R30 33K R36 33K 6 68 C41 C38 0.1uf 10nf C44 10nf R37 3 33K 8 R33 10.5K R34 10K 8 R35 22K JP1 2 L6 4 D17 1N5818 10uH 2.6V 1 JUMPER R38 4.7 6 C45 0.1uf Q5 NTD60N02R 1 7 68 C37 1nf R32 2 C43 10nf 6 R31 1 5 5 5 7 1 + C35 680/16V 1 8 R29 4.7 1 NCP1580 2 3 JP2 1 2 JUMPER U9 1 1 + 2 1 U8 NCP1580 2 2 3 C33 0.1uf 12V-BUCKS JP4 4 + C48 680/16V C49 1200/6.3V C50 0.1uf 1 C46 1nf Q6 NTD60N02R 3 1 0.1uf 1 3 10uH 2 1 L7 C47 3 3 1 3-3V 0.1uf 2 C36 D16 MUR110 NTD60N02R Q4 3 2 D14 MUR110 Title Schematic - 60W set-top box Size Date: www.onsemi.com 21 Document Number <Doc> Tuesday , May 31, 2005 Rev C Sheet 1 of 1 Conclusion • Multiple output switched-mode power supplies save space, save cost, and can have high performance. – The “tricks” you’ve seen here can make them even better! • Flybacks are popular, because there is only one magnetic component. • They work best where the load ranges of the outputs are wellknown. – This allows the designer to tailor the regulation characteristics to the load regulation requirements, favoring certain loads when necessary. • For good cross-regulation, construction of the transformer is important. – Beware of changing vendors during production! www.onsemi.com 22 For More Information • View the extensive portfolio of power management products from ON Semiconductor at www.onsemi.com • View reference designs, design notes, and other material supporting the design of highly efficient power supplies at www.onsemi.com/powersupplies www.onsemi.com 23