2. Indoor Air Quality

advertisement

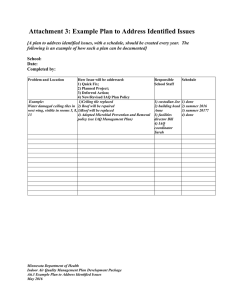

ASIDcover2sp.qxd 11/7/06 6:42 PM Page 1 2. Indoor Air Quality Interior Design and Global Impacts 2007 Where Design Comes to Life® ASIDcover2sp.qxd 11/7/06 6:42 PM Page 2 INTERIOR DESIGN AND GLOBAL IMPACTS 2007 1. Beyond Interior Design 2. Indoor Air Quality 3. Materials & Products 4. Selling Green 5. Reference Guide SPONSORED BY Where Design Comes to Life® American Society of Interior Designers Indoor Air Quality Interior Design and Global Impacts 2006 ONE OF FIVE PAPERS ON TOPICS IN SUSTAINABLE DESIGN Other papers in the series Beyond Interior Design Selling Green Materials and Products Reference Guide Research/Writing Team Kirsten Childs, ASID, LEED AP Cris Argeles, 7 group Holley Henderson, H2 Ecodesign, LLC Scot Horst, 7 group Nadav Malin, BuildingGreen, Inc. Editors Tristan Roberts and Allyson Wendt, BuildingGreen, Inc. Design and Layout Julia Jandrisits, BuildingGreen, Inc. Graciously sponsored by Lightolier® Steelcase® TOTO® Tricycle VISTA® Wilsonart® Laminate © 2006 American Society of Interior Designers 608 Massachusetts Ave., NE Washington, DC 20002-6006 www.asid.org All rights reserved. This publication, or parts thereof, may not be reproduced in any form without written permission of the American Society of Interior Designers. Printed in the United States of America. Table of Contents 1 INTRODUCTION AND OVERVIEW OF KEY CONCEPTS ........... 3 2 INDOOR AIR QUALITY IN CONTEXT ....................................... 3 Indoor Environmental Quality (IEQ) ...................................... 3 Indoor Air Quality (IAQ) Defined ........................................... 4 3 RISKS RELATED TO POOR INDOOR AIR QUALITY ................. 4 Assessment ............................................................................. 4 Health Risks .............................................................................5 Increased Costs ...................................................................... 5 Liability Risks ......................................................................... 6 4 STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY (IAQ) ............................................... 7 Common Contaminants .......................................................... 7 Source Control ....................................................................... 9 Attributes of Materials ......................................................... 10 Construction ......................................................................... 14 Ventilation ............................................................................ 16 5 BENEFITS OF PREMIUM INDOOR AIR QUALITY .................. 18 6 INTEGRATED OPPORTUNITIES AND DESIGN PROCESS ......19 Commissioning .................................................................... 20 Post-Occupancy ................................................................... 20 7 INDOOR AIR QUALITY (IAQ) AND GREEN BUILDING RATING SYSTEMS ..................................................................... 21 USGBC / LEED Rating System .............................................. 21 NAHB / Green Home Building Guidelines ........................... 21 ENDNOTES .................................................................................... 21 APPENDIX: QUESTIONNAIRE ..................................................... 22 INTRODUCTION AND OVERVIEW OF KEY CONCEPTS — INDOOR AIR QUALITY IN CONTEXT 1 Introduction and Overview of Key Concepts Interior designers shape the experience of interior space. While the work of the designer can involve as much interior engineering as art, usually the artful side of the profession receives more emphasis. This paper will look at how designers can contribute to occupants’ enjoyable and healthy use of a space by looking past visual design elements to the engineering of good indoor air quality, or IAQ. Indoor air quality refers simply to the quality of the ambient air in an interior environment. On average, people ingest almost six pounds of fluids and 1.5 pounds of food daily, but they inhale 33 pounds of air each day, and Americans spend well over half of their time inside. Research has shown that indoor air in buildings can be two to five times—and occasionally up to 100 times—more contaminated than outdoor air. In fact, the U.S. Occupational Safety and Health Administration (OSHA) estimates that 30 percent of workers in non-industrial buildings—including offices, schools and hospitals—are exposed to poor indoor air quality. Indoor air pollution consistently ranks among the top five environmental risks to public health. For these reasons, indoor air quality is a crucial component of the safety and well-being of building occupants in all buildings, including schools, offices and homes.1 To understand how to create premium air quality, this paper will begin by investigating poor IAQ and the resulting negative effects on health, productivity and associated costs. This paper will then discuss how to incorporate design techniques and strategies to promote good IAQ. Some of the main practices to be discussed include preventing pollutants from entering the space, filtering and diluting remaining pollutants, and coordinating with other team members throughout the design and construction process. 2 Indoor Air Quality in Context Even the most active people typically spend a minimum of 12 hours per day inside the home and workplace, and the most vulnerable members of society—infants, the elderly and those with chronic diseases—spend 90 percent or more of their time indoors. Indoor environmental quality, or IEQ, encompasses the quality of all comfort and health factors in the interior environment. Indoor Environmental Quality (IEQ) As defined by the National Institute of Occupational Safety and Health (NIOSH), IEQ includes » Indoor air quality – Good indoor air quality depends on high levels of well-filtered fresh outside air, a low contaminant load, and minimization of particulates and mold spores. » Thermal comfort – Thermal comfort is affected by air temperature, humidity, mean radiant temperature and air speed, as well as human variables, such as clothing and activity levels. Most complaints from building occupants relate to their inability to control the temperature of the space. » Visual comfort – Visual comfort depends on many variables, including lighting quality, minimization of glare, variable light levels, lighting controls, such as local switching and dimmers, visual connection with the exterior, and access to natural lighting. » Acoustical quality – Acoustical quality involves the minimization of noise levels and vibration to achieve appropriate physical comfort and sound isolation levels for Indoor Environmental Quality (IEQ) Encompasses more than air quality, including thermal comfort, visual comfort and acoustical quality. 3 4 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS For more information on IEQ, see these additional ASID white papers • Beyond Interior Design • Materials & Products • Selling Green work and speech intelligibility. According to the U.S. Census Bureau, people complain about noise in their neighborhoods more than any other problem, including crime and litter. Common ways to achieve acoustical comfort include sound isolating partitions, floor/ceiling assemblies that limit the transmission of impact noise, and appropriate insulating materials or enclosures that protect from exterior noise and from noise generated by building systems, such as fans, ductwork and plumbing. Increased attention to IEQ provides a number of benefits to occupants, employers and building owners. The health and well-being of occupants improves as colds and infectious diseases spread less widely. Rates of respiratory illnesses, such as asthma, decrease, and designers, builders, employers and owners have decreased liability for occupant health. Susceptible populations—who spend the most time indoors—are protected from hazards, and all occupants are more productive and make fewer complaints. When IEQ is considered, buildings deteriorate less and cost less to maintain. This paper focuses on IAQ specifically, as a primary element of IEQ. The other aspects of IEQ are addressed in other white papers available from ASID. Indoor Air Quality (IAQ) Defined Indoor Air Quality The quality of air in the home or other environment. Indoor air quality refers to the presence or absence of air pollutants in buildings. There are many different types of pollutants that can affect indoor air, and they come from a wide range of sources. IAQ is one of the most important areas of IEQ, particularly in terms of the impact of a building on the health of occupants. The three key elements that contribute to the quality of the air people breathe when they are inside, according to the U.S. Environmental Protection Agency (EPA) and NIOSH, are » Introduction and distribution of adequate ventilation air » Control of airborne contaminants » Maintenance of acceptable temperature and relative humidity2 3 Risks Related to Poor Indoor Air Quality Poor IAQ leads to a variety of health risks that have significant costs for the people affected directly, as well as for their family members, employers and society at large. These risks also lead to increased liability for landlords, facility managers and employers. Assessment How can you tell if an interior is at risk for poor IAQ? If building occupants answer “yes” to any of the following questions, there is a high chance that poor IAQ is to blame. » Does the space feel stuffy or stale when entered from the outdoors? » Do cooking odors linger for several hours? » During the winter, is there excessive condensation on the windows or walls? » If the space is heated with a gas or oil furnace, is there an associated odor? » If the space is heated with wood, is there an associated odor? RISKS RELATED TO POOR INDOOR AIR QUALITY Does anyone frequently experience any of the following symptoms while in the space but not when away? » Headaches » Itchy, watery or burning eyes » Feelings of confusion or dizziness » Breathing difficulties » Nasal congestion » Dry, sore throat » Drowsiness There are technical terms for this group of symptoms that can occur in both commercial and residential construction. A more in-depth look at how each of these risks associated with poor IAQ could affect the building occupants follows. Health Risks Health conditions associated with poor IAQ can be categorized as either building related illness (BRI) or sick building syndrome (SBS). Building Related Illness (BRI) As defined by the World Trade Center Resource Guide, BRI includes specific, identified maladies attributed to an identified material, product or system in a home or building. Examples include Legionnaire’s Disease, hypersensitivity pneumonitis, humidifier fever and asthma-like symptoms in non-asthmatic individuals. Often, BRI is associated with a longer recovery time than SBS symptoms (see below). Approximately 25 percent of the ailments associated with indoor air quality can be identified specifically and are attributed to BRI.3 Sick Building Syndrome (SBS) SBS refers to a general set of symptoms that affect building occupants during the time they spend in the building and that diminish or go away during periods when they leave the building. SBS cannot be traced to specific pollutants or sources within the building, and it typically is multifactorial, or caused by a number of factors combined with or exacerbated by inadequate ventilation. About 75 percent of building-related health cases are classified as SBS. Common SBS symptoms include headaches, nose, eye and throat irritation, a dry cough, dry skin irritation, dizziness or nausea, difficulty concentrating and fatigue. SBS and BRI are frequently confused with each other. BRI usually entails a specific diagnosis of a set of symptoms caused by a specific environmental factor, one that has developed into an illness that persists whether that factor is present or not. SBS refers to more general symptoms of malaise or discomfort, which are temporary and limited to time spent in the building. Increased Costs Costs associated with poor indoor air quality include health problems, medical expenses, productivity loss and decreased childhood learning. When physical remediation Sick building syndrome affects occupants when they are in the building. Photo: Gizmo/Dreamstime.com 5 6 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS of a facility is called for, costs can also be significant, not only to correct poor IAQ, but to repair deterioration of the building that may result from the root causes of poor IAQ, such as condensation that causes mold or mildew. Tenants could have difficulty hiring and retaining staff, and building managers could lose tenants and have difficulty filling vacancies. The EPA estimates that the cost of poor IAQ to our economy is in the “tens of billions of dollars” per year. According to a recent report, IAQ-related illnesses were a factor in 40 percent of recent absenteeism cases. The same report showed major increases of worker compensation claims connected to IAQ-related issues from 1980 to 1994. Cases rose by almost 5,000 claims within that period and have continued to rise since then. The average cost of these claims was $27,850, not accounting for the costs of absenteeism, re-hiring and other effects on productivity.4 The University of Chicago states there is “clear evidence” that poor air quality contributes to negative effects on those with asthma. In the United States the annual direct health care costs of asthma are approximately $9.4 billion, while indirect costs, such as lost productivity, add another $4.6 billion, for a total of $14 billion dollars. According to the American Lung Association, there were nearly two million emergency room visits and nearly 500,000 hospitalizations in 2000, at a cost of almost $2 billion. Nearly thirteen million (12.8 million) school days are missed each year due to asthma.5 One study conducted in California showed that exposure to environmental tobacco smoke (ETS) in children’s households was associated with a 27 percent increased risk of respiratory-illness-related school absences. In a household with two or more smokers, children ran a 75 percent risk of such absences.6 Asthma is the most common reason for school absence; it is responsible for 12.8 million lost school days each year. Photo: Mzagajewska|Dreamstime.com The payoff for avoiding these kinds of problems is enormous. The U.S. Department of Energy estimates that improving indoor environments could increase productivity by $30 billion to $170 billion annually through reduced health care costs, reduced sick leave and increased performance.7 Liability Risks Poor IAQ and the associated health risks to building occupants have led to lawsuits in all regions of the country. Insurance claims and litigation over IAQ problems stemming from mold have seen incredible growth, particularly since the 1990s. Multiple parties, from employers to building owners, general contractors, subcontractors, facility managers and equipment manufacturers, have been implicated. Between health costs and remediation expenses, damages frequently run into six and seven figures, and at least one plaintiff in a New York City apartment building has sought awards in excess of $1 billion.8 In a case in Martin County, Fla., the municipality filed suit against the general contractor, architect and concrete masonry construction company for breach of contract and negligence. The courthouse in question had to be evacuated due to IAQ problems created by improper design and construction that caused SBS in more than half of the employees. The county won $16.75 million in damages.9 According to an April 2006 NBC “Dateline News” report, Brian and Lorinda Couch bought a new home from one of the largest home builders in America. Among many examples of poor craftsmanship was a door that was framed so that rain leaked in, resulting in the growth of mold in the foyer, a condition which spread throughout the house. The Couches had to move out of their unhealthy home and make payments while they arbitrated the situation. A frequent cause of poor IAQ is mold growth, which stems from water damage and associated building defects. Remediation efforts for mold and other IAQ problems almost always go hand in hand with building modifications, with costs often approach- RISKS RELATED TO POOR INDOOR AIR QUALITY — STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY ing replacement cost for the building. Hilton Hotels closed its 25-story, $95 million Kalia Tower in 2002 after mold was found throughout the building and guest quarters. It cost Hilton $55 million to fix the building, and in a lawsuit it has sought to recoup that much and more in damages.10 Since insurance claims and lawsuits mushroomed in the 1990s, many homeowners’ policies began excluding coverage for mold, and many commercial policies have followed suit. Building owners and managers, architects, engineers and contractors also have found that policies often exclude coverage of IAQ and mold problems. Given the enormous health and economic consequences of poor IAQ, and the legal liabilities and costs of fixing problems, the use of healthy, sustainable building practices for premium indoor air quality has taken on great importance for many homeowners, building owners, contractors, architects and interior designers. Understanding how to achieve good air quality will be the focus of the next section. 4 Strategies for Creating Premium Indoor Air Quality By applying strategies reviewed in this section, all of the costs and risks associated with poor IAQ can be transformed into benefits and opportunities. Creating premium IAQ, either in new construction, renovation or in remediation, can translate to greater occupant health and safety, greater productivity, and decreased maintenance costs and liability. These strategies include identifying and eliminating common contaminants, practicing source control, making wise choices of materials, following preventative strategies during construction and post-occupancy, and providing good ventilation. Common Contaminants Many of the strategies for improving IAQ involve reducing contaminants in the indoor environment. In this section, common indoor air contaminants will be reviewed. While there are possible health effects from all of the contaminants listed below, specific risks depend on, among other factors, the duration and concentration of exposure, the potency of the contaminant, and individual susceptibility. Biological Contaminants The basics: Biological contaminants are a natural and unavoidable part of the world. They are so small, so numerous and so adaptable that they cannot be eliminated from most indoor environments. The built environment can be made less hospitable to them, however. For example, mold thrives when it has a food source, such as carpet, backing paper for drywall or wood; a source of moisture, such as a plumbing leak or condensation; and warmth. Control strategies for mold generally start with reducing sources of moisture, particularly moisture occurring in closed spaces, such as wall cavities, basements and HVAC systems. Common contaminants: Bacteria, mold spores (including mildew and fungi), viruses, pollens and dust Common sources: People, animals, water, soil, flowering plants, water damaged buildings or standing water in HVAC system, and plant debris Combustion Products The basics: Combustion—in heating, cooking, smoking, transportation and power generation—is intrinsic to the activity of people and buildings. Unfortunately, combus- The growth of mold due to moisture intrusion leads to poor IAQ, causing serious health problems. Photo: Air Quality Sciences, Inc. 7 8 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS tion also releases numerous compounds that can potentially contaminate indoor air. Many of these are the result of incomplete combustion. Relatively clean fuels, such as natural gas, can still produce toxic carbon monoxide. Burning of other fuels, including oil, coal and wood, can also produce polycyclic aromatic hydrocarbons (PAHs). Common sources: Unvented or malfunctioning gas appliances, tobacco smoke, fireplaces, furnaces, automobile exhaust from attached garages, blackened meat Common contaminants: Carbon monoxide, nitrogen oxide, particulates, aldehydes, sulfur dioxide, PAHs Radon Carbon monoxide alarms can be used to warn occupants of health hazards. Photo: Kidde The basics: A variety of soil gases can, in certain situations, infiltrate buildings and cause IAQ and health problems. The most common and widespread concern is radon, a radioactive gas present in the air in areas throughout the United States. According to the U.S. Environmental Protection Agency (EPA), indoor radon gas is the number one cause of lung cancer in the United States among non-smokers. Radon can be detected with a simple test and fixed through well-established ventilation techniques. In a new home, the cost to install passive radon-resistant features during construction is usually less than $500. Common sources: Radon is present due to radioactive decay of small amounts of radium and uranium in rock formations. Radon becomes hazardous when it becomes concentrated, for example, when encapsulated inside a building that has been constructed over a radon source. Conditions, such as cracks in the foundation and unsealed holes between the basement and living spaces, allow radon to accumulate in living spaces. Due to geological differences, some regions of the country are at much higher risk than others. Particulates For additional information and a list of state and regional radon offices, visit www.epa.gov/iaq/whereyoulive.html. The basics: Virtually any material within a building can, under certain conditions, emit or form particulates, which could then be inhaled and possibly lead to health risks. For example, textured fabrics or carpets can shed fibers that can become airborne; printers and copiers emit airborne particulates; and any source of combustion, such as tobacco smoke or fireplaces, can be a source of soot and tars. Although the human body is accustomed to inhaling and filtering certain amounts of particulates, large amounts or specific types can cause health problems at higher-than-average rates. Specific particulates are too many to list here. A basic recommendation is to be aware of particulate sources in your indoor environment, research specific concerns when they arise, and follow other IAQ guidelines, such as those in this paper, for source control and ventilation. Common sources: Tobacco smoke, fireplaces, furnaces (see combustion products, above), aerosol sprays, carpet (shedding fibers), ceiling tile, insulation, textured fabrics, printers and copiers Volatile Organic Compounds (VOCs) The basics: A volatile organic compound, or VOC, is a molecule, containing one or more carbon atoms, that is released into the air at typical ambient conditions. Some VOCs are carcinogens, suspected carcinogens or known irritants at typical levels. One known carcinogen, formaldehyde, is covered in detail below. Common sources: Generally, building materials and cleaning products are the most common sources of VOCs that could contaminate indoor air. Common building materials with VOCs include: adhesives, sealants, caulks, paints, coatings, sealers, insulation, STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY carpet and carpet cushion, cleaning products, manufactured or composite wood, vinyl, printers, copiers, resilient flooring, textiles, wallcoverings, panel systems and window coverings. Formaldehyde The basics: Formaldehyde is a naturally occurring substance that is both irritating and, according to the World Health Organization, carcinogenic. Due to its widespread use in building materials and furnishings, formaldehyde levels indoors tend to be much higher than the levels found in ambient air. Common sources: Adhesive resin, including urea formaldehyde and phenol formaldehyde, used in manufactured wood products, such as particle board, fiberboard, plywood and medium-density fiberboard (MDF); glues; manufactured wood products, such as millwork and furniture; preservatives; permanent press fabrics; paints; inks; paper product coatings; insulation; pesticides Source Control Although efforts to reduce or eliminate potential sources of air pollution are very important, air pollution is also produced through the normal activity of almost all buildings. A rigorous program of source control, integrated into the design process, prevents pollutants from reaching occupied building zones when they occur as a result of activities inside the building. The interior designer has a role to play in implementing a number of these practices. First, consider strategies that eliminate potential contaminants at the source, preventing their entry into the building. For example, the inclusion of permanent foot grilles located at all major entryways to commercial buildings, and efficient coir or similar mats at residential entrances, minimize the tracking of soil and water into the building or home. This practice reduces the potential for moisture and particulates, as well as cleaning and maintenance needs. Source isolation is another source control practice, in which the designer creates a physical separation between potential sources of contaminants and the breathable air stream. Copy rooms are necessary for many businesses, but they are also a source of particulates and toxic emissions. A source isolation design solution includes the construction of slab-to-slab partitions—from structural floor to structural ceiling—which encapsulate the contaminants within the area. To provide good air quality for copy room users, and to prevent contaminants in the copy room air from mingling with air in other rooms, this room should be exhausted directly to the outside and it should be operated under negative pressure, i.e., depressurized so that air from surrounding areas will naturally flow into the room, but only out through exhaust vents. Other rooms that should receive source isolation treatment include laboratories, janitors’ supply closets and food-preparation areas. In homes, the garage can be a major source of air pollution. Engine idling generates carbon monoxide (CO), as well as other hydrocarbon gases, and pesticides, household paints and other chemicals that are often stored in the garage can produce toxic emissions. If possible, design the garage to be unattached from the main house or otherwise thoroughly isolated. Isolation strategies for parking are also important considerations in commercial and high-rise residential buildings, where garages are often provided under or adjacent to the facility. While source isolation is not usually possible with residential heat sources, such as gas or other fuel-burning appliances, space heaters, gas-fired furnaces, water heaters or fireplaces, source control should be practiced. These systems may release carbon monoxide and other combustion pollutants, particles, organic chemicals or water vapor, Formaldehyde One of the more common indoor air pollutants. At concentrations above 0.1 mg/kg in air, inhaled formaldehyde can irritate the eyes and mucous membranes, resulting in watery eyes, headache, a burning sensation in the throat and difficulty breathing. 9 10 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS which all contribute to contaminated indoor air and can be dangerous where there is a significant build-up of gases. Direct-venting of these appliances and eliminating the use of non-vented space heaters improves IAQ. While these combined strategies represent a strong approach to eliminating contaminant sources, inevitably some pollutants will reach the indoor air. Most buildings emit some level of contaminants, and occupants themselves reduce air quality through the exhalation of carbon dioxide (CO2) and through contaminants such as dry-cleaning chemicals that may remain in clothing, tobacco smoke and microbes released into the air through breathing, coughing or sneezing. When the pressure inside a space is lower than it is outside, the space is under negative pressure. For these situations, another source control strategy—source dilution—is most feasible. Dilution of the air stream by introduction of high levels of outside air through ventilation, combined with good filtration in the ventilation system, is an indispensable part of any IAQ strategy. Ventilation will be covered in detail below. Attributes of Materials One of the biggest impacts interior designers have on the built environment is that they are responsible for the specification of more than 90 percent of the materials and products used in the building. Selection of materials involves balancing considerations like a product’s function, cost, aesthetic, durability and a number of other characteristics. The designer of healthy environments who makes good IAQ a project goal adds the IAQ impact of a product to this list. One of the goals of this paper is to offer the designer basic guidelines, as well as detailed recommendations and trusted sources for further information. “Selection and use of low-emitting, non-toxic materials to construct and furnish the buildings are the most effective ways” to meet a goal for good air quality, says Marilyn S. Black, Ph.D., and founder of Greenguard Environmental Institute, which certifies products and processes that meet Greenguard’s standards for low-emissions. When there is no difference between the indoor and outdoor pressure, the space is under neutral pressure. The evaluation process for materials calls for understanding the emissions or offgassing potential of each product under consideration. Several categories are considered in a standard testing procedure, including amount of particulates, total volatile organic compounds (TVOCs), and aldehydes, to list a few of the most common. Materials and products that are third-party certified for conformance with accepted IAQ standards are a good place to start. Examples of IAQ Third-party Certification Programs: » Greenguard Environmental Institute » SCS (Scientific Certification Systems) Indoor Advantage » FloorScore Whether or not a product is certified by a third party, the designer can request copies of the Technical Data Sheet and the Material Safety Data Sheet (MSDS) associated with each product from the product manufacturer. These resources provide a great deal of information on a product, including hazardous ingredients, toxicological properties, other potential product hazards and safe working procedures. When the pressure inside a space is higher than it is outside, the space is under positive pressure. Source: Homeowner’s Guide to Ventilation/NYSERDA Product or technical data sheets are often the best sources for finding the VOC content of a material, which is key to IAQ considerations. This information is given in grams per liter (g/L) or in pounds per gallon (lbs/G), and most standards list the permissible VOC content in g/L. A hazardous chemical component measured as less than one percent of the material’s content does not have to be listed on the MSDS; however, if it is an OSHA-identified carcinogen, that limit drops to 0.1 percent. STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY A typical MSDS has a 16-section format according to ANSI standards. The following sections are particularly relevant to the interior designer pursuing high IAQ: » Section 3, Hazards Identification. Gives potential hazardous effects on human health and carcinogenic potential. It lists the “chemicals of concern,” or those that are known to be toxic to human beings, as well as the amount of the chemicals present. » Section 11, Toxicological Information. Details toxicity levels and IAQ impacts. » Section 13, Disposal Considerations. This section gives proper disposal instructions and may indicate if the product is identified as by the EPA a hazardous waste. Materials safety data sheet MSDSs are provided by product manufacturers as the main resource for detailed “ingredients” and test results of a product. At times MSDSs can seem confusing and unclear due to technical terms and unfamiliar names of chemical components. However, many manufacturers have technicians and chemists available on staff who can discuss MSDSs relative to human health impacts and air quality goals. In the next section, specific materials will be discussed in terms of IAQ considerations. The following checklist refers to general principles guiding those considerations: » Avoid materials with potentially high emissions rates. » Take special care in selecting materials that will be used in large quantities. » Carefully consider materials located near the occupants’ breathing zone or exposed directly to the ventilation air. » Check for high VOC levels in materials associated with “wet” processes, including paints and coatings, adhesives, sealants, sealers, caulks, etc. » Specify materials that install with mechanical fasteners instead of adhesives. » Specify durable products that are easy to maintain without the use of toxic solvents or cleaners. A number of Web sites offer resources that demystify MSDSs by defining unfamiliar terms, for example. The following site converts unfamiliar terms from MSDSs into hyperlinks to facilitate further research: www.ilpi.com/msds/ ref/demystify.html » Applications like flooring and furniture often use manufactured or composite wood products, such as plywood, particleboard or chipboard. Use only composite wood products made without urea-formaldehyde resin, which off gasses formaldehyde at room temperature. » Eliminate specification of materials that contain known carcinogens and toxins. » Avoid the “VOC sink effect,” in which porous materials with large surface areas, such as carpets and upholstery, adsorb VOCs and release them over a long period of time, thereby becoming another VOC source. One way to minimize this problem is to install porous materials only after wet-applied finishes have cured. With these general guidelines in mind, the following list of some of the more commonly specified building materials, organized by the MasterFormat Specifications structure from the Construction Specifications Institute (CSI), will be examined. This list is focused on common materials that typically contribute to poor IAQ. It is not intended to include every possible hazardous material, but to provide the designer with a roadmap to assist in the process of selecting environmentally preferable materials. Common Building Materials with Potential IAQ Impact and Specification Considerations Division 6: Wood and plastics, finish carpentry (prefabricated), plastic laminate Adsorption The property of many solid surfaces, especially porous ones like carpet or ceiling tile, to attract and retain molecules from the air, of for example, volatile organic compounds (VOCs). 11 12 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS Main issue for IAQ: Potential for high VOC emissions Specification strategies for minimizing IAQ impacts: » Specify a low-VOC installation adhesive. » Consider water-based and contact adhesives. » Consider melamine resin over phenol resin. » Select kraft (brown, unbleached) paper. » Look for third-party certification systems such as Greenguard, SCS Indoor Advantage and FloorScore. Division 7: Thermal and moisture protection sealants Main issue for IAQ: Potential for high VOC emissions Specification strategies for minimizing IAQ impacts: » Specify low-VOC sealants. Division 8: Doors and windows, flush wood doors Main issue for IAQ: Potential for high VOC emissions Specification strategies for minimizing IAQ impacts: » Specify “No added urea formaldehyde” for the core material. » Specify “low-VOC, formaldehyde-free laminating adhesives.” Division 9: Finishes Acoustical Panel Ceilings Main issue for IAQ: Potential for VOC emissions or VOC sink effect Strategies for minimizing IAQ impacts: » Chose ceiling tiles free of formaldehyde. » Install ceilings after wet finishes have dried and solvents have cured, so that VOCs are exhausted and not adsorbed by surfaces. Wood Flooring Main issue for IAQ: Potential for high VOC emissions Strategies for minimizing IAQ impacts: » Consider water-based polyurethane finishes for wood floors in lieu of solvent-based polyurethanes and other specialty finishes. » Specify pre-finished wood flooring to reduce off-gassing on site. Using water based finishes, such as the fruitwood stain and clear finish shown on the reclaimed wood panel above, can help avoid VOC emissions. Photo: Endura Wood Products » Consider nailing down wood floors to reduce adhesives use. Resilient Flooring Main issue for IAQ: Potential for high VOC emissions Strategies for minimizing IAQ impacts: » Specify adhesives and leveling compounds that contain minimal VOCs. STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY » Consider tile instead of sheet products to reduce exposure to emissions from adhesives and from plasticizers. Carpet Main issue for IAQ: Potential for VOC emissions or VOC sink effect Strategies for minimizing IAQ impacts: » Make sure carpet or carpet system is in compliance with independent third-party certification, such as Environmentally Preferable Purchasing (EPP) or, alternatively, that it meets a recognized industry standard, such as The Carpet and Rug Institute (CRI) Green Label Plus program. » To prevent sink effect, phase construction so that carpet is installed after offgassing period when wet finishes have dried and solvents have cured. » Specify low-VOC adhesives that are in compliance with SCAQMD Rule 1168, as well as with the carpet manufacturer’s requirements, in order to maintain warranty of the installation. » Wherever possible, consider a “tackless,” or non-adhesive, carpet installation. Wallcoverings Main issue for IAQ: Potential for creating conditions for mold growth and highemitting VOCs Strategies for minimizing IAQ impacts: » Specify vapor-permeable wallcovering. Vinyl and rubberized wallcoverings have very low moisture permeability, and if water occurs between the wall and the wallcovering, as can happen through condensation in humid climates, mold growth and IAQ problems can ensue. » Specify low-VOC installation adhesive. Fabric Wrapped Panels Main issue for IAQ: Potential for acting as VOC sink Strategies for minimizing IAQ impacts: » To avoid sink effect and ensuing VOC emissions, install fabric-covered panels after wet finishes have dried and solvents have cured. Painting Main issue for IAQ: Potential for high VOC emissions. Paint products contain a wide variety of VOCs, many of which are known to be harmful to human health and many of which persist in indoor air for months after application of paint. Strategies for minimizing IAQ impacts: » Specify water-based latex or acrylic primers and paints with no aromatic hydrocarbons and zero or low VOCs. » Green Seal Standard-11 and the South Coast Air Quality Management District Rule 1113 offer VOC limits for paints used in the building industry, as well as lists of manufacturers and products that meet their criteria. » Specify light colored paints or paints with zero-VOC pigments to avoid the VOCs that are often added when tinting paint. 13 14 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS » To minimize sink effect, complete painting before installation of porous materials. Division 10: Furnishings Main issue for IAQ: Potential for high VOC emissions Strategies for minimizing IAQ impacts: » Consider Greenguard or equivalent third-party certification of furniture products. » Request blanket wrapping of furniture, rather than plastic wrapping, during shipping to encourage off-gassing before the furniture enters the interior space. » If schedule permits, request in the specifications or arrange with the contractor or furniture dealer to have the furniture unwrapped and allowed to off-gas in an offsite warehouse location for at least several days prior to installation. For more tools in the green product selection process, cross-reference these principles and recommendations with the ASID Materials and Products white paper. Construction The indoor air in buildings and homes can be compromised by construction activities even before occupants move into a space. In both residential and commercial sustainable projects, a “Construction IAQ Management Plan” should be prepared by the contractor and approved by the client or designer prior to commencement of the work. Sizing the HVAC system appropriately and protecting it during construction are important in achieving good indoor air quality; leaving the ductwork open to view, as in the office shown above, helps reduce material use and waste. Photo: ai3 This plan should call for the contractor to educate all subcontractors and site workers as to their role in supporting IAQ. The plan should also call for updates on IAQ efforts at regularly scheduled construction meetings. The architect and interior designer, along with the contractor and his or her team, should review submittals, samples, and product literature to determine compliance with the IAQ plan and other goals for the project. Just prior to occupancy, or in some cases during a partial occupancy, an IAQ test of the space to measure levels of specific indicator pollutants can verify the quality of the indoor air and quantify the level of harmful elements or toxins. Any Construction IAQ Management Plan should require the contractor’s compliance with Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) IAQ Guidelines for Occupied Buildings During Construction, 1995, Chapter 3. This guide and other leading IAQ management plans typically focus on the following five main areas of IAQ control measures. Although each project is unique, most commercial projects should follow all of these guidelines during the construction process, while their applicability to residential projects should be reviewed case by case. HVAC Protection For more information on the principles of selecting the appropriate air filter, visit www.ci.austin.tx.us/ greenbuilder/fs_airfilters.htm. » All ductwork and HVAC equipment should be protected during construction from pollutants and dust infiltration. » The HVAC system should not be operated during construction, to avoid spreading VOCs and other construction pollutants through the building and needlessly contaminating the HVAC system itself. If the system does need to be in service, ensure that the return receives protection with temporary filters. » Using filters to capture pollutants generated by the construction process is critically important. The most efficient filters have Minimum Efficiency Reporting Value (MERV) ratings or values and are numbered from one to 16. The higher the MERV value the more efficient the air filter is at removing particles, dust and airborne pollutants. More efficient filters improve IAQ, but also are generally more expensive, STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY require more frequent replacement and increase energy loads. Not all filters are either suited or appropriate for use in every application. Typically, the MEP engineer will determine the level of filtration and specify the correct filter. » Isolate plenum ventilation spaces by having acoustical ceiling tile installed to minimize the construction dust entering the space. » Return air ducts and plumbing should be checked for leaks and repaired quickly. Water from construction can persist during occupancy, potentially causing deterioration and mold problems. » Protect materials stored on site from moisture and animal infiltration by establishing dry, secure storage both inside the building and out. Regularly inspect for moisture damage, and replace damaged materials immediately. For IAQ protection, the mechanical room should not be used for storage. » When construction is complete, replace the filtration media in the HVAC system with the highest appropriate MERV value filters to maintain clean indoor air during occupancy while still balancing energy efficiency strategies. Source control » Identify methods for controlling emissions from building materials that contain high-VOC levels during installation. » Specify finishes that are low emitting and low VOC. » Avoid specifying additional layers of finish when possible. For example, specify a polished concrete floor instead of a floorcovering. » Isolate containers with known high-VOC content, and ventilate spaces where emitting materials are stored and mixed. » Limit idling of vehicles or construction equipment and keep these vehicles away from air intakes and building openings. Source isolation » Separate areas of contamination from clean or finished areas of work. » Use ventilation strategies to depressurize areas where dusty or odorous work is happening, thereby containing dust and protecting finished areas from contaminated air. » Ventilate with 100 percent outside air when outdoor temperature and humidity conditions allow, especially when VOC-containing materials are being installed. » Provide temporary barriers to define the construction area and limit its impact. Housekeeping » Implement dust and contaminant control measures, including high-efficiency vacuum filtrations, a high frequency of cleaning and dust removal, and use of wetting agents to control airborne dust. » Protect adsorptive materials, such a ceiling tile and carpets, from moisture infiltration, dust and off-gassing of wet materials, such as paints and adhesives. Scheduling » Phase work to minimize potential for cross contamination between occupied and construction areas. The fresh air intake for this Cambridge, Mass., building is located next to the loading dock, exposing occupants to diesel exhaust from passing trucks—even if they read the sign and don’t idle. Photo: Mara Baum 15 16 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS » Specify sequencing of finish installation during construction so that wet materials will be installed before adsorbent materials to reduce the “sink effect,” in which VOCs released from wet materials are adsorbed or captured by porous materials. » Target low-occupancy times for higher-VOC material installations. » Allow time in the construction schedule for a flush-out and for IAQ testing prior to occupancy. Ventilation Ventilation Naturally or mechanically induced movement of fresh air into or through an enclosed space. Ventilation involves introducing exterior air into an interior space while exhausting stale interior air to the outside. A variety of common strategies and technologies can be used, including operable windows and exhaust fans. Mechanical systems with more sophisticated technologies include air-to-air heat exchangers and ventilation that is integrated with heating and cooling systems. The purpose of ventilating interior spaces is to introduce targeted amounts of outside air to dilute or reduce contaminants that cannot be controlled at the source and to remove used or contaminated air from the space. Following the energy crisis of the 1970s, model energy codes were published by several U.S. federal, state and regional entities. To save energy, these codes often modified existing ventilation codes to allow for a reduction in the required ventilation rates, or outside air ratios, distributed to interior spaces in commercial buildings. In many cases these reduced ventilation rates contributed to inadequate IAQ. While the code has since been changed to require higher thresholds for outside air, depending on the building or interior use, the outside air ratios established by code generally represent the minimum considered acceptable for human well-being. Higher levels of fresh air, which enhance human well-being and comfort and contribute to increased productivity, are often targeted in sustainable projects. In order to balance the needs of energy conservation and appropriate ventilation, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has established a set of standards, including the following key documents: » ASHRAE 52.2 (1999): Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size » ASHRAE 55 (2004): Thermal Environmental Conditions for Human Occupancy » ASHRAE 62.1 (2004): Ventilation for Acceptable Indoor Air Quality » ASHRAE Standard 62.2 (2004): Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings » ASHRAE 90.1 (2004): Energy Standard for Buildings Except Low-Rise Residential Buildings » ASHRAE Standard 90.2 (2004): Energy-Efficient Design of Low-Rise Residential Buildings ASHRAE recommendations are voluntary standards that only become enforceable when a state or locality adopts the standards in its building codes. Current Standards and Recommendations » ASHRAE currently recommends 20 cubic feet per minute (cfm) of outdoor air per STRATEGIES FOR CREATING PREMIUM INDOOR AIR QUALITY person for office spaces and conference rooms, and at least 15 cfm of outdoor air for other non-residential environments, such as school classrooms. » See ASHRAE 90.1 (2004) for current commercial building ventilation rates. ASHRAE recommends a minimum ventilation rate of 0.35 ACH (air changes per hour) for new homes. The ACH rate measures how many times per hour the total air inside the house is replaced with fresh outside air. Increasing a building’s ventilation rate up to or beyond recommended ASHRAE rates is not always enough to improve air quality, but it can be an important step. Ventilate for Occupant Comfort Typically the top two complaints of building occupants are that the air is too hot or too cold. Poor ventilation, which contributes to poor air quality, is closely associated with these complaints, and systems that contribute to good ventilation often contribute to good IAQ, thermal comfort and visual connections with the outdoors. When building use and climate are both suitable, natural ventilation can be both effective and energy efficient. Cross ventilation makes use of windows and doors to introduce cool exterior air inside and to vent warm, used air. In more advanced designs, convection and the natural buoyancy of air can ventilate buildings through the “stack effect,” in which the building design essentially creates a chimney that exhausts hot air. Prior to the development of mechanical ventilation, all buildings relied on natural ventilation—often very effectively. Operable windows are standard in homes, but they are rare in large commercial buildings. When they are available, they are useful for providing natural ventilation in climates and seasons in which the outdoor air is not too hot, cold or humid. In buildings with large floor plates, in which few of the occupants are adjacent to windows, operable windows provide limited benefit. In addition, some engineers worry that operable windows will be used inappropriately by occupants, making it harder for them to manage the air distribution in the building effectively and heat or cool the building efficiently. If operable windows are not practical, then other systems, including under-floor air distribution and furniture control systems, can provide good air distribution and occupant comfort. Displacement ventilation is a form of ventilation typically seen with an under-floor air distribution (UAD) system paired with a raised access floors, in which the ventilation distribution system is beneath the floor, as opposed to in the ceiling plenum. Clean, conditioned air is delivered to the occupant zone through a diffuser at or near the floor, and heat from occupants and equipment draws clean air upward along with pollutants generated in the space. At the ceiling, air is collected by a return and exhausted to the outside, or filtered and cleaned prior to recirculation. Research shows that UAD provides cleaner air in part because the fresh air supply does not circulate with the stale air return, and the air moves at a lower velocity, thereby reducing particulate distribution. In-floor diffusers in UAD systems commonly allow for occupants to have some control of the air flow to their individual office or workstation areas. See the ASID white paper, Selling Green, for additional benefits of UAD systems. A second method of achieving individual control over air flow is provided by a number of major furniture manufacturers who offer an option for individual controls in their furniture systems. Quite common in Europe, these systems are gradually gaining acceptance in the United States, where the benefits of personnel satisfaction are beginning to outweigh the initial cost premium. No matter how the ventilation system is designed, the designer should be aware of basic factors that help improve IAQ. For example, placement of ceilings, access doors and furniture should provide clear and easy access to the HVAC system When outdoor conditions permit, operable windows provide natural ventilation and allow occupants to control their indoor environment. Photo: Timothy Hursley 17 18 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS components for proper functioning, maintenance and operation. Problems can occur if the air supply and return vents within each room are located too close together, allowing the ventilation system to short-circuit, or if the supply vents are blocked, closed down or positioned such that the air supply is prevented from reaching the breathing zone of the occupants. From where does a building bring in its outside, “fresh” air? Architects all too frequently locate outdoor air intakes near sources of air pollution, such as loading docks where trucks may idle, designated exterior smoking areas, cooling towers and the building’s own exhaust ducts. Avoiding this mistake and placing intakes higher on the building offers the best potential for clean source air. Ventilation Monitoring In commercial interiors, computerized energy management systems (EMS) can provide automatic feedback to the building facility manager or engineer. These systems can monitor variables, such as temperature, humidity levels, and CO and CO2 levels. An alarm system alerts the manager to unsafe or uncomfortable air quality conditions in the building, allowing for prompt adjustments to be made. For a residence, a thermostat can be set to engage the HVAC system at specific times of the day and night, thereby optimizing energy for peak use times. Hygrometers may be used to monitor relative humidity, and air quality can be monitored with inexpensive home kits and detectors for smoke, CO, radon and VOCs released from materials. Ventilation Operator Training The operations and maintenance of a building support air quality and efficient system performance. Three system components ensure effective operations and maintenance. » A well-trained staff familiar with operating procedures for all building systems. The MEP engineers and others who select, design and install systems, or the commissioning agent (see page 20) should be required to train maintenance staff on system operation. The building owner or occupant should ensure that whenever there is turnover, new staff members are trained. » Adequate documentation of the mechanical systems equipment and procedures. » Good maintenance management practices. For clean and effective cycling of air, all components of the HVAC system need to be kept clean, free of debris, condensation and standing water, as well as in good working condition. While this may seem like an obvious strategy, these components are often neglected as “out of sight, out of mind.” 5 Benefits of Premium Indoor Air Quality The potential for increased health care costs and liability associated with poor IAQ, as covered in earlier in this paper, are of growing concern among building owners, corporations and families. Benefits associated with premium IAQ include increases in productivity and reduced absenteeism. In a large-scale field study of illness symptoms at work, researchers in Europe found that workers that reported sick building syndrome (SBS) symptoms worked 7.2 percent more slowly while undertaking a vigilance task and had 30 percent more errors on a cognitive test.11 These results are typical of what many employers are seeing—that even employees who do not develop a specific building-related illness (BRI) may still exhibit reduced BENIFITS OF PREMIUM INDOOR AIR QUALITY — INTEGRATED OPPORTUNITIES AND DESIGN PROCESS effectiveness. According to the National Science and Technology Council, productivity losses from building-related health problems are equivalent to more than 10 days per employee per year. In an incident reported by the National Science and Technology Council, an accounting firm that suffered from poor IAQ in its offices decided to move, and hired a design firm for the project. The design firm gave detailed attention to the selection of construction materials, furnishings and finishes to ensure low emissions. Following the project, the accounting firm found that VOC concentrations were 50 percent to 70 percent lower than similar offices in another part of the building. They also reported a year after occupying the space that individual absenteeism was six percent to 10 percent less than it had been in its previous building. By designing healthy buildings and interiors, with high IAQ, good lighting, heating and cooling, productivity has been shown to increase by six percent to 16 percent. In another case study, one company that specializes in computer network and software applications was told that for its 80,000-square-foot building it would cost $900,000 extra for natural building materials that would reduce toxins and for devices that would cut electrical consumption. However, by spending this money to make a healthy and sustainable building, the company is saving $110,000 per year in energy costs, and productivity has increased by more than five percent. Eighteen months after moving into the new building, absenteeism rates for this company fell 40 percent from what they had been for the same people doing the same jobs in the older building next door. 6 Integrated Opportunities and Design Process Opportunities for an environmentally sustainable project with high-quality ambient air are enhanced when IAQ is viewed in conjunction with holistic, collaborative strategies for indoor environmental quality (IEQ). Realizing that synergies exist between team members—including the client, architect, interior designer, MEP engineer and contractors—as well as building systems, and working to capitalize on the opportunities this team approach offers, contributes to achieving high performance, comfortable and safe buildings interiors and long-term financial benefits. A number of strategies for an integrated process, such as following an IAQ Management Plan during the construction process, have been discussed elsewhere in this paper. The following summarizes several key recommendations: » Make sure the client is informed about IAQ and IEQ, and discuss the client’s goals. » Begin considering IAQ early in the project—ideally in the pre-schematic phase. » Collaborate with all team members, sharing and discussing project goals. Avoid duplication of effort and working at cross purposes. » Investigate opportunities for improved IAQ and IEQ with specific team members who may have a vital connection with certain aspects of the work. For example, discuss IAQ goals with the MEP engineer who designs ventilation and filtration systems. » Incorporate the client’s IAQ goals and good IAQ strategies into design and contract documents. » Coordinate with the contractor on the implementation of technologies and strategies required, and make sure he or she understands the importance of adhering to the sustainable principles and requirements indicated in the documents. For additional information and additional case studies, visit www.dc.lbl.gov/IHP. 19 20 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS » Carefully check any proposed product substitution for conformance to the environmental characteristics of the original product. » Make sure all building systems are functioning at optimum level and as intended: Use the commissioning process where available to calibrate all systems or, at a minimum, be sure the MEP engineer balances the system to achieve the best possible performance. » Once systems are in place, instruct the facility manager or homeowner in the best practices for operations and maintenance relative to premium IAQ. Collaborating with all members of the design and construction team during every phase of construction is central to the integrated design approach to sustainable buildings. Photo: Steelcase Inc., and Jeremy Frechette Photography » Evaluate occupant comfort with a post occupancy evaluation (POE). When possible, act on this information to adjust the systems to operate at an optimum level, or make changes to meet the original goals. » Document lessons learned on the project and apply them to the next project. Commissioning Commissioning is the process of checking the performance of a building against the owner’s goals during design, construction and occupancy. A commissioning agent can be hired to analyze and test all building systems to check performance in terms of energy use, ventilation effectiveness, lighting and much more. The fee for this service is often offset many times over by increased efficiency and effectiveness of systems that may have been installed improperly or not used as intended. The process is growing as a standard protocol in green buildings, and particularly in government, institutional and health care buildings. For homes, the equivalent of a commissioning agent would be a home inspector who verifies that the home’s systems are properly installed and working correctly. Post-Occupancy Two good Internet sources for post occupancy evaluations are California Division of the State Architect - Facilities Performance Evaluation (FPE) www.poe.dgs.ca.gov/default.htm Occupant Feedback Tool - Center for the Built Environment (CBE) www.cbe.berkeley.edu/research/ briefs-feedback.htm Efforts to maintain premium indoor air quality, and the role of the designer in those efforts, shouldn’t end as soon as occupants move in. After working hard to create a healthy space, the designer can help ensure that the results of that effort are maintained. The designer can help protect IAQ over the long term by verifying that proper maintenance practices are in place for the building’s HVAC systems. A three-pronged approach is called for: regular inspection, cleaning and filter replacement. Additionally, the designer and occupants should be aware of preventing condensation and plumbing leaks, which can cause building damage and mold growth. A designer can discuss the use of a low-impact cleaning program with the facility manager or homeowners, emphasizing the use of low-VOC products, such as those approved by Green Seal. Offering a post-occupancy evaluation (POE) to the building owner, homeowner or facility manager in order to collect data for feedback from occupants can inform future renovations in the building and best practices for the future. Finally, buildings inevitably undergo change, with new furniture, paints and floor coverings being installed because an owner’s tastes have changed or the building’s use has shifted. IAQ standards for materials selection should be maintained throughout these changes, and the designer can help by creating a plan in advance or offering services on an ongoing basis. IAQ AND GREEN BUILDING RATING SYSTEMS 21 7 IAQ and Green Building Rating Systems USGBC / LEED Rating System Within LEED for Commercial Interiors (LEED-CI), the system most likely to be used by interior designers, approximately 27 percent of the 57 points available are directly related to the design topics and environmental quality issues discussed above. In the indoor environmental quality section, the following points are particularly relevant: » Provide carbon dioxide monitoring. For additional details, visit the USGBC Web site at www.usgbc.org. » Increase ventilation rates. » Manage on-site pollutants during construction and test IAQ prior to occupancy. » Specify low-emitting materials. » Practice indoor chemical and pollutant source control. » Design for individual control of lighting, air flow and thermal comfort. » Allow for maximum access to daylight and views to the exterior for occupants. For additional details, visit the NAHB Web site at www. nahbrc.org/greenguidelines. Additionally, successful compliance with LEED requires coordination with project team consultants. For example, LEED-CI EQ Credit 4.1, “Low emitting adhesives and sealants,” must be coordinated with the MEP engineer to insure that ductwork and plumbing sealants are in compliance. The related LEED-NC (LEED for New Construction) credits are very similar to those in LEED-CI, although furniture is not required to be part of the equation (as it is in LEED-CI). LEED-H (LEED for Homes) credits contain many of the same concepts related to environmental quality, such as combustion venting, outdoor air ventilation and environmentally preferable products, as well as additional credits related to emissions reduction, radon protection and contaminant control. Similarly, LEED-EB (LEED for Existing Buildings), where a great number of interior design projects will be found, has a set of requirements that is closely aligned with the other LEED rating systems, but accommodates the more restrictive opportunities that are typically experienced when working with existing conditions. NAHB / Green Home Building Guidelines Within the “Indoor Air Quality” section of the National Association of Home Builders (NAHB) Model Green Home Building Guidelines there are 22 sustainable initiatives that can be implemented, each with an assigned point value. Main IAQ considerations include » Isolating mechanical and combustion systems » Designing for tightly sealed fenestrations » Specifying low-emitting materials » Masking HVAC outlets during construction and vacuum ducts and grilles prior to HVAC start up » Exhausting from kitchen, garage and other areas directly to exterior » Insulating pipes and ductwork » Checking moisture content of wood prior to installation Endnotes 1 www.healthgoods.com/Shopping/Indoor_Air_ Quality_Products/Indoor_Air_Quality_Products. htm 2 Spiegel / Meadows, Sustainable Design & Green Building Materials Book, NCARB: Professional Development Program 3 ww2.whas11.com/Global/story.asp?S=1980209 4 Mary Jane Gilhooley, “Plants in the workplace have been proven to improve employee productivity and reduce stress,” Facilities Design and Management magazine, Vol. 21, No. 9, October 2002. 5 American Lung Association® Fact Sheet: Asthma in Adults. American Lung Association, New York, NY, March 2003. 6 Frank Gilliland, William J. Gauderman, and John Peters, “Exposure to second-hand tobacco smoke increases school absenteeism in children,” Environmental Health News, July 2003. 7 “Indoor Environment,” The National Council of Architecture Registration Boards Professional Development Program monograph, Washington, D.C., 2002, page 22. 8 Cristina Merrill, “Spreading Mold Lawsuits Threaten New York Infection,” Crain’s New York Business, Vol. 19, No. 7, February 7, 2003. 9 “Legal Implications of Mold Contamination of HVAC Systems,” Emily Wheeler, HPAC Engineering, May 2000. 10 Andrew Gomes, “Multi-million dollar liability fight watched nationally,” Honolulu Advertiser, April 27, 2003. 11 EERE Report on IAQ, www1.eere.energy.gov/ femp/pdfs/buscase_appendixf.pdf 22 INDOOR AIR QUALITY — INTERIOR DESIGN AND GLOBAL IMPACTS Appendix: Questionnaire The following questionnaire is offered for the benefit of the reader, to evaluate whether the learning objectives of the paper have been achieved: 1. What are some important characteristics or attributes of materials that contribute to premium indoor air quality? 2. List three risks associated with poor indoor air quality for clients and occupants. 3. Explain why an owner or employer would be interested in pursuing good indoor air quality practices within his or her space. 4. Explain a source control design strategy and what benefits result from its implementation. 5. Define and explain the difference between BRI and SBS. 6. List three biological contaminants contributing to poor IAQ to be avoided in homes and commercial buildings. 7. List five construction practices that may be employed to promote a healthy indoor environment. 8. List the ASHRAE standards relative to IAQ, and explain their use and importance. 9. What steps could a facility manager in charge of operations and maintenance take in the pursuit of a healthy indoor environment? 10. List two items to investigate while assessing technical data and/or MSDS relative to protecting IAQ. 11. Explain the differences and overlaps between IAQ and IEQ. 12. Name two environmental rating systems or guidelines available in the residential or commercial building industry for evaluating indoor emissions from products.